Types of brick packing

For the convenience of shipment and transportation, brick products are placed on wooden boards (pallets) made of planks connected by bars. Shields are of two types and have standard sizes:

Shields are of two types and have standard sizes:

- small - 0.52 x 1.03 m, carrying capacity up to 0.75 t;

- large - 0.77 x 1.03, holds up to 0.9 tons of cargo.

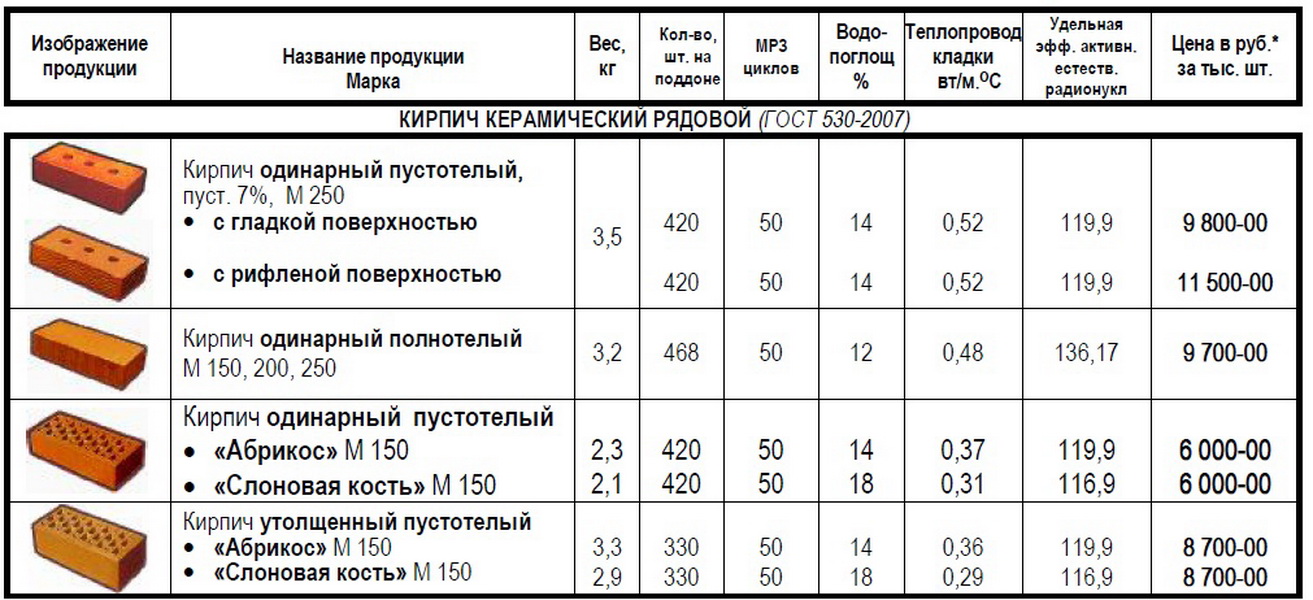

Often the manufacturer indicates the number of bricks, but there are also options when he does not. The approximate number of items on a pallet is not difficult to determine by calculation. To do this, the area of the shield is divided by the area of the base of one product - this is how the number of products in the first layer is obtained. Then multiply the result by the number of rows in the purchased package.

Calculation rules

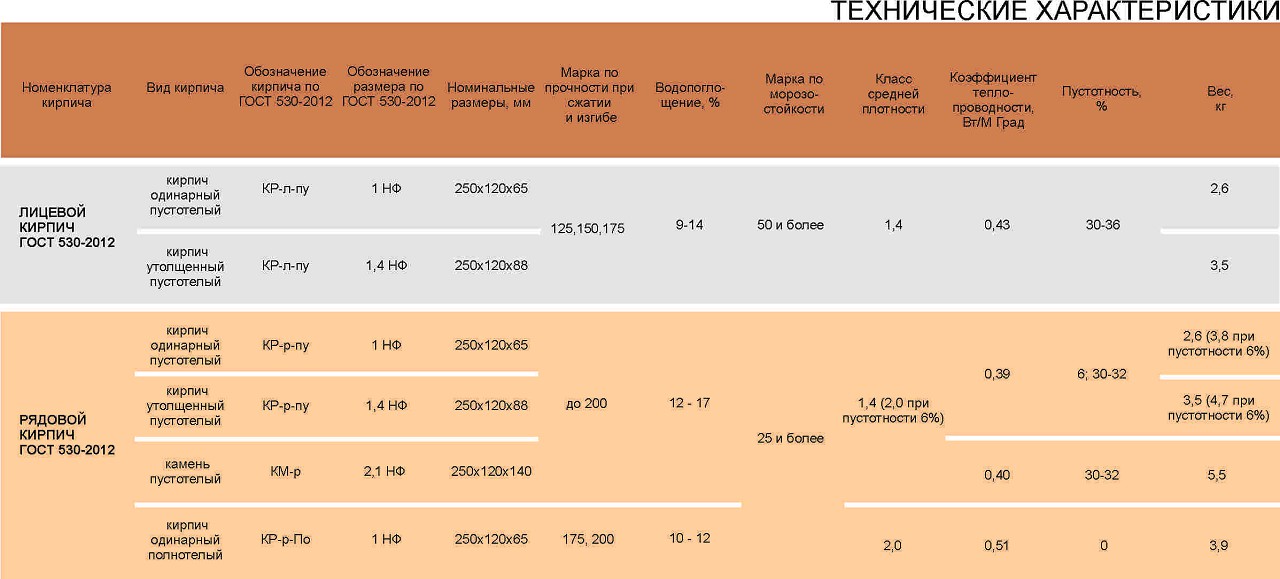

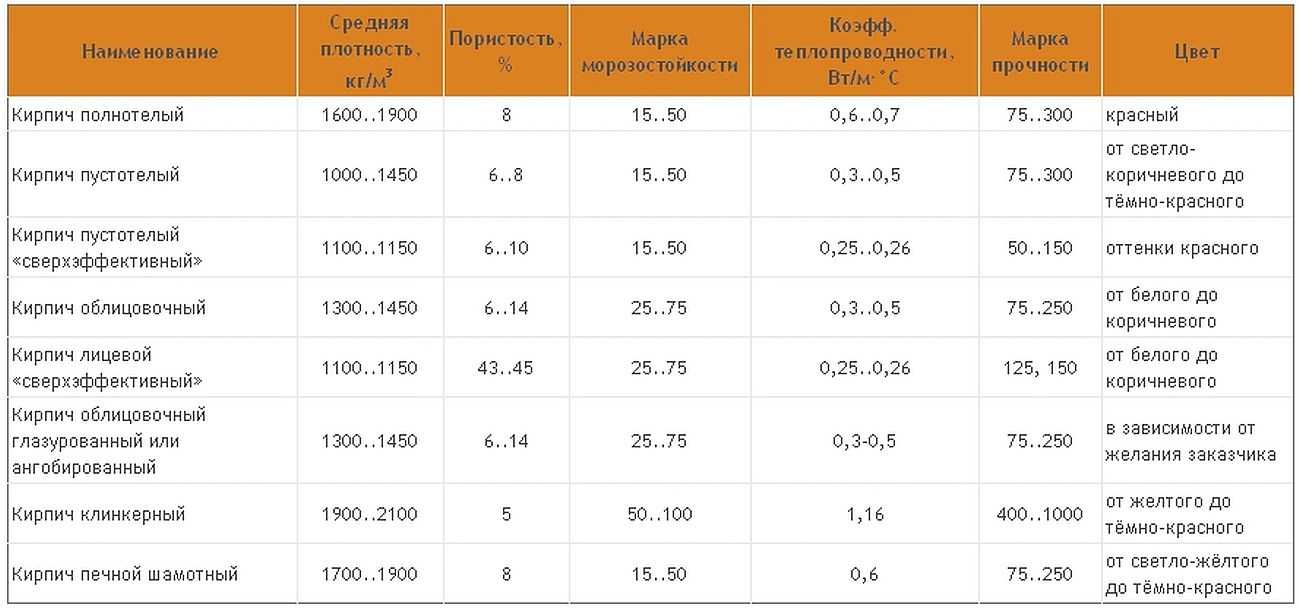

Before proceeding with the calculation of the mass of brickwork, you should familiarize yourself with some terms. There is a specific and volumetric weight of a brick. Specific gravity is determined by the ratio of weight to volume and is calculated according to the following formula: Y = P * G, where P is the density of the brick, and G denotes a constant value of 9.81. The specific gravity of a brick is measured in newtons per cubic meter and is denoted as N / m3. To translate the numbers obtained into the SI system, they must be multiplied by a factor of 0.102. Thus, with an average weight of 4 kg for full-bodied models, the specific weight of the masonry will vary from 1400 to 1990 kg / m3.

Another important parameter is the volumetric weight, which, in contrast to the specific weight, takes into account the presence of cavities and voids. This value is used to determine the mass of not each brick separately, but immediately a whole cubic meter of products. It is the volumetric weight of products that serves as an indicative value and is taken into account when calculating the mass of brickwork directly during construction.

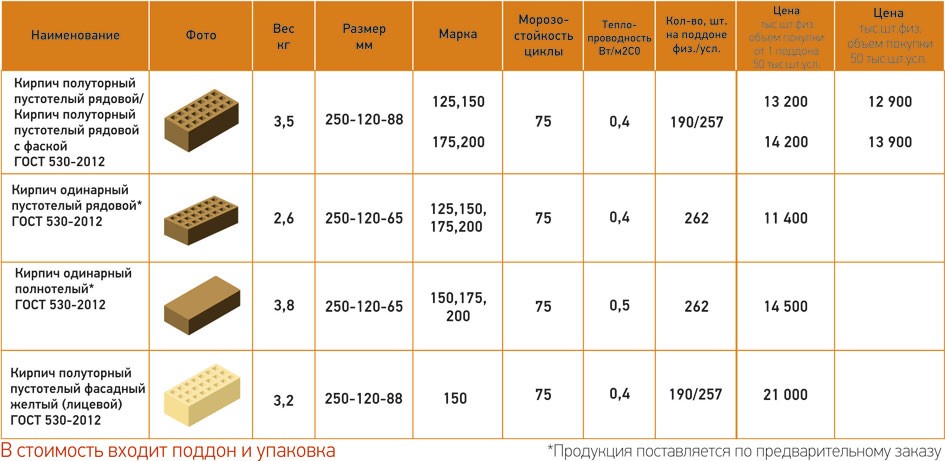

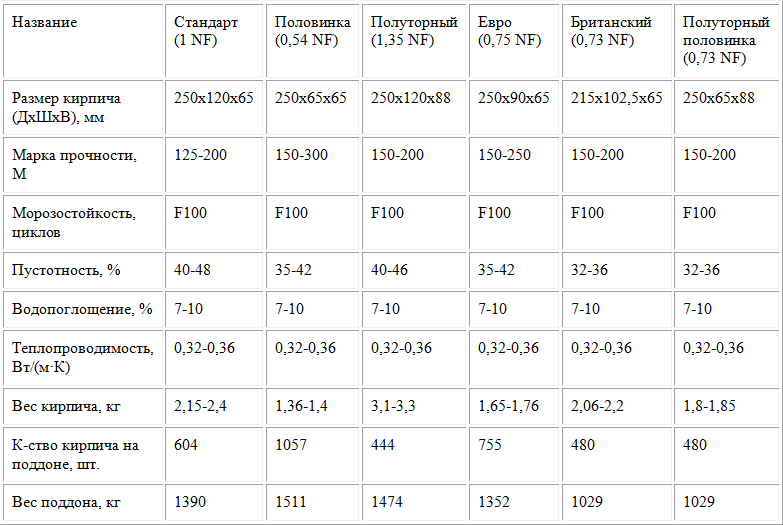

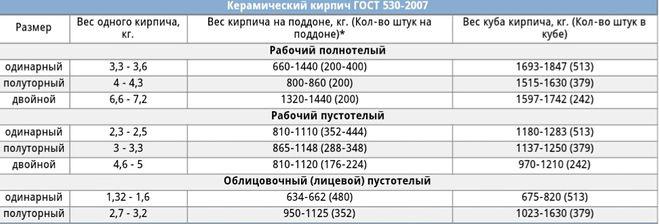

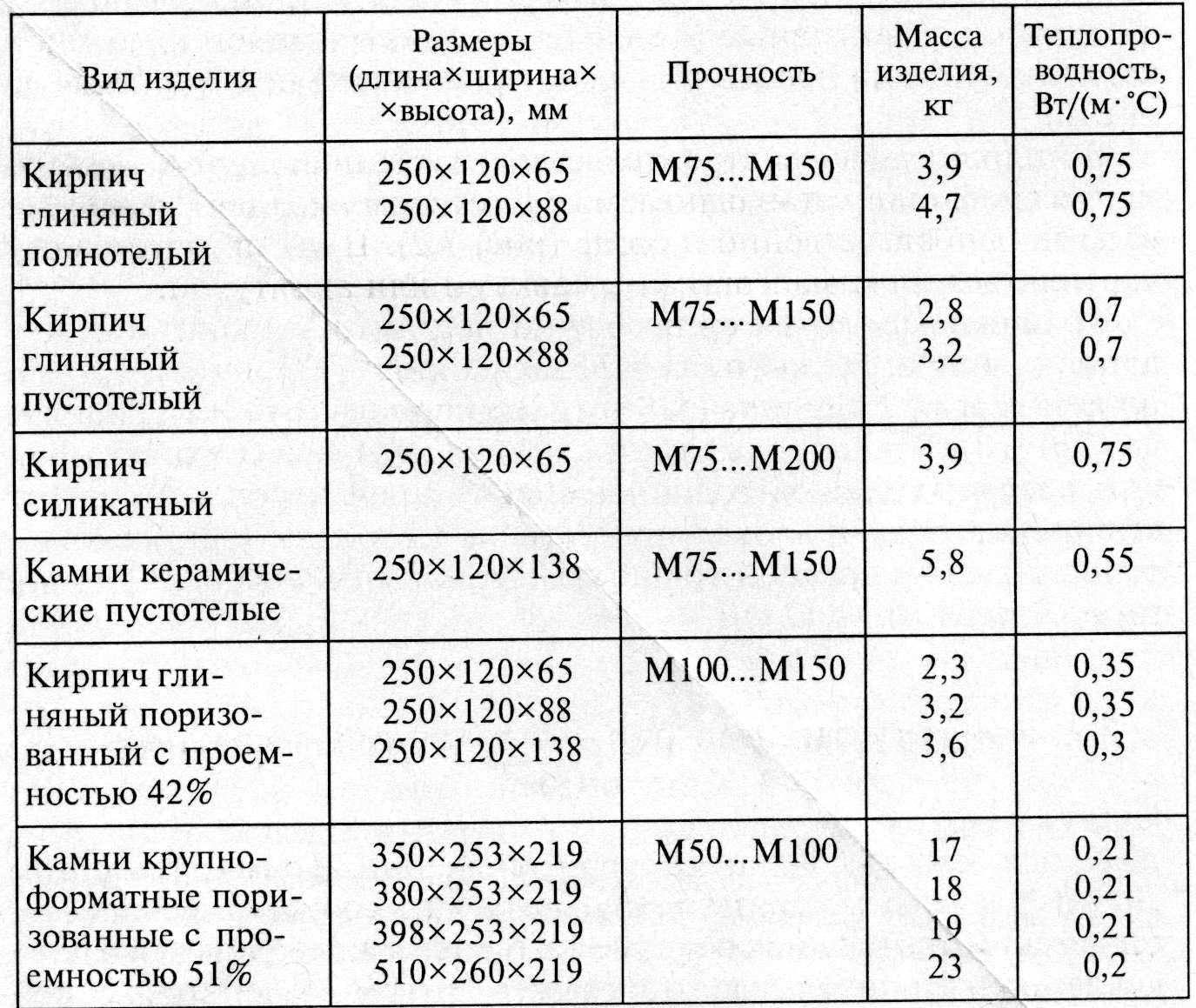

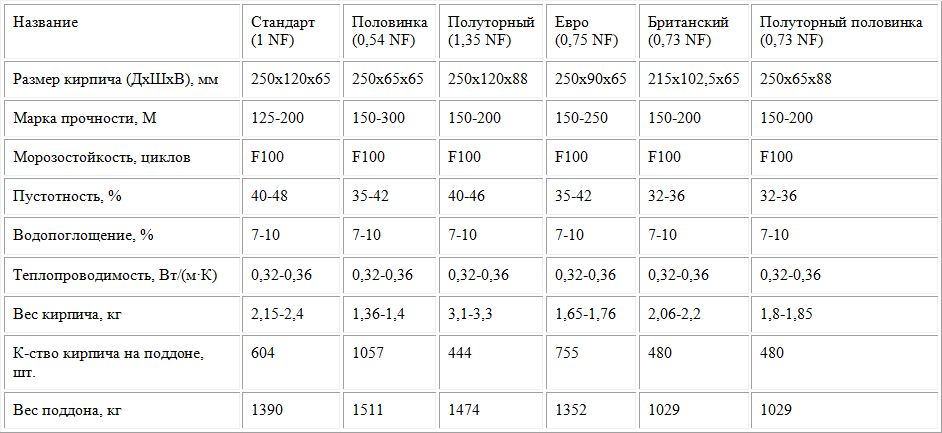

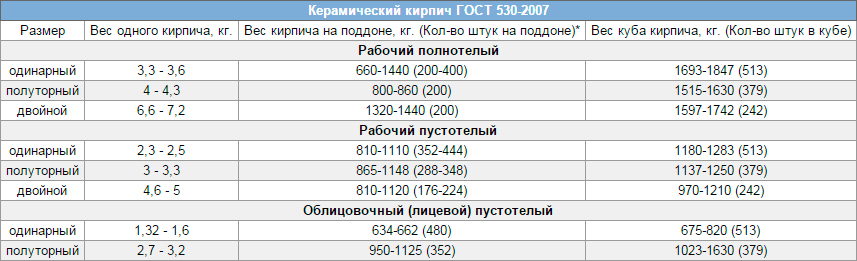

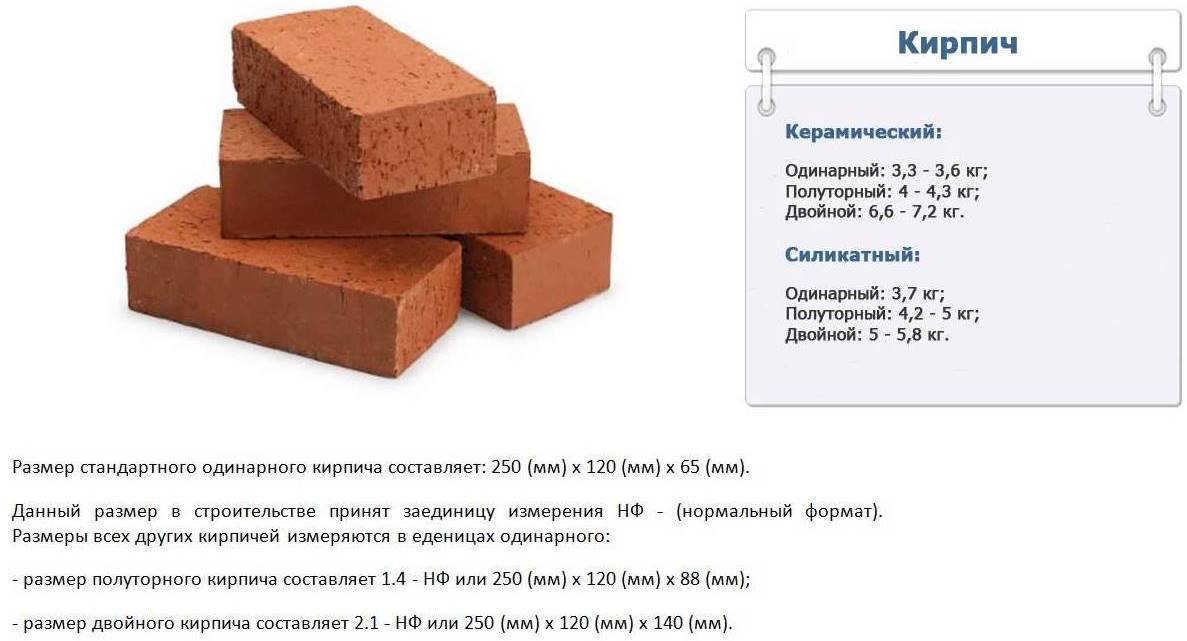

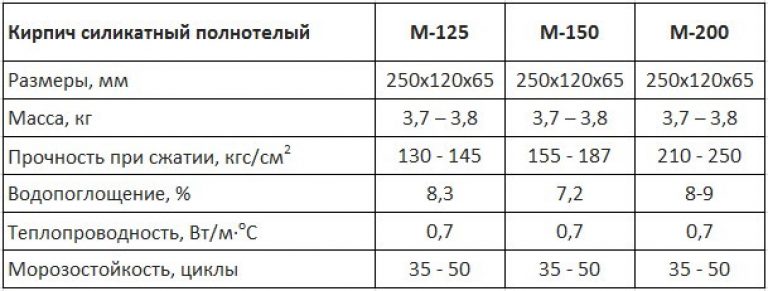

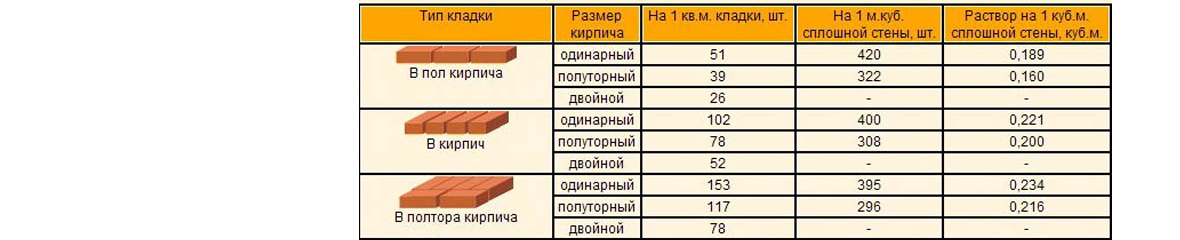

Knowing the weight of one brick and the number of copies in one cubic meter of masonry, you can easily calculate how much the entire masonry weighs. To do this, it is enough to multiply both numbers and add the mass of cement mortar to the obtained value. So, in one cubic meter, 513 solid single silicate products of a standard size 250x120x65 mm fit, and the weight of one brick is 3.7 kg. Therefore, one cube of masonry will weigh 1898 kg without taking into account the weight of the mortar. One and a half silicates already weigh about 4.8 kg per piece, and their number per cubic meter of masonry reaches 379 pieces. Accordingly, a masonry of such a volume will weigh 1819 kg, also without taking into account the mass of cement.

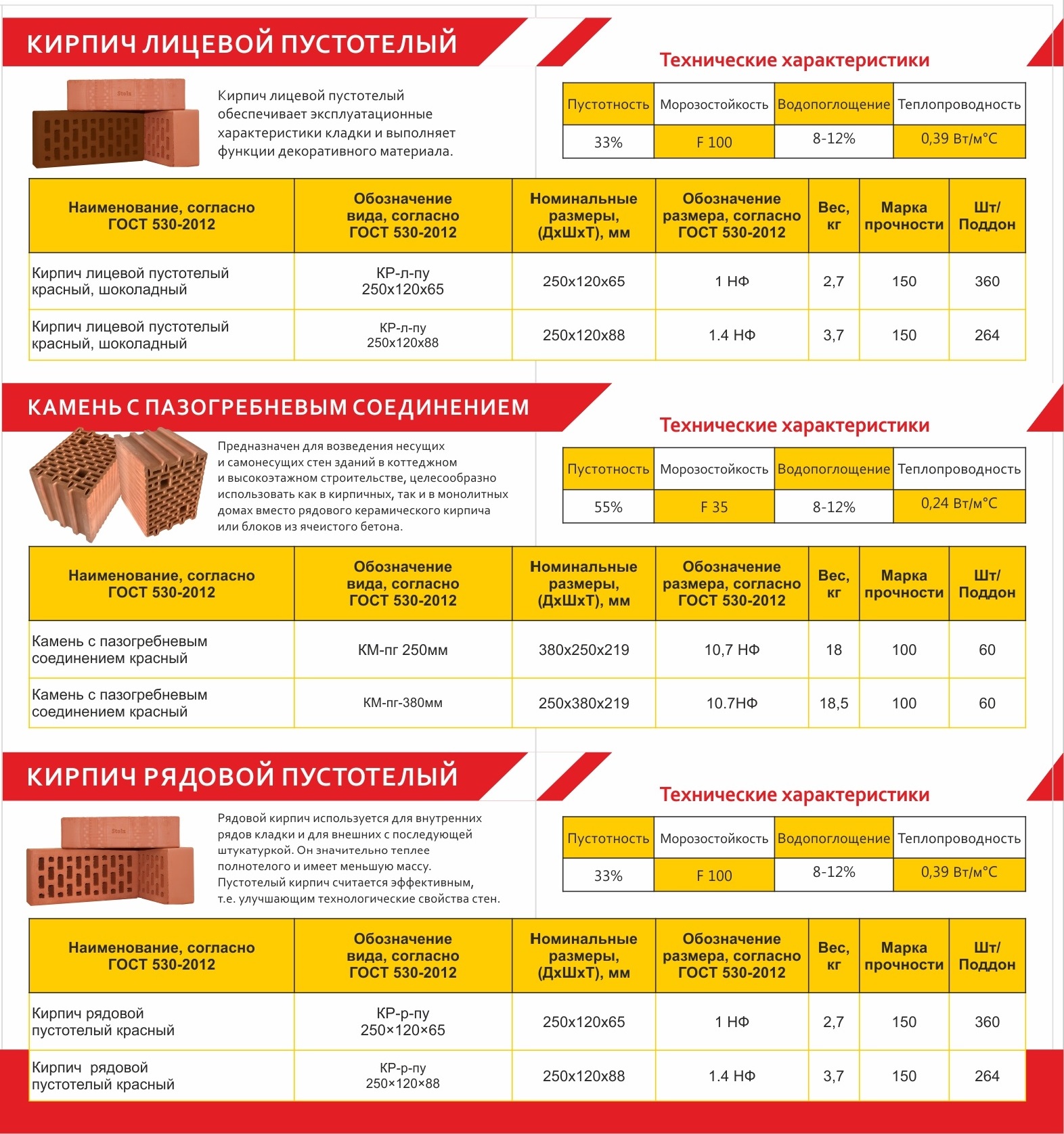

The calculation of the mass of red brick masonry is carried out according to the same scheme, but with the difference that single full-bodied models weigh 3.5 kg, while the weight of hollow ones reaches 2.3-2.5 kg. This means that one cube of ceramic masonry will weigh from 1690 to 1847 kg excluding cement mortar. However, it should be noted that these calculations are only suitable for products with a standard size of 250x120x65 mm. So, narrow hollow models with a width of not 120, but 85 mm will weigh only 1.7 kg, while the weight of dimensional copies of 250x120x88 mm will reach 3.1 kg.

However, these calculations are only approximate. To determine the weight of a structure with an accuracy of a kilogram, a number of factors that are purely individual for each case should be taken into account. These include the conditions for storing bricks and the coefficient of its water absorption, the grade of cement, the consistency of the mortar and the total weight of the reinforcing elements.

For information on how to calculate the brickwork, see the next video.

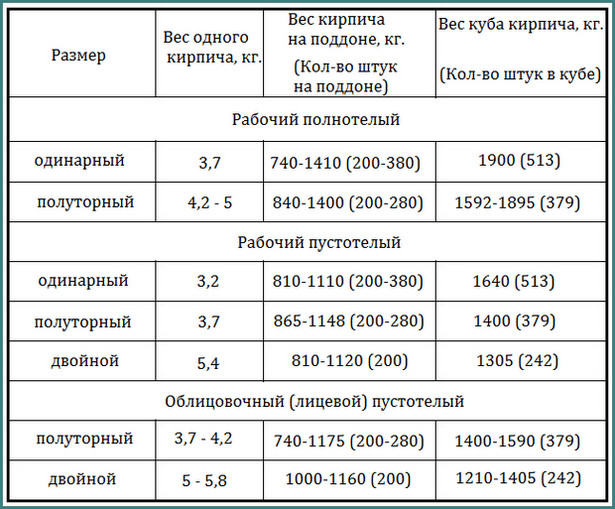

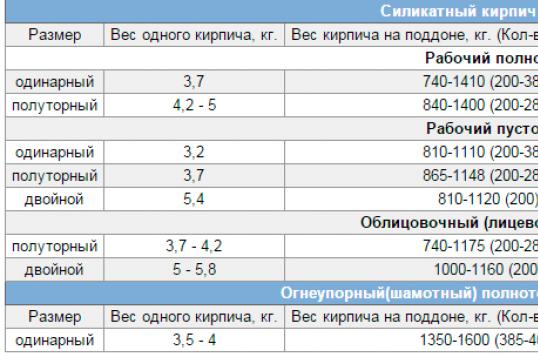

Volume and specific gravity of silicate brick

The first characteristic directly depends on the degree of voidness of the product and the density of the material. It is defined as follows: the mass of a brick is divided by the product of its geometric dimensions.The lightest are facing hollow products: 1200 kg / m3 (double); 1400 kg / m3 (one and a half). In working blocks with voids, the volumetric weight ranges from 1300 to 1640 kg / m3. The heaviest are solid ordinary bricks: a single cube weighs 1900 kg, and a one-and-a-half cube weighs an average of 1700 kg. By multiplying the volumetric weight by the cubic capacity of the masonry, the load on the foundation of the structure is determined.

The specific gravity depends on the porosity of the product, the quality of the raw material. To calculate the value, you first need to find the net volume - subtract the volume of voids from the total, and then divide the mass of the brick by the resulting number. The standard specific gravity for silicate blocks is 2000 - 2400 kg / m3. A decrease in the actual value, in comparison with the norm, leads to a deterioration in the strength characteristics.

Scope and features of solid silicate brick

Solid silicate blocks (ordinary brick, corpulent) differ in the minimum proportion of technological pores - no more than 13%. The corpulent is used for the following types of construction:

- external and internal load-bearing walls;

- partitions;

- columns;

- one-story and multi-story houses;

- country cottages;

- outbuildings.

The weight of a single sand-lime brick without voids is 3.7 kg (it is 10 - 30% denser than a hollow brick). To speed up the masonry, blocks are used whose thickness is increased by 1.5 times. The weight of one-and-a-half silicate bricks is from 4.2 to 5 kg.

The advantage of an ordinary block is its increased strength, but a small number of voids also increases thermal conductivity - therefore, a wall from a corpulent body turns out to be cold. On the other hand, the frost resistance of a dense product is higher (up to 50 cycles), therefore, it is preferable for the northern regions.

Scope and features of hollow silicate brick

The volumetric weight of brick products is reduced by creating slot-like holes - they are through or deaf and have the shape of a circle, oval or square. The voids are small: due to this, the solution practically does not get into the holes, and they become a heat-insulating barrier. The advantages of hollow bricks:

- low thermal conductivity;

- reducing the load on the foundation;

- the ability to reduce the number of rows of masonry and wall thickness;

- solution saving - up to 10 - 15%.

Working bricks with voids are used for the construction of houses of various storeys, for laying internal partitions, and facing bricks for decorating facades. The weight of 1 silicate brick depends on the degree of voidness and dimensions - this is shown in the table.

Hollow brick weight

As you can see from the table, the weight of sand-lime brick 250 x 120 x 88 deviates from the average within half a kilogram. This is due to the fact that according to GOST 379-95, 3 types of one-and-a-half blocks are produced according to the degree of voidness:

- 28 - 31% - have 14 holes with a diameter of 30 - 32 mm;

- 22 - 25% - 11 voids with a diameter of 27 - 32 mm;

- 15% - 3 cells, the diameter of which is 52 mm.

What you need to know when buying sand-lime bricks

- Usually brick blocks are dispensed on pallets, which can hold from 200 to 380 bricks. By multiplying the weight of one product by their number in the package, it is easy to find the total weight;

- To select a delivery vehicle, you need to know the weight of the pallets. Depending on the material, the container weighs from 18 to 40 kg - this is a significant addition if the machine has a small carrying capacity;

- The above weight information applies only to GOST products. But not all brick factories adhere to technological regulations. When purchasing products from a small manufacturer that does not have a certificate, it is worth weighing the brick and making sure that it does not differ too much from the standard and calculate the total weight;

When determining the load on the foundation, it is taken into account that the mortar is also included in the masonry. Depending on the thickness of the seam, its share can be significant

When calculating the weight of the wall, this should be remembered;

For special accuracy of calculations, attention is also paid to the method of masonry - in the process, different types of bricks are sometimes used.

For different types of silicate bricks, the weight is significantly different, therefore, it is necessary to build from it only after a full calculation, having weighed all the pros and cons.

- Foam block production at home: is it profitable?

- Making an opening in a concrete wall

- How to close up a crack in a wall: classification of destruction and methods of their elimination

One Comment to “The weight of sand-lime brick: Compliance with the standard is the guarantee of quality”

Solid brick pallet weight

When carrying out such calculations, you need to know the mass of one specific material, the weight of the pallet itself and the number of products in the package, as mentioned above. As for the pallet, it looks like a wooden lattice, and its weight rarely exceeds 40 kilograms. Usually, manufacturers lay out bricks on a pallet in the form of a cube, which allows them to count materials as quickly as possible.

It is known that one package contains 200-330 pieces of ceramic solid bricks, let's calculate how much a pallet of bricks weighs, provided that the mass of such a product ranges from three to four kilograms:

- if there are 200 pieces of building materials in a pallet, and the mass of an individual copy is 3 kilograms 200 × 3 = 600 kilograms; when using 330 pieces of bricks in a pallet, 330 × 3 = 990 kilograms;

- if the weight of the product is 4 kilograms, for packaging containing 200 bricks 200 × 4 = 800 kilograms, for containers with 330 products 330 × 4 = 1320 kilograms.

To all results, add the weight of the pallet itself 30-40 kg.

Properties and characteristics

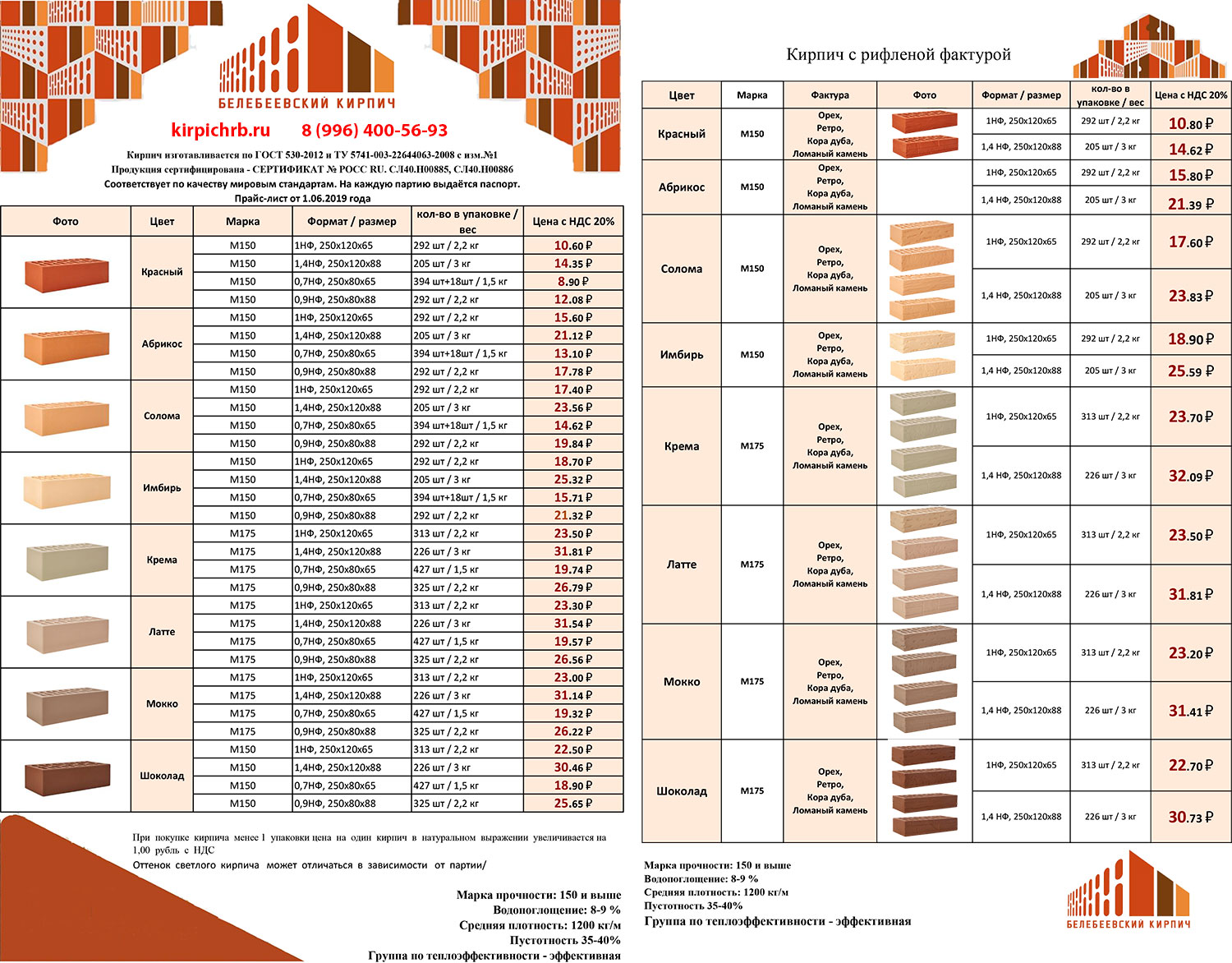

It is more profitable to equip the walls with white silicate bricks, in contrast to ceramic ones, because, in addition to physical properties, it is also an excellent finishing material that does not require additional use of foreign materials for the outer side of the building.

White

Silicate brick is an artificial building material, which contains a number of synthetic substances that can increase its strength.

Also, in recent years, bricks of different textures of all colors have become popular, giving the structure a special zest.

Various colors

But before any construction, it is imperative to take into account the various parameters of this brick, its volume, size and weight. All this is taken into account even at the stage of project creation in order to accurately calculate the necessary proportions for the base of the building, the foundation.

Like any building material, sand-lime brick has its own advantages and disadvantages. It is not used in the construction of basements or basements. The reason for this is high moisture absorption, which reduces the strength of the building, if the material was used for building in places with high humidity.

But there are undoubtedly more advantages of this material:

- environmental friendliness of the material. When creating a brick, only natural components were used, so any building made of this material will not harm the environment in any way;

- the strength of the material is preserved even in areas with increased seismic hazard;

- isolation of external sound. For this reason, the exterior of the building is often trimmed with silicate;

- wide scope of application in construction work. Due to the different shapes and colors, silicate can be used for cladding the facades of buildings;

- high frost resistance.

The weight of a silicate brick depends on its shape and density.

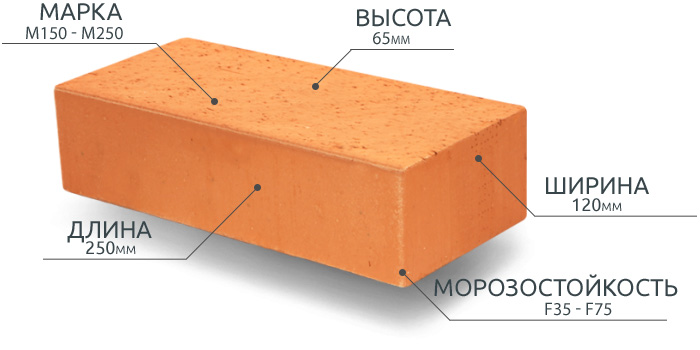

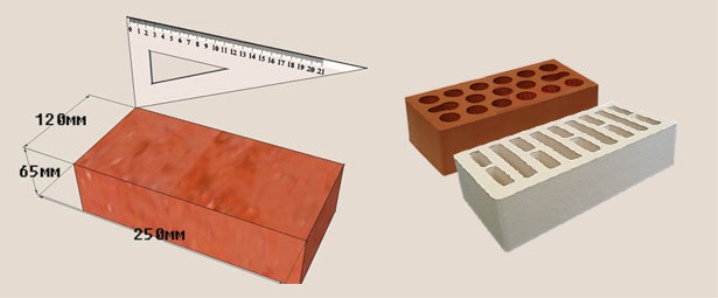

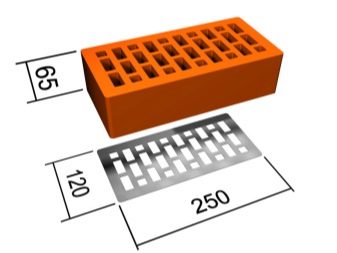

The standard form of silicate according to GOST is considered:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

The weight of the silicate brick 250x120x65 is about 4 kg.

Brick mass depends on several factors:

- size;

- forms;

- presence or absence of cavities;

- components in the composition when mixing the silicate mass.

Therefore, when planning to use silicate in construction, you should calculate in advance how many bricks will be needed for masonry.