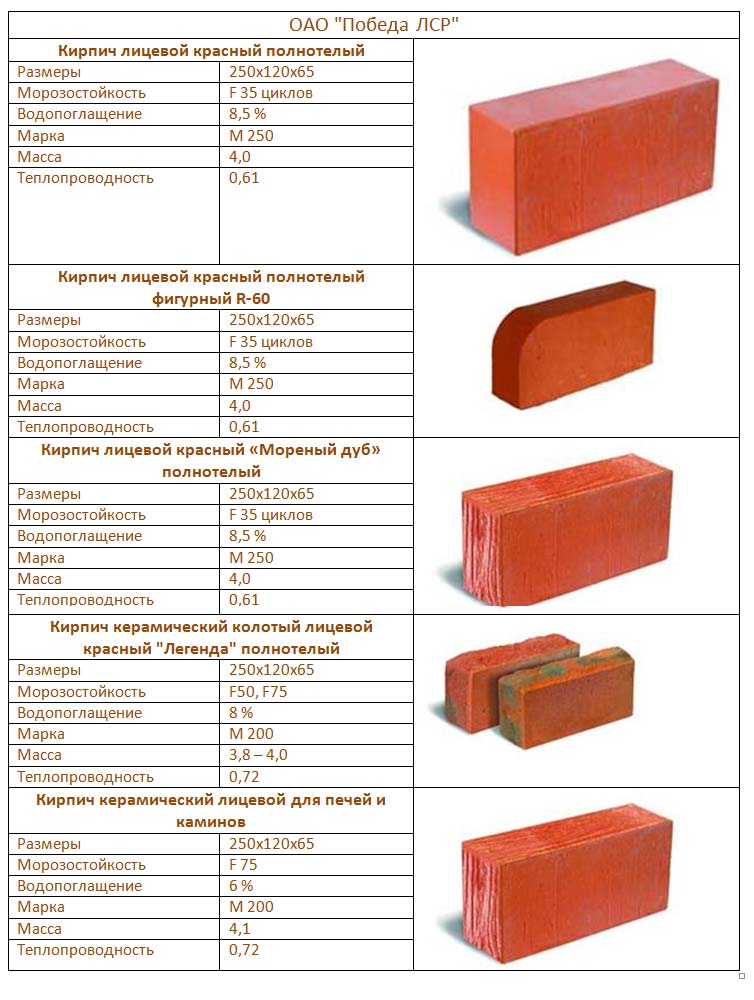

Dimensions and weight according to GOST

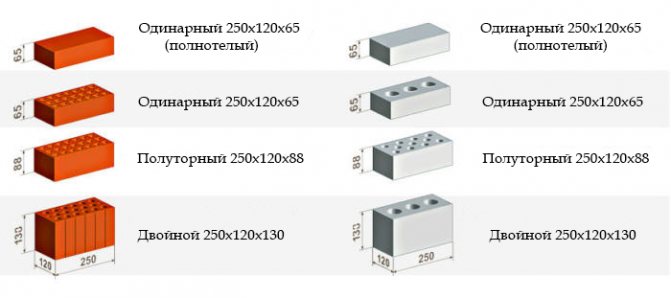

Standard sizes for single, one and a half and double products:

When designing buildings and structures, all characteristics are taken into account, including the overall dimensions and weight of red brick.

Manufacturing products according to uniform dimensions allows the designer to easily select elements of a certain format for construction or cladding, and knowing their approximate weight - correctly calculate the loads of the structure being erected on the foundation.

It will be possible to purchase the material from any manufacturer and at any time after the preparation of the project.

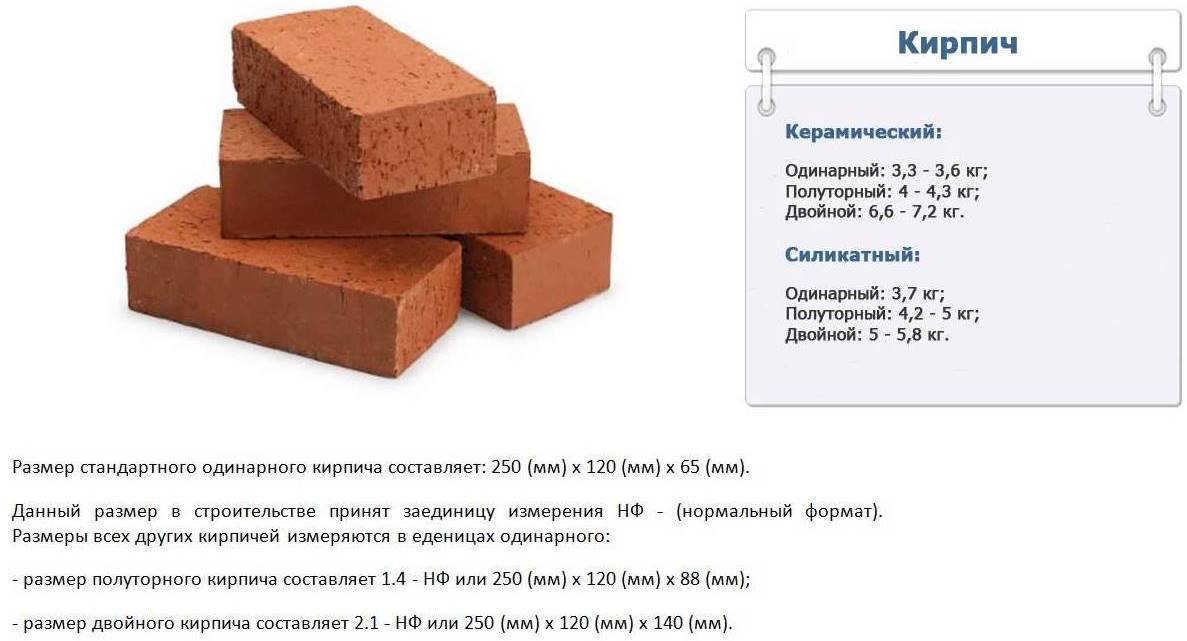

Standard sizes of red brick in normal (regular) 1NF format:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

It is the dimensions of single elements provided for by GOST that are a kind of starting point - i.e. a material with other parameters will have a different marking instead of 1NF, where the number denotes its proportions of the ratio with a single one.

So, the size of a one-and-a-half red brick will already be 250 × 120 × 88 mm, and will be designated as 1.4 NF. Products of these formats are produced as ordinary and facing.

The list of sizes of facing red bricks can be supplemented with euro format products (0.7NF, 250 × 85 × 65 mm), and ordinary ones - with double elements (2.1 NF, 250 × 120 × 138 mm).

Dimensions of red brick euro format

Thin face material (euros) will help reduce the financial costs of facing, and a large stone (double) will significantly speed up the process of building a house.

Many are often interested in the question of how thick the red brick is. For materials of basic formats (single, one and a half and double) it is standard - 120 mm.

The exception is euro size elements, the width of which is reduced to 85 mm.

Deviations from standard dimensions

According to GOST, the maximum permissible deviations from standard sizes on one element (regardless of the format) are:

- in length ± 4 mm;

- in width ± 3;

- in thickness ± 2 mm for front and ± 3 for ordinary material.

Standard red brick weight

The GOST does not reflect information on how much a single or red brick of other dimensions weighs - the standard indicates only material classes in terms of average specific gravity.

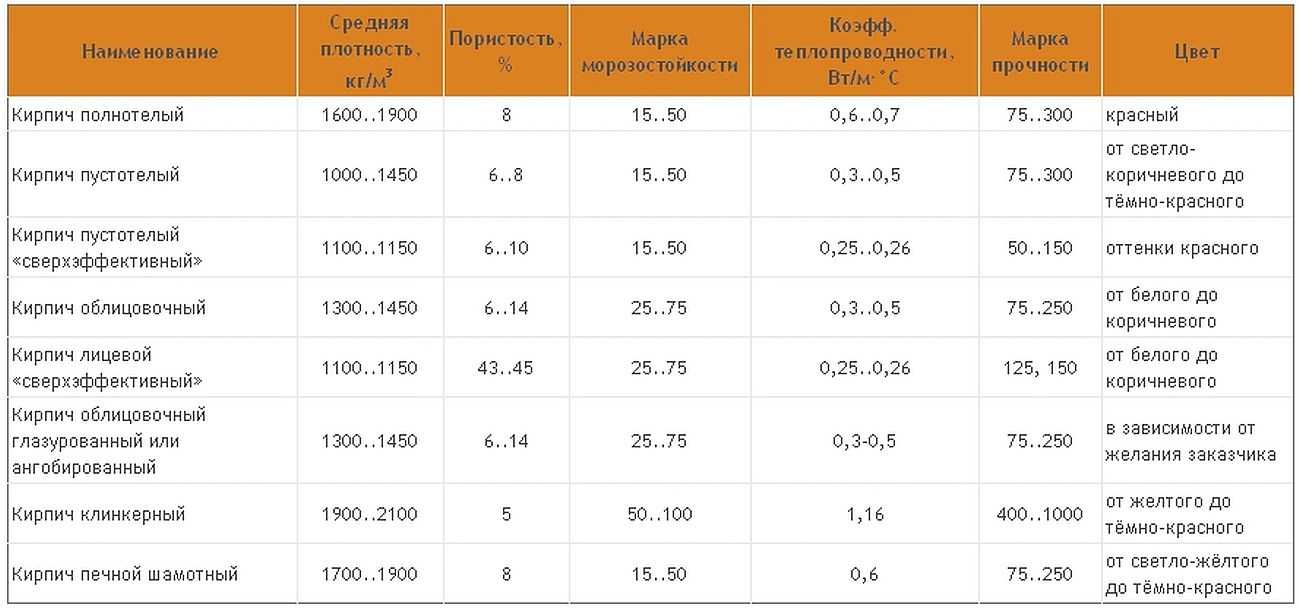

Depending on the class of average density, the products are divided into several groups according to thermal characteristics:

- 2.0 and 2.4 - ineffective (normal);

- 1.4 - conditionally effective;

- 1.2 - effective; 1.0 - increased efficiency;

- 0.7 and 0.8 - high efficiency.

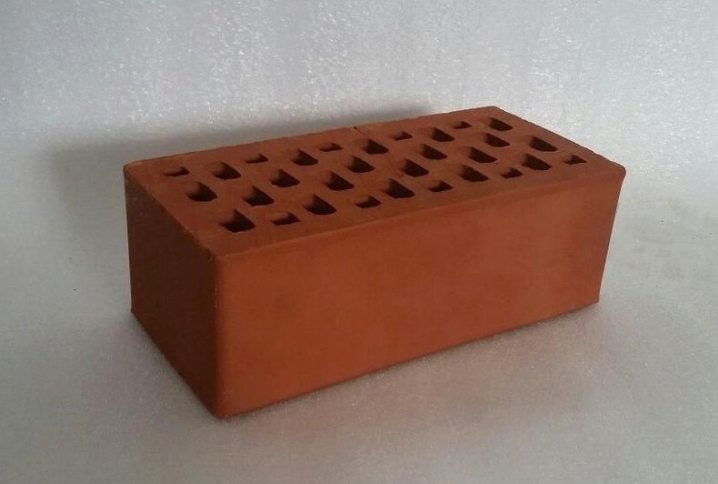

Before proceeding directly to the question of how much 1 standard red brick weighs, you need to consider its types depending on the structure.

The material is available in several options:

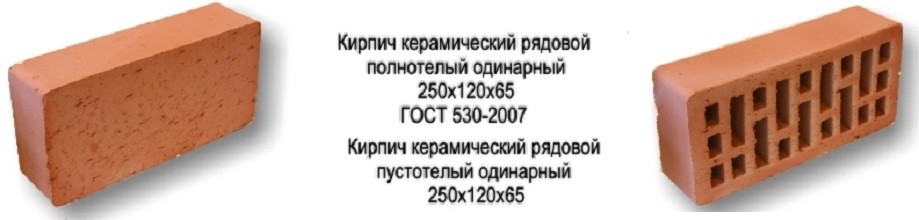

Hollow (slotted)

With the amount of voids up to 45%. It is much lighter than corpulent, but less durable.

Corpulent - the number of voids is no more than 13% of the total volume of red brick. It differs in a larger mass, but the strength characteristics of the elements are an order of magnitude higher.

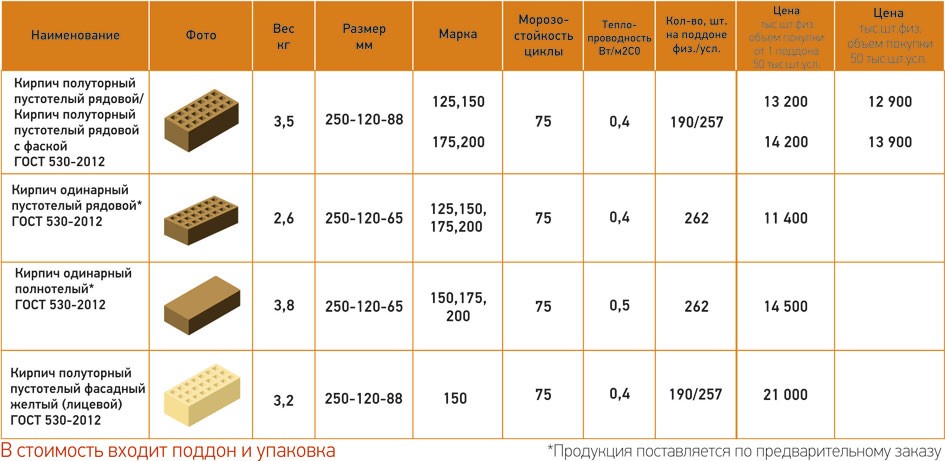

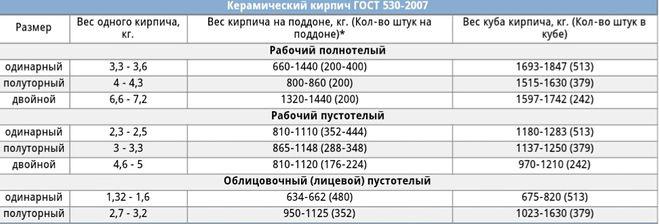

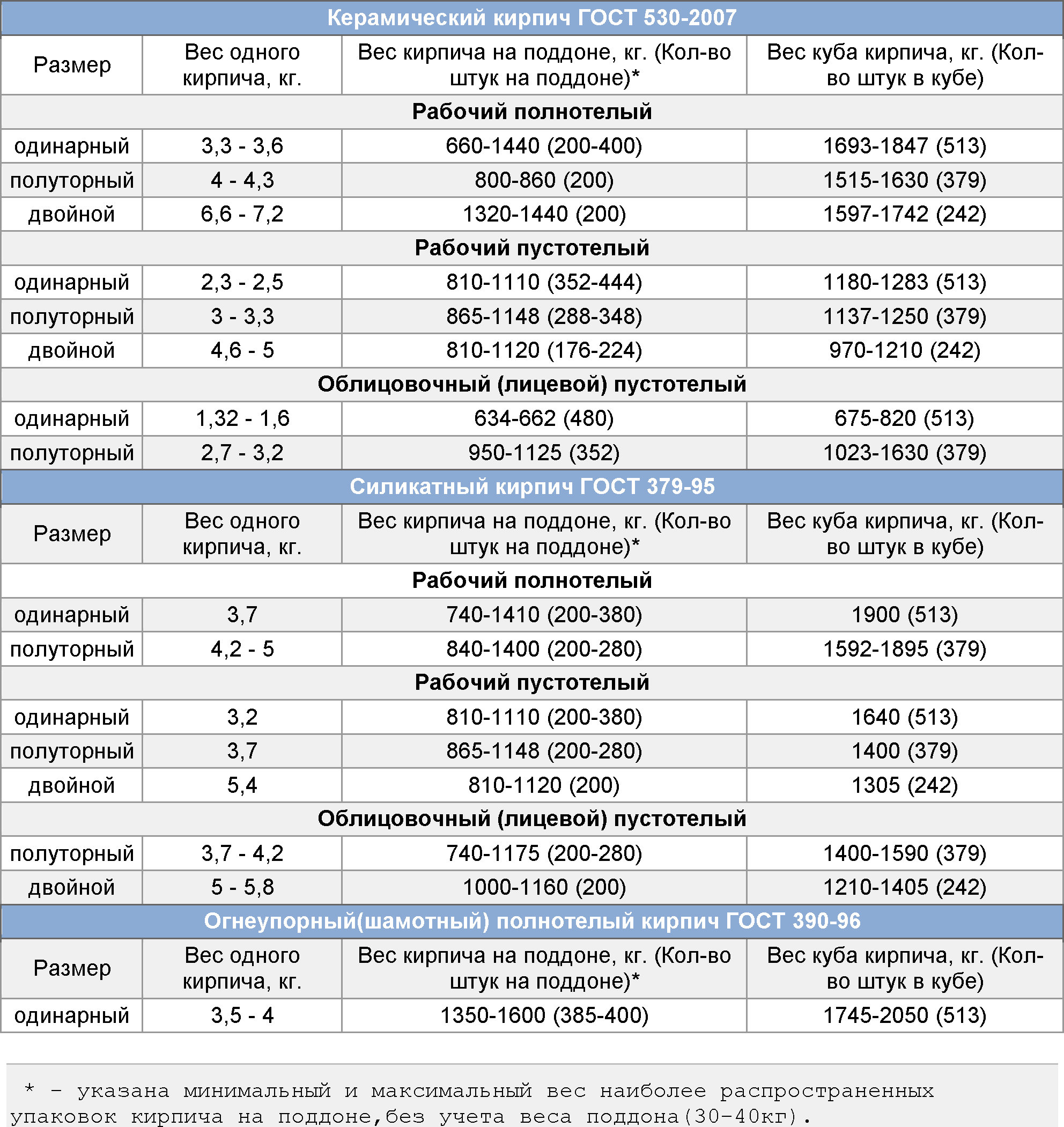

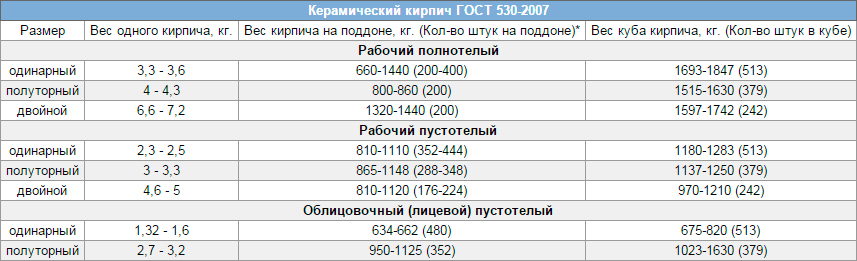

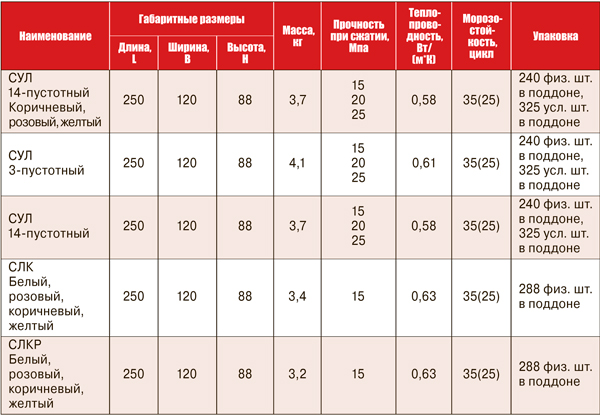

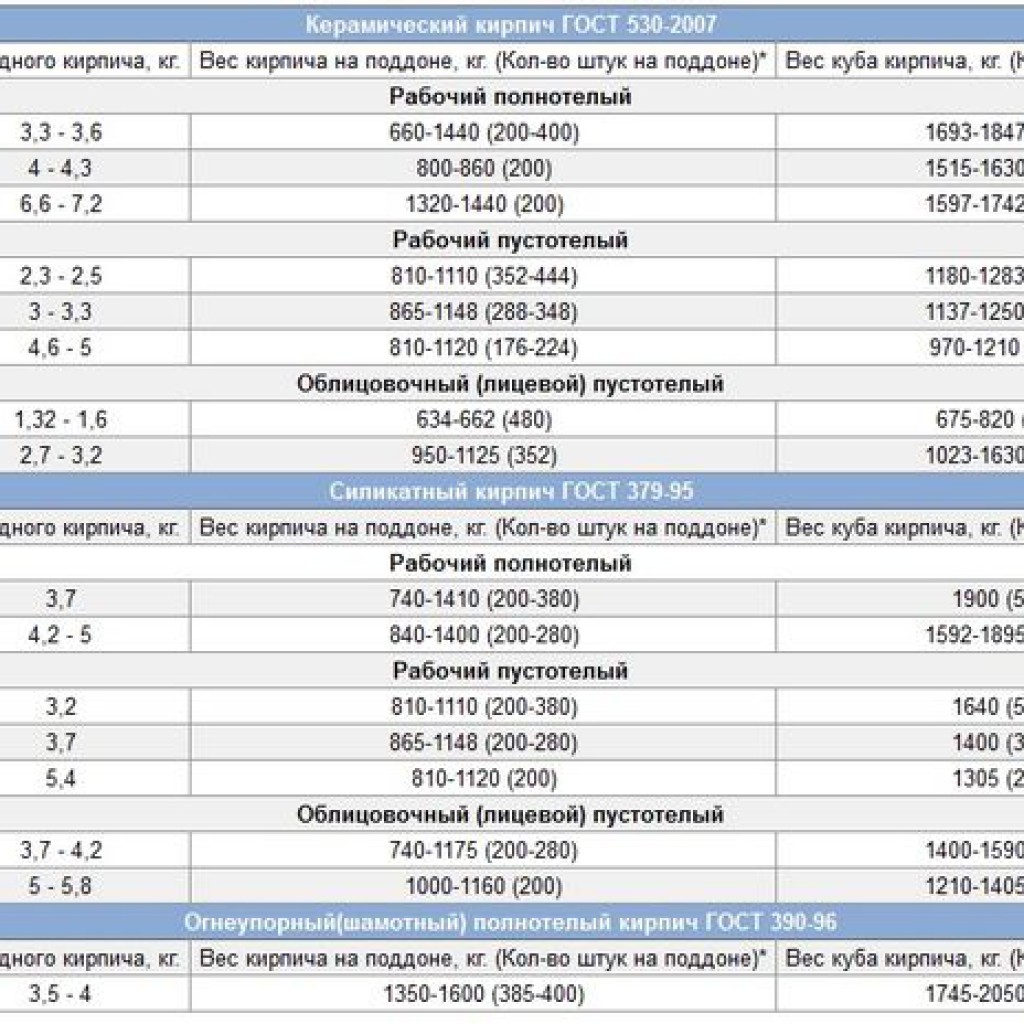

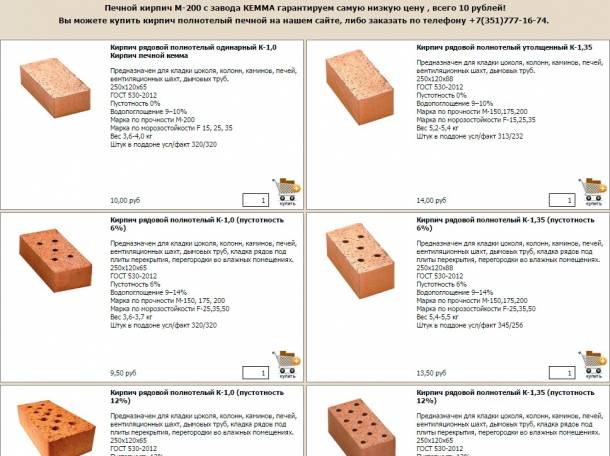

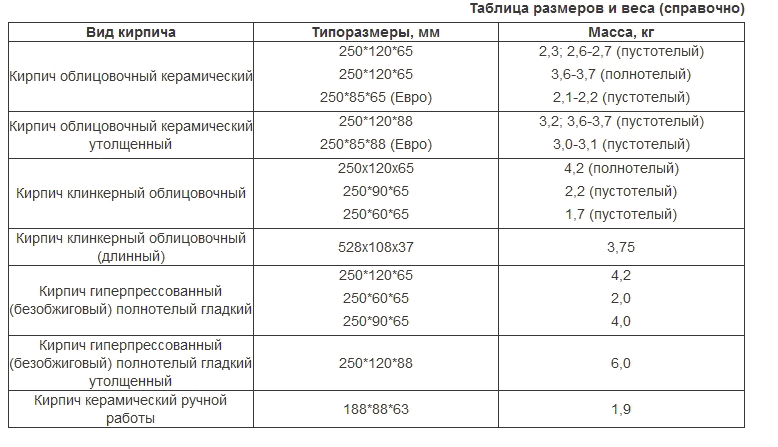

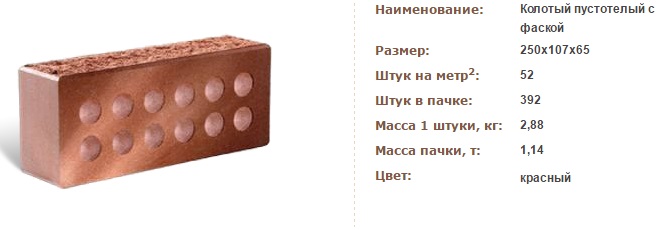

Table 1. Weight (weight) of red bricks of single (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm), double (250 × 120 × 138 mm) and euro (250 × 85 × 65 mm) formats:

The weight of a red facing brick does not differ from the weight of an ordinary hollow brick. The only thing worth noting is that cladding products are produced only 0.7NF, 1NF and 1.4NF, and there are no double formats for finishing work.

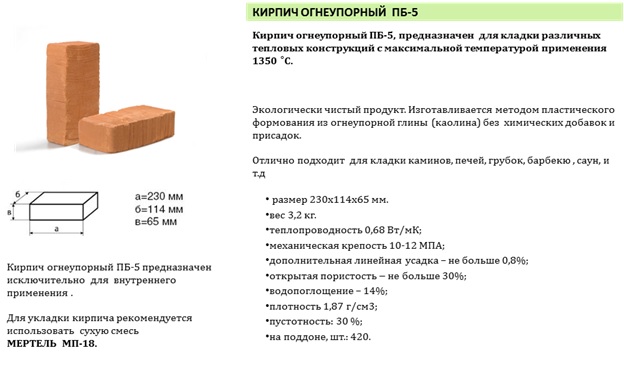

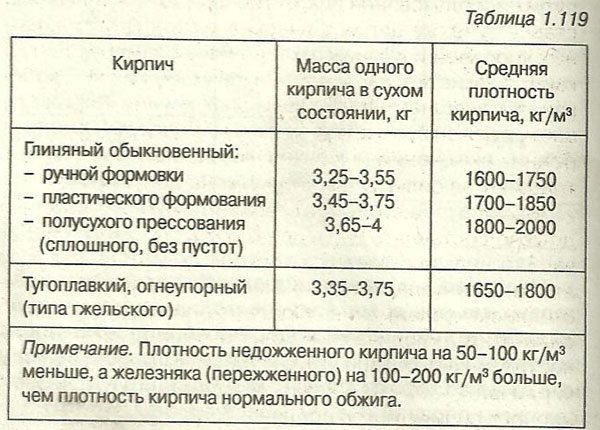

How much does an oven red brick weigh?

Kiln brick

Interested in the weight of red oven bricks, many consumers do not know its main purpose - this is a brick with increased characteristics, but not refractory.

Note! A material made of ordinary clay is intended for laying the body of the stove and chimney. If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products made from special types of clay are used.

If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products are used, made of special types of clay.

Standard kiln material also has a fairly high heat resistance and increased density compared to traditional building or cladding products.

In this regard, to the question of how much a red brick weighs for a stove, one can unequivocally answer that it is heavier than the usual corpulent one and its mass is in the range of 3.7-4.2 kg.

Properties and characteristics

It is more profitable to equip the walls with white silicate bricks, in contrast to ceramic ones, because, in addition to physical properties, it is also an excellent finishing material that does not require additional use of foreign materials for the outer side of the building.

White

Silicate brick is an artificial building material, which contains a number of synthetic substances that can increase its strength.

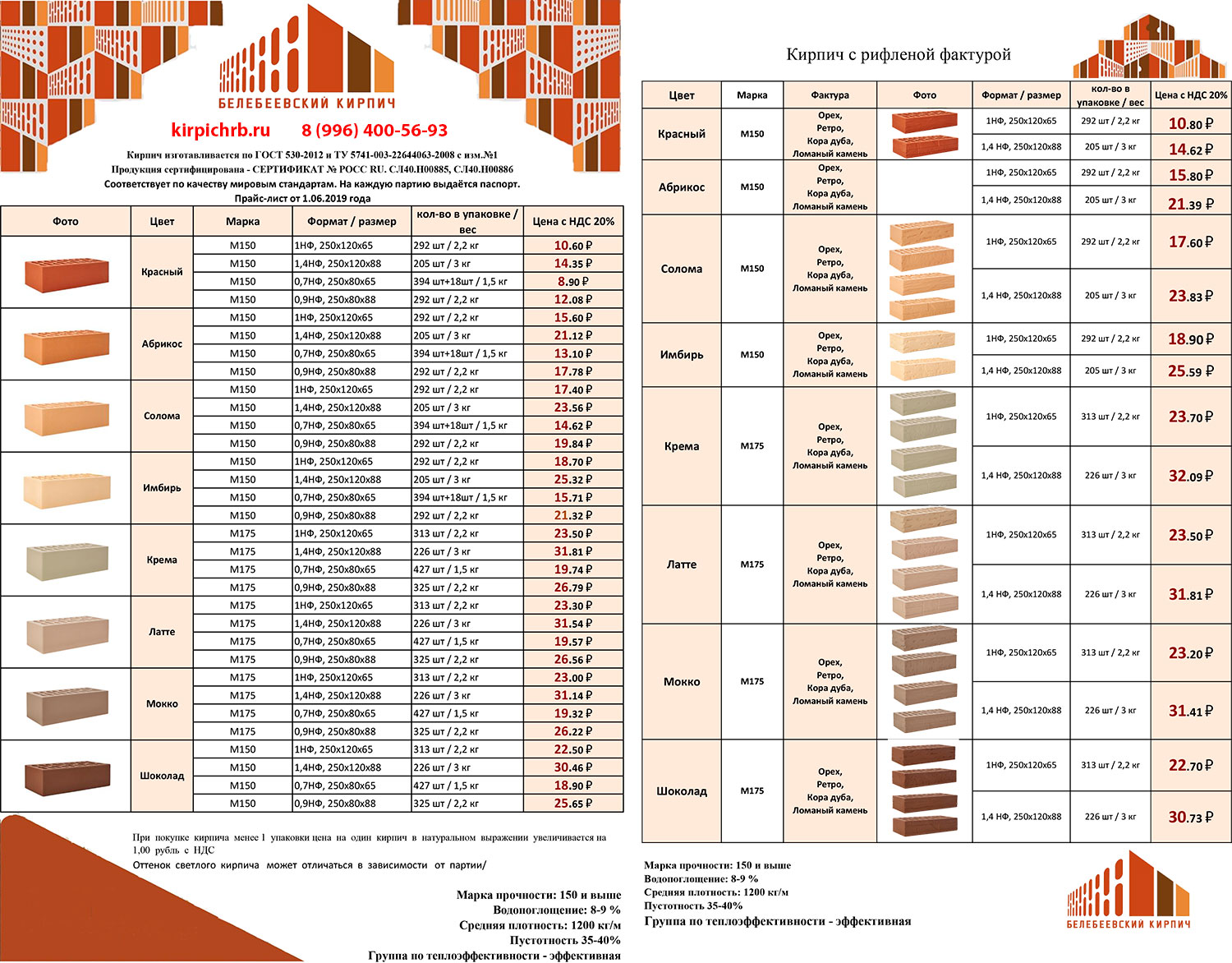

Also, in recent years, bricks of different textures of all colors have become popular, giving the structure a special zest.

Various colors

But before any construction, it is imperative to take into account the various parameters of this brick, its volume, size and weight. All this is taken into account even at the stage of project creation in order to accurately calculate the necessary proportions for the base of the building, foundation.

Like any building material, sand-lime brick has its own advantages and disadvantages. It is not used in the construction of basements or basements. The reason for this is high moisture absorption, which reduces the strength of the building, if the material was used for building in places with high humidity.

But there are undoubtedly more advantages of this material:

- environmental friendliness of the material. When creating a brick, only natural components were used, so any building made of this material will not harm the environment in any way;

- the strength of the material is preserved even in areas with increased seismic hazard;

- isolation of external sound. For this reason, the exterior of the building is often trimmed with silicate;

- wide scope of application in construction work. Due to the different shapes and colors, silicate can be used for facing the facades of buildings;

- high frost resistance.

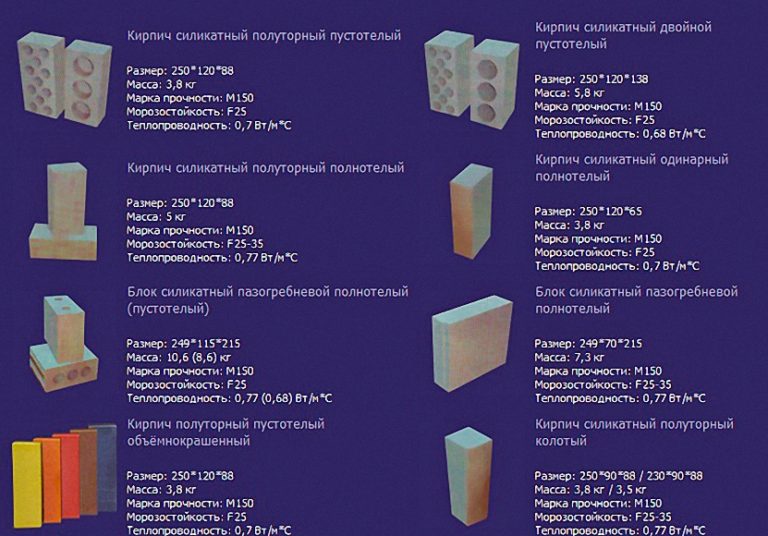

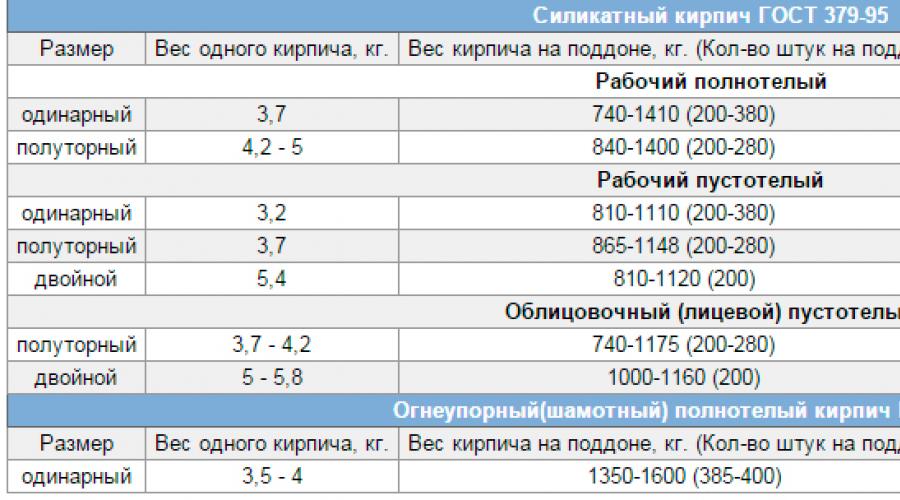

The weight of a silicate brick depends on its shape and density.

The standard form of silicate according to GOST is considered:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

The weight of the silicate brick 250x120x65 is about 4 kg.

Brick mass depends on several factors:

- size;

- forms;

- presence or absence of cavities;

- components in the composition when mixing the silicate mass.

Therefore, when planning to use silicate in construction, you should calculate in advance how many bricks will be needed for masonry.

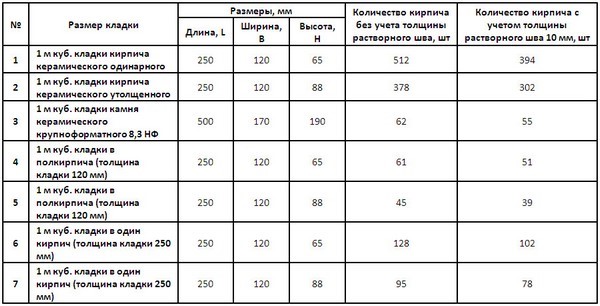

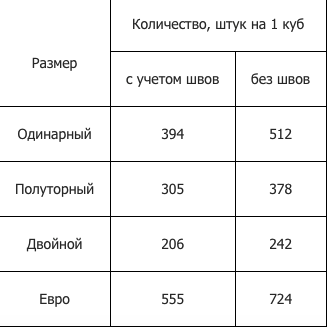

How many bricks are there in 1m3?

Determine how many red bricks in 1 cube is required when calculating the amount of material for the construction of a building or structure.

There are several calculation methods - with and without mortar joints.

The first method is relevant if it is necessary to calculate the number of products for masonry, and the second - when ordering products, since some manufacturers in transport characteristics reflect the volume of material (in m3) in 1 pallet.

To calculate how many pieces of red bricks are in a cube, you need to calculate the volume of one product (using the example of a single format):

0.25 x 0.12 x 0.065 = 0.00195 m3.

Then you need to divide the original volume (1 cube in our case) by the resulting value:

1 / 0.00195 = 512 pieces.

Now let's calculate how much single red brick in 1 m3 of masonry (i.e.taking into account the seams) - for this you need to add the estimated thickness of the seam to the standard dimensions (length and height) (for example, add 15 mm) and calculate the volume of 1 element:

0.265 x 0.12 x 0.08 = 0.00254 m3 1 / 0.00254 = 394 pieces.

For example, if the weight of 1 single product is 3 kg, and there are 512 pieces in a cube, then the mass of the total volume of the material will be 1536 kg.

Table 2. Amount of masonry material in a cube:

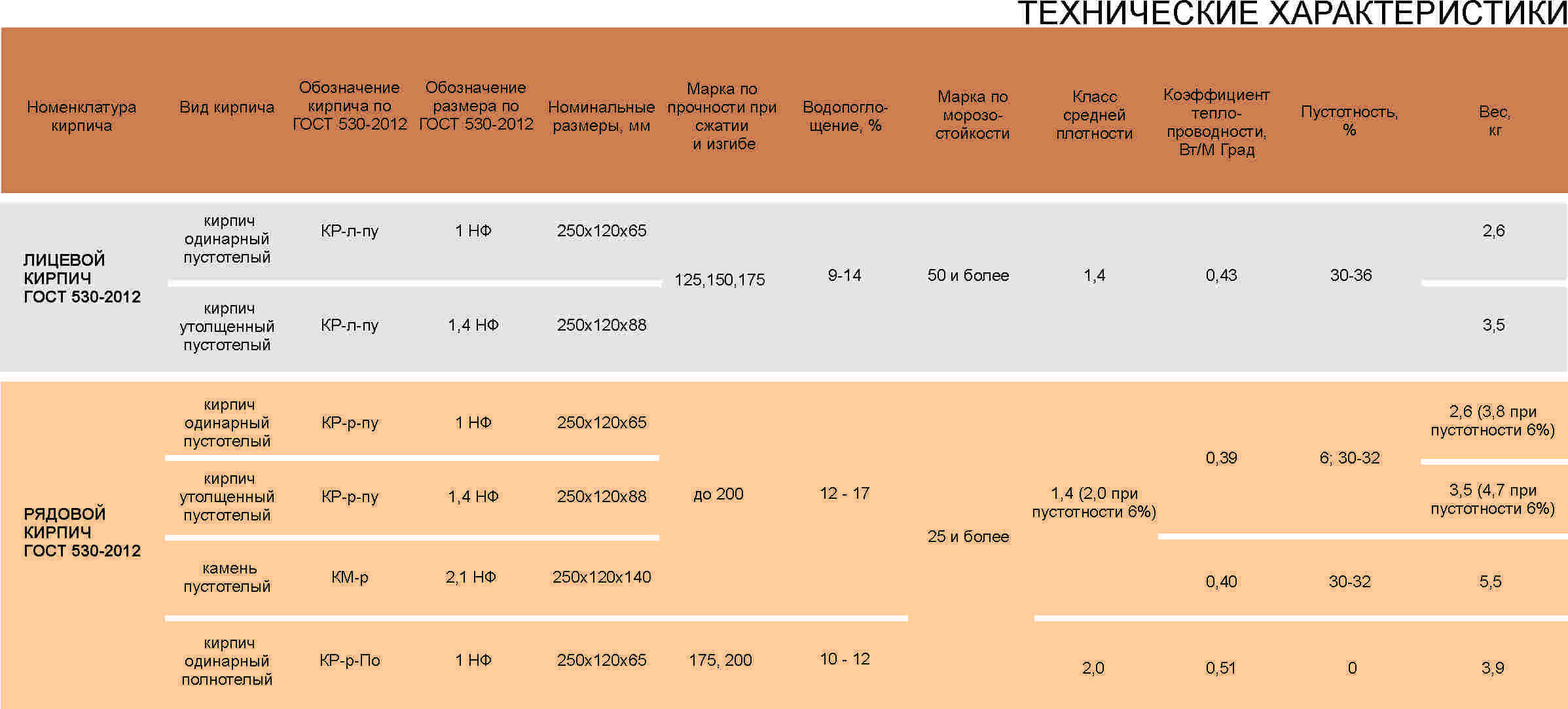

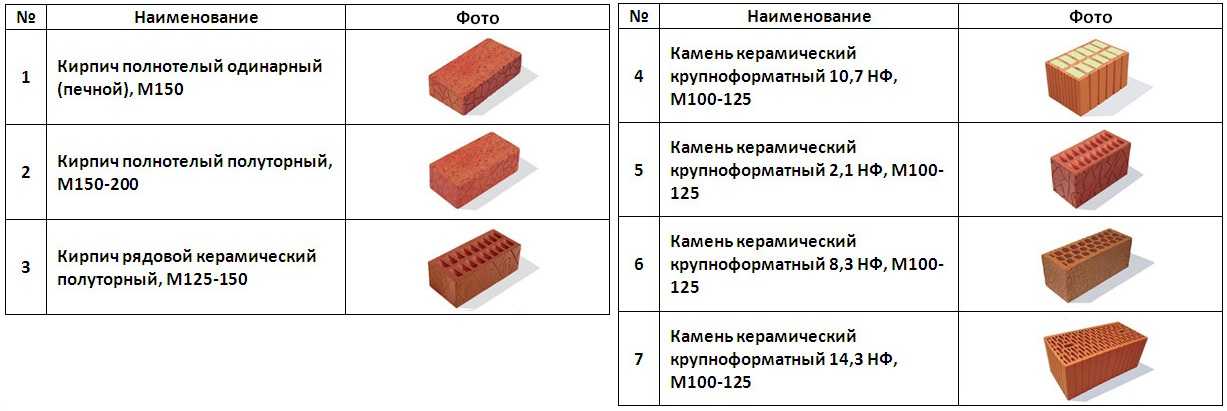

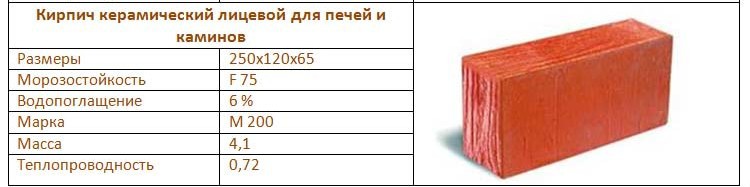

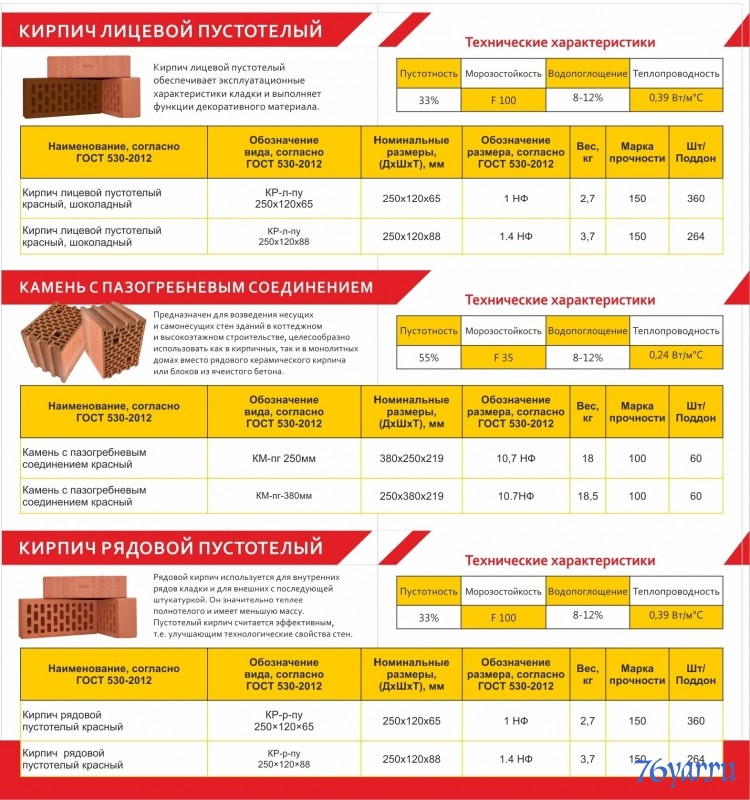

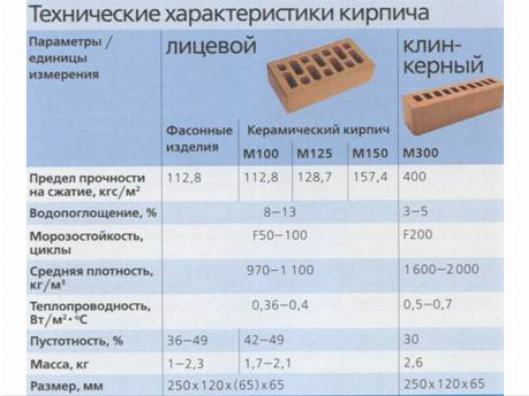

Types and characteristics of ceramic bricks

The variety of brick products allows them to be divided and classified.

Brick types

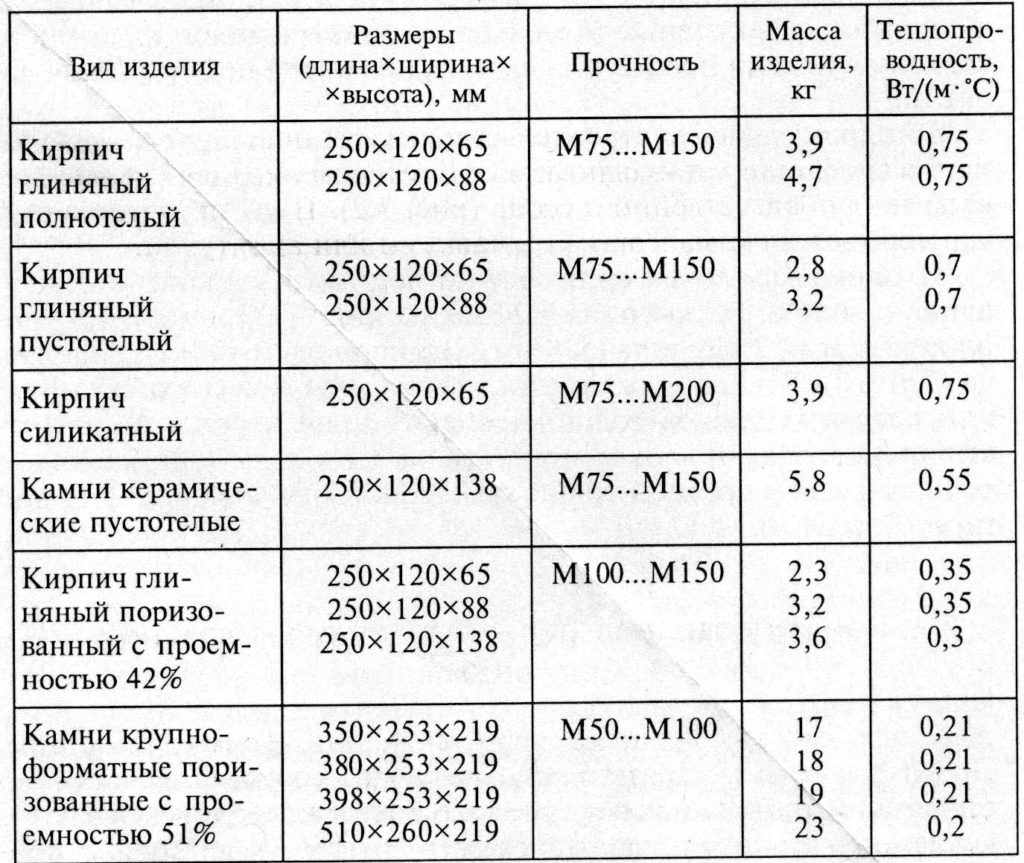

An artificially produced stone, with given shapes, sizes, mass and composition, can be divided into bricks:

In common parlance, it is often divided into red (ceramic) and white (silicate). The difference is mainly in the raw materials in their manufacture. For red it is clay, for white it is a silicate mixture (sand and lime).

Ceramic products, in turn, according to their purpose and application, are divided into the following type:

- Private. It is used in the masonry of load-bearing, enclosing walls and partitions.

- Facial. Used for cladding.

- Special. It is used in the laying of stoves, fireplaces, chimneys (stove, refractory fireclay bricks).

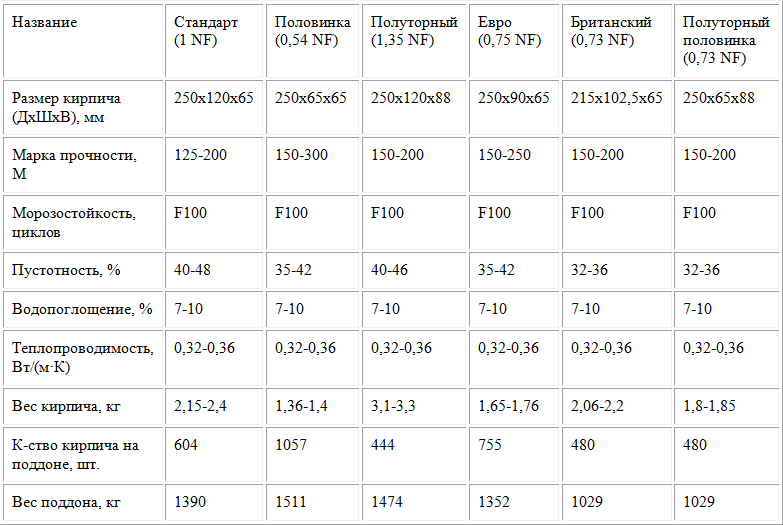

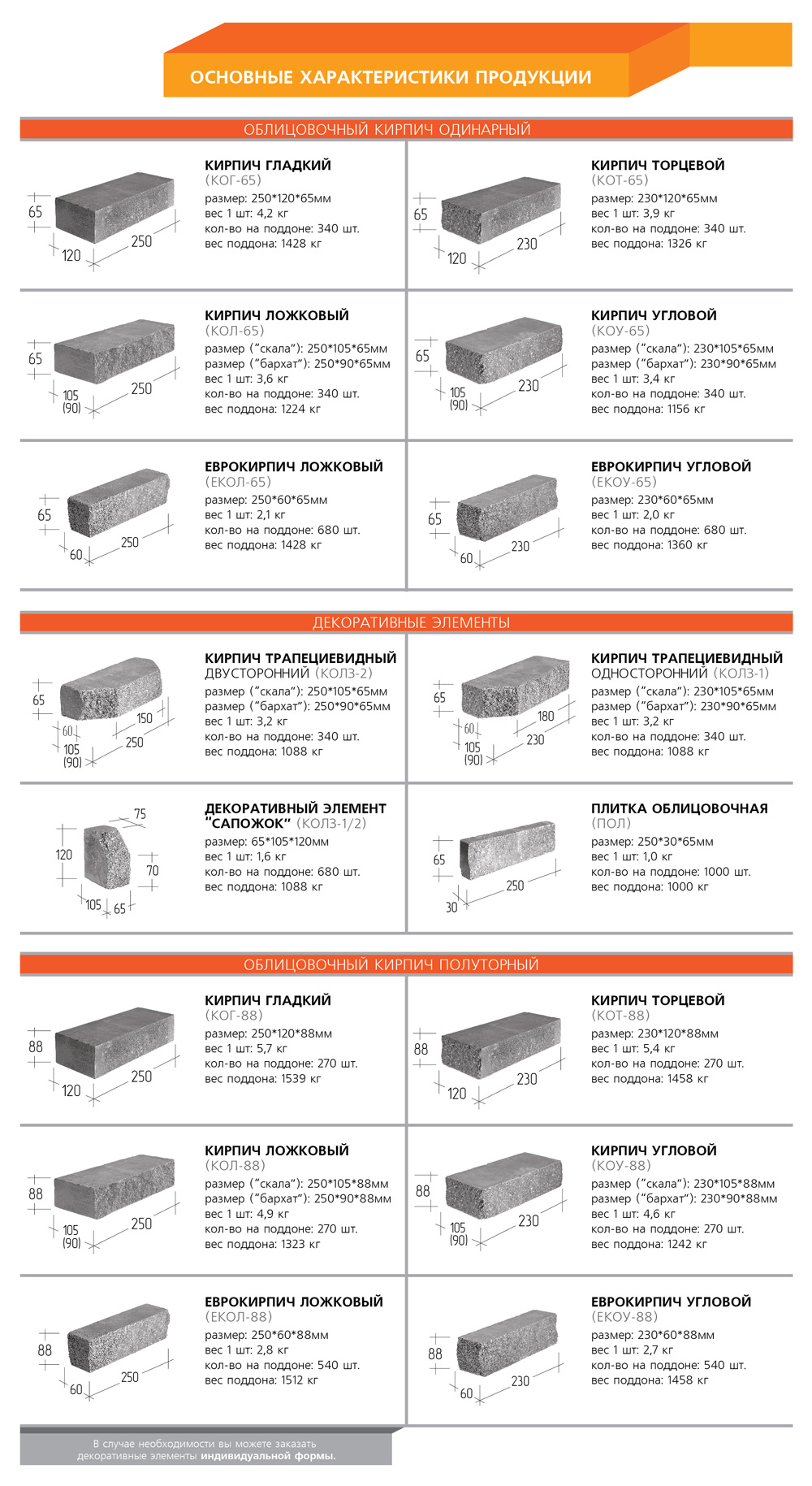

Sizes, their designations

According to the above regulatory construction documentation, all types of this building material in Russia are standardized in their standard sizes.

Size designation

Since 1927, brick products have been standardized. There is a normal format (NF), its geometric dimensions are 250x120x65 (mm).

The name of other standard sizes comes from the normal format:

- 250x120x65 - single (NF);

- 250x120x88 - one and a half (1.4 NF);

- 250x120x140 - double (2.1 NF).

In the current documents, they are divided, classified according to other sizes:

- 250x85x65 - "euro" (0.7 NF);

- 288x138x65 - modular single (1.3 NF).

By the absence or presence of voids in the body, they separate solid and hollow brick products. By voidness, the following varieties are distinguished:

The mass of the product, the weight of the masonry, the cost of its construction, and most importantly, the heat-shielding characteristics of the wall, depend on the number of voids (the percentage of voids from the total volume).

Layout: Two-layer wall (full-bodied front and hollow "warm ceramics")

Weight characteristics

Photo: the weight of a single ceramic brick depends on the volume of voids in it

Designers should take into account the mass to calculate the load of the masonry on the foundation, to determine the carrying capacity of transport, warehouse equipment (loader, crane) during logistics operations with it.

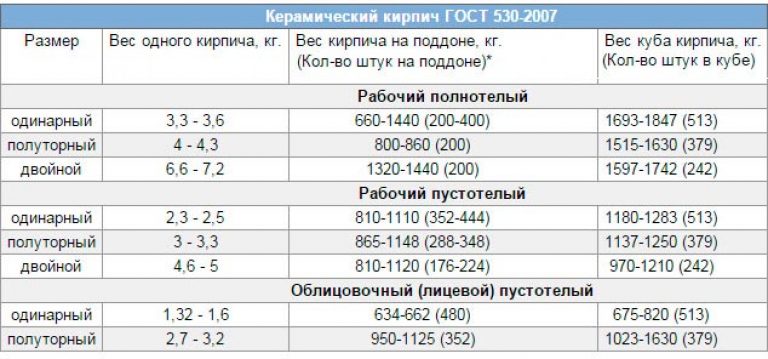

It is useful for an estimator, foreman or bricklayer who works with him with his own hands to know that, for example, 1 m3 of single solid brick masonry (about 500 pieces) is approximately 1690 - 1847 (kg). A cube of one-and-a-half brick is about 380 pieces, and of a double brick - about 200 - 240 pieces.

Attention! When calculating, you can focus on the following numbers: about 7 rows of double, 10 rows of one and a half and 13 rows of single bricks fit in a 1 meter high masonry. Here are the main weights for standard sizes (in accordance with the current documents on building materials)

Here are the main weights for standard sizes (in accordance with the current documents on building materials).

Designation according to GOST

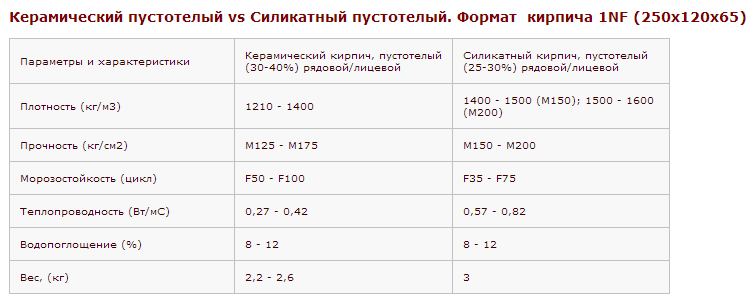

Hollow double silicate brick m 150, dimensions 250x120x138, weighs 5.4 - 5.8 (kg), and hollow double ceramic brick m 150, 250x120x140, weighs 4.3 - 5.0 (kg).

The mass of a full-bodied 250x120x65 is 3.3 - 3.6 (kg), and the same porous in volume - 2.4 kg.

Thus, we see that a large volume (size) does not necessarily mean that its mass will be large. Its weight characteristics are more influenced by the structure.

When choosing the type of building material for walls, one must take into account their thermophysical characteristics, structure, weight and geometric parameters, what is the price of their purchase, delivery and their further operation.

When laying a large array of walls, it is advisable to pay attention to one-and-a-half and double bricks, to large-format blocks of "warm ceramics". To simplify approximate calculations, you can focus on the average weight indicators.

Solid with less than 13% void - about 4 kg, hollow with more than 15% void - about 2.5 kg

To simplify approximate calculations, you can focus on average weights. Solid with a voidness of less than 13% - about 4 kg, hollow with a voidness of more than 15% - about 2.5 kg.

Weight of 1 m3 of brickwork

The quality factor of brickwork depends on the type of building material and the correctness of its laying.

To determine the number of bricks per cube of masonry, it is necessary to take into account the volume indicators of the entire structure. In addition, the consumption of material is determined by the typical characteristics of the brick and the thickness of the joints.

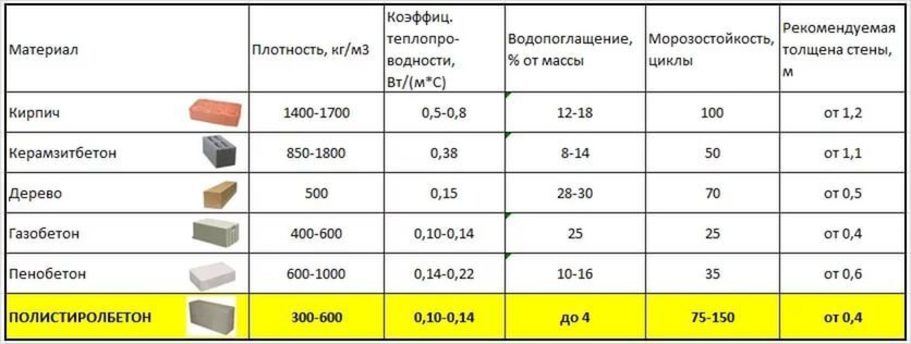

The raw materials used in the manufacture and the processing conditions determine the dimensions (see Standard size of red brick) and the specific gravity of the brick (see Weight of sand-lime brick). With regard to brickwork, this parameter also depends on the number of seams, the mass of the mortar used and the type of masonry. Thus, the specific weight of brickwork is in the range of 1400-1990 kg / m3. The next value required for the calculation is the volumetric weight (unlike the previous one, the presence of voids and pores is taken into account).

The mass of the masonry wall must be calculated in order to determine the optimal and boundary loads on the base. This value predetermines not only the type of foundation to be built and its material, but also many other design and design parameters.

Today, brickwork remains the most common type of wall. It is characterized by stability and strength, along with this, it has a decent mass, which affects the foundation of the building.

The most demanded material in this case is red brick, the standard dimensions of which in millimeters are as follows: 250x120x65, weight - about 4 kilograms. Rough counting takes place because each brick has structural voids, which are allowed by the standards, but their number is not constant. That is why it is more expedient for calculations to take the weight of 1 m3 of brickwork, and not one brick.

When designing any structure, many nuances must be taken into account. In order to fully compose a picture of the upcoming loads on the building, plan the base and correct the dimensions of the building, you need to familiarize yourself with the technical characteristics of the material - brick.

Through these parameters, it is possible to give an objective assessment of the bearing capacity and strength of the future building, therefore, when designing, they must be taken into account.

Quite often, the decent weight of a brick wall prevents the use of this material. This is not possible if the ground under the base of the building is unstable, moist or mobile. In such cases, alternative materials are used that have an advantage over traditional red bricks in weight:

- expanded clay concrete blocks;

- foam concrete;

- gazosipikate;

- cinder blocks.

Indeed, all of the above materials allow you to build fairly practical and lightweight buildings in less time and with some savings. Nevertheless, they are significantly inferior in strength to classic bricks, and some of them shrink during operation.

Do not forget that the weight of the masonry cube can be affected by the reinforcement of the walls or individual components of the supporting structures. Sometimes the mass of mortar and reinforcing mesh is not inferior to the weight of the entire wall (see.Cement consumption for brickwork)

Standard weight and specific gravity of solid and hollow building bricks

We have already said that not only the dimensions of the brick, but also its type will affect the weight of this product. First, consider the weight of solid bricks of different types:

the weight of a red solid brick 250x120x65 mm will be equal to 3.5 to 3.8 kg per one product;

Corpulent single

the weight of a red solid brick 250x120x88 mm will be equal to 4 to 4.3 kg per piece;

Corpulent one and a half

the weight of the double brick will be 6.6 to 7.2 kg per block.

Let's compare these indicators with the weight of hollow bricks of the same dimensions:

the weight of 1 red hollow brick 250x120x65 mm is from 2.3 to 2.5 kg;

Hollow single

the weight of a red hollow brick 250x120x88 mm will be equal to 3 to 3.3 kg;

Corpulent one and a half

the mass of double hollow bricks is from 4.6 to 5 kg per block.

Hollow double

The weight of an ordinary red brick allows you to determine the potential load on the foundation of a building, so this information needs to be known at the design stage of the building.

However, such a calculation is more convenient to calculate not in relation to the weight of one brick, but in relation to the specific weight of the building material per cubic meter of area.

Here the values will be as follows:

- the weight of 1 m3 of red solid brick 250x120x65 mm will be equal from 1693 to 1847 kg;

- the weight of 1 m3 of one and a half red brick will be from 1515 to 1631 kg;

- the weight of 1 m3 of double red brick is from 1597 to 1742 kg.

It would seem that the weight of a single red brick is less than the weight of one and a half and a double, but the total mass of this building material, located on one cubic meter, is higher. What's the matter?

Everything is simple enough. The fact is that one cubic meter of space accommodates a larger number of single bricks - about 513 pieces. As for one-and-a-half bricks, there are only 379 pieces in 1 m3.

The double brick is even smaller due to its large dimensions. On average, 242 pieces are placed on one cubic meter of area. We found out the weight of a red solid brick 250x120x65 per cubic meter.

Let us now consider similar parameters, but for hollow bricks:

- the specific gravity of a red hollow brick 250x120x65 mm per cubic meter will be from 1180 to 1283 kg;

- the weight of 1 m3 of one-and-a-half hollow brick will be from 1137 to 1250 kg;

- the weight of one cubic meter of double hollow brick will be from 970 to 1210 kg.

As for the number of pieces in one cubic meter, this indicator fully corresponds to the number of solid bricks in 1 m3. Bricks are often sold in batches. It is clear that rarely will anyone need to purchase a brick by the piece, so they buy pallets with bricks.

So, the weight of a pallet of solid red brick 250x120x65 mm is from 660 to 1440 kg. At the same time, one pallet can hold from 200 to 400 items.

One pallet of double solid bricks will weigh from 1320 to 1440 kg. The pallet also holds about 200 pieces. We found out the weight of one standard red brick, which is about 3.5 kg. Various supporting structures, foundations and other elements of each building are made from it.

But people use other types of bricks as well, so they need to know about all of their parameters. In addition to standard bricks, there are two more types - facing and refractory. So, the weight of a red facing brick without voids will be from 3.6 to 3.7 kg.

If voids are present, i.e. the brick is hollow, its weight will be from 2.1 to 2.7 kg. One-and-a-half facing brick will have the following parameters:

- the weight of hollow bricks ranges from 2.7 to 3.2 kg;

- the weight of 1 solid red brick is from 4.2 to 6 kg.

The weight of the red brick oven will be from 3.5 to 4 kg. It should be noted that refractory bricks are produced only in full-bodied, i.e. without any voids and holes.

For more information on the weight of the brick, see the video:

Calculating the weight of a brick

How much a solid brick weighs can be calculated by knowing its dimensions and specific gravity. We emphasize once again that such calculations are only suitable for solid bricks.If the brick contains any holes or relief, its weight will be significantly reduced.

For example, you have a brick measuring 250 * 120 * 65 mm and a density of 1.8 g / cm 3. To calculate its weight, follow these steps:

- First, convert mm to cm (25 * 12 * 6.5), because density is given in cm 3;

- Calculate the volume of one brick - multiply the length, width and height (25 * 12 * 6.5 = 1950 cm 3);

- Then multiply the volume by the density (1950 * 1.8 = 3510 g or 3.510 kg).

Such a calculation is more accurate, however, it also does not give you the opportunity to calculate the weight of your entire building with absolute accuracy. The fact is that the dimensions of bricks in each batch may vary slightly and, accordingly, their weight will change.

In addition, when calculating the weight of the masonry, one must not forget that there is a mortar between the bricks. Its weight can also be calculated by knowing the volume required for the construction of 1 sq. m. masonry and density of the solution. Weight of one cubic meter m. of cement is about 1300 kg.

You may also be interested in the article How to make a brick yourself.

Criteria and Requirements

In order for the heating structure to serve for a long time, it is necessary to perform masonry from high-quality raw materials, suitable for specific conditions. The material is chosen individually for each house or room, taking into account the wishes of the owner, based on the main characteristics of brick products. The criteria for which brick it is better to lay the stove from may be different, but the requirements for this building material are the same.

Marking

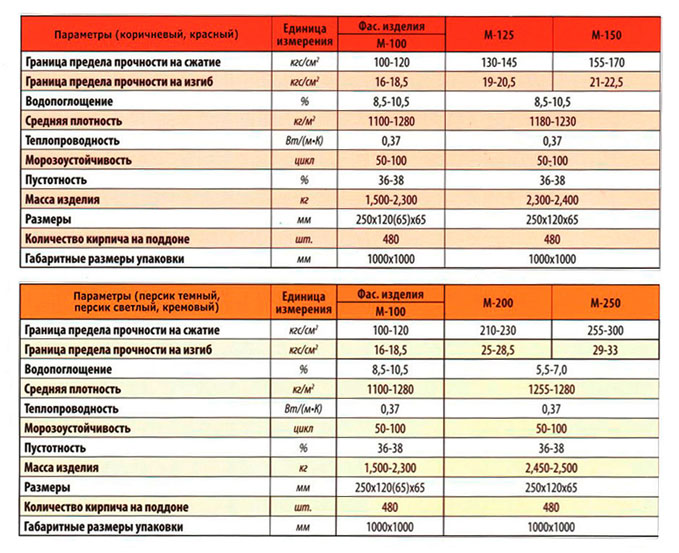

Blocks for assembling furnaces have a separate marking with the letter M, after which they put a digital designation of the withstand weight load. The numerical parameter is calculated for each square centimeter of the product and can vary from 150 to 250 kg.

It is better to skip other letter designations - the letters U (thickened) or P (hollow, hollow) are completely unsuitable for the construction of furnaces.

Fireclay blocks are designated by the letter W, after which the presence of signs A or B is a direct indicator of the purpose for laying furnaces. When a number is printed instead of the second letter, it means that the manufacturer deviated from the standard procedure during the manufacture of bricks. But this method of release must be carried out in accordance with the approved technical conditions.

Marking

Heat-resistant bricks for stoves, which are best suited for a heating structure, are most often not marked in any way.

What kind of brick is needed for laying a stove? When choosing raw materials, you should pay attention to the presence of a label about the frost resistance of products, which is also important when building a structure. The optimal indicators are any in the range from 75 to 100

The size

There are many options for bricks, among which there are standard sizes of red bricks for laying the stove - 25 * 12 * 6.5 cm. This option is optimal for oven equipment, it is very convenient to use.

There are wedge-shaped blocks, one half of which is 2-3 cm narrower than the other. This option is used at turning points, when laying out the outer part of the crucible, if it is supposed to cook or heat food using an oven.

Dimensions (edit)

It is possible to use europroducts of a thickened or modular type, which differ slightly in dimensions: 25 * 8.8 * 6.5 cm.

The form

Brick blocks may vary slightly in shape. The best option is a standardized rectangular look, but for a more complex look, you can use one of three options: wedge-shaped, ribbed or end blocks. The wedge shape assumes smoothing one corner, which helps to make the corner sections as beautiful as possible or lay out interesting decor. For the end and edges, the blocks differ mainly in thickness.

Form options

Most often, wedge-shaped bricks are used in the formation of an arched vault, in which one side is narrowed, which helps to perform a neat turn.

Colour

Brick color is a direct indicator of the quality of production. Uneven color or stains indicate a defective product.

Also, the color scheme helps to determine the intended purpose of the manufactured products: which ones are used for the construction of buildings, and from which brick ovens are often laid. For the laying of furnaces, red refractory blocks are used, since they are characterized by resistance to temperature extremes, thermal pressure without violating the integrity of the structure.

Color spectrum

At the places where the firebox and ash pan are formed, yellow bricks are used, since there is no direct effect of fire and heat at these places. Otherwise, such blocks are called chamotte.

The white chamotte block is excellent in all characteristics as the main material for the oven masonry, but it costs noticeably more than the red analogue. If there are general parameters, it does not always make sense to overpay for a shade.

A more detailed analysis of brick products for building stoves is shown in the following video review:

Weight measurement

In terms of its severity, silicate is similar to fireclay brick. Some manufacturers may add iron oxide to the raw materials for brick making, as a result of which the product will look like ordinary red brick. But when choosing, you need to be careful, since this type of stones cannot be used to decorate fireplaces or stoves. With intense heating, they will crumble and turn into powder.

It is also important to know the weight of the brick, which is determined by the type of product. Depending on the use, silicate can be as follows

Ordinary. It is used for simple masonry and has rough sides. The presence of small chips on the surface is allowed.

The weight of any body can be calculated in a certain form and perform such work yourself

Also, when calculating, it is important to take into account the presence of voids in the product and its moisture content, which affects the weight characteristics. The specific gravity of standard silicate is 1300-1900 kg per cubic meter

Correctly made preliminary calculations will make it possible to find out how much weight will affect the basement and provide a reliable foundation that will withstand all loads and at the same time will not allow the walls to crack during construction. Also, the manufacturer must always indicate the specific gravity of the finished product, which simplifies the calculations.

The strength of the stone is determined by the brand, which must also be taken into account when choosing. For example, grade M75 is used for the construction of structures with a height of no more than one floor. It is also assumed the possibility of constructing load-bearing walls from them with a small load. The M100 brand is suitable for constructions of objects with two or three floors. For tall buildings, a brick with a strength of M200 is used.

Any silicate brick is distinguished by fire safety, which is ensured by the absence of flammable components in it. Walls made of this material should, in any case, be additionally finished with insulation. A disadvantage of silicate is a high rate of water absorption.

To know the weight of 1 cube of brick in the masonry, you must initially determine the number of products in it. Experts note that in the cube of masonry there are 414 single pieces, and thickened - 314. This amount is approximately, since it all depends on the thickness of the seams and the type of masonry. For example, the average joint width is one and a half cm, and therefore this value must be added when calculating the number of bricks in one cubic meter of masonry. All the data on which the calculations are made apply only to products manufactured in accordance with GOST.

- The formula for calculating the number of bricks in a cube of masonry: 100x100x 65 (88, 206).

- The formula for calculating the weight in a cube of masonry: 414 pcs. x 3-4 kg.

The bricks to the site are usually delivered in stacked pallets containing one cube of brick. This allows developers to navigate the calculations and order the required number of products. The sizes of silicate are standardized so that it is convenient to calculate their volume and number of units.

These bricks can be used for load-bearing foundations, columns, pillars and other objects, and therefore, before buying, you need to decide on the type of masonry that will be used. The choice of the product in terms of thickness and other parameters depends on this. For example, a single brick is usually used for the construction of load-bearing walls in structures. To fill the voids, you can use one and a half bricks.

Also, when choosing this material, it is necessary to take into account the ability to absorb water by it, which reduces characteristics and reduces resistance to low temperatures. Therefore, it is not recommended to use such products without additional waterproofing in basements or other places where high humidity is observed. It must be remembered that silicate does not tolerate high temperatures well, and therefore it is not recommended to use it near heating devices.

Loaded pallet weight

This value must be known exactly when a truck is ordered to transport ceramic blocks. Since the weight of the package, which is also called pallets, determines the number of freight transport flights and the total cost of transportation services.

For example, a single brick weighs 3.7 kg, while the weight of one-and-a-half blocks is 5 kg. One and a half hollow stone weighs 4 kg, double in weight reaches 5.2 kg. Block sizes 250x120x65 have different weights: shortened type - 2.1 kg, hollow type - 2.6 kg, solid blocks - 3.7 kg.

After the calculation, it turns out that the mass of a large filled pallet with a single brick will weigh 1554 kg. This figure is obtained from the calculation of 420 pieces. brick stones multiplied by the weight of each brick of 3.7 kg.

Themselves standard pallets made of wood usually weigh no more than 25 kg, and metal and non-standard wooden ones - 30 kg.

The mass of one red hollow brick 250x120x65 mm in size reaches 2.5 kg, no more. That's just the price of a slotted block is several times lower than a full-bodied one. The use of this building material will allow you to get advantages not only in weight, the use of such a brick will help to retain heat, and will reduce the total expenditure of funds for construction.

What buyers and builders need to consider

According to the requirements of GOST 530-2007, single ceramic bricks are produced only with a size of 250x120x65 mm. A similar material is used if you need to lay out load-bearing walls and a number of other structures. Its severity differs depending on whether hollow or full-weight facing blocks will be laid. A red facing brick that has no voids will weigh 3.6 or 3.7 kg. And in the presence of internal grooves, the mass of 1 block will be at least 2.1 and maximum 2.7 kg.

When using a one-and-a-half facing brick that complies with the standard, the weight is 1 pc. taken equal to 2.7-3.2 kg. Both types of decorative blocks - single and one and a half - can be used to decorate arches and facades. Full weight products can contain a maximum of 13% voids. But in the standards for material including voids, it is indicated that cavities filled with air can occupy from 20 to 45% of the total volume. The lightening of the brick 250x120x65 mm allows to increase the thermal protection of the structure.

Additional Information

All of the above applies to ceramic facing bricks. But it also has a silicate variety. This material is stronger than an ordinary product, it is created by combining quartz sand with lime. The ratio between the two main components is selected by technologists. However, when ordering sand-lime bricks 250x120x65 mm, as well as when buying its traditional counterpart, you must carefully calculate the mass of the blocks.

On average, 1 piece of building material with such dimensions weighs up to 4 kg. The exact value is determined:

-

product size;

-

the presence of cavities;

-

additives used in the preparation of the silicate block;

-

geometry of the finished product.

A single brick (250x120x65 mm) will weigh from 3.5 to 3.7 kg.The so-called one-and-a-half corpulent (250x120x88 mm) has a mass of 4.9 or 5 kg. Certain types of silicate, due to special additives and other technological nuances, can weigh 4.5-5.8 kg. Therefore, it is already quite clear that a silicate brick is heavier than a ceramic block of the same size. This difference must be taken into account in projects, to strengthen the foundation of buildings under construction.

Hollow silicate brick measuring 250x120x65 mm has a mass of 3.2 kg. This makes it possible to significantly simplify both construction (repair) work and the transportation of ordered blocks. It will be possible to use vehicles of lower carrying capacity. In addition, there is no need to reinforce the walls. And therefore, the foundation of the building being built will be easier to make.

The situation is slightly different with hollow products. Such a single sand-lime brick weighs 3.2 kg. Standard packaging includes 380 pieces. The total weight of the pack (excluding the substrate) will be 1110 kg. Weight 1 cub. m. will be equal to 1640 kg, and this volume itself includes 513 bricks - no more and no less.

Now you can consider one-and-a-half silicate brick. Its dimensions are 250x120x88, and the mass of 1 brick is still the same 3.7 kg. The package will include 280 copies. In total, they will weigh 1148 kg. And 1 m3 of silicate one-and-a-half brick contains 379 blocks, the total weight of which reaches 1400 kg.

There is also chipped silicate 250x120x65 with a weight of 2.5 kg. In an ordinary container, 280 copies are placed. Therefore, the packaging is very light - only 700 kg exactly. Regardless of the type of bricks, all calculations must be carried out very carefully. Only in this case will it be possible to ensure the long-term operation of the building.

If you need to determine the weight of the masonry, you can skip calculating its volume in cubic meters. You can simply calculate the mass of one row of bricks. And then a simple principle is applied. At a height of 1 m there are:

-

13 rows single;

-

10 bands of one and a half;

-

7 strips of double bricks.

This ratio is equally true for both silicate and ceramic varieties of the material. If you have to revet a large wall, it is more correct to choose a one-and-a-half or even double brick. It is recommended to start your selection with hollow blocks because they are lighter and more versatile. But if there is already a solid, solid foundation, you can immediately order full-weight facing products. In any case, the final decision is made only by the customers of the construction or repair.

See below for details.