Helpful hints

So that there are no problems in working with the putty, you can take into account the main nuances of preparation and application tricks.

Usually, preparation according to all the rules looks like this:

- the room is freed from furniture;

- carry out a visual inspection of the coating;

- I remove the old coating, grease, oil stains;

- dust from the surface is removed with a semi-dry sponge;

- after drying, the base is treated with a primer.

These are the basic steps for base material.

At this stage, it is important to choose the right primer, since the leveling of the floor structure and the level of adhesion of all layers will depend on it. A primer is needed so that the starting and then the finishing material does not fall off the walls or ceiling

The base is treated with soil with a higher penetrating ability. This will make the structure of the walls uniform.

The primer will bind dust particles and micro-cracks. It is applied with a roller on the main part of the floors and with a flat brush in corners and hard-to-reach places. The application should be uniform, since when the primer dries, a crystal lattice will form on the surface, which enhances adhesion. After the primer has dried, the surface is leveled with starting material. If necessary, it is trimmed after drying and then re-primed. Now for bonding the starting and finishing layers.

For example, to prevent the putty from sticking to the trowel, you should not use a wooden spatula. It will absorb moisture, and with it, the mixture itself will be retained on the working canvas. If the area of the room is small, you can try a 30 cm wide metal spatula or a two-handed tool. The mixture should not be applied to damp floors. You need to dry the wall (ceiling).

Antiseptic treatment is also important. For example, to exclude the formation of mold and mildew on the surface of the wall or ceiling being trimmed, the floors can be initially treated with a special compound

In addition, in the process of work, it is important to observe the temperature conditions in the room. If the plaster mix is applied in several layers, it is important that their thickness is minimal.

If the surface is being polished, you need to wipe off the dust every time, which is easier to do with a semi-dry sponge. It will not scratch the finished surface

When applying each new layer, it is important to wait until the previous one is completely dry. The ironer is also used in the case of decorative application, and even relief

In this case, the pressure on the tool should be minimal.

Comparative review finishing putties Vetonit LR with other manufacturers, see the following video.

Tips & Tricks

In general, work with dry building mixes Vetonit is carried out according to the same algorithm as work with mixes from other manufacturers. The instructions for creating a solution are always indicated on the manufacturer's packaging and is the best option for its preparation.

- Putty of this brand can be applied to the work surface both with the help of special mechanisms and installations, and manually, using a rule and a spatula.

- The surface must be pre-prepared - free from old finishes, dirt and dust. It must be dry, free from oil or grease stains, and sufficiently firm.

- There should be no drafts in the room being finished, so it is better to close windows and doors.

- The mixture does not have harmful vapors or strong odors, so working even in a completely closed room will not cause any deterioration in well-being.

In order to prepare the mixture according to the instructions on the package, it is best to choose a plastic container.The water into which the powder is gradually poured should be at room temperature 20 - 25 degrees. Do not change the sequence and pour water into the powder, as this can lead to the mixture becoming too liquid, and there will be no excess powder left to correct the error.

The resulting solution must be thoroughly mixed with a drill with a special nozzle or mixer for 5 minutes and let it brew for 5-10 minutes. After that, the solution is mixed again and started to work.

Vetonit plaster

- When working with plaster, the surface cleaned of dust, old coating and dirt, if necessary, is additionally reinforced with a special mesh. Grease and oil stains are removed, irregularities are putty. If the surface of the wall or ceiling is concrete, then a primer must be applied to them in front of the plaster in two layers so that the concrete does not draw moisture from the applied solution.

- Dry powder is added to warm (20 - 25 degrees) water and stirred with a drill or mixer. In order to increase the adhesion coefficient of the plaster, 10% of the water in the solution can be replaced with a liquid primer. Stir the plaster until all the lumps disappear. It is not necessary to insist on such a solution, otherwise it will immediately begin to harden. In the process of working with plaster, you should not add water to the solution; stir it without adding liquid.

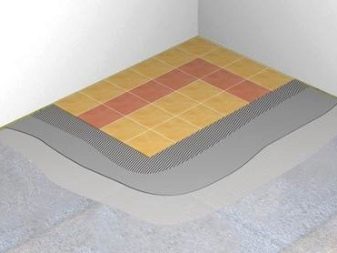

Self-leveling floor

- The prepared surface is best treated with a primer of the same brand. If the floor is applied in several layers, then each of them is primed after drying. Such processing will avoid the appearance of air bubbles inside the frozen solution and will improve the adhesion of the self-leveling floor to the base. A solution is prepared in a plastic container or a special silicone container. Pour dry powder into warm water and stir the solution with a drill or mixer.

- The prepared solution should not be left "to infuse", you must use it immediately. Filling is done manually or using special installations in separate strips with a width of 30 to 50 centimeters, starting from the corner. The solution poured onto the base is leveled with a metal spatula. To release random air bubbles from the solution, you can roll a needle roller over an uncured surface.

According to the reviews of real buyers, the products of the Vetonit trademark, at a fairly affordable price, are superior in quality to many analogues in the domestic market. Dry mixes allow you to quickly and easily solve repair and construction issues both in small private apartments and in huge warehouse and industrial premises.

The assortment of goods is so wide that you can choose the material to work in any weather conditions, with any bases and decoration. The ease of use of Vetonit mixtures allows not only professionals to work with them, but also those who first undertake to make repairs in their own home.

In the following video, Vetonit presents a complete solution for the perfect wall in a living room or bedroom.

Instructions for use

In order for the leveler to be a good base for the finishing material, the technology is performed according to all the rules. The instruction consists of several step-by-step points.

Preparation

Initially, the base is examined. It is cleaned of debris, dust and dirt. They remove all objects from the room, sweep the floor. To prevent dust from settling on the walls and ceiling material, it is better to use an industrial-type vacuum cleaner.

A few hours before leveling, the surface must be treated with a primer. You can use Vetonit MD16 or Prim Multi primer. You can apply the primer with a brush, although it is more convenient to use a roller.

Preparation

When preparing the working solution, it should be taken into account that the manufacturer's data are approximate. Sometimes, instead of 3.5 liters, 2.8-2.9 liters of water are consumed per bag of dry mix. Water is poured into a clean container and the powder composition is poured into it (not vice versa).The mixture is stirred until a homogeneous mass is formed. For this, a construction mixer is used.

It is worth considering that the more you stir, the shorter its life will be. This rule applies to all plaster and leveling mixtures. If there is a lot of water, this will cause cracks during drying and operation, while the strength of the solution decreases, which will affect the service life. It is undesirable to work with the composition after a certain period of time.

Alignment

Before starting the installation work, close the windows and doors - no drafts should be allowed during the work and when the Vetonit 5000 composition dries up. The prepared solution is spread on the floor surface and immediately stretched. The thickness of the layer depends on the available height difference. In order for the surface to be flawlessly even, it is trimmed with a rule, and, if necessary, sanded with a special float.

Seams

There are times when a quick-drying mixture is used under a tile without additional leveling. In this case, expansion joints are made on the surface after a few hours. This can be done when the surface has hardened and walking on the coating is allowed.

If the seams were originally on the old base, then they can be transferred. If they are absent, it is necessary to cut squares with a side of 6 m along the edges. The seam depth should, on average, be 1/3 of the thickness of the used screed.

Finish coating

If you plan to put tiles or porcelain stoneware on top, the joints must be filled with a special sealant for expansion joints. Waterproofing must be done before flooring. When you plan to lay a thin-layer floor covering, for example, linoleum, you can start work in a day from the moment you apply the leveling agent. The same applies to the self-leveling floor. Ignoring the drying time will lead to shrinkage and deformation of the leveling compound.

Peculiarities

"Vetonit 5000" is a powder-type leveling compound for floors. The product is semi-finished and needs to be diluted before use. To do this, the powdered leveling agent is poured into a separate container and diluted with clean water at room temperature. Then it is kneaded for one minute to the consistency indicated by the manufacturer on the product packaging.

This composition is the basic leveling agent for cement-sand screeds and concrete analogs. It is compatible with the "warm floor" system (including water) and is a good material for local repairs. The leveling device marked 5000 is suitable for leveling a drop of up to 8 cm. It is a high-quality building material, but it can be applied exclusively by hand.

The leveler is a good base for further floor finishing. On top of it, you can perform the installation of a self-leveling coating or laying tiles and porcelain stoneware. It is characterized by the speed of drying. Subject to the manufacturer's conditions after installation, it will be possible to walk on the surface after 3-4 hours.

It is permissible to carry out further finishing of the floor in 3-5 days. It is undesirable to do this after a day, since the material has a slight shrinkage. Until the coating is completely cured, no further finishing can be carried out.

Can plaster be applied to old paint?

If you at least once in your life have come across the independent treatment of walls, then you probably know that the instructions for finishing materials clearly indicate the need to remove the old coating before applying the plaster. This is due to the fact that when the old paint interacts with the leveling solution, the latter can gradually begin to fall off and lose its original appearance.

Can plaster be applied over old paint? In most cases, there is no difficulty in removing old paint, it can be easily removed with a spatula.However, old paint often holds up quite well and is very problematic to remove. In such situations, experienced professionals recommend applying the plaster directly over the paint layer.

It should be noted that oil paint after plastering does not lose its technical, in particular adhesive characteristics. However, after a while, the plaster will begin to crumble, fall off. There is a very effective way to avoid this problem - the surface under the plaster must be covered with a layer of primer.

Application

First you need to prepare a working solution.

- To dilute one bag (25 kg) of Vetonit KR dry putty, 10 liters of water are required. Do not use hot liquid. The temperature should not exceed 40 degrees.

- The powder must be poured into the water in portions while stirring vigorously. Further, mixing must be continued until the dry base is completely dissolved. For a faster and better result, it is best to use a drill with a special attachment. In this case, complete dissolution can be achieved in 3-5 minutes.

- After the water-powder mixture has become completely homogeneous, it should be left to settle for 10-15 minutes. After this time, the solution must be mixed again.

- The finished putty will be suitable for use within 24 hours from the moment of mixing.

- Special instructions: the remaining solution must not be poured into the sewer or other drainage systems, this can lead to blockage of pipes and hoses.

Substrate preparation:

the surface to be putty must first be well cleaned of dirt, dust, particles of debris or traces of oil and paints and varnishes;

adjacent surfaces that do not require the application of putty (for example, window glass, already finished sections of the walls, decorative elements) should be protected from the ingress of mortar onto them using film, newspapers or other covering materials;

it is important to ensure that the room temperature is not lower than + 10 ° C during the application and drying of the putty layer.

The process of applying the ready-made mortar of Vetonit KR putty consists of several stages.

- The ready-to-use leveling layer can be applied by spraying or using a two-handed construction trowel. In case of partial, rather than continuous filling, it is possible to use an ordinary narrow spatula.

- If it is necessary to apply several layers of leveling putty, each subsequent layer should be applied only after the previously applied one is completely dry.

- Excess mortar is removed from the surface and can be reused.

- Further decorative wall decoration can be carried out only after the applied putty has completely dried. At a room temperature of about + 20 ° C, a layer of 1-2 mm dries out within a day. It is recommended to provide sufficient constant ventilation while the applied filler dries.

- After the layer has hardened, it must be leveled by sanding the surface with sandpaper. Further, surface painting or wallpapering is permissible.

- The tool that was used in working with the mortar must be placed in a container with water immediately after the application of the putty is completed. Then it should be thoroughly rinsed with running water.

What to look for when choosing?

For outdoor work, a composition that includes cement is suitable. All remaining mixtures from this company are suitable for interior decoration.

If you are going to level the surface (concrete, brick, wood), purchase a finishing compound. If you need to mask serious defects, then first use the cement, and then the finishing mixture.

If you need a composition for rooms where the level of humidity is high (swimming pool, kitchen, bathroom, sauna), then purchase a composition based on cement (this substance tolerates moisture well).

If you are going to make a perfectly flat ceiling or walls in a room with a high level of humidity, then in this case, too, choose a composition based on cement.

Finishing putty Vetonit is used for leveling walls and ceilings on drywall or mineral materials. Use the product for finishing plastered surfaces and plasterboard partitions. With the help of a ready-made pasty mixture, you can get a perfectly flat surface for subsequent painting or wallpapering. Vetonit offers a wide range of products, each with its own purpose. The choice of the composition depends entirely on the nature of the work.

Peculiarities

The company produces powdery building mixtures, which are widely used in decoration and construction. The most popular are the finishing putty and screed of this brand, as well as tile adhesive. In our country, there is an industry division of the international group of companies Saint-Gobain called Weber-Vetonit, which represents dry mixes of the Vetonit brand on the domestic market.

Putty

The mixture is used at the stage of final leveling of various surfaces. The quality and general appearance of the finished work depends on the correctness of the application. Vetonit putty is intended for filling cracks and crevices and creating a perfect surface after basic work.

Depending on the composition, there are three types of such a mixture: gypsum, polymer and cement. They can be applied both on ordinary concrete or brick, and on drywall and even on painted walls, both inside and outside the room. And on the putty itself, it is allowed to apply any decorating coatings - tiles, wallpaper, various paints and decorative plasters.

The advantages of Vetonit products are the versatility and environmental friendliness of the putty. Created from components that are safe for both nature and humans, it can even be used to decorate the indoor pool. The powder particles of such a mixture are so small that the finished putty layer has an almost mirror-like smoothness. It is resistant to aggressive weather conditions such as frost or hail, therefore it is suitable for facade finishing and can be applied even at sub-zero temperatures.

Plaster

On the domestic markets, there are several types of dry plaster from the Vetonit company, which are supplied both from abroad, for example, Finnish mixtures, and are made directly at Russian factories. As a rule, these are cement mixtures with sand or limestone and additional components in the composition in the form of various microfibers.

One of the advantages of Vetonit dry mix is the ability to apply to almost any surface, from concrete and brick to ceramics and plaster. Subsequent finishing is also possible with most of the known coatings - wallpaper, tiles, putty and even glass decorative plates. The plaster is waterproof and not subject to deformation in frost, which makes it possible to use it for exterior decoration of facades and rooms with high humidity. It adheres perfectly to most surfaces and hardens without shrinkage.

Self-leveling floors

The self-leveling Vetonit mortars, used as screeds, make it possible to create an ideal self-leveling floor with a thickness of 1 to 250 mm in one pass. The solution is suitable for the renovation and decoration of both new residential and office premises and buildings with a long service life.

The advantage of the brand is its high compressive strength, which allows the coating to withstand significant loads. Additional internal regulation will further strengthen this indicator. The self-leveling floor can be covered with even very thin finishing materials or left without finishing at all, since it has a smooth surface and does not require sanding.

The mixture quickly gains strength, which implies the ability to walk on such a floor within two to three hours after laying.It can be poured even over wood or ceramics due to the presence of special polymers in the composition.

Features and Benefits

Putty is a paste-like mixture, thanks to which the walls acquire a perfectly smooth surface. To apply it, use metal or plastic spatulas.

Weber Vetonit VH is a cement-based, super moisture resistant finishing filler for both indoor and outdoor use in dry and wet conditions. Its distinctive feature is that it is suitable for many types of walls, be it brick, concrete, expanded clay blocks, plastered surfaces or aerated concrete surfaces. Vetonit is also suitable for finishing pool bowls.

The benefits of the tool have already been appreciated by many users:

- ease of use;

- the possibility of manual or mechanized application;

- frost resistance;

- ease of applying multiple layers;

- high adhesion, ensuring perfect alignment of any surfaces (walls, facades, ceilings);

- preparation for painting, wallpapering, as well as for facing with ceramic tiles or decorative panels;

- plasticity and good adhesion.

Scope of application

The manufacturing company offers modern customers whole complex solutions in the field of construction: from starting and finishing walls to thermal insulation of facades.

Most of the mixtures are made on the basis of polymer components that are ready-made binders. After the putty is applied to the wall or ceiling, it hardens, after which you can glue wallpaper on it or simply paint the surface.

Depending on which filler is chosen: for dry rooms or rooms with high humidity, Vetonit will provide an ideal appearance of the treated surfaces. Once the walls have dried, they can be finished with tiles, glass or plastic.

Putty is also used for high-quality sealing of gypsum plasterboards, on the surface of which, after that, cracks are excluded.

After the process of filling the walls is completed, an unpleasant odor may appear in the room. However, it will wear off immediately after the mixture is dry. This feature is inherent in many materials for construction work.

If the gypsum plaster "Vetonit" is used, then after the work performed, you can apply a putty on it - a high-quality mixture will extend its service life. Choosing a moisture-resistant mixture marked VH on the package for work in wet rooms (in the bathroom, in the kitchen or in the pool), you do not have to worry - it is not afraid of a humid environment. That is why such a composition is often used in the processing of warehouses and the facade of the building.

Such special mixtures as "Vetonit TT" are also used on surfaces consisting of ceramic bricks or aerated concrete. Such a putty is frost-resistant, neither mold nor fungus will appear on it, which is very important in regions where a cold and humid climate prevails.

weber.vetonit V (formerly vetonit V) - putty

weber.vetonit V (formerly vetonit V) is a cement-based filler for leveling walls and ceilings in dry, damp, wet rooms and facades. Designed for manual and machine application.

Application area:

- surfaces of the following bases: brick, concrete, lightweight concrete, expanded clay blocks, plastered surfaces, including weber.vetonit TT, TTT plaster (vetonit TT, TTT);

- facade surfaces;

- leveling the surfaces of walls and ceilings during renovation and new construction with a layer thickness of 1-3 mm in one application (5 mm for partial leveling)

Advantages:

- ease of use;

- high adhesion to surfaces;

- moisture resistance;

- the possibility of mechanical spraying.

Instructions for use:

Substrate preparation The substrate must be firm, clean, free of dust and dirt. Substances that weaken the adhesion, such as grease, dust, etc. must be removed. If necessary, moisturize dry and absorbent surfaces.Windows and other surfaces that are not treated must be carefully protected.

Preparation of the mixture Pour 7-8 liters of clean water into a container and pour 25 kg (bag) of weber.vetonit V gray., The mixture must be added to the water, and not vice versa. The recommended water temperature is 20 ° C. Mixing is carried out with a powerful drill with a nozzle for 3-5 minutes. For better dissolution of the binder, the mixture is allowed to stand for 10 minutes. After light re-mixing, the mixture is ready to use. The mortar mixture is suitable for use within 3 hours from the moment of mixing with water. The temperature of the mortar mixture must be above +10 degrees C

Attention! Do not pour the mortar mixture down the drain so as not to clog the pipes!

Application The mortar is applied by mechanical spraying or by hand and leveled with a steel trowel. For full leveling, use a two-handed steel trowel 80 cm wide, and for partial leveling, use a small, 30 cm wide

When leveling in several layers, it is necessary to apply each subsequent layer to the completely dried previous one (after 1-2 days). The dried surface of the putty must be sanded and dust-free before applying the next layer. In dry conditions, to ensure the necessary curing conditions, the leveled surface is moistened with water using a spray gun. Slightly hardened surfaces can be wiped off with a damp sponge. After sanding, the leveled and finally hardened surface can be painted with alkali-resistant (cement-resistant) paint, wallpaper or tiled, after removing dust from the surface after sanding. Weber.vetonit Dispersio can be replaced with 10% mixing water to increase the wear resistance of the material and improve adhesion. In wet areas such as saunas, showers, etc. waterproofing must be done according to separate instructions. When smoothing old painted surfaces, weber.vetonit RF can be used as an adhesion layer or the base coat can be applied with weber.vetonit 410 mortar. Facade surfaces can be painted with weber.vetonit420 and weber.ton micro V silicon facade paints.

Attention! Weber.vetonit V (vetonit V) putty is not suitable for application on painted or plastered surfaces with weak lime mortars, leveled with water-soluble fillers containing polymer and organic binders, as well as for leveling floors. Drying time for one layer of the recommended thickness is 1-2 days with good ventilation

Drying time depends on layer thickness, ventilation and temperature. The level of 50% of the final strength is reached within 7 days at 20 degrees C, with a decrease in temperature, the process of strength gaining slows down

Drying time for one layer of the recommended thickness is 1-2 days with good ventilation. Drying time depends on layer thickness, ventilation and temperature. The level of 50% of the final strength is reached within 7 days at 20 degrees C, with a decrease in temperature, the process of gaining strength slows down.

Work tools and equipment are washed with water immediately after the end of work.

Precautionary measures:

- when working, you must use rubber gloves;

- avoid prolonged contact with skin and eyes;

- in case of contact with eyes, rinse with plenty of water;

- keep away from children.