Views

After annealing, the tying wire becomes convenient for knitting knots while fastening reinforcement and other parts. For fittings, 2 types of annealing are used: light and dark. Despite the external differences, there are no differences in technical properties between the types of annealing.

The galvanized type has excellent anti-corrosion properties, it is not afraid of precipitation, and its long service life allows it to be used in open areas. There is a kind of knitting wire produced specifically for fastening fittings: "Kazachka". It is sold in ready-made pieces, which allows you to significantly save time on blanks for tying.

All types of knitting wire, its sizes, types, nomenclature specifics are regulated by GOST 3282-74:

- products that have undergone heat treatment are marked with the letter "O" and are divided according to their resistance to rupture into subgroups I and II;

- the smooth surface is marked "B", the changing profile - "BP";

- marking "C" means bright annealing, "CH" - dark annealing;

- the galvanized type is divided into classes: "1C" - a thinner layer of zinc coating, "2C" - a thicker layer;

- "P" marking means increased manufacturing accuracy.

Galvanized

As you know, steel belongs to metals that corrode quite easily, which significantly reduces the service life of products made from it. The problem is solved by galvanizing steel wire.

The best steel wire is obtained by hot-dip galvanizing, as this method of coating provides the strongest adhesion to the wire itself.

Such products are not only not afraid of corrosion, but also have a high degree of protection against environmental factors such as direct sunlight, wind, exposure and temperature extremes.

Galvanized wire manufacturing technology

Wire is obtained by hot rolling from different grades of steel. Wire without a protective coating is highly susceptible to corrosion and does not serve for a long time, and is zinc-plated to protect it from weathering.

Galvanizing is done in two ways:

Electroplating is the use of a brine bath through which an electric current is passed. The wire acts as a cathode, and any electrode outside the container becomes the anode.

The hot method involves dipping the wire into molten zinc. The melting point of zinc is significantly lower than that of steel, due to this, this galvanizing process takes place. With strong heating, the protective properties of the coating weaken.

Hot-dip galvanizing is considered to be of higher quality and more reliable than galvanic method, since the layer of hot-applied zinc is more wear-resistant.

The relative density of steel is 7850 kg / m3, based on this value, you can calculate the reference weight of a meter of wire of any diameter, and then compare with the actual weight. As a result of such calculations, it is calculated whether the proposed product meets the declared parameters.

How to choose the diameter

The diameter of the filler wire should be selected based on the thicknesses to be welded. The standard range includes the following sizes: 0.6 mm; 0.8 mm; 1.0 mm; 1.2 mm; 1.6 mm. For powder electrodes, this range is increased to 6 mm.

For welding parts with a thickness of 3-5 mm, a wire with a diameter of up to 1.2-2 mm is suitable. For thin-walled products, it is better to use 0.8-1 mm electrodes. This will save you from burn-through. Remember that the hole diameter of the welding tip must match the size of the wire.

The second selection criterion is the current value set during welding. To compare diameters and currents, it is necessary to consult the corresponding tables.

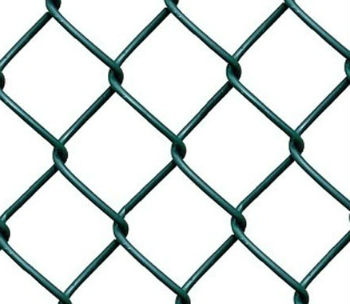

1 Features of mesh and wire

The chain-link mesh is a special type of mesh made from braided wire. The wire is taken thin, up to 3 mm in diameter. Most often, samples with a cross-sectional size of 1-1.5 millimeters are used.

The wire is knitted on a special machine, interwoven into a mesh with rectangular cells of certain sizes.

The convenience of using a chain-link mesh is obvious. Its weight is quite low, you can mount the structure yourself. Wire consumption is comparatively small, easy to determine and not expensive.

At the same time, the fence performs its tasks. Its dimensions are sufficient to qualitatively protect the site from the street, thereby protecting your space from unwanted guests, animals, etc.

Plain fence made of chain-link mesh

They use it for a wide variety of tasks, ranging from fencing enclosures with animals, and ending with full-fledged fences at security companies.

The wire itself plays an important role. It is the only and main component of the mesh, therefore its characteristics, dimensions and thickness have a huge impact on the final result.

In terms of the diameter of the section, as we have already noted, the samples are selected rather thin, their thickness rarely exceeds the 2 mm mark.

For a large-sized mesh, the use of which is reasonable in army or industrial facilities, models and thicker can be used, but in civilian conditions there are no particular advantages from it, and the cost of producing a thick mesh of the chain-link is much higher.

1.1 Coverage

The second point is coverage. The coating of the wire affects how long it will last under the operating conditions.

By the type of coating, the wire for the fence the chain-link is:

- Black.

- Galvanized.

- Polymerized or plasticized.

Black wire is a wire for a fence that has not been processed by anything. It is cast from standard grade rough steel. This steel is very good and is perfect for fastening a fence, if not for its weak resistance to corrosion.

The fence mesh made of a black wire sample will begin to rust in a few years, and after a dozen it will completely rust. Not that this is a very big problem.

The fence will not crumble due to rust, but will lose its presentation, as well as the initial strength indicators.

Polymer Treated Wire

Galvanized wire mesh is the simplest and most effective solution. Galvanized mesh withstands the influence of external factors longer, less likely to corrode.

However, galvanized products will also begin to deteriorate over time, but much later. But it is more durable, is not inferior to the first option in strength and does not cost much more.

Polymerized or plasticized mesh is the most popular and convenient option. Here, steel wires are coated with polymer compounds, forming a kind of protective sheath.

Corrosion is unknown to polymers, so the mesh is protected from all sides. For a fence made of polymer-finished wiring, a period of 50-80 years is far from the limit of possibilities.

Marking

If you look at the photo of the welding wire, you will notice that it is supplied in coils. Each coil must have a tag containing information about the brand, batch, manufacturer, OTK acceptance.

Domestic wire is designated according to GOST 2246. The marking consists of an alphanumeric code, where letters are the names of chemical elements, and numbers are their percentage. If the amount does not exceed 1%, then the number is not indicated. The abbreviation "Sv" indicates that the wire is welding.

Imported content is labeled according to AWS standards.

Benefits of Galvanized Wire

The positive qualities of galvanizing are:

Suitable for both indoor and outdoor use. A zinc layer extends the life of the product by at least three times, since it is not affected by atmospheric moisture, which causes rust.

From an aesthetic point of view, galvanized wire looks much better than unprotected with any coating, that is, it simply does not corns the eyes with rust spots.

Possibility to use galvanized wire that has undergone a certain heat treatment as nails. The most common eight- and three-millimeter nails are galvanized.

Can be used in the backyard as cables, bucket handles, clothes hangers and for other everyday needs.

When buying galvanized wire made of low-carbon steel, you should make sure that it complies with the existing national GOSTs, since Chinese-made products are often made of low-quality steels.