What buyers and builders need to consider

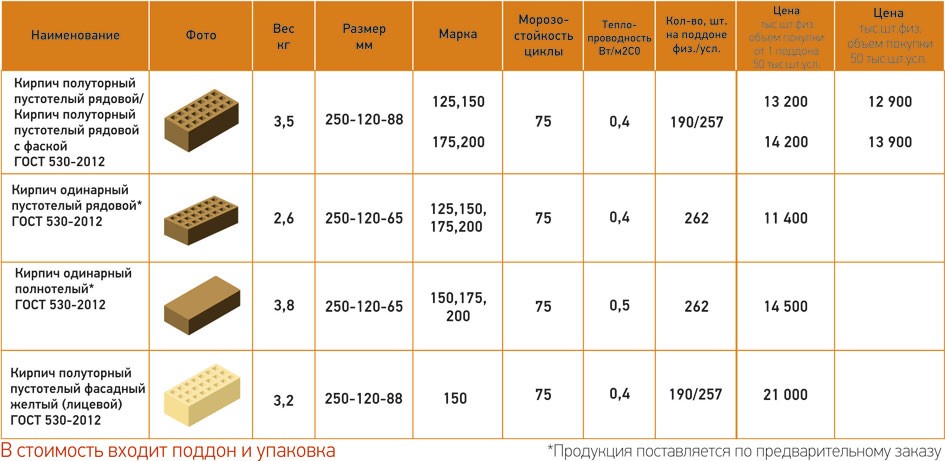

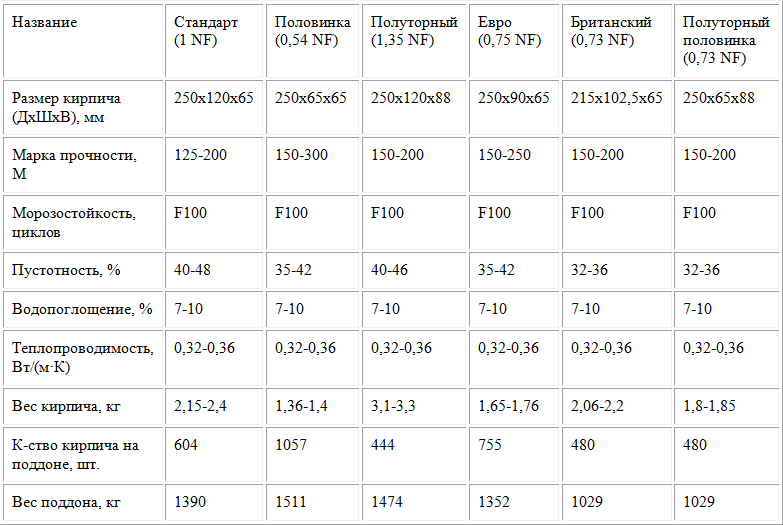

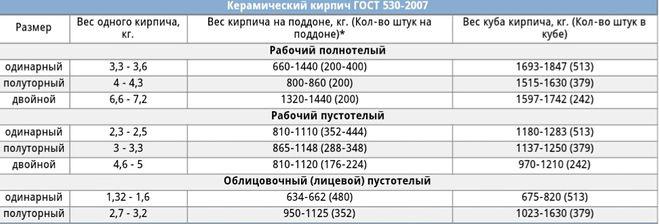

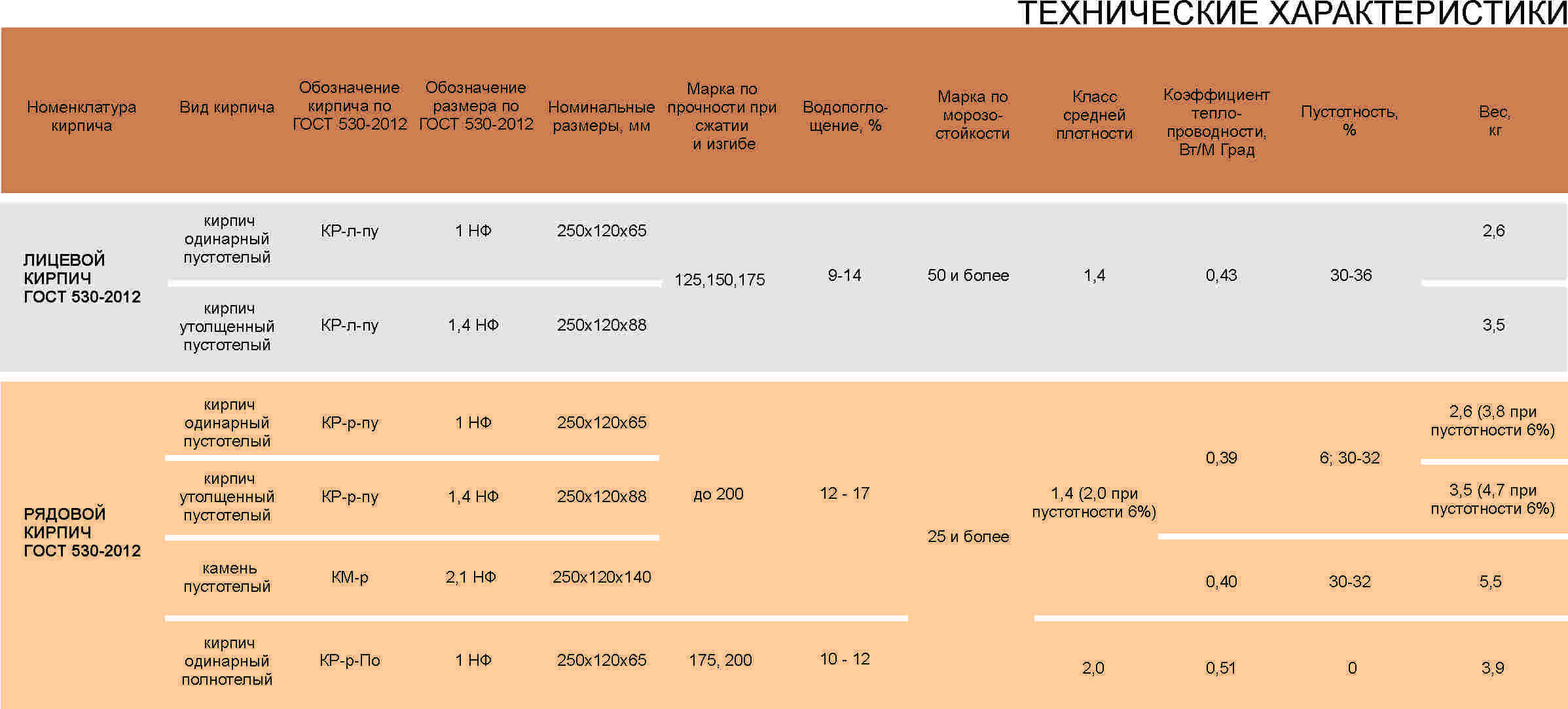

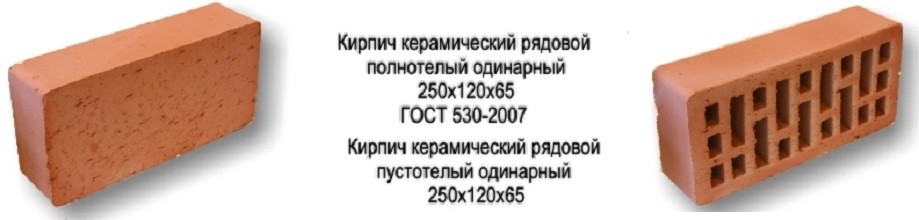

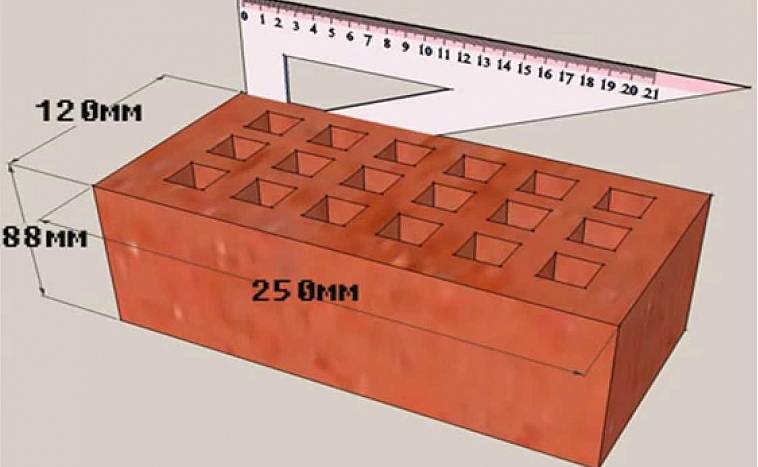

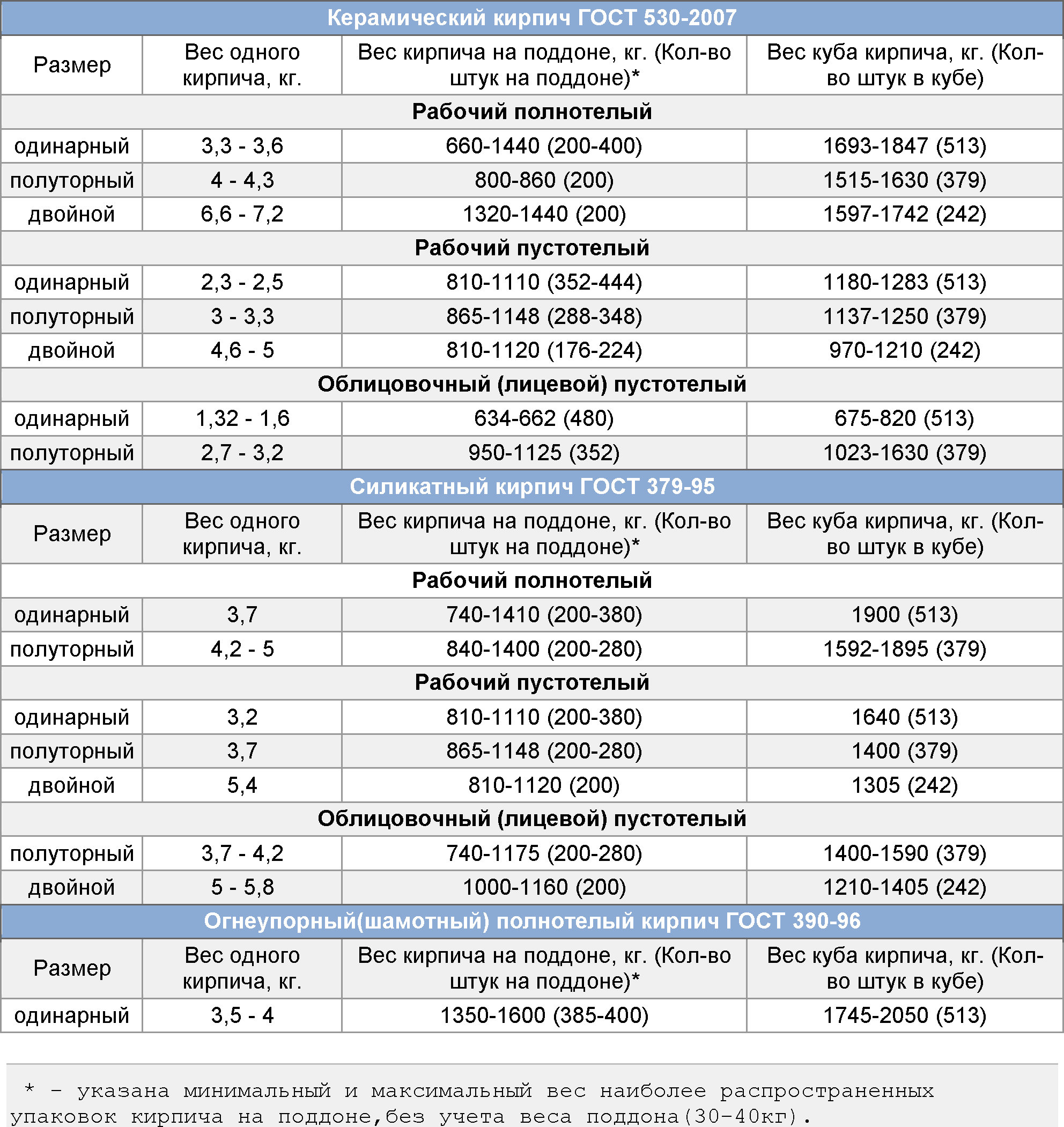

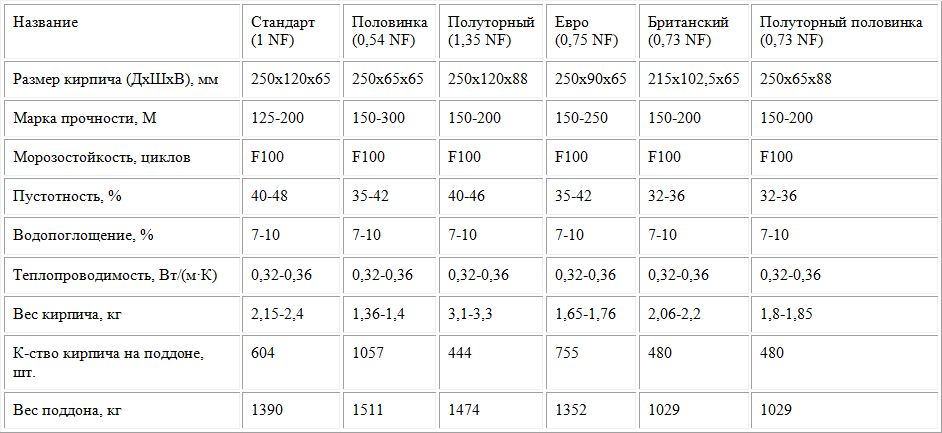

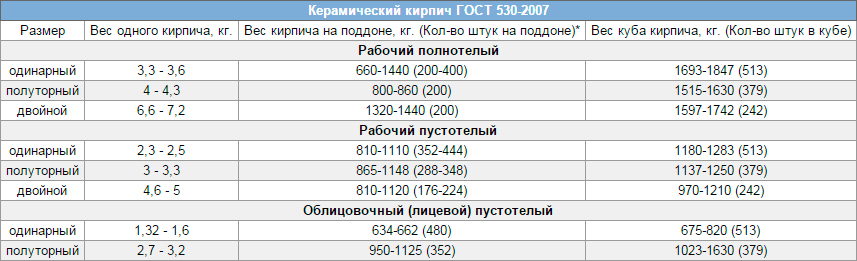

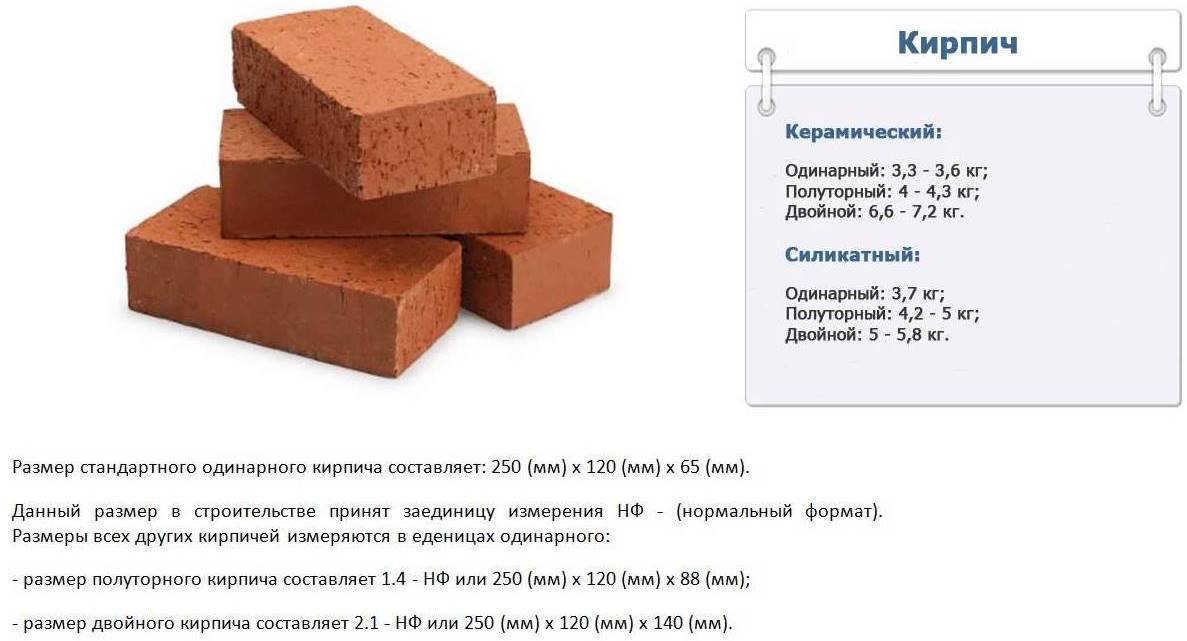

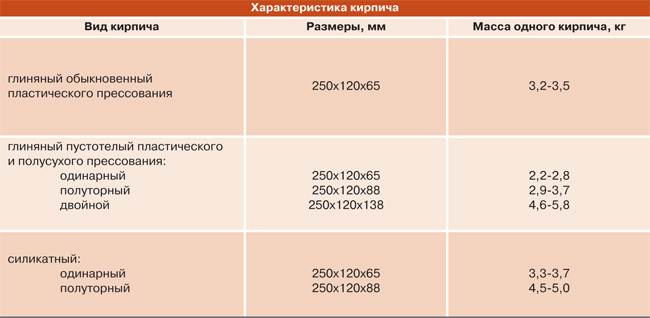

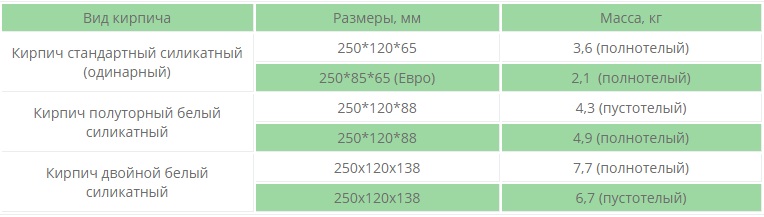

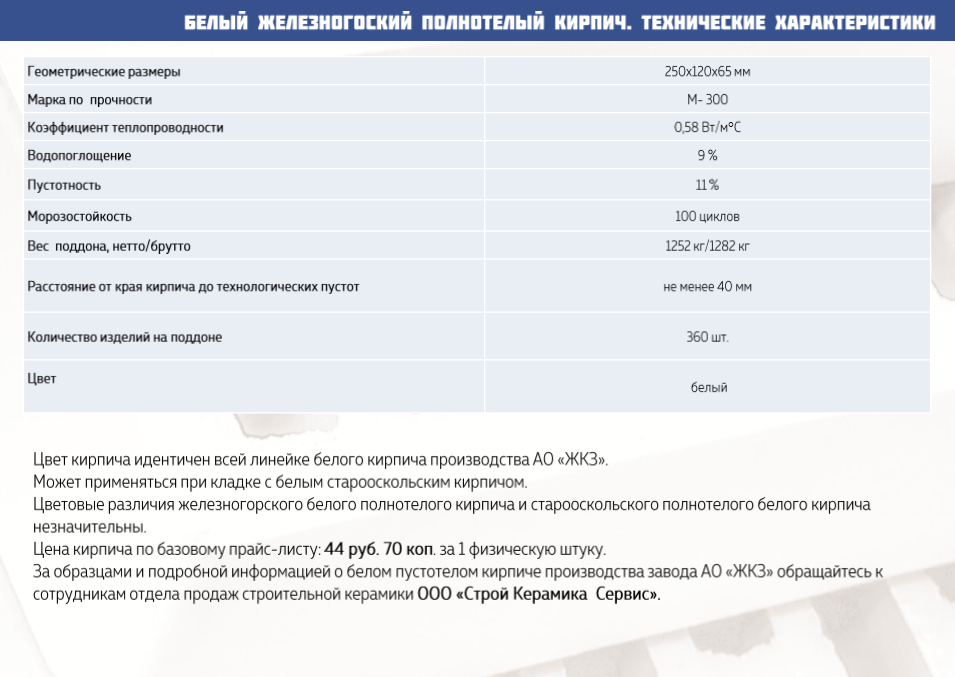

According to the requirements of GOST 530-2007, single ceramic bricks are produced only with a size of 250x120x65 mm. A similar material is used if you need to lay out load-bearing walls and a number of other structures. Its severity differs depending on whether hollow or full-weight facing blocks will be laid. A red facing brick that has no voids will weigh 3.6 or 3.7 kg. And in the presence of internal grooves, the mass of 1 block will be at least 2.1 and maximum 2.7 kg.

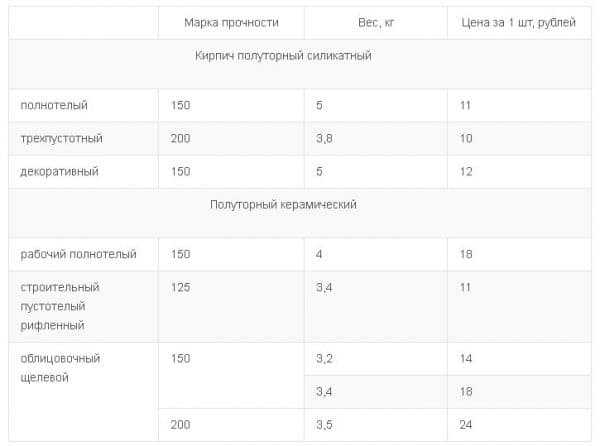

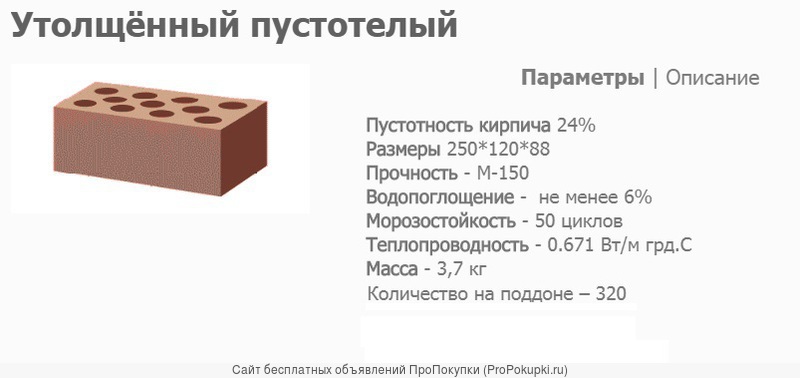

When using a one-and-a-half facing brick that complies with the standard, the weight is 1 pc. taken equal to 2.7-3.2 kg. Both types of decorative blocks - single and one and a half - can be used to decorate arches and facades. Full weight products can contain a maximum of 13% voids. But in the standards for material including voids, it is indicated that cavities filled with air can occupy from 20 to 45% of the total volume. The lightening of the brick 250x120x65 mm makes it possible to increase the thermal protection of the structure.

Additional Information

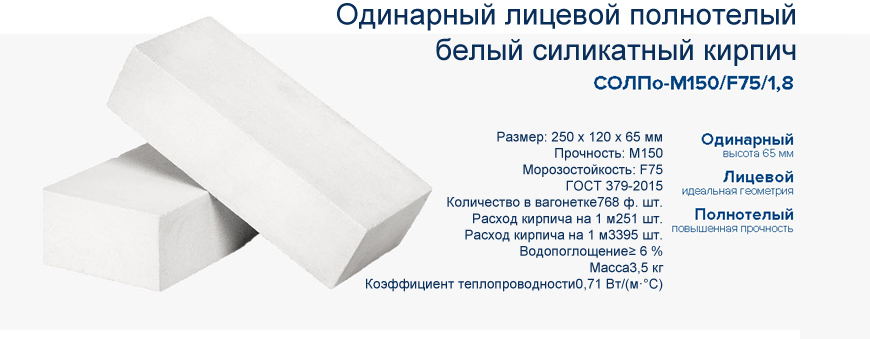

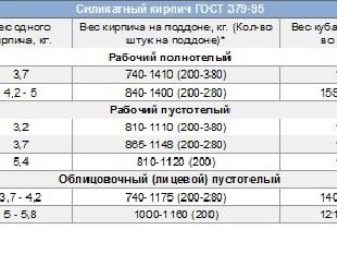

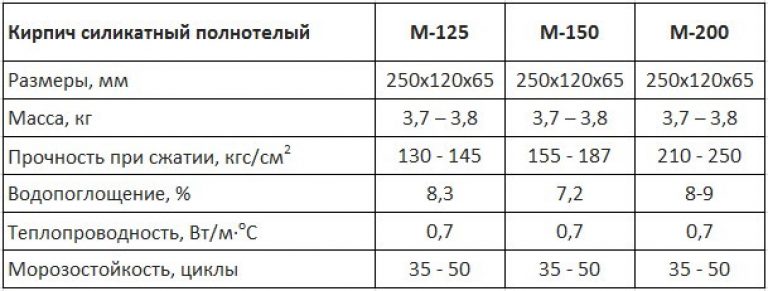

All of the above applies to ceramic facing bricks. But it also has a silicate variety. This material is stronger than an ordinary product, it is created by combining quartz sand with lime. The ratio between the two main components is selected by technologists. However, when ordering sand-lime bricks 250x120x65 mm, as well as when buying its traditional counterpart, the weight of the blocks must be carefully calculated.

On average, 1 piece of building material with such dimensions weighs up to 4 kg. The exact value is determined:

-

product size;

-

the presence of cavities;

-

additives used in the preparation of the silicate block;

-

geometry of the finished product.

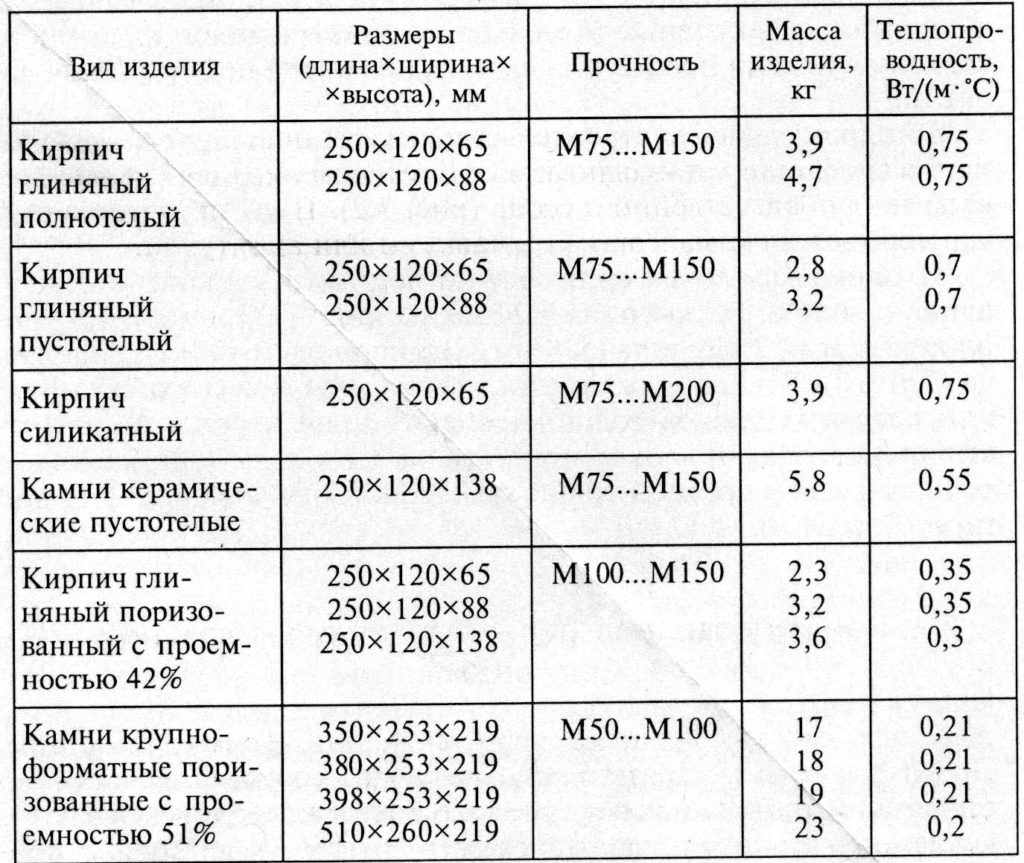

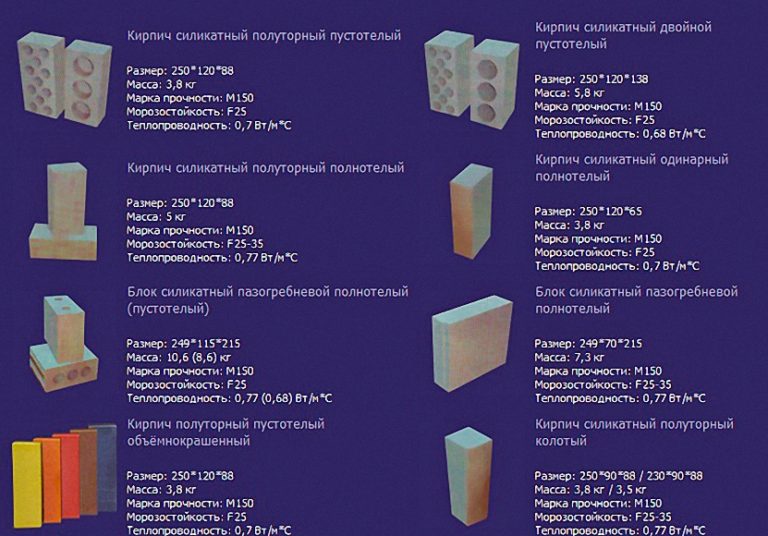

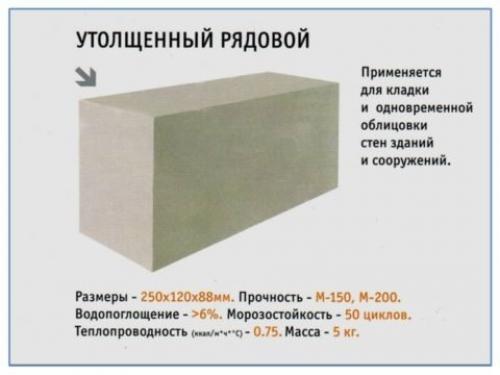

A single brick (250x120x65 mm) will weigh from 3.5 to 3.7 kg. The so-called one-and-a-half corpulent (250x120x88 mm) has a mass of 4.9 or 5 kg. Certain types of silicate, due to special additives and other technological nuances, can weigh 4.5-5.8 kg. Therefore, it is already quite clear that a silicate brick is heavier than a ceramic block of the same size. This difference must be taken into account in projects, to strengthen the foundation of buildings under construction.

Hollow silicate brick measuring 250x120x65 mm has a mass of 3.2 kg. This makes it possible to significantly simplify both construction (repair) work and the transportation of ordered blocks. It will be possible to use vehicles of lower carrying capacity. In addition, there is no need to reinforce the walls. And therefore, the foundation of the building being built will be easier to make.

The situation is slightly different with hollow products. Such a single sand-lime brick weighs 3.2 kg. Standard packaging includes 380 pieces. The total weight of the pack (excluding the substrate) will be 1110 kg. Weight 1 cub. m. will be equal to 1640 kg, and this volume itself includes 513 bricks - no more and no less.

Now you can consider one-and-a-half silicate brick. Its dimensions are 250x120x88, and the mass of 1 brick is still the same 3.7 kg. The package will include 280 copies. In total, they will weigh 1148 kg. And 1 m3 of silicate one-and-a-half brick contains 379 blocks, the total weight of which reaches 1400 kg.

There is also chipped silicate 250x120x65 with a weight of 2.5 kg. In an ordinary container, 280 copies are placed. Therefore, the packaging is very light - only 700 kg exactly. Regardless of the type of bricks, all calculations must be carried out very carefully. Only in this case will it be possible to ensure the long-term operation of the building.

If you need to determine the weight of the masonry, you do not need to calculate its volume in cubic meters. You can simply calculate the mass of one row of bricks. And then a simple principle is applied. At a height of 1 m there are:

-

13 rows single;

-

10 bands of one and a half;

-

7 strips of double bricks.

This ratio is equally true for both silicate and ceramic varieties of the material. If you have to revet a large wall, it is more correct to choose a one-and-a-half or even double brick. It is recommended to start your selection with hollow blocks because they are lighter and more versatile. But if there is already a solid, solid foundation, you can immediately order full-weight facing products. In any case, the final decision is made only by the customers of the construction or repair.

See below for details.

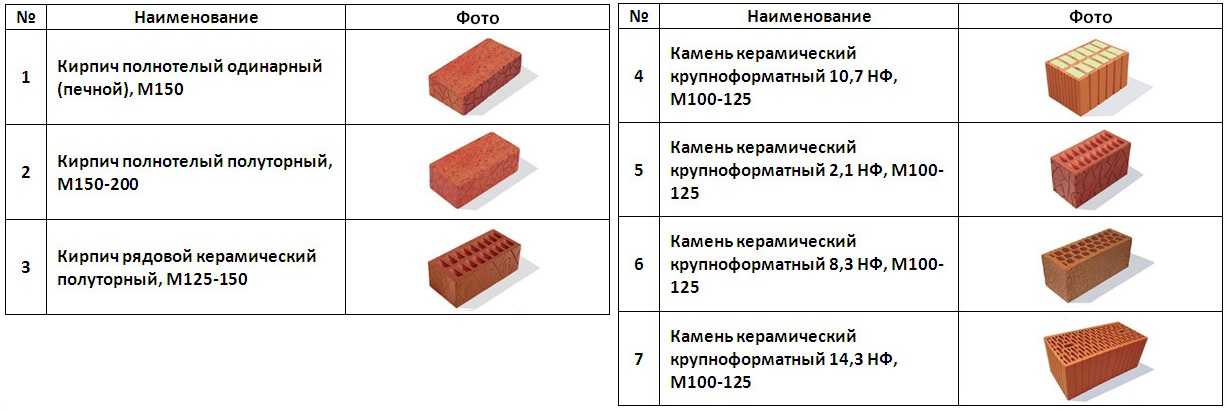

Varieties

The popularity and huge demand for double brick is due to its high performance. It can differ in texture, size, number of slots and shapes of voids. There are two types of blocks depending on the raw materials used for the manufacture.

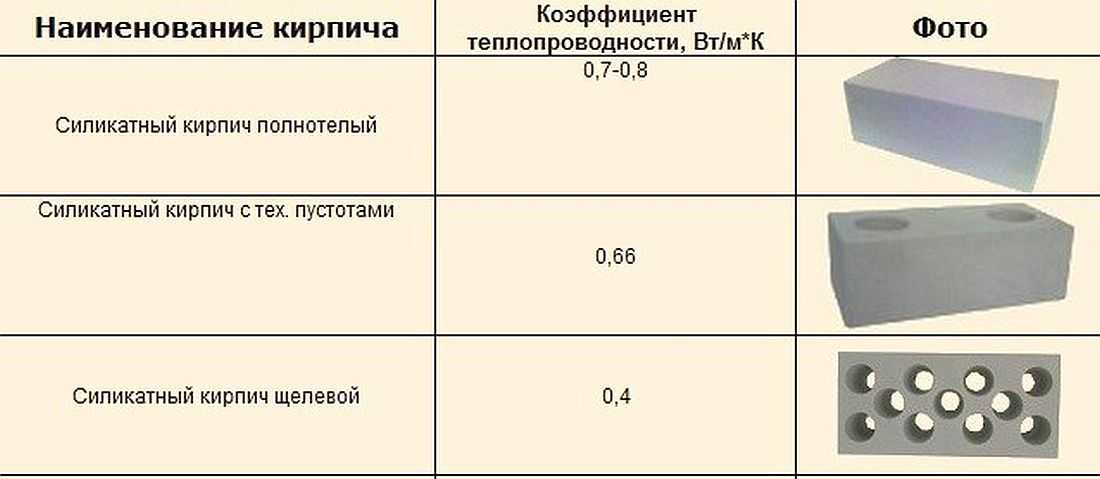

Silicate

Their main feature is that the production is carried out from a mixture of 90% sand and 10% water. In addition, the product also contains additives that increase its quality. This is an absolutely environmentally friendly material that looks like natural stone. The process of making double silicate bricks is carried out by pressing a moistened mixture of lime and sand, after which various pigments are added to it, and sent for steam treatment. It can be either hollow, slotted or porous. By strength, silicate blocks are divided into grades from 75 to 300.

These blocks are most often used for laying out internal and external partitions. It is impossible to use silicate brick for the construction of basements and foundations of buildings, since the product is not resistant to moisture, and in the absence of a waterproofing layer, it can be subject to destruction. It is not recommended to make double silicate bricks and laying pipes, ovens. It will not withstand prolonged exposure to high temperatures.

As for the advantages, this product has excellent sound insulation and has the correct geometric shape. Despite the large weight of such bricks, their laying is quick and easy. In terms of their density, silicate products are 1.5 times higher than ceramic ones, therefore they provide durable and high-quality masonry. In addition, silicate double blocks are 30% cheaper than other types.

Ceramic

They are a modern building material that is used in almost all types of construction work. Its feature is considered to be large, which is usually 250 × 120 × 138 mm. Thanks to such non-standard dimensions, construction is accelerated, and the consumption of concrete pouring is significantly reduced. In addition, double ceramic bricks are in no way inferior in strength to conventional blocks, therefore it can be used for the construction of load-bearing and self-supporting structures in buildings no more than 18 m high.The product is also characterized by high thermal insulation, the buildings laid out of it are always warm, and they are constantly maintained optimal microclimate.

The main advantage of double ceramic bricks is its affordable cost, while many manufacturers often make good discounts when purchasing blocks for the construction of a large object. These blocks, in addition to high quality, also have an aesthetic appearance. Usually brick is red in color, but depending on the additives, it can also acquire other shades. The product is environmentally friendly, and even with prolonged use and exposure to the external environment, it does not emit harmful substances.

These blocks are transported on pallets, where they usually hold up to 256 pieces. As for the marking, it can be different, more often people choose M-150 and M-75 bricks for the construction of objects. In addition, double ceramic blocks are subdivided into solid and hollow; not only their price, but also their heat capacity depends on this parameter.Hollow bricks cannot be used to build load-bearing walls, in this case only solid bricks are allowed. Despite the fact that the first is lightweight and significantly reduces the overall load on the foundation, the inherent cracks in it affect the thermal conductivity.

In addition, double bricks are subdivided into the following types.

- Private. These blocks are ideal for laying stoves, fireplaces and foundations. The only thing is that the front layout requires additional finishing.

- Facial. It is produced in clinker and hyper-pressed versions. It can be either solid or hollow bricks. Unlike ordinary blocks, face blocks are produced in curly, trapezoidal, rounded and twisted shapes. As for the color, it is dark brown, gray, red, yellow and brown.

Brick types

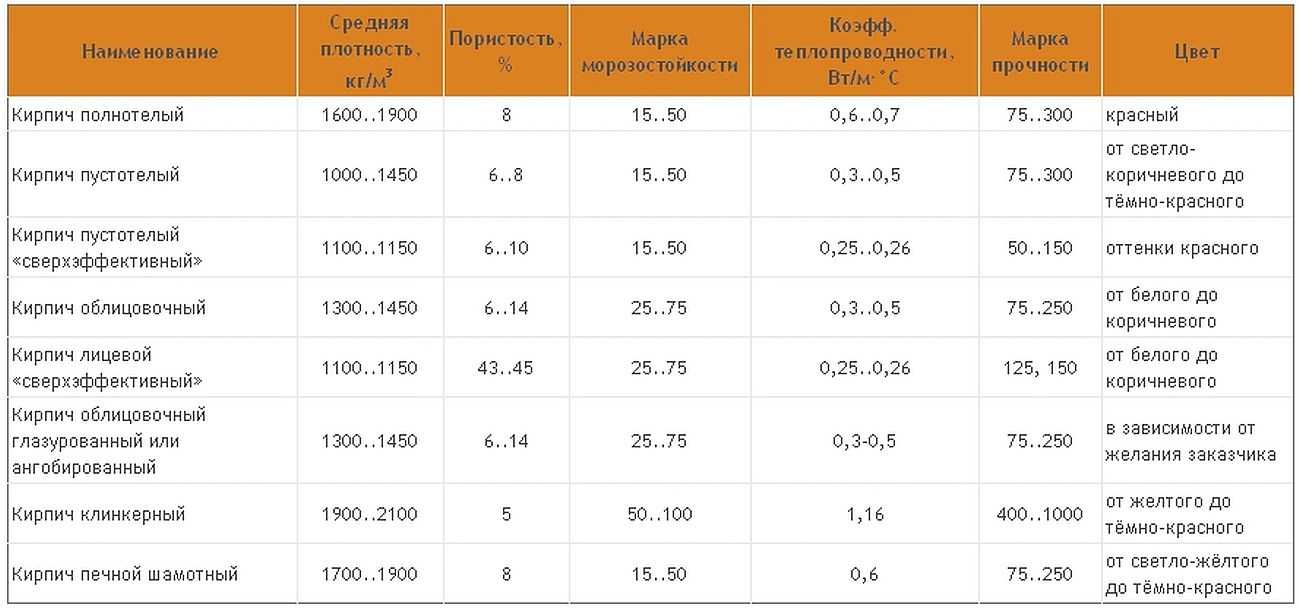

In order to choose the right brick for various types of masonry, you need to know its technical characteristics and purpose. All currently manufactured product can be classified according to the following criteria:

- used raw materials;

- appointment;

- the nature of the filling;

- appearance and size.

In addition, various production technologies and molding techniques can be used to make the ceramic product.

Classification of bricks by the type of raw materials used

It is from the material that the production depends on the performance characteristics, purpose and service life of the product.

Ceramic

This type of brick is made from high quality clay, purified from sulfates and marl. At the first stage of the technological process, molding takes place. After drying, the workpieces are placed in special furnaces, where they are fired at a temperature of 10,000C. A quality product is characterized by a semi-matte surface and a porous structure.

Silicate

The main ingredient in the product is refined quartz sand. In addition to it, up to 10% lime is added to the working mixture. Such material can be used to build both load-bearing walls and internal partitions.

Hyperpressed

The raw material for such a brick is the screening of marble, limestone, dolomite or shell rock, their share in the working mixture accounts for up to 90%. Portland cement is used as a binder, the mass fraction of which can be from 6 to 8%. The resulting mixture is poured into special molds and pressed. On the building materials market, you can find smooth and textured hyper-pressed bricks. Both modifications are widely used in the cladding of buildings.

Classification by purpose

The scope of this or that type of material depends on its technical characteristics and operating conditions.

Construction (private)

The technical characteristics of building bricks are regulated by GOST 530-2007. Scope - the construction of load-bearing walls and partitions. Since the appearance and thermal insulation properties leave much to be desired, the facade is additionally insulated with mineral materials and decorative cladding panels are attached.

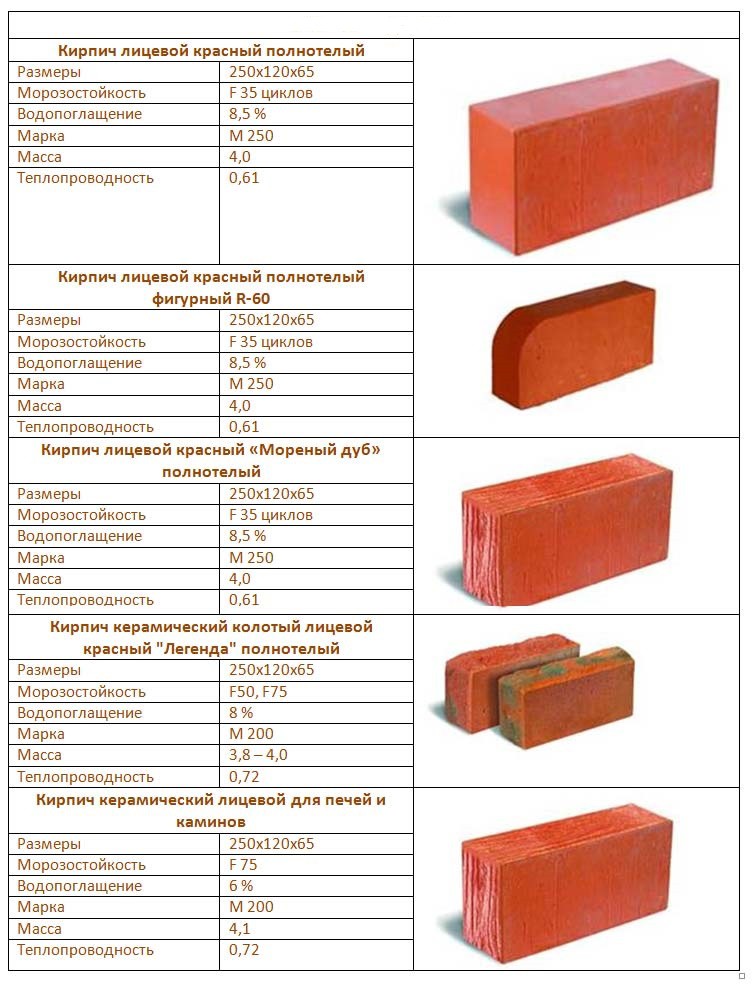

Facing

The main features are high surface quality and minimal deviations in size and shape. For decorative facade cladding, two types of cladding material can be used.

Textured facing

The product can be produced with both smooth and textured edges. Textured bricks are used for decorative cladding of facades and the construction of capital fences.

Shaped facing

Such a product is specially made for facing decorative elements (arches, columns, window slopes, etc.) and can have a very different configuration. High-quality styling can only be provided by top-class professionals.

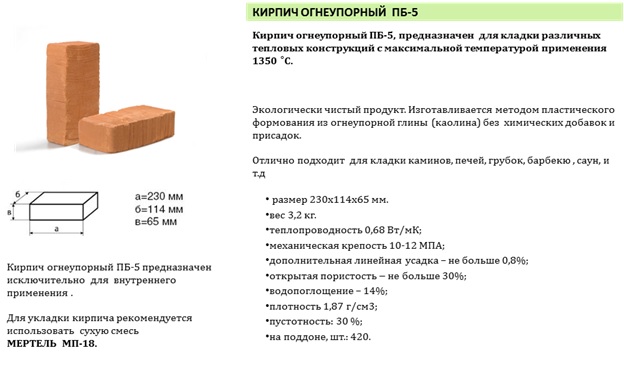

Chamotny

The main distinguishing feature of fireclay (stove) bricks is its high heat resistance and minimal thermal conductivity. It is used for laying stoves, fireplaces and other refractory structures.High-quality fireclay products can withstand temperatures up to 10000C for a long time.

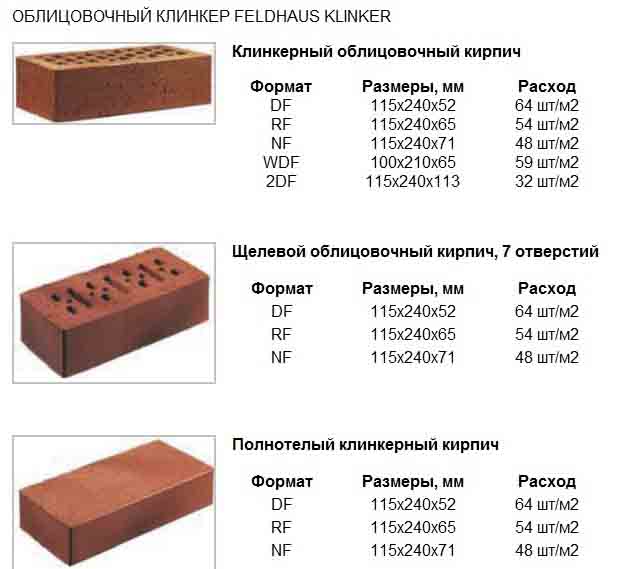

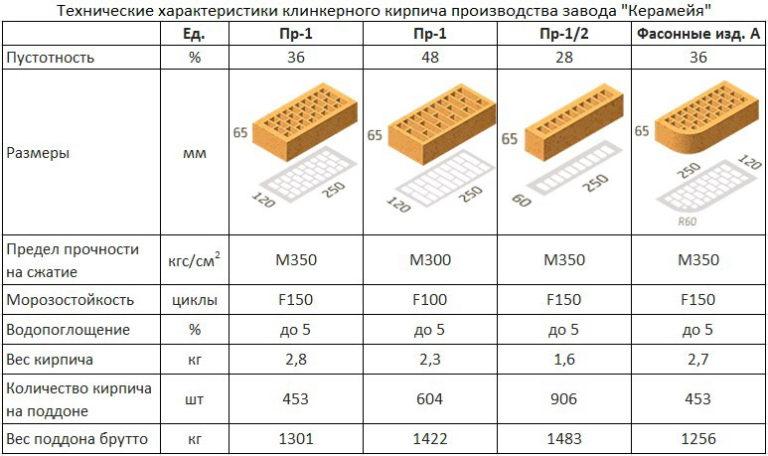

Clinker

This variety is obtained by sintering refractory clay layers. The clay used is thoroughly cleaned from impurities of chalk, alkali metal salts and other impurities. Clinker brick is distinguished by its high strength and hardness, practically does not absorb moisture and does not lose its properties in the temperature range from +50 to -500C.

Its use as a facing material provides reliable protection of the facade from weathering and mechanical damage.

Content classification

Depending on the purpose of the building, a solid or hollow look can be used.

Corpulent

This variety does not have any voids and is a monolithic parallelepiped. Used for masonry bearing walls of buildings.

Hollow

The mechanical strength of such a material is significantly lower than that of a monolithic material, but it has a lower thermal conductivity. In a silicate brick, voids can be from 25 to 30% of the volume of the product. Most often, hollow bricks are used for cladding and erection of internal partitions.

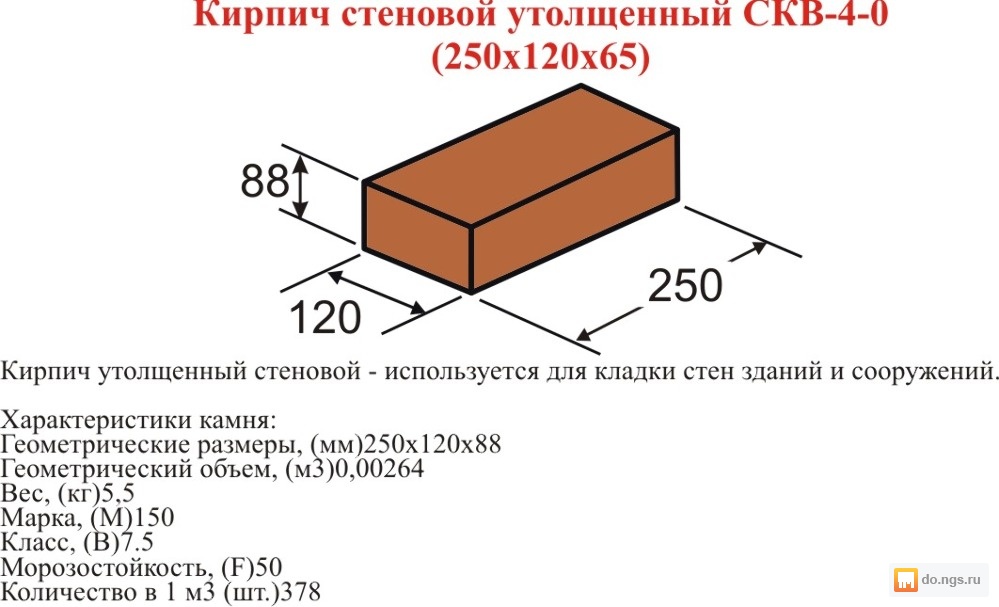

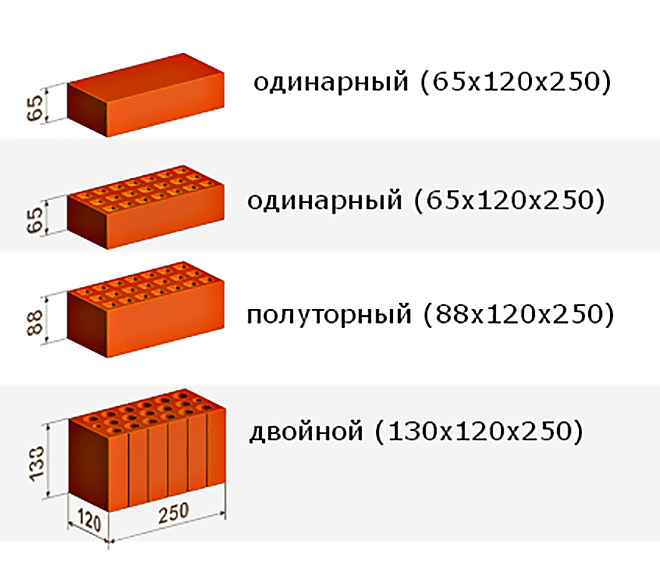

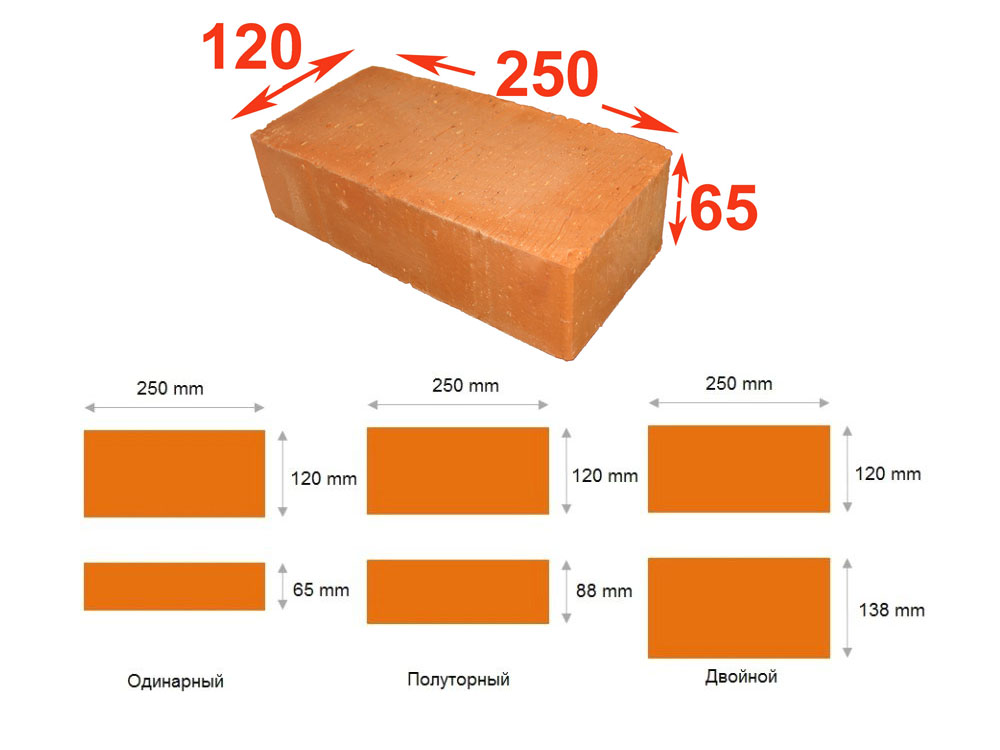

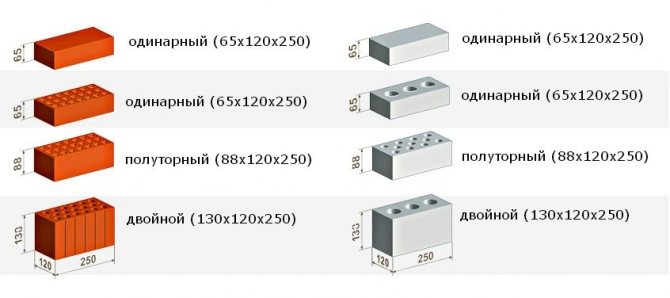

Size classification

In order to correctly calculate the number of bricks, you need to know its overall dimensions. There are three main sizes.

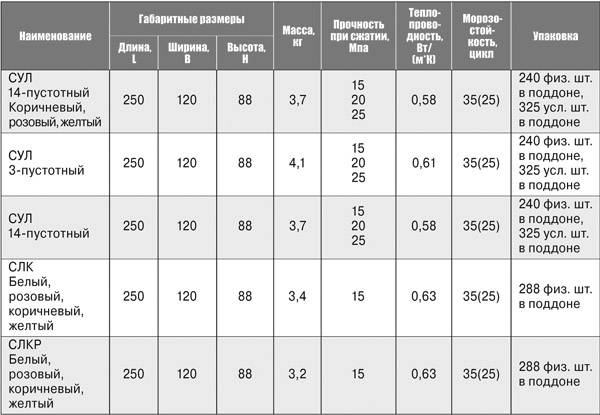

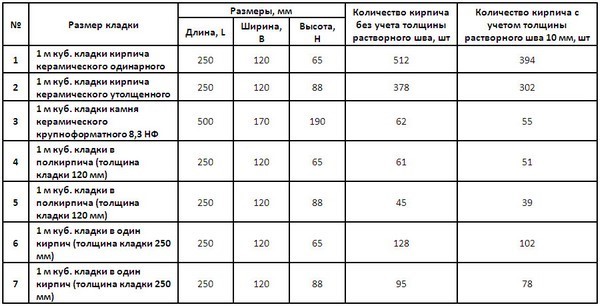

| Brick size | Overall dimensions, mm |

| Single | 250x120x65 |

| One and a half | 250x120x88 |

| Double | 250x120x138 |

Solid brick pallet weight

When carrying out such calculations, you need to know the mass of one specific material, the weight of the pallet itself and the number of products in the package, as mentioned above. As for the pallet, it looks like a wooden lattice, and its weight rarely exceeds 40 kilograms. Usually, manufacturers lay out bricks on a pallet in the form of a cube, which allows them to count materials as quickly as possible.

It is known that one package contains 200-330 pieces of ceramic solid bricks, let's calculate how much a pallet of bricks weighs, provided that the mass of such a product ranges from three to four kilograms:

- if there are 200 pieces of building materials in a pallet, and the mass of an individual copy is 3 kilograms 200 × 3 = 600 kilograms; when using 330 pieces of bricks in a pallet, 330 × 3 = 990 kilograms;

- if the weight of the product is 4 kilograms, for packaging containing 200 bricks 200 × 4 = 800 kilograms, for containers with 330 products 330 × 4 = 1320 kilograms.

The weight of the pallet itself, 30-40 kg, should be added to all results.

The nuances of packaging and consumption of silicate bricks

How many pieces in 1m2

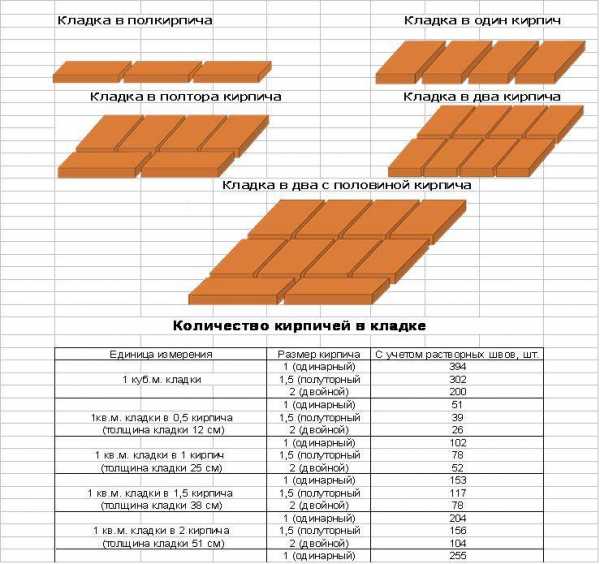

During construction, it is important to accurately calculate the amount of material in order to avoid unnecessary costs. Brickwork is calculated according to two parameters: area and volume

Therefore, let's figure out how many bricks will go to 1 meter of the wall in each case.

For 1 m2 of silicate brick masonry, a different amount of material can be used. Much depends on the size of the product. For example, to erect a wall one brick thick, the material consumption will be as follows:

- Single - 204 pcs.

- One and a half - 156 pcs.

- Double - 104 pcs.

If the wall is standard (2.5 bricks), the consumption will be as follows:

- Single - 255 pcs.

- One and a half - 195 pcs.

- Double - 130 pcs.

How to calculate the quantity in a cube (1m3)

Calculating the volume will be a little trickier. As an example, let's take a standard sand-lime brick with dimensions 250 * 120 * 65 mm. To find out how much material will go for 1 m3 of masonry, you need to calculate the volume of one unit of building material. To do this, translate the size into meters and multiply the sides.

After simple calculations, we get 0.00195 m3 - this is the volume of one brick. After that, we divide the cubic meter by the volume of one brick. On average, 512 blocks are used for 1 m3 of masonry.

Note that in both cases, the actual material consumption will be less: when calculating, you need to take into account the thickness of the mortar joint.

How many bricks are in the pallet

When ordering a brick, you need to take into account the number of pieces in a package. It looks like this:

On a pallet - depending on the size, 240-380 pieces of single and one-and-a-half bricks can be accommodated, respectively.

The amount of building material in one pack

In a pack - a standard form of polyethylene packaging can contain 480-560 pieces of hollow and monolithic bricks.

Note that there are no special requirements for the packaging of the material. Therefore, the number of bricks on pallets and in bundles may vary depending on the manufacturer.

Standard weight and specific gravity of solid and hollow building bricks

We have already said that not only the dimensions of the brick, but also its type will affect the weight of this product. First, consider the weight of solid bricks of different types:

the weight of a red solid brick 250x120x65 mm will be equal to 3.5 to 3.8 kg per one product;

Corpulent single

the weight of a red solid brick 250x120x88 mm will be equal to from 4 to 4.3 kg per piece;

Corpulent one and a half

the weight of the double brick will be 6.6 to 7.2 kg per block.

Let's compare these indicators with the weight of hollow bricks of the same dimensions:

the weight of 1 red hollow brick 250x120x65 mm is from 2.3 to 2.5 kg;

Hollow single

the weight of a red hollow brick 250x120x88 mm will be equal to from 3 to 3.3 kg;

Corpulent one and a half

the mass of double hollow bricks is from 4.6 to 5 kg per block.

Hollow double

The weight of an ordinary red brick allows you to determine the potential load on the foundation of a building, so this information needs to be known at the design stage of the building.

However, such a calculation is more convenient to calculate not in relation to the weight of one brick, but in relation to the specific weight of the building material per cubic meter of area.

Here the values will be as follows:

- the weight of 1 m3 of red solid brick 250x120x65 mm will be equal from 1693 to 1847 kg;

- the weight of 1 m3 of one and a half red brick will be from 1515 to 1631 kg;

- the weight of 1 m3 of double red brick is from 1597 to 1742 kg.

It would seem that the weight of a single red brick is less than the weight of one and a half and double, but the total mass of this building material, located on one cubic meter, is higher. What's the matter?

Everything is simple enough. The fact is that one cubic meter of space accommodates a larger number of single bricks - about 513 pieces. As for one-and-a-half bricks, there are only 379 pieces in 1 m3.

The double brick is even smaller due to its large dimensions. On average, 242 pieces are placed on one cubic meter of area. We found out the weight of a red solid brick 250x120x65 per cubic meter.

Let us now consider similar parameters, but for hollow bricks:

- the specific gravity of a red hollow brick 250x120x65 mm per cubic meter will be from 1180 to 1283 kg;

- the weight of 1 m3 of one-and-a-half hollow brick will be from 1137 to 1250 kg;

- the weight of one cubic meter of double hollow brick will be from 970 to 1210 kg.

As for the number of pieces in one cubic meter, this indicator fully corresponds to the number of solid bricks in 1 m3. Bricks are often sold in batches. It is clear that rarely will anyone need to purchase a brick by the piece, so they buy pallets with bricks.

So, the weight of a pallet of solid red brick 250x120x65 mm is from 660 to 1440 kg. At the same time, one pallet can hold from 200 to 400 items.

One pallet of double solid bricks will weigh from 1320 to 1440 kg. The pallet also holds about 200 pieces. We found out the weight of one standard red brick, which is about 3.5 kg. Various supporting structures, foundations and other elements of each building are made from it.

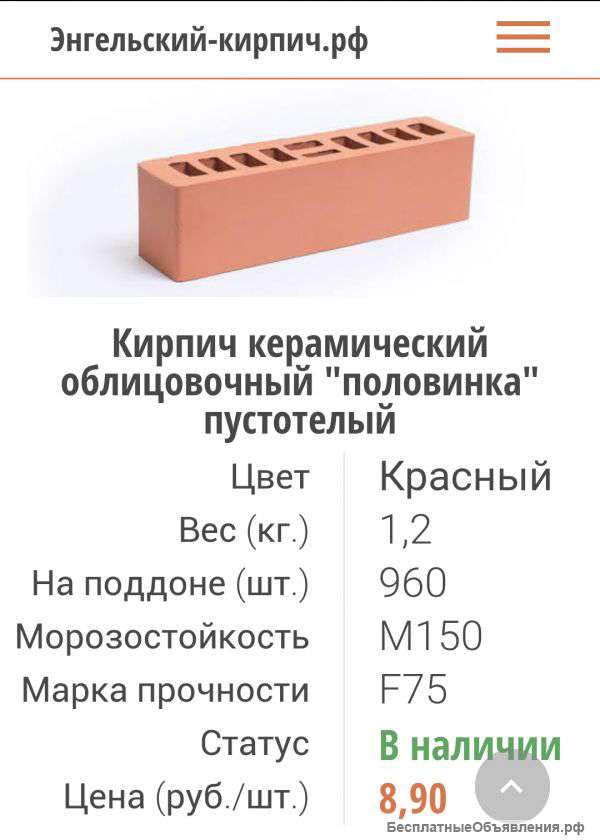

But people use other types of bricks as well, so they need to know about all of their parameters. In addition to standard bricks, there are two more types - facing and refractory. So, the weight of a red facing brick without voids will be from 3.6 to 3.7 kg.

If voids are present, i.e.the brick is hollow, its weight will be from 2.1 to 2.7 kg. One-and-a-half facing brick will have the following parameters:

- the weight of hollow bricks ranges from 2.7 to 3.2 kg;

- the weight of 1 solid red brick is from 4.2 to 6 kg.

The weight of the red brick oven will be from 3.5 to 4 kg. It should be noted that refractory bricks are produced only in full-bodied, i.e. without any voids and holes.

For more information on the weight of the brick, see the video:

Red pattern

With the help of stoves and fireplaces, it is possible to create cozy and comfortable conditions in the house, give it warmth and pleasant notes. Red stone, the dimensions of which can take on a variety of values, is used not only for the construction of stoves and a fireplace, but also for other structures, which are characterized by the influence of a very high temperature regime.

The red stone is able to easily withstand high temperatures - 1400-1800 degrees.

Red and its dimensions depend on what type of product is used for the construction of a particular structure.

You can learn about the disadvantages of silicate bricks from this article.

There are such varieties of the product in question:

- Simple. Such a stone, in comparison with a refractory one, gains heat very quickly and is able to withstand temperature extremes. A simple stone can be used for the construction of stoves and fireplaces, since they are able to heat a building and give off heat energy perfectly.

- Refractory. The production process of the product in question involves the use of special, high-strength types of clay. After that, the raw material is quenched. The resulting stone perfectly tolerates high temperature indicators, and it can be used in places where there is an effect of too high temperature conditions.

You can find out how much the kiln brick weighs from this article.

The dimensions of the red material can take on different values. However, the manufacturer can produce a red stone of standard sizes - 65x120x250 mm. This size is considered normal for the product shown. Thanks to them, red brick is one of the most suitable materials for making transverse-longitudinal masonry walls.

Brick yellow facing one and a half price and other technical data of the building material are indicated in the article.

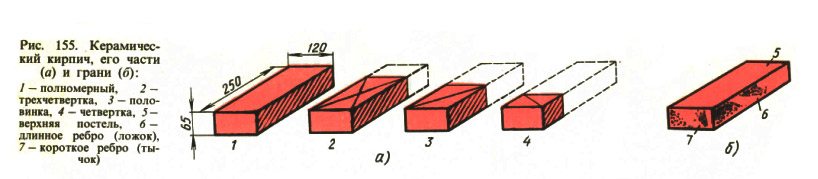

Each facet of the material according to GOST 530-2007 has its own name: poke, spoons and bed. Normal format brick can be divided into the following types:

Table 1 - Sizes of red