What is a pallet?

Pallet (pallet) - a specific device designed for the transportation of ceramic materials, in particular, brick products. It allows you to safely deliver brick blocks anywhere with minimal risk of damaging or spoiling them on the road. Pallets are a special shield, knocked down from separate boards. They are:

- Depending on the materials used:

- wooden;

- metal;

- wood-metal.

- Based on the type of attachment:

- on supports;

- on hooks.

With the help of a pallet, not only the transportation of brick products is carried out, but also its storage and loading. In addition, the pallet plays the role of packaging (a kind of pack), and its cost is paid by the customer of the building materials separately. Accordingly, the more expensive the materials from which the container is made, the higher its price. The most popular are wooden products, since they are the cheapest and, unlike wood-metal ones, can be transported by all major modes of transport: water, rail and road.

Despite the unsightly appearance of the pallet, it must be manufactured in compliance with certain standards regulated by GOST. The following rules must be followed:

- complete technical equipment of the production line;

- proper manufacturing control;

- compliance with all necessary technical standards and parameters;

- checking the quality of the finished product;

- familiarization of buyers or persons who will use it, with the rules of operation.

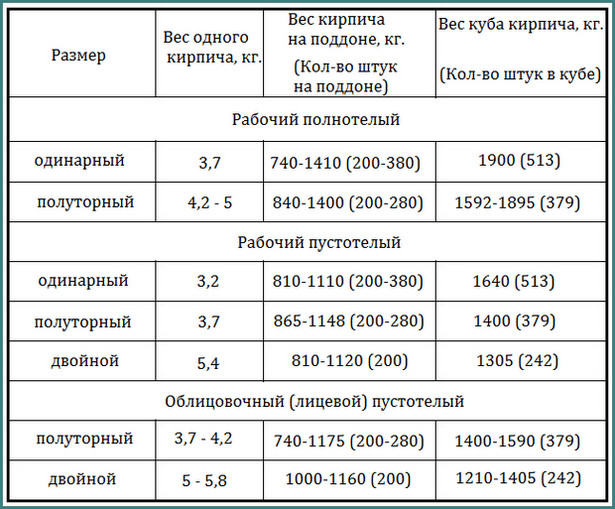

Pallet weight with brick

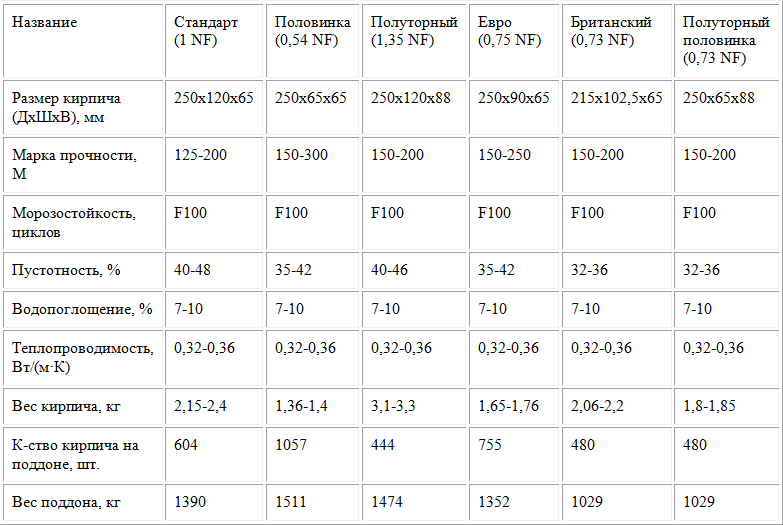

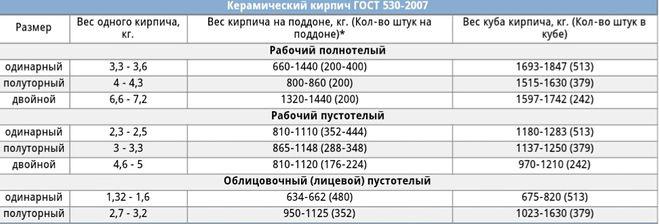

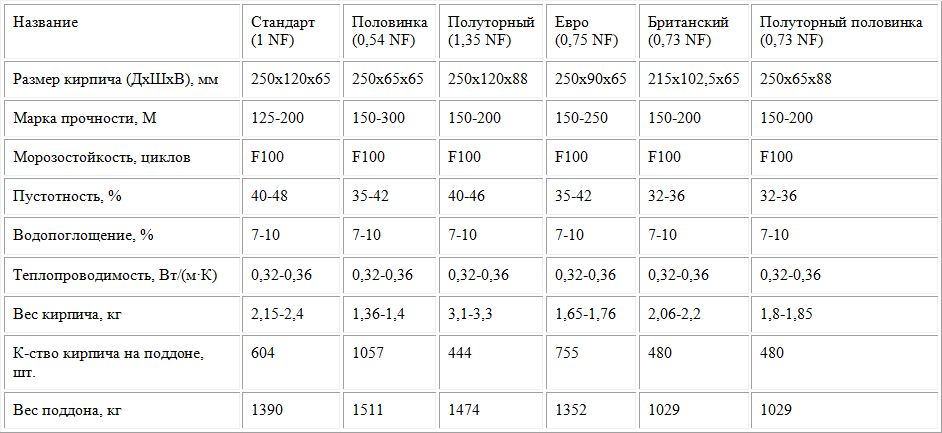

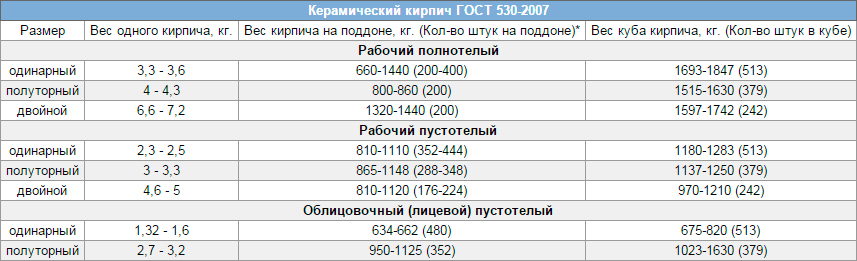

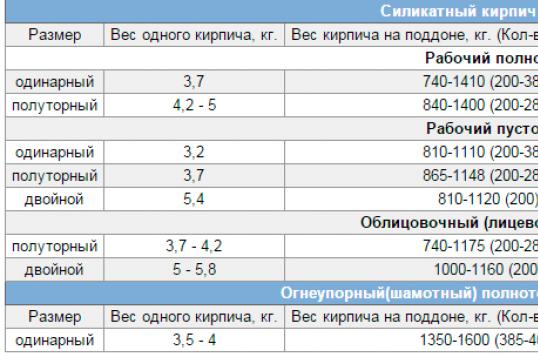

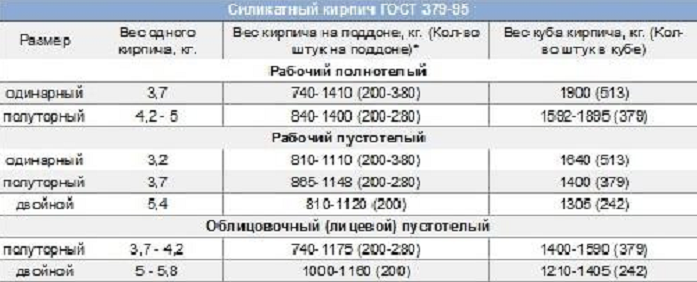

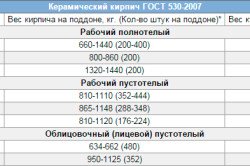

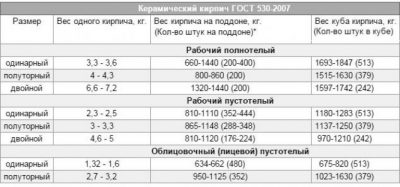

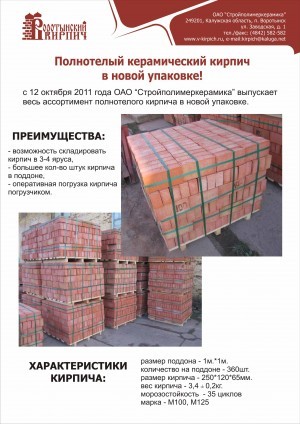

It represents the total mass of both the container and the brick itself. To calculate how much "clean" building material weighs, you need to know the mass of one and the total number of blocks, multiply these values and subtract the mass of the pallet. The weight must be specified with the supplier and checked in accordance with GOST, taking into account the type, density, purpose of the block. Full-body and single blocks can be transported in 200-400 blocks. Considering that the weight of each is 3.3-3.6 kg, pallets can weigh both 660 and 1440 kg. The weight of one and a half is less variable, since one block has a mass of 4 kg. No more than 200 bricks can be stacked on one container at a time, and, therefore, the weight is 800 kg.

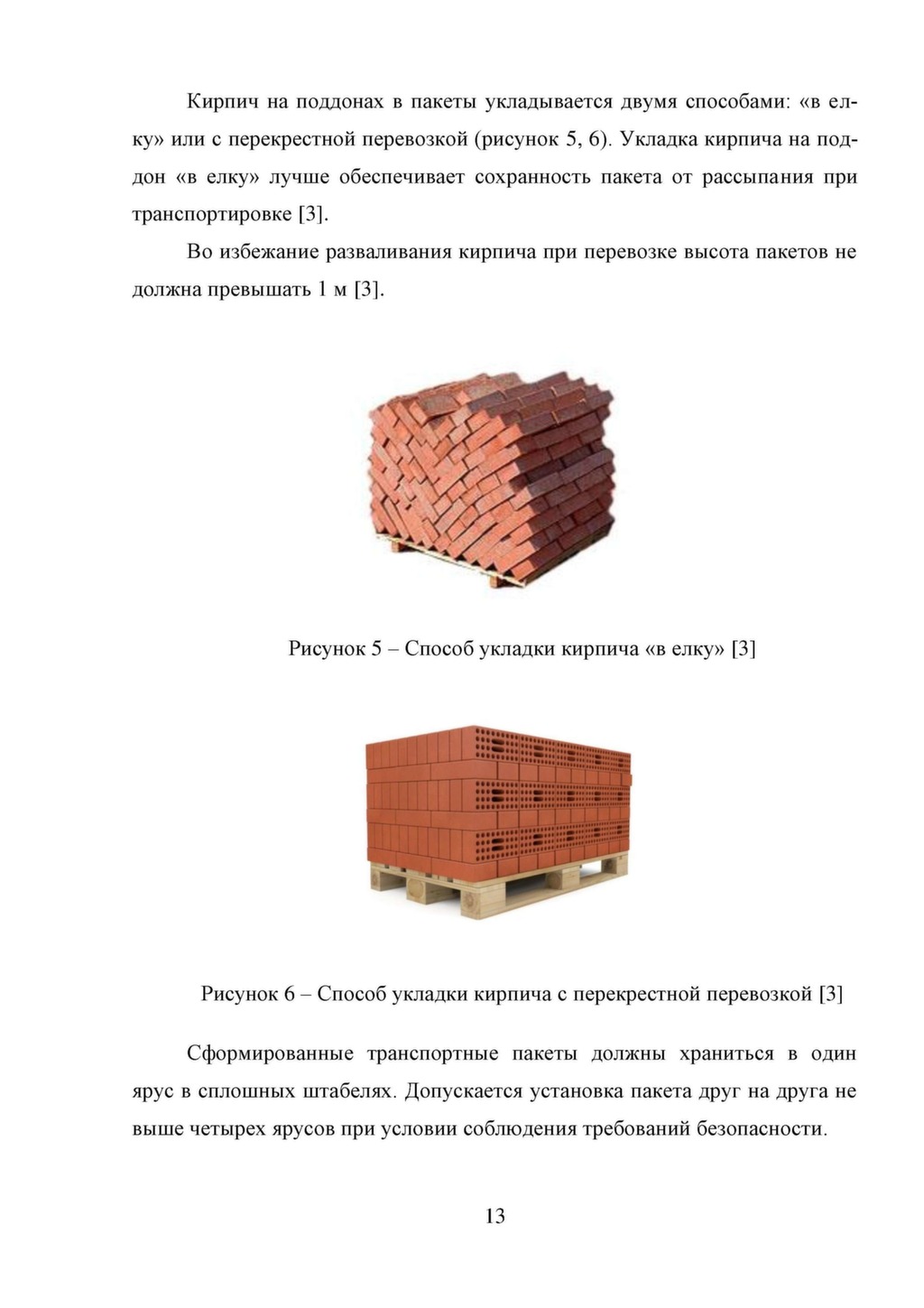

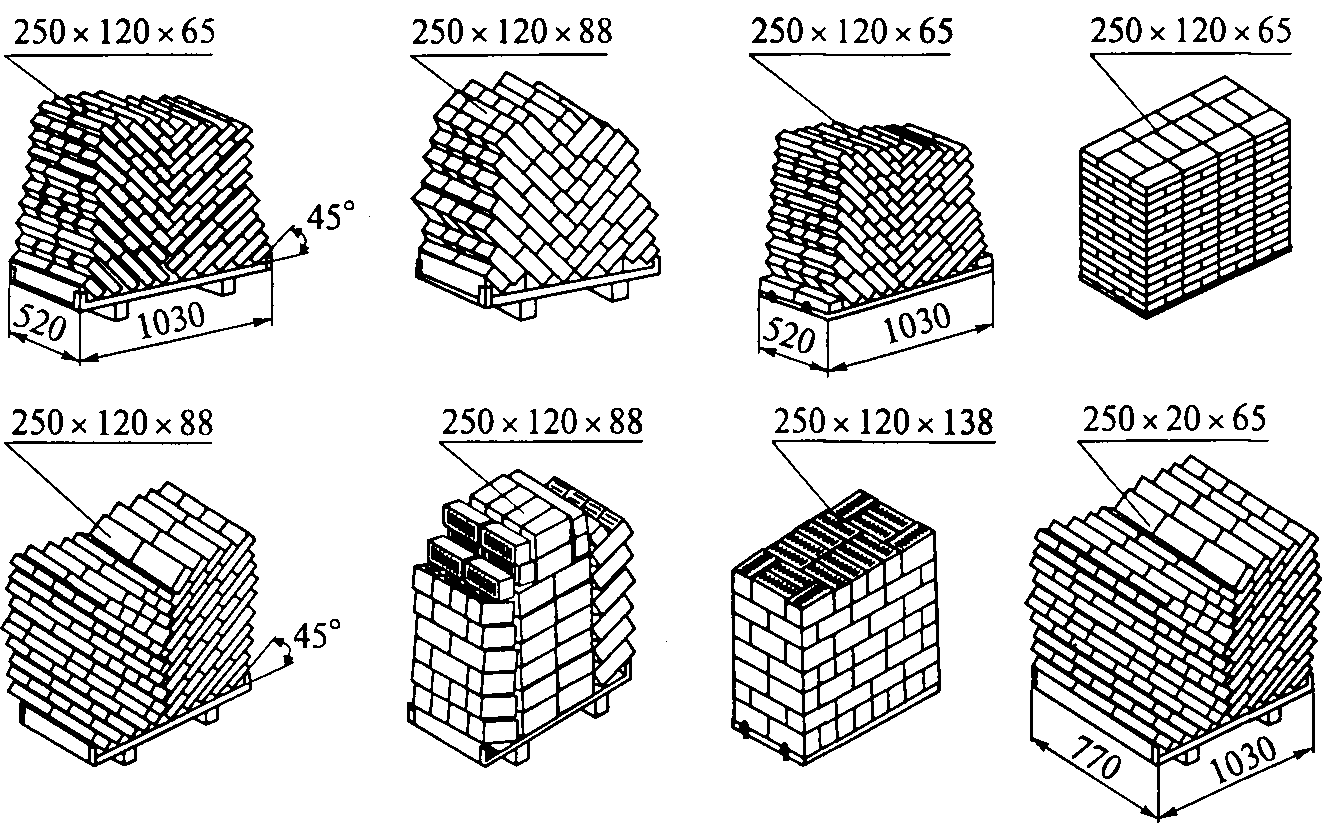

The state building codes indicate that the weight of a pallet with solid or hollow bricks should not exceed 850 kilograms, but such rules are often ignored by the manufacturer and the mass of material, taking into account packaging, can exceed one ton or exceed the recommended figure by two or more times. According to the requirements, the product can be stacked on pallets "herringbone", "on the edge" or "plate" with the obligatory banding of elements. The same building rules say that pallets with materials can be placed on a construction site in no more than two tiers.

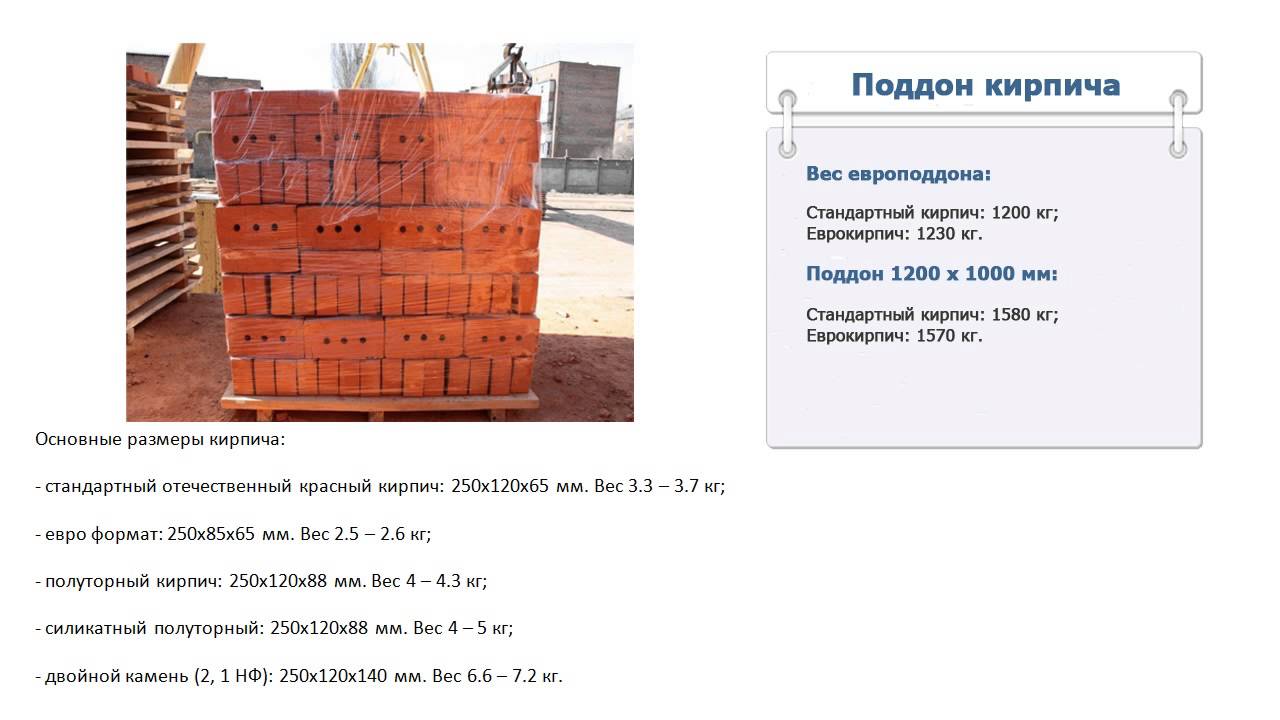

For the convenience of transportation and preservation of goods, the container is wrapped with a special thickened film and tied with a metal tape. After manufacturing, bricks are sorted by type and brand and sent to separate zones for storage in a warehouse.

The weight of a pallet with a brick can be obtained from the seller or calculated independently, with the exception of products laid out at a certain angle - here the mass indicator may differ. When carrying out independent calculations, you need to have the following information: know the mass of a particular product and their number in the pallet.

How much does a brick weigh?

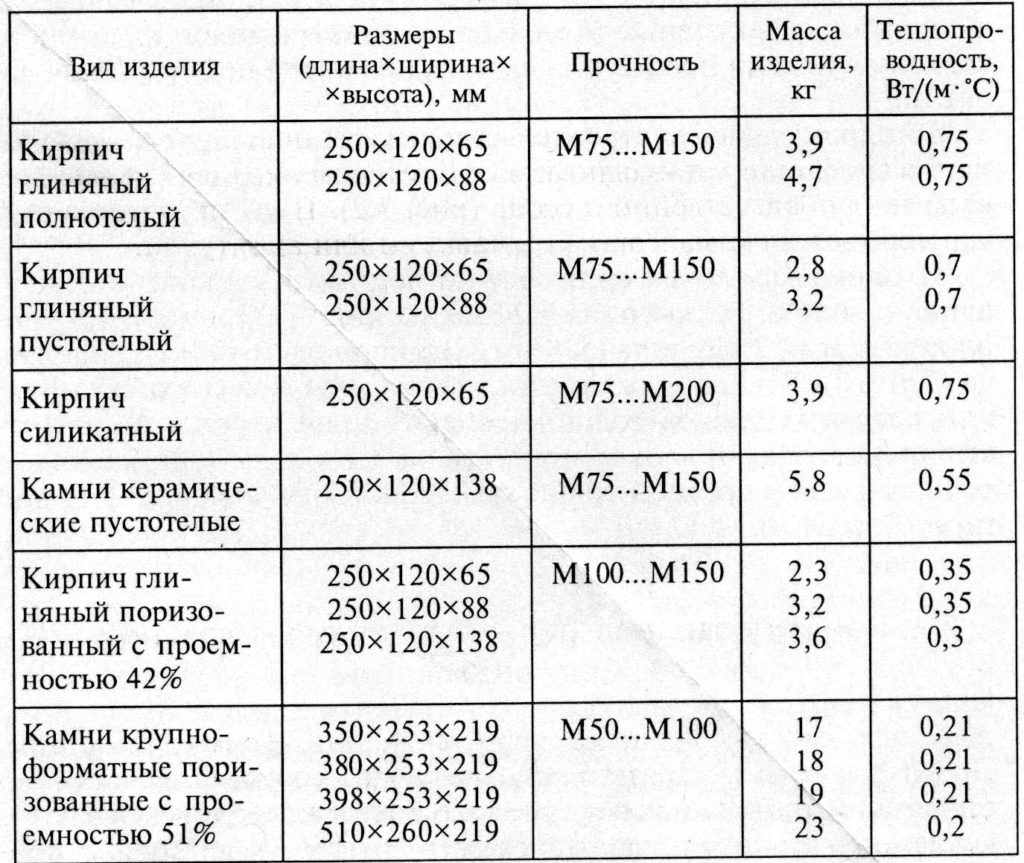

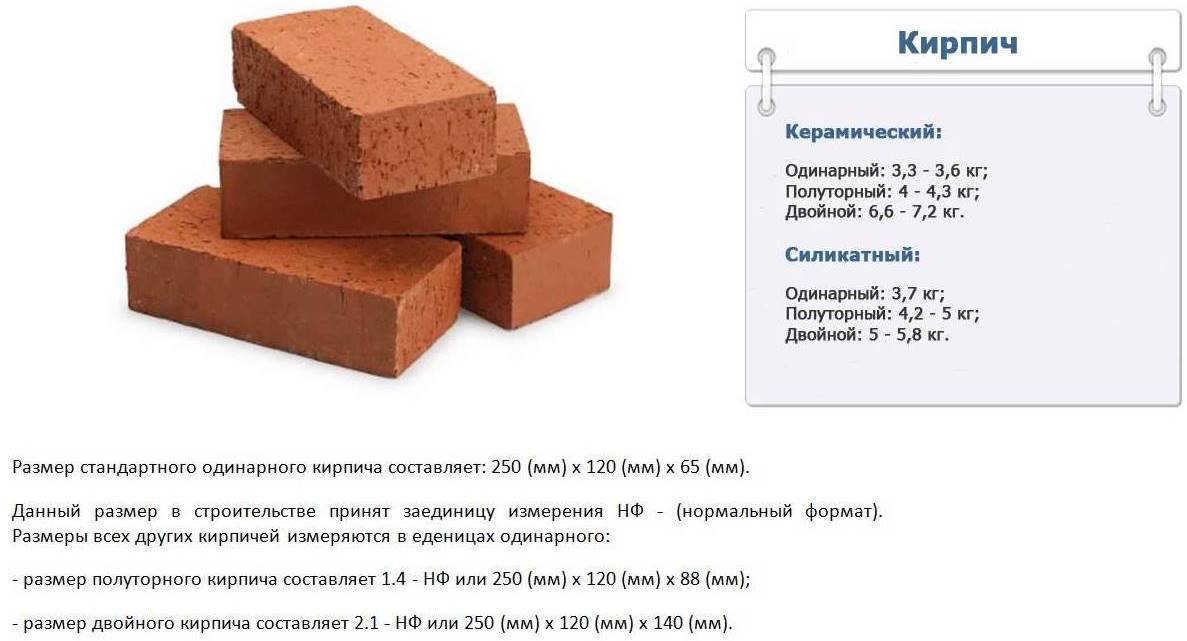

The block weight is variable. It depends on the size and density of the building material, ranging from 2 to 6 kilograms. To find out the net weight of blocks transported by pallets, you need to know what it is.Brick is classified according to several criteria:

- by type - silicate or white, ceramic or red;

- by functional purpose - working, refractory, clinker, facing;

- in size - single, one and a half, double;

- in shape - slotted or dense.

Each type of building structural material has its own purpose, and, therefore, is determined with the weight of a separate block at the design stage, taking into account which brick is supposed to be used.

How is building material stacked on a pallet?

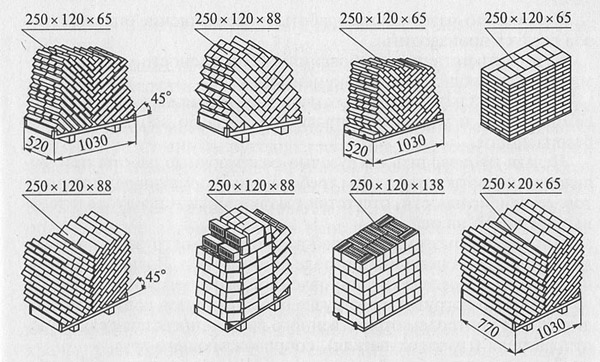

Placing brick blocks on pallets is done in several ways, approved by GOST. The height of bricks in the package is also regulated and should not exceed 1 m. At the same time, the types of briquettes do not affect the way of laying, the same technologies are used to accommodate backing, refractory, furnace and other types. Methods for placing ceramic products on a pallet:

- Bandaging the rows. Brick blocks are laid on the board with an edge or flat, depending on the types, sizes, methods of transportation. After that, they are secured using horizontal cross-knitting.

- "Herringbone". This is the safest way to lay brick briquettes. It consists in placing the transported products strictly at an angle of 45 ° to the center, and at the edges of the pallet, they are fixed with triangular beams. Using this method allows you to transport building material without scattering or violating its integrity.

A certain number of blocks can fit into a brick package, which depends on the type, weight, dimensions and the presence of voids in the material. There are varieties of ordinary, cinder block, stove, Karasevsky, zabutovochny, ordinary (M 150) material from which brickwork is made. They are used in the construction of load-bearing walls, interior partitions, the construction of stairs, fences, as well as in the construction of a basement room.

Number of bricks in one pallet

Despite the abundance of fundamentally new building materials, traditional brick is still one of the most popular and relevant options for laying walls and building individual houses. Bricks are sold in pallets, which greatly facilitates their storage, transportation and handling. But the majority of private developers prefer to calculate the purchase volume by the piece. In addition, quite often manufacturers set the price not per unit of goods, but per pallet. Therefore, in order to know the total cost, it is necessary to correctly calculate how many bricks are in the pallet.

Brick and its varieties

In order to calculate the amount of material that fits in one pallet, you should understand which of its types you need to buy in a particular case. Depending on the raw materials used, a distinction is made between silicate and red bricks. By its structure, it can be:

1. Red.

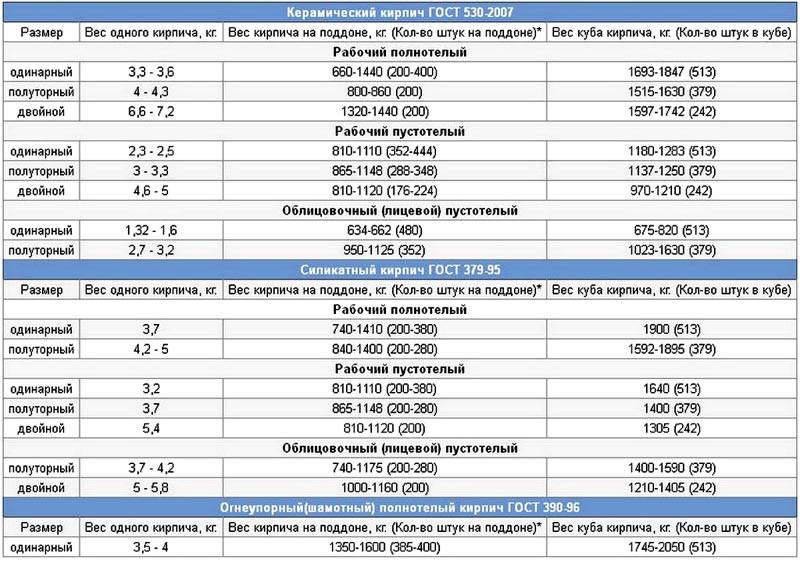

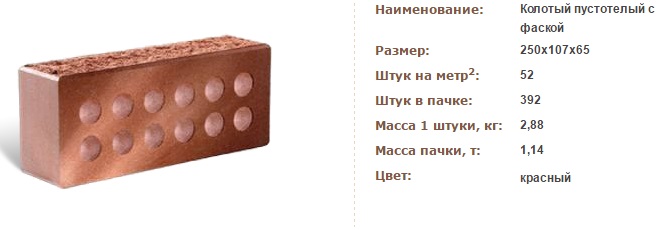

Red brick is mainly used in the construction of houses and cottages. It is made from various types of clay using firing. It is strong enough, not too heavy (full-bodied weighs about 3.6 kg, hollow - 2.5 kg) and successfully withstands harmful atmospheric influences. The standard size is 250 x 120 x 65mm.

No less popular is the silicate briquette, which is autoclaved from sand with various additives. This species has excellent heat and sound insulation properties, as well as high frost resistance. The weight of the product is slightly more - corpulent weighs 5 kg, hollow - no more than 4.

Number of blocks in a pallet

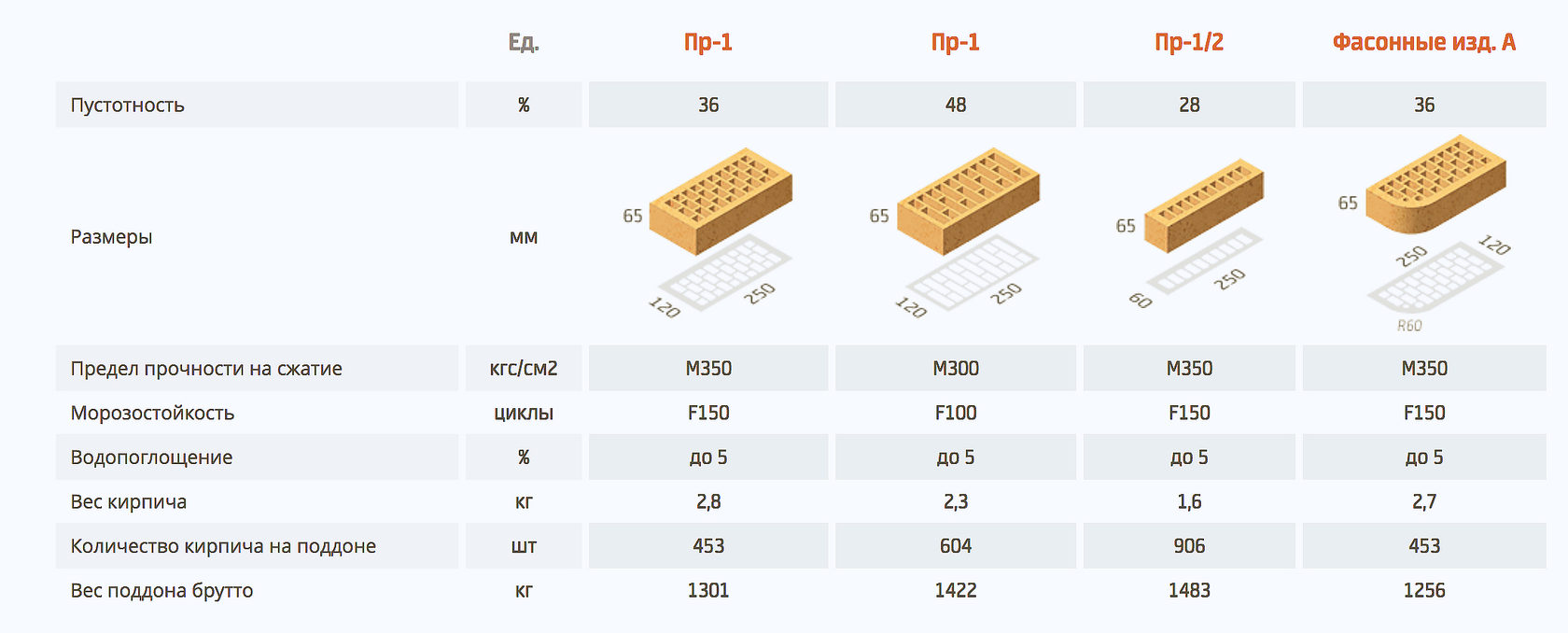

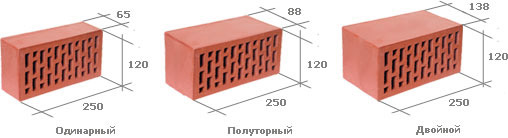

The capacity of the platform depends on the size of the bricks placed on it, as well as on the dimensions of the platform itself. There are single, one and a half and double bricks. In all cases, the dimensions of the product remain unchanged, only the height differs:

- for single - 6.5 cm;

- for one and a half - 8.8;

- for double - 10.3.

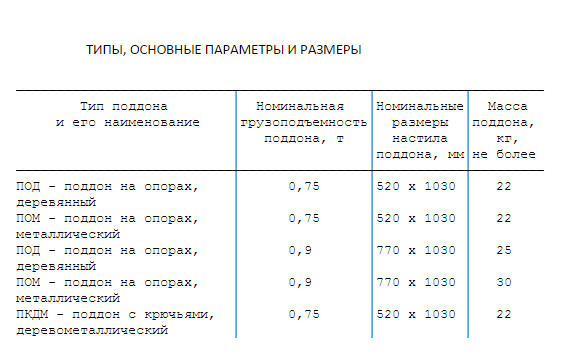

As for pallets, they are of two types:

- standard - 103 x 52 cm, carrying capacity - 750 kg;

- reinforced - 103 x 77 cm, carrying capacity - 900 kg.

Knowing the weight of the material, as well as its basic parameters, you can calculate how many pieces the platform can hold. For this, the base area is divided by the area of one product. Multiplying the resulting number by the number of rows on the pallet, we find the total amount:

- no more than 420 pieces, if it is a single brick;

- about 390 units, if it is one and a half;

- up to 200 doubles.

Such calculations will not work if the laying on the base took place at an angle of 45 degrees - "herringbone". In this case, you can find out the number of blocks using simple geometry, namely, by counting in one cubic meter.

The information obtained allows you to optimize costs. The price of wall material, which accounts for a significant proportion of the total cost of building a house, does not allow buying it "just in case." In addition, an excessive amount will increase the cost of transport and handling.

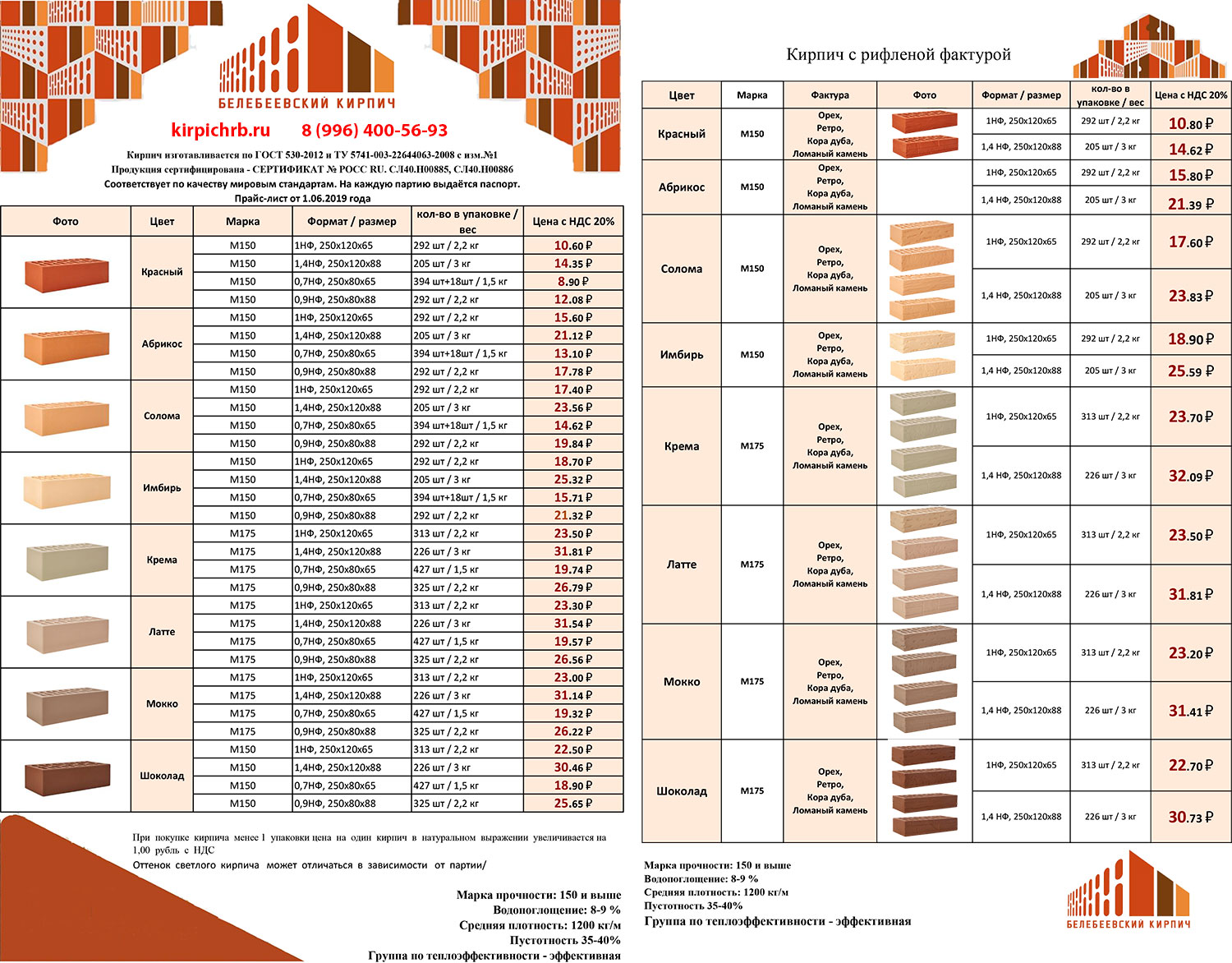

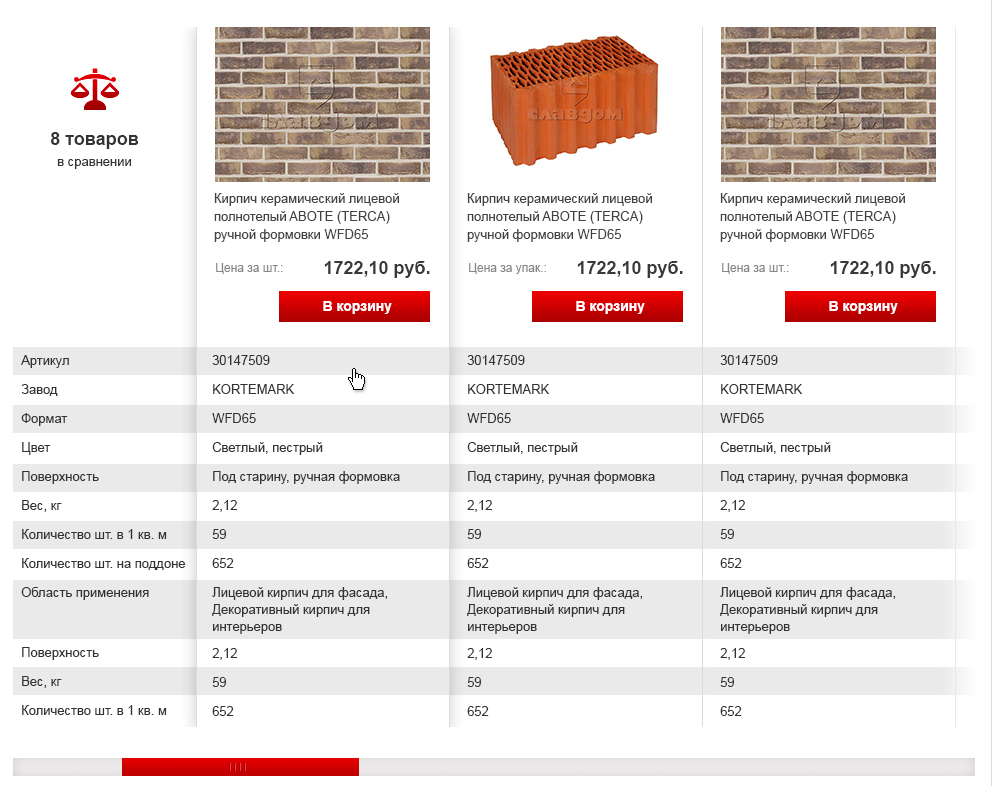

Pricing is influenced by the following points:

1.brand and country of origin;

2. specifications and dimensions;

3. strength and ability to withstand multiple freeze cycles;

4. remoteness from the construction site.

Brick types

In order to choose the right brick for various types of masonry, you need to know its technical characteristics and purpose. All currently manufactured product can be classified according to the following criteria:

- used raw materials;

- appointment;

- the nature of the filling;

- appearance and size.

In addition, various production technologies and molding techniques can be used to make the ceramic product.

Classification of bricks by the type of raw materials used

It is from the material that the production depends on the performance characteristics, purpose and service life of the product.

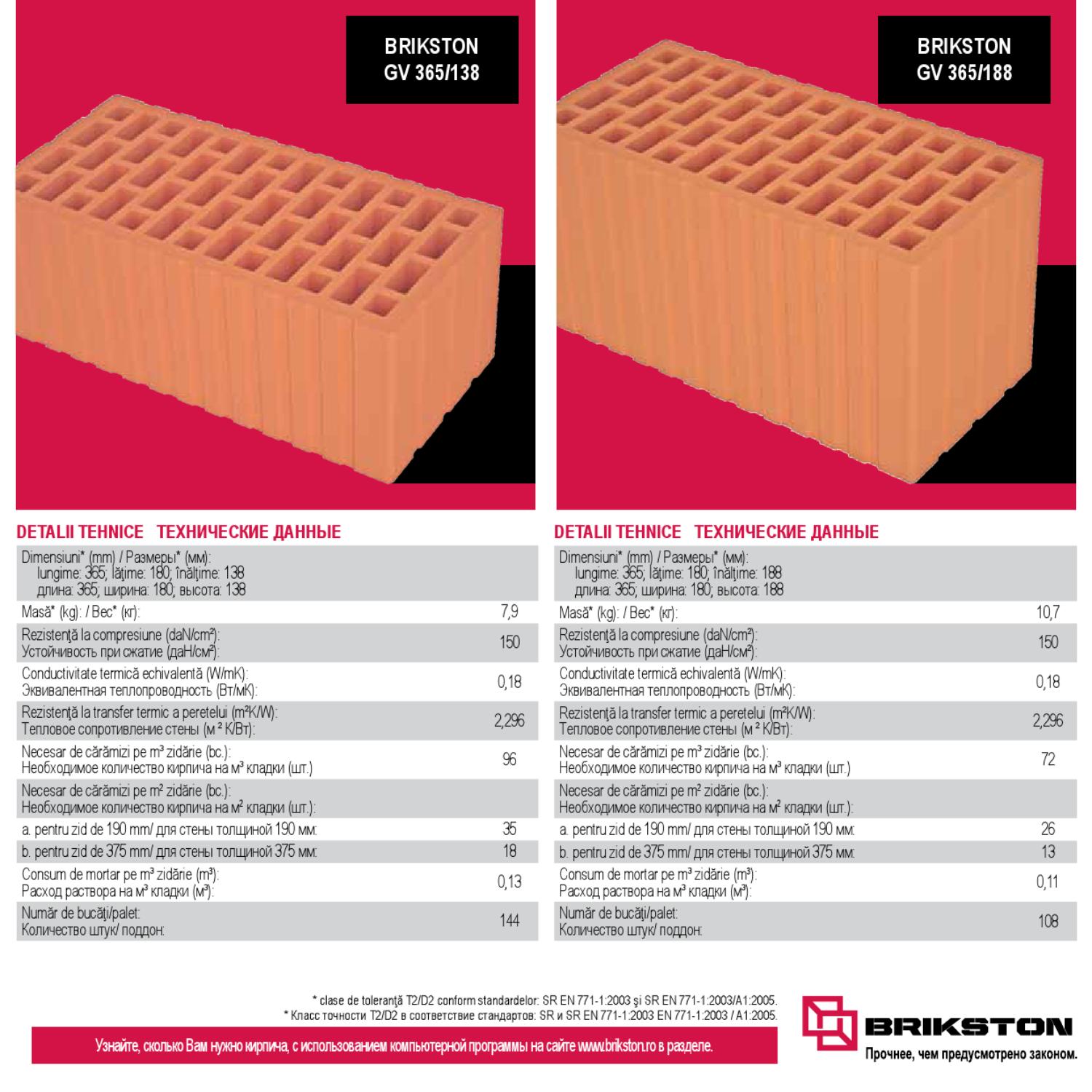

Ceramic

This type of brick is made from high quality clay, purified from sulfates and marl. At the first stage of the technological process, molding takes place. After drying, the workpieces are placed in special furnaces, where they are fired at a temperature of 10,000C. A quality product is characterized by a semi-matte surface and a porous structure.

Silicate

The main ingredient in the product is refined quartz sand. In addition to it, up to 10% lime is added to the working mixture. Such material can be used to build both load-bearing walls and internal partitions.

Hyperpressed

The raw material for such a brick is the screening of marble, limestone, dolomite or shell rock, their share in the working mixture accounts for up to 90%. Portland cement is used as a binder, the mass fraction of which can be from 6 to 8%. The resulting mixture is poured into special molds and pressed. On the building materials market, you can find smooth and textured hyper-pressed bricks. Both modifications are widely used in the cladding of buildings.

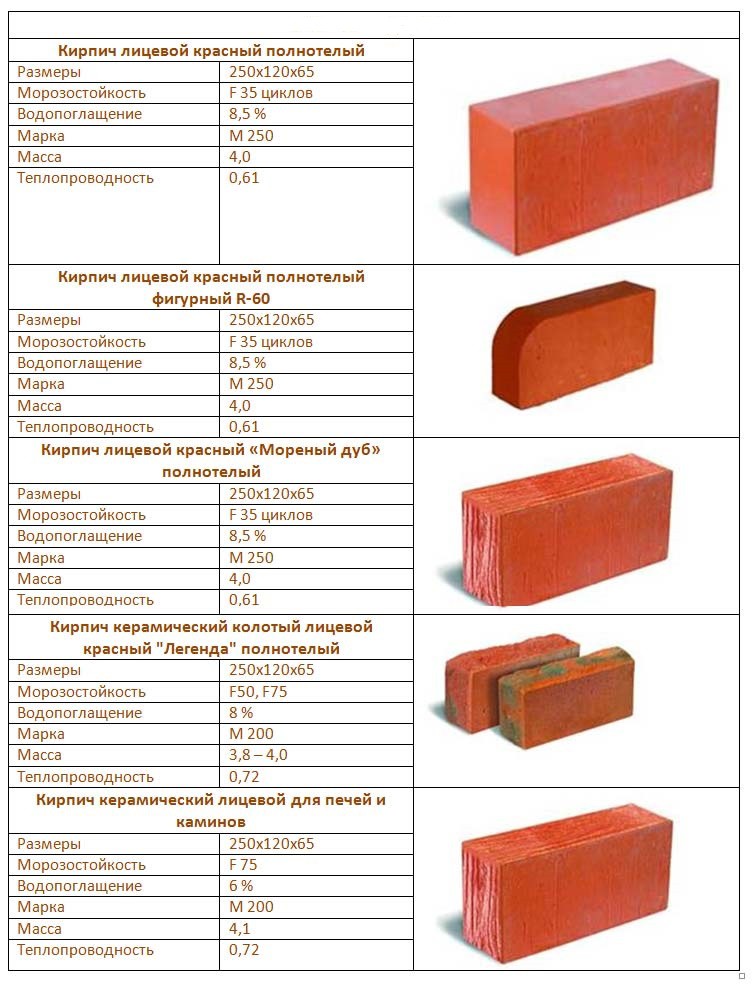

Classification by purpose

The scope of this or that type of material depends on its technical characteristics and operating conditions.

Construction (private)

The technical characteristics of building bricks are regulated by GOST 530-2007. Scope - the construction of load-bearing walls and partitions. Since the appearance and thermal insulation properties leave much to be desired, the facade is additionally insulated with mineral materials and decorative cladding panels are attached.

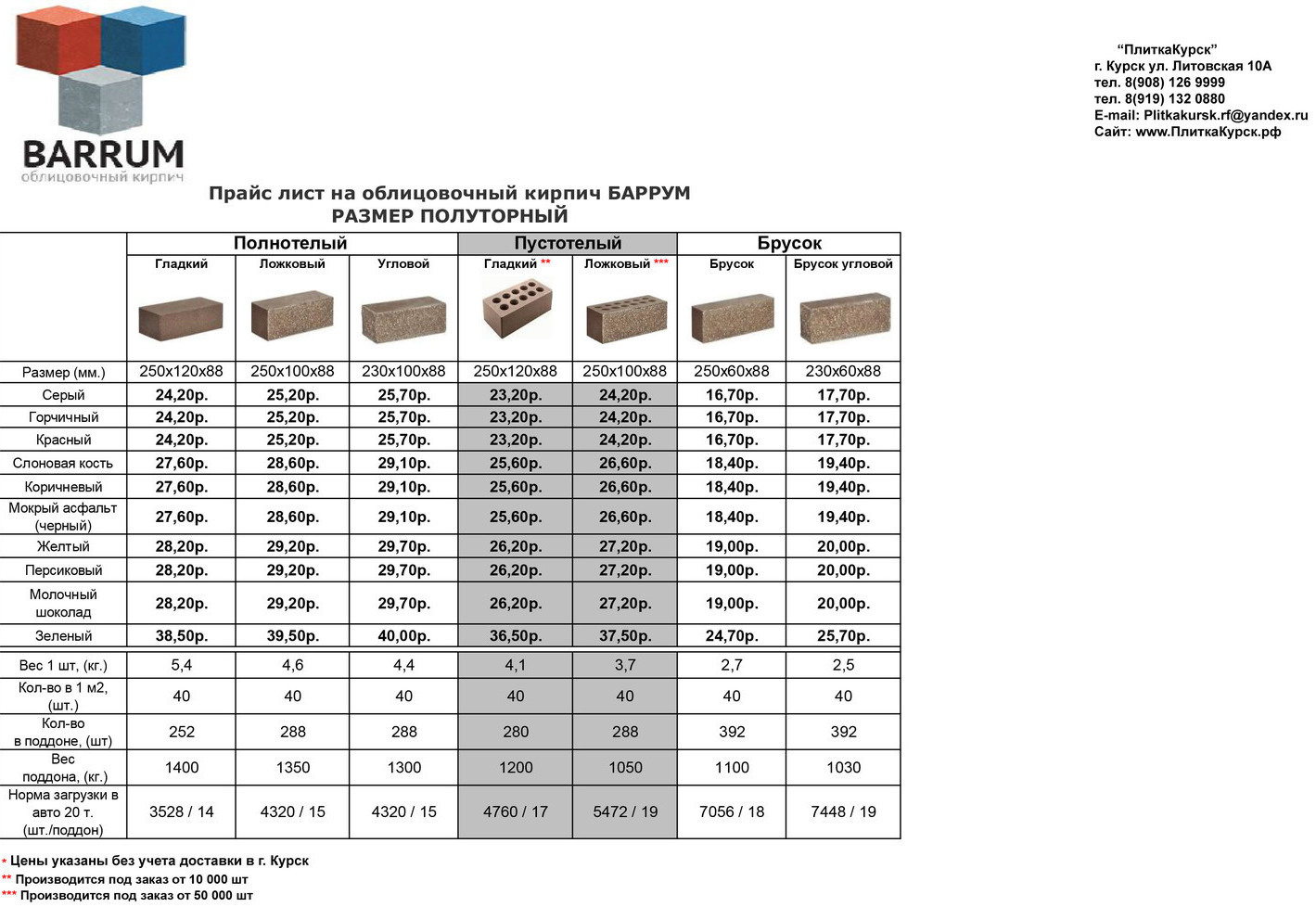

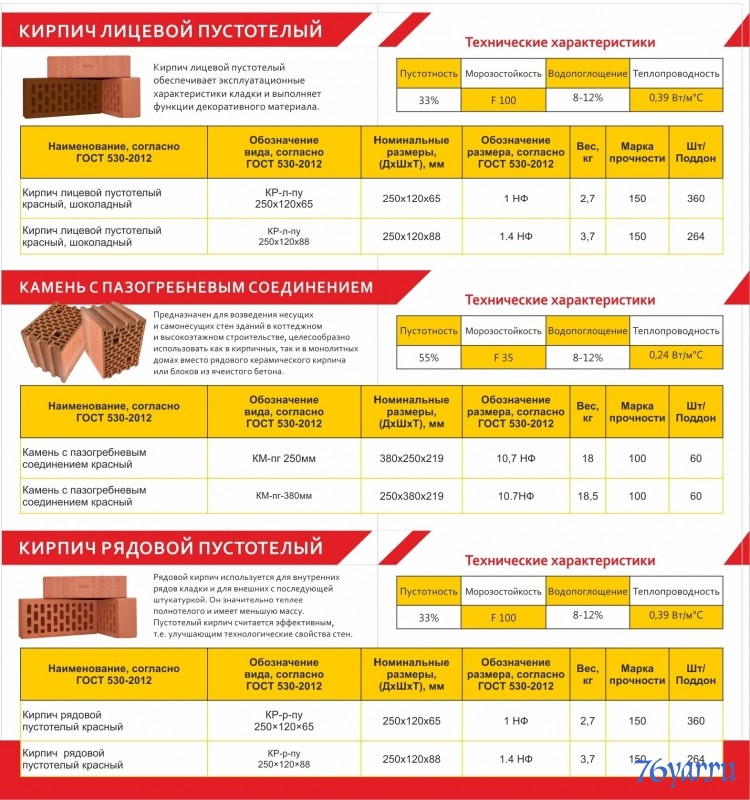

Facing

The main features are high surface quality and minimal deviations in size and shape. For decorative facade cladding, two types of cladding material can be used.

Textured facing

The product can be produced with both smooth and textured edges. Textured bricks are used for decorative cladding of facades and the construction of capital fences.

Shaped facing

Such a product is specially made for facing decorative elements (arches, columns, window slopes, etc.) and can have a very different configuration. High-quality styling can only be provided by top-class professionals.

Chamotny

The main distinguishing feature of fireclay (oven) bricks is its high thermal resistance and minimal thermal conductivity. It is used for laying stoves, fireplaces and other refractory structures. High-quality fireclay products can withstand temperatures up to 10000C for a long time.

Clinker

This variety is obtained by sintering refractory clay layers. The clay used is thoroughly cleaned from impurities of chalk, alkali metal salts and other impurities. Clinker brick is distinguished by its high strength and hardness, practically does not absorb moisture and does not lose its properties in the temperature range from +50 to -500C.

Its use as a facing material provides reliable protection of the facade from weathering and mechanical damage.

Content classification

Depending on the purpose of the building, a solid or hollow look can be used.

Corpulent

This variety does not have any voids and is a monolithic parallelepiped. Used for masonry bearing walls of buildings.

Hollow

The mechanical strength of such a material is significantly lower than that of a monolithic material, but it has a lower thermal conductivity. In a silicate brick, voids can be from 25 to 30% of the volume of the product. Most often, hollow bricks are used for cladding and erection of internal partitions.

Size classification

In order to correctly calculate the number of bricks, you need to know its overall dimensions. There are three main sizes.

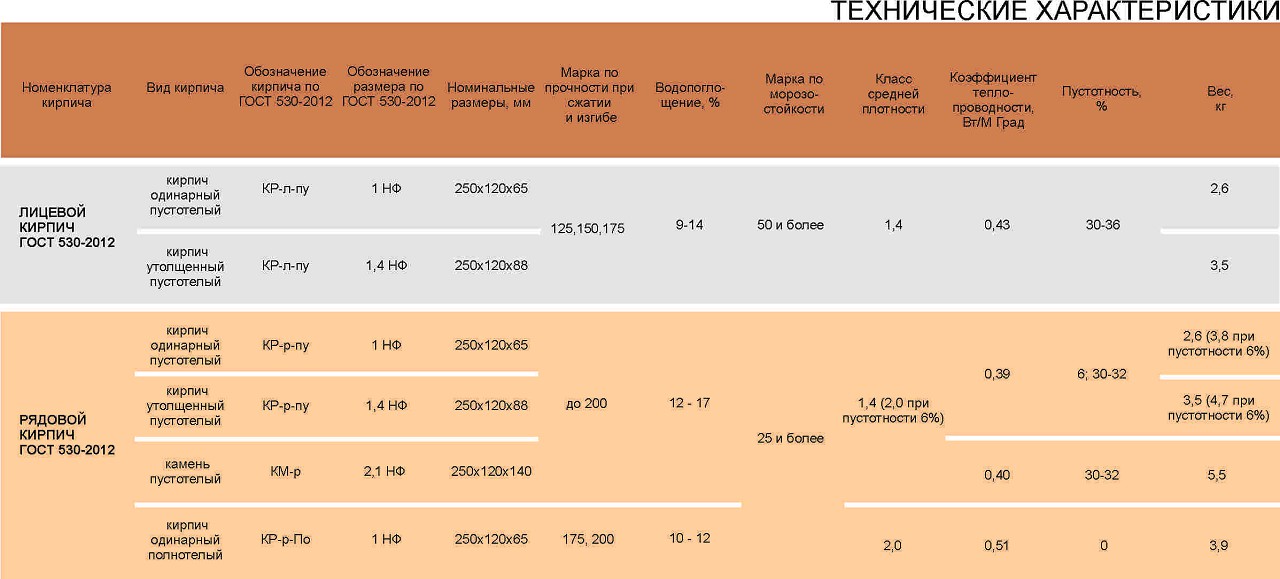

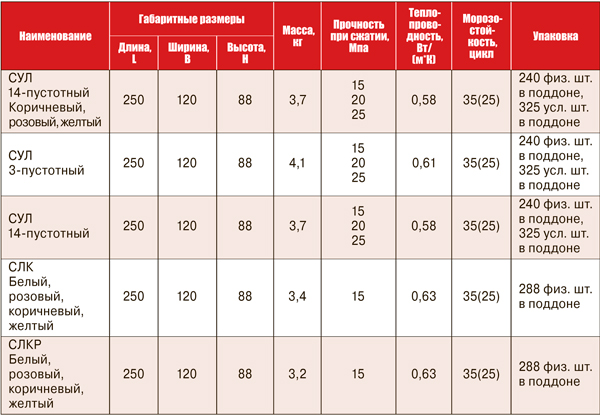

| Brick size | Overall dimensions, mm |

| Single | 250x120x65 |

| One and a half | 250x120x88 |

| Double | 250x120x138 |

Number of single bricks on a pallet

The correct calculation of the required amount of material for any building allows not only to complete the construction on time and without delay, but also to save the owner's money.

If the brick is calculated incorrectly, the deficiency will have to be compensated for by a new purchase, and the surplus will have to be sold for 50% of the cost

Therefore, it is important to consider all options for construction work even before purchasing material.

Heavy building materials such as bricks are stored and

are stored, transported and transported using pallets. On

transport pallet the materials are secured thanks to

special anchorage straps. Also as packing bricks on pallets

use a special shrink film.

The pallets are transported by an electric car,

therefore, the shipping container is divided into two types. The first type of pallets

designed for transportation by an electric car using a double container engagement

with a fork, and the second from four sides.

For the production of pallets, plastic, metal,

wood, so they have a disposable and reusable lifespan. Weight of one

transport container is 16-22 kg, and allows to transport more than 1 ton.

cargo.

Reusable pallet size

calculated based on transport trucks and their internal dimensions.

Therefore, the size of the container corresponds to international standards, and the usual wooden

the pallet has a size of 0.8x1.200x0.145 m. The sizes of Finnish

pallets: 1x1.2x0.145 m.

Variety of bricks and their capacity in a pallet

Brick, depending on production, is divided into silicate and ceramic, solid or hollow inside.

The variety of brick sizes depends on its dimensions: single, one and a half, double.

The parameters of an ordinary brick are 250x120x65, which is very convenient for construction.

- Building bricks are used to build walls.

- For the outer part of the walls, facing brick is used.

- For stove masonry, a special fireclay brick is used that can withstand high temperatures.

Carrying capacity of pallets

Maximum permissible load capacity of a pallet with

parameters 1030x520 mm 750 kg, for pallet 1030x770 - 900 kg, and for 1200x800 -

1500 kg. When calculating the required amount of building material, use

not only the carrying capacity of the pallet, but also the procedure for laying bricks on it.

When laying in regular rows, counting is done

simply. We multiply the number of rows by the number of bricks in it. But if the styling

made at an angle of 45, that is, a herringbone, the calculations will be

much more difficult.

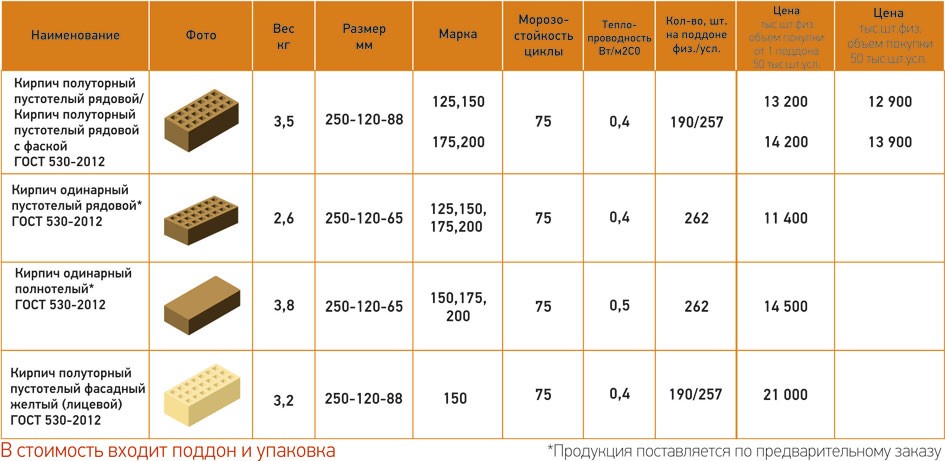

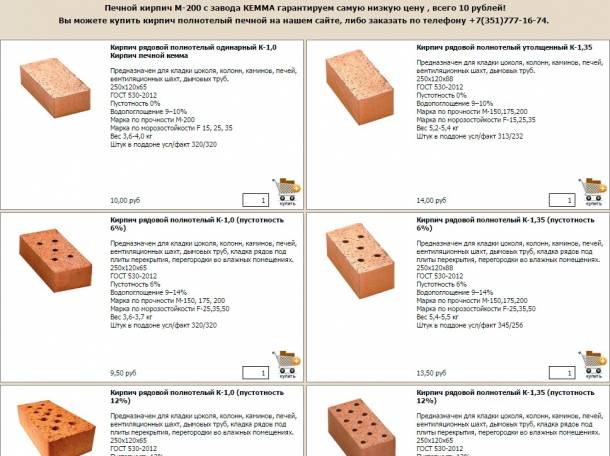

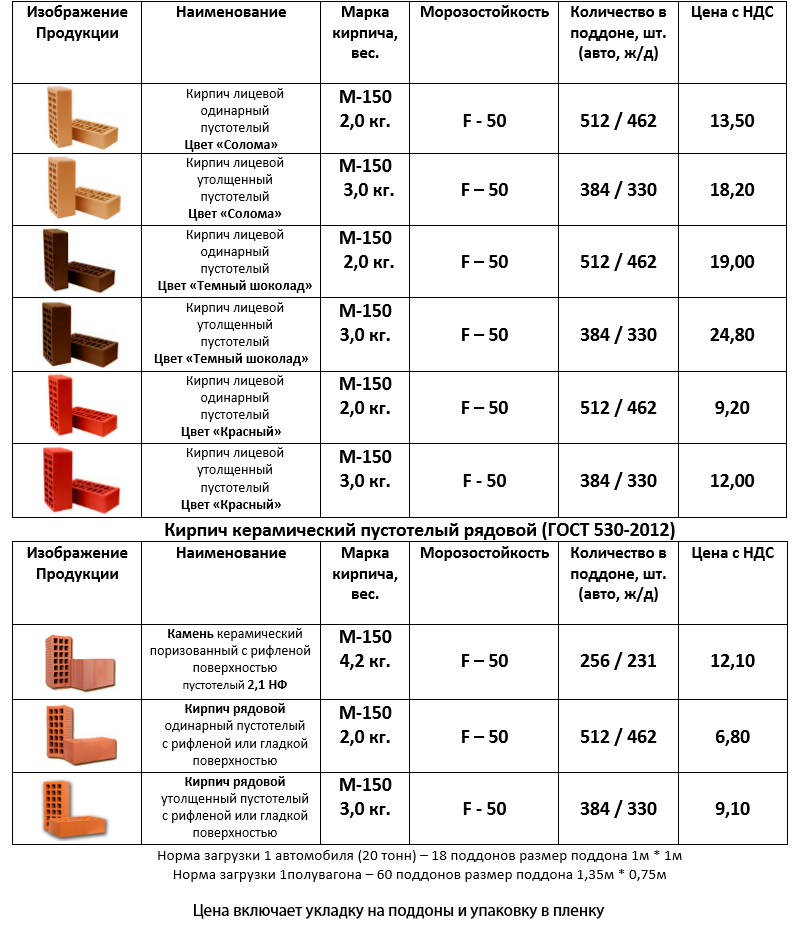

Number of red bricks on a pallet

The weight of one solid red brick is 3.5

kg, and hollow - 2.4 kg. Knowing the possible options for loading areas

a brick manufacturer, it is easy to calculate the number of bricks on a pallet.

The dimensions of the ceramic bricks correspond to

0.25x0.12x0.065 m. This means that 480 pcs can be placed on the pallet. solid brick

and 309 pcs. with voids inside.

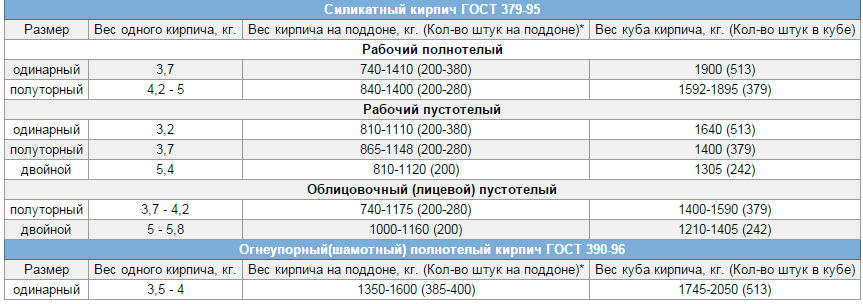

How many sand-lime bricks on a pallet

The weight of a solid silicate building brick is 5

kg, and with voids 4 kg. Therefore, 325 pieces are placed on 1 pallet.

whole and 240 pcs. hollow sand-lime brick.

Number of facing bricks on a pallet

Its size is 0.25x0.09x0.005 m. Since

stacking on a pallet higher than 1 meter is not performed, then with normal stacking on

the stand holds 360 pieces of facing bricks.

Number of single, one and a half and double bricks

To calculate the quantity, you need to know the area of the load support and the area of the brick.

By dividing the area of the stand by the area of the brick, we get the amount of building material placed on one stand. Multiply by the number of coasters and get the number of bricks on the pallet.

You can just remember that a standard pallet holds 420 single bricks, 390 pcs. one and a half and 200 pcs. double.

Interesting articles:

- Do-it-yourself brick gazebo with barbecue, options

- Country luxury: how to make a brick tandoor with your own hands and enjoy delicious dishes

- Two-story brick house: what you need to know before starting construction

- Brick fence reliability and protection

- DIY fence made of corrugated board and brick

- How can you use old brick in the country

How many pallets fit in a truck, KamAZ, length

If you need to load bricks into lengths, and the size of a pallet is, say, 1130x520, then their number will be 32. If loading is carried out in KamAZ, then with European sizes of pallets, their number will be 10-12 pieces. When transporting material in a wagon, their number reaches 32-33.

Brick is a very popular building material that is actively used today for various purposes. But today the process of transportation of the specified product takes place in special pallets. Thanks to them, it is possible to ensure simplicity and ease of transportation. In addition, it facilitates the process of recalculation to the seller, which is carried out by the sale of the specified product. Choose only high-quality goods, and then your building will serve you for a long time.

- Terrace board - a practical material for steps and porch

- How and at what temperature can a brick be laid?

- Primer "Betonokontakt" Knauf: properties and technical characteristics

Discussion 2 comments

Brick has long been valued as a reliable building material. Our grandfathers also built houses of brick and they were always strong and you could live in them for more than a dozen years. Now, of course, they began to make bricks from a different material, but the basis is the same. I personally ordered four pallets of red bricks to build my house. Although it took a long time to raise the house, I am very pleased that I chose this particular material.

When we were building a house, they sold us bricks only with a full pallet. So they are not damaged at least during transportation. Unfortunately, the factory does not report bricks - for the sake of interest, they counted and were always missing about 30-35 bricks - this is a lot.One pallet came in ruins, so it is worth choosing a quality manufacturer, now we doubt the quality of the brick itself.

The state building codes indicate that the weight of a pallet with solid or hollow bricks should not exceed 850 kilograms, but such rules are often ignored by the manufacturer and the mass of material, taking into account packaging, can exceed one ton or exceed the recommended figure by two or more times. According to the requirements of the product, it can be stacked on pallets "herringbone", "on edge" or "plate" with obligatory banding of elements. The same building rules say that pallets with materials can be placed on a construction site in no higher than two tiers.

For the convenience of transportation and preservation of goods, the container is wrapped with a special thickened film and tied with a metal tape. After manufacturing, bricks are sorted by type and brand and sent to separate zones for storage in a warehouse.

The weight of a pallet with a brick can be obtained from the seller or calculated independently, with the exception of products laid out at a certain angle - here the mass indicator may differ. When carrying out independent calculations, you need to have the following information: know the mass of a particular product and their number in the pallet.

How many bricks are in the pallet, the size of the facing and standard

In order to deliver brick blocks to a construction site with minimal transport costs and not miscalculate when buying, you should know how many bricks are in a pallet and how many such packages you need to purchase, what kind of transport to order. At the same time, it is easier to compare prices from different manufacturers (they are often set on a per pallet basis), to determine the total costs.

Types of brick packing

For the convenience of shipment and transportation, brick products are placed on wooden boards (pallets) made of planks connected by bars.

- small - 0.52 x 1.03 m, carrying capacity up to 0.75 t;

- large - 0.77 x 1.03, holds up to 0.9 tons of cargo.

Often the manufacturer indicates the number of bricks, but there are also options when he does not. The approximate number of items on a pallet is not difficult to determine by calculation. To do this, the area of the shield is divided by the area of the base of one product - this is how the number of products in the first layer is obtained. Then multiply the result by the number of rows in the purchased package.

Palletizing rate

How many brick products on a large pallet:

- single (standard brick size 250 x 120 x 65 mm) - about 420 pieces;

- one and a half (250 x 120 x 88 mm) - about 390 pieces;

- double (250 x 120 x 138 mm) - about 200 pieces;

- double grooved - 192 pieces;

- tortoiseshell М150 - 280 pieces;

- with a torn edge (single) - 308 pieces;

- with a ragged edge (angular) - 352 pieces;

- basement - 478 pieces.

How much does a pallet with bricks weigh

It is important to know the answer to this question when ordering a vehicle with a certain carrying capacity - the number of flights and payment for transport depends on the weight of one loaded pallet. For reference, below is information on what is the mass of one brick block

- Weight of 1 piece of solid silicate brick:

- single - 3.7 kg;

- one and a half - 5.0 kg.

- Hollow brick weight:

- one and a half - 4.0 kg;

- double - 5.2 kg.

- Ceramic products are lighter:

- single hollow - 2.6 kg;

- single corpulent - 3.6 kg;

- shortened - 2.1 kg.

Thus, you can calculate how much, for example, a small pallet of a single brick weighs: 275 x 3.7 = 1017 kg. If you add the tare weight (15 kg), the gross weight is 1032 kg.

How many cubes of material need to be purchased

- The first step is to calculate the total volume of brick walls with mortar, taking into account their size and number of walls, as well as the type of masonry. Multiply the height, length and width, and then add the volumes.

- Usually, when planning a construction, they calculate how many bricks are in a masonry cube. In this case, the volume of the masonry mortar (1.5 cm) must be discarded.For example, if the size of a one-and-a-half brick is 250 x 120 x 88 mm, then its volume is 0.00264 m3, and together with the mortar - 0.00327 m3. Based on this, the masonry cube contains 306 one-and-a-half blocks. You can take ready-made table values.

- The next number you need to know is how many bricks are in a pallet in cubic meters? You will need the volume of the product without solution. For one and a half brick, the result is already ready - 0.00264 m3; single - 0.00195 m3; double - 0.00414 m3. Next, we multiply the number of brick blocks in a container by the volume of one block. For example, the cubic capacity of a single brick on a large pallet: 420 x 0.00195 = 0.82 m3.

It remains to find out the number of packages - for this, the need for brick in cubes is divided by a number indicating how many bricks are in a pallet in m3.