GOSTs for softwood sawn timber

There is no GOST for edged boards made of coniferous wood, therefore other standards are used. They use GOST 8486 86 and GOST 24454 80. They talk about the general characteristics of all sawn timber. According to the norms, lumber from coniferous tree species is divided into:

- selected grade

- first

- second

- third

- fourth.

Selective grade

Dry knots and rotten ones are not allowed in products of this type. Accepted, but healthy knots, edging and ribbing are allowed. The tables on the standards indicate the amount allowed for such sawn timber. Deep end cracks should be no more than 10%, and shallow no more than 16%. Any manifestations and signs of the fungus should be absent. Slight warping or uneven edges should not exceed 1% of the total area.

First grade

Such lumber must have the correct geometric shape. Compared to the previous variety, the indicators change slightly. The number of healthy knots is 10% higher. And the number of shallow cracks is 26%. Mold, fungus coloration and heart spots should occupy no more than 10% of the entire area.

Rotten places should be completely absent. Such defects are appropriate for rocks in the summer. Therefore, they do not carry any consequences in themselves, the structure of the wood will not collapse. Let's say "pencil" wane. Along the length and edge, it should be no more than 10% of the length. Edged boards of the 1st grade are used for roof installation, construction of houses, beams and ceilings.

Second grade

The most important positive side is the low cost. The grain slope value is much higher than that of grade 1 boards. Resin pockets are also acceptable for these boards. The shedding may be significant. Fungus staining and blue spots are typical for type 2 boards. Use material for formwork, lathing.

Third grade

Resin pockets are allowed here in the amount of 4 pieces. for 1 meter of length. A double core and significant roll are characteristic of these boards. Acceptable 20% sound spots. Through cracks that come out to the end and healthy and unhealthy knots are typical for such boards, but the amount should not be more than half of the area of the board. As a result, all the properties of coniferous boards are significantly reduced. Therefore, the material is not used everywhere.

All floorboard sizes can be found in this article.

Usually used, if you need to build a temporary building, a change house, usually used for the manufacture of pallets.

Fourth grade

The number of black spots increases to 6 pieces per meter. Rot is allowed in the amount of 10% of the total area. Shedding can be dull and sharp, warping and wingedness are also allowed.

According to GOST, the external surface and linear parameters must have the following characteristics:

- the roughness of the ends should be no more than 250 microns, also applies to the rough side;

- the roughness of the front side, as well as the longitudinal edges, no more than 40 microns;

- deviation in thickness of 1 running meter is not more than 0.3 mm;

- in parallelism, the deviation of the edges from the side is not more than 0.3 mm;

- relative humidity or when realized from 12 to 15%.

How many edged boards 50x150x6000 in one cube can be found in this article.

In work

Working with linden clapboard when lining a bath is no different from working with any other clapboard.

Direction of strip placement

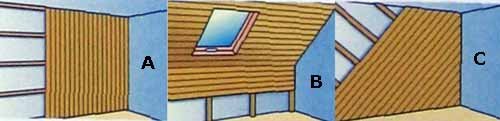

At your disposal are all the same 3 directions of placement:

“A” - strictly vertically;

The choice of the direction of laying largely determines the entire further strategy of work.

- “B” - horizontally;

- "C" - diagonally, usually at 45 degrees, although it can be any angle.

Finishing

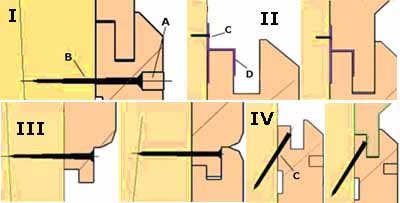

Finishing instructions are shown in steps in the photo:

A - after thorough leveling and drying of the rough working surface, fastening with screws or dowels of staples for fixing the battens; we advise you to treat the wall surface with an antiseptic already at this stage;

B - lathing fastening; insulation is usually inserted between the strips of the crate; if the bath was not famous for its high temperature and humidity, then any insulation from fiberglass to foam would fit, but the conditions of the bath require a more careful choice - in this regard, we advise you to pay attention to the foam glass, as it is stable and unchanging under any external influences;

C - waterproofing - an extremely important operation, especially in a bath; already through the waterproofing and the lining is attached to the crate.

The stages of laying the lining no longer depend on the type of wood used (see the description in the text)

Separate note on fastening

Which method of fixing the lining to choose depends on the preferences of the master and, to some extent, on the type of wood and its quality.

Linden in this sense is a very fertile material:

- I - it is possible to mount on one side only using pins (A) and nails (B); the spike of the adjacent strip (in the figure - above) is simply inserted into the groove;

- II - you don't have to make "holes" in the lining - the nail (C) goes through the cleaimer (D), which also serves as a seal for the strip from above (assembly - on the right);

But the method of attaching the lining to the crate should be coordinated with the breed - and here the linden again will not create any problems (see the description in the text)

- III - the nail goes through the spike, which requires the use of high strength wood - oak, just right; linden is not suitable for this method of fastening, there is a possibility of cracking of the thorn;

- IV - a nail through a thorn at an angle; but here the linden is just in place - inserting the nail at an angle is in itself difficult, and if the tree is also too tough! Therefore, it is better to use this method of fastening on softer rocks.

Selection Tips

Before choosing a product, first of all, you should decide on the lining material. Wooden lining has long established itself on the market as an affordable and reliable material for interior decoration. Of the positive qualities of wood, it should be noted good sound and heat insulation, as well as the convenience of working with the product itself. Wooden lining has a wide range of applications: it is used for sheathing both baths and living rooms, both inside and outside.

Lining made of wood can be made from different types of wood, respectively, all of them are divided by properties

When choosing a wooden lining, attention should be paid only to the euro lining. The main difference is quality

A thicker lock, high requirements for wood and its moisture content, as well as surface treatment make the Euro lining incomparable in quality with the usual version. However, if you need to save a budget, then the classic lining is also a good option. But you should closely monitor the quality when choosing a material, and also be prepared for difficulties in the form of a poorly connecting lock, a rough surface, falling out knots and possible cracks if the installation is carried out in a damp room.

Fasten the wooden lining with clamps. A kleimer is a bracket that is attached to the crate with nails or self-tapping screws and presses the lining lock to the base, but at the same time itself is not rigidly fixed to the board. This allows the lining to change its dimensions without problems due to thermal expansion and humidity and move vertically, which guarantees the reliability of the fastening and the absence of cracks or extraneous sounds in the future.

Separately, it is worth noting such a scope of lining, as finishing baths and saunas.Coniferous lining is rarely used in baths, as it can release resin, but this helps it to resist aggressive conditions, such as changes in temperature and humidity, as well as fungi and microorganisms. In saunas and baths, alder or linden lining is most often used - such wood, after processing, does not emit tar at all. Hardwood lining has a shorter service life due to the porous structure of the material, but thanks to the same porosity, this wood can withstand high temperatures.

Plastic panels appeared on the market not so long ago, however, they have gained a good reputation. They are not suitable for external decoration, but are great for cladding loggias and bathrooms or showers. Since plastic is insensitive to water, the panels can withstand any humidity and are also insensitive to sunlight. Unlike wood, plastic lining can have any pattern or pattern that repeats wood or stone. You just have to beware of low-quality panels, which, at the slightest drop in temperature, become extremely fragile due to the fact that the manufacturer saves on the quality of plastic.

MDF lining is laminated, veneered and painted. Laminated options are covered with PVC film, have a lower price and are more wear-resistant than veneered ones, which are covered with premium wood veneers. Painted panels, as the name implies, have a uniform color. Overall, this is a good alternative to the previous options. MDF lining has all the advantages of a wooden version and is produced in a wide range of colors. This alternative is suitable for the entire apartment - it can be used both in the kitchen and in the corridor, using it in the wall or ceiling cladding.

It is imperative to monitor the quality of the material when choosing it: the surface of the product should be even and smooth, uniform in color, without darkening and cracks. Do not trust the exhibition samples, as the sample may be from a different batch, or the lining could be stored in unheated and damp rooms. Unfortunately, it is impossible to know exactly the quality of storage of the material, therefore, as an option, you can buy one or two packs of material and see what will happen to it at the installation site.

No. 2. What is the difference between ordinary lining and euro lining?

On the construction market, you can find both ordinary wooden lining and material with the prefix "euro". The latter is significantly superior to conventional wall paneling in a number of performance indicators. So, the main differences are as follows:

- the size. The lining of the Soviet model is much thicker, and its thickness can reach 25 mm, the thickness of the Euro lining is 13, 16 or 19 mm. The maximum width of the euro lining is 120 mm, the usual one - up to 150 mm;

- lock. The protrusion of the lock in the Euro lining is about 8-10 mm, which allows the elements to hold securely, even with strong changes in temperature and humidity. In an ordinary lining, the lock is often very tiny, so the lamellas diverge during operation;

- the presence of ventilation holes on the back of the Euro lining, which prevent the formation of cracks in the event of temperature changes. There are no such grooves on a regular lining;

- humidity. The lining is forcibly dried until a moisture content of 10-15% is reached, thereby ensuring the absence of any deformations during transportation, installation and operation of the finished coating. The humidity of an ordinary lining reaches 20-25%, which negatively affects both the process of working with it and its behavior during operation;

- appearance. Since the Euro lining is made in accordance with strict European standards and on European equipment, the front side is always smooth. If there are knots on it, they are carefully processed. Manufacturers usually have several types of profiles. The elements of the lock fit exactly together.An ordinary lining rarely boasts such an ideal appearance and clarity of the execution of the lock connection, often its surface is rough and fleecy;

- Euro lining is sorted into classes. Depending on the presence of defects on the wood itself and defects acquired during processing, as a rule, four classes are distinguished.

It is clear that when the euro-class lining appeared on the market, many builders began to use it. Nevertheless, ordinary lining can also be used and is sometimes used for external cladding, and in cases where the quality of the finished surface and its appearance are not so important, but the task of saving comes to the fore.

Peculiarities

Wooden lining is a versatile facing material, its installation on any type of surface is not associated with special difficulties. The features of the operational properties allow the use of wooden lining in almost any conditions.

Advantages and disadvantages

Wooden lining is a practical and reliable material with extensive advantages, and its disadvantages can be compensated for by additional processing of the coating.

Several characteristics can be attributed to the positive qualities of the lining.

- Completely natural product. Non-toxic, does not cause allergic reactions, does not emit toxic substances when burned.

- Nice smell. The wood, depending on the species, exudes a certain specific smell, thereby creating an excellent atmosphere that has a positive effect on the health and mood of the residents.

- Great appearance. From an aesthetic point of view, the texture of the wood grain is attractive. A wide selection of different patterns, colors and shades is provided by a variety of wood species, allows you to create a unique interior design and fully satisfy the most sophisticated taste.

- Acceptable price.

- Camouflages communication lines. Gas and heating pipes, wiring, distribution units and other objects will perfectly hide under the clapboard.

- High vapor permeability. Provides ventilation of the walls, as a result of the "breathing" of the premises and the absence of dampness.

- Easy installation. The surface finished with clapboard does not require scrupulous processing, the panels can be easily cut to size. The products are fastened by the lamellar method - for each other and can be assembled by a person without perfected skills, subject to familiarization with the technology.

- Durability. With the correct selection of impregnations and timely maintenance, wooden lining can be used for up to 50 years.

- Additional finishing. The surface of the lining can be coated with various types of finishing materials: paint, varnish, artistic decoration, etc.

- Weak moisture resistance. A double quality, in a positive sense, it is considered as a natural regulator of humidity, when, when it rises, the wood absorbs excess, and when it decreases, the moisture evaporates back into the air.

- Excellent heat and sound insulation.

The weak qualities of wooden lining include:

- weak moisture resistance;

- vulnerability to sudden changes in temperature;

- high flammability;

- the possibility of deformation of the structure.

The main characteristics of the material

To better understand the features of the lining, it is worth familiarizing yourself with the main characteristics of the material from which it is made - wood.

Several indicators are the main quality parameters.

- Strength. A property that characterizes the ability of a tree to withstand mechanical stress. The strength depends on the thickness of the panel and the type of wood. When choosing lamellas, the specifics of their operation should be taken into account and the appropriate option should be selected.

- Hardness. As the hardness increases, processing becomes more difficult, such as trimming panels, however, this property directly affects the surface's ability to withstand objects attached to it, such as a TV.

- Moisture resistance.Determines the conditions in which this or that wood species can be exploited, can be enhanced with the help of impregnation.

Grade. Determines the quality of the raw materials from which the lining is made. The main standards are European DIN and GOST, in addition, the manufacturer may have its own grade criteria, so it is worth knowing the general differences.

- "Top grade", "Extra", "Premium". The ideal product texture without defects such as knots or cracks, color irregularities or roughness is possible only on the back of the bar.

- "Class A". The presence of knots with a diameter of up to 1 cm, no more than 1 piece per linear meter, small, possibly putty cracks, is acceptable. Minor flaws on the back.

- "Class B". Knots with a diameter of no more than a third of the panel width, quantitatively - 4 pieces per running meter. Hollow resin pockets, minor through cracks may be present.

- "Class C". All lining that does not meet the above criteria. A significant number and strength of defects, violation of the monotony of color with spots and other flaws.

Wear resistance

An important quality when decorating rooms with constant contact with the surface, for example, a bathhouse or a gym.

Fire resistance. Determines the speed of wood combustion, can be modified by impregnations

The characteristic is important when used in places with an open source of fire, for example, in baths or near fireplaces.

Aesthetic features.

Therapeutic effect.

Which lining is better to choose for cladding a house and a bath

In order not to be mistaken with the choice of lining, you need to know what parameters you need to pay attention to. The main ones are listed below: wood species and its quality

The above describes what properties each of the most common types of wood has;

wood species and its quality. The above describes what properties each of the most common types of wood has;

length. We have already noted - the longer the board, the more expensive the lining will be;

drying quality. The drier the wood, the better the finished lining will be. So, you should know that classic lining is considered to be of high quality with a natural moisture indicator (up to 20%), euro lining - with a relative (up to 12%);

Measurement of wood moisture with a device - a moisture meter Moisture is measured with a special device - a moisture meter, which allows you to determine the moisture content of the board at the time of sale, i.e. taking into account the influence of the storage conditions of the lining.

Every self-respecting seller should have such a device;

the specifics of woodworking. Panels made on modern equipment will differ in less deviations from the standard indicators for roughness and geometry. It is worth considering that on the market you can find lining strips made of solid wood and spliced. Each of these types has its own advantages.

One-piece has a more beautiful appearance, but it has a higher price. Spliced lining - has a less aesthetic appearance, because seams are visible

But, at the same time, its obvious advantage is that the lamella will not lead during storage and installation.

It is also important to pay attention to the direction of the cut. Often found - radial or tangential;

Type of wood cut Direction of cut wood

sorting. It is at this stage that the type of wood is determined. Sorting is done manually;

Note: in a consignment of goods, it is allowed to cross the lining by grades up to 10%. Those. in a pack of 1 grade lining, 10% of 2 grade panels are allowed

It is important that many manufacturers allow the return and exchange of lining of the 1st and 2nd grade, but not the third.

storage. The lining should be stored in a dry, closed, well-ventilated area. However, many domestic sellers leave boards outdoors under the influence of moisture and ultraviolet radiation. Blue on the lamellas will indicate that the wood is infected with a fungus;

manufacturer. Clapboards from the northern regions of Russia are considered to be of higher quality.This is due to the climatic conditions in which the feedstock for production grows. A harsher climate slows down the growth of wood, while making it stronger.

In addition to the characteristics of the lining, the choice can be influenced by:

place for finishing. Rather, the purpose of the premises. For example, for a bath, a living room or a corridor, you can choose lining of different varieties and breeds. External finishing requires additional processing. Internal requires more environmental friendliness of the material;

the size of the room. If it is necessary to sheathe a significant area, a choice can be made in favor of a less expensive and, accordingly, less quality material;

for cladding a small room, you should purchase a narrow board. This technique will visually expand the room;

surface quality. For cladding a flat surface, you can use a thinner lining than for an uneven one;

the volume of the budget for the purchase of lining. Also an important factor, which is often the key argument when choosing.

What else to pay attention to

Check the quality of the joint at the time of purchase. To do this, connect several pairs of lamellas to each other. Low-quality lining will have cracks.

It is also important to immediately agree on the conditions for the exchange or return of the lining that does not correspond to the purchased grade. Often there is a situation when the seller refuses to unpack a pack of Euro planks offering to assess visually the quality of the goods

Needless to say, such a seller should raise doubts, because the first and last slats in a pack are usually of perfect quality

Often there is a situation when the seller refuses to unpack a pack of Euro-planks offering to evaluate visually the quality of the goods. Needless to say, such a seller should raise doubts, because the first and last slats in a pack are usually of perfect quality.

Selective grade

The selected grade of sawn timber is used in shipbuilding and autobuilding. Intergrown healthy knots are allowed within the following limits: bed and rib knots - 20% of the diameter or no more than 2 per meter of length. Rotten and rotten knots are not allowed.

Reservoir and edge cracks, including those coming out to the butt end: shallow - 16%, deep - 10%. End cracks, excluding shrinkage cracks, are not allowed.

The slope of the fibers is 5%. Root on the lumber area is not allowed.

One-sided germ, cancer, poisonous mushroom stains, mushroom sap stains, mold, rot, foreign inclusions, sharp wane are not allowed.

Dimensions of wooden lining

Wooden lining is made from various types of trees. Most often, such trees as pine, larch, cedar, linden, alder, oak, and aspen are used for the manufacture of lining. Depending on the material, the cost of the lining also varies.

Please note that wooden lining - aspen, oak, pine is mainly manufactured according to the same standards - DIN 68126 for euro lining and GOST 8242-88

Aspen

Aspen lining is used for interior decoration of premises, especially it has found its application for decoration of baths and saunas. On sale you will find products of this material from both domestic and foreign manufacturers. In imported samples of products, there are increased requirements for the quality of wood, for moisture, and for dimensions. From this, its price is much more expensive, and it is manufactured according to the European standard DIN 68126 - where quality is clearly laid.

Domestic manufacturers do not adhere to this standard, in most cases they work in accordance with GOST, where the product quality is slightly lower. But in both cases, manufacturers adhere to the following sizes:

- Lining thickness: from 12.5 mm to 15.0 mm. (Euro lining - 12.5 mm);

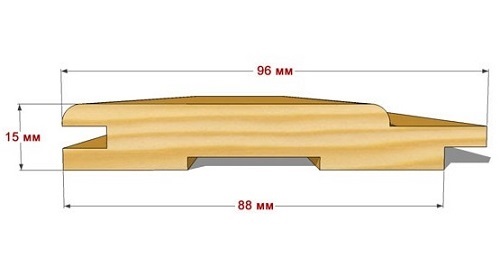

- Working width: 88 mm .;

- Overall width: 96 mm .;

- Length: from 1000 mm to 3000 mm .;

Oak

The lining made of oak is a very durable material, although it is heavy in comparison with other types of wood, but thanks to this type of wood, the material is very durable, strong and wear-resistant.It is used for decorating living quarters, it has a very beautiful, natural appearance.

- Lining thickness: from 12.5 mm to 15.0 mm. (Very often - 14 mm, or 12.5);

- Width: from 50 mm to 108. (depending on the manufacturer);

- Length: 1000 mm to 3000 mm. (most often 3000 mm, 2700 mm, 2500 mm, 1800 mm);

Pine

Pine lining is the most versatile material, and is used more often than lining from other materials. This is largely due to the price, because it is actually the cheapest wood that can be easily processed.

- Lining thickness: from 12.5 mm to 15.0 mm. (Very often - 13 mm, or 12.5);

- Width: from 50 mm to 108. (depending on the manufacturer);

- Length: from 500 mm to 3000 mm. (most often 3000 mm, 2000 mm);

From guitars and spoons to furniture and bath finishes

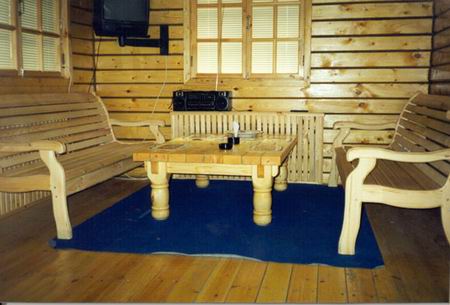

Lining for a bath - linden here is in place for many characteristics, including the appearance that remains unchanged over time

But the competition is very high - and oak, and pine, and larch, and cedar. Nevertheless, linden takes a very worthy place in this ranks at the head of the list, and all thanks to its remarkable merits.

Why is there nowhere without linden

The properties of this wood species are asked to be used as a clapboard decoration for the interior of baths.

Among these properties:

- Ease of processing - and hence the wide selection of linden lining profiles, making the thinnest chamfers, grooves and spikes on the linden is not difficult;

- Over time, the linden surface does not change its shape, neither cracks, nor signs of drying, you will not wait for a long time;

- At the same time, the drying of linden occurs up to 8-10% rather quickly, and if you are looking for a perfectly dried tree, then strive for it to be a linden;

- The high quality of the very base of the tree - a very small number of knots - by itself allows you to create lining from linden of the class "Extra" and "A", and at minimal prices, because the yield of unusable is practically reduced to zero;

- Linden practically does not emit resin, unlike pine, for example, which allows it to be safely used in heated rooms - the surface temperature remains unchanged regardless of the ambient temperature;

- A very pleasant color and smell, which is especially appreciated for large areas of decoration, and here the baths are in undoubted leadership.

And furniture made from this type of wood looks great too.

The quality of linden lining

The good thing about linden lining is that you will hardly be able to "get caught" even with an average quality "B".

In total, there are 4 classes:

- Extra (premium or zero) - the highest class; 50% of linden lining is from here, because there is not a single knot in it and a perfect even color;

- “A” - another 30% of linden in this class, which allows no more than one knot per one and a half meters in the absence of problems with color;

- "B" - the remaining 20% here, when you can already find 3-4 knots on one and a half meters, there are noticeable spots;

- "C" - this class with chips and cracks leads only out of the desire to present a complete list of classes, linden has nothing to do with "C".

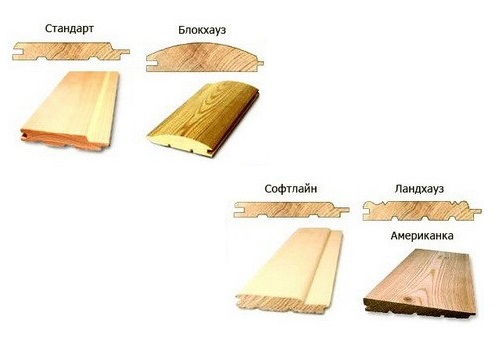

Linden lining profiles

Ease of processing allows you to create whatever your heart desires with this type of wood. We give 5 of the most common profiles, but linden significantly liberates the design idea, and you can often come across completely unexpected proposals for linden lining profiles.

So, the 5 most popular:

- Euro (“A”) - a generally accepted European standard with a special groove for water drainage and increased connection depth;

- Soft-light (“B”);

- Calm (“C”);

All 5 most popular profiles are subject to linden lining (see description in the text)

- Thorn - groove and chamfer along the entire length (“D”);

- Thorn - groove lengthwise (“E”) - there is no chamfer here.

Price

Talking about the cost of wooden structures is not very rewarding - it all depends on such a number of mutually exclusive factors that in Penza a meter can cost 10, and in Kaliningrad - already 100.

And yet, for orientation, we give the prices for an extra-class lime lining with a Euro profile, which you most likely will have to face:

- with a strip size of 2 to 3 meters - a square meter of area costs 640 rubles;

- from 1.8 to 1.9 m - 490 rubles;

- from 1.0 to 1.7 - 410.

For class "A":

- 2,0-3,0 – 490;

- 1,8-1,9 – 350;

- 1,0-1,7 – 245.

For a rare linden tree "B":

- 1,8-3,0 – 245;

- 1,0-1,7 – 175.

Dimensions of domestic and euro lining

The dimensions of the lining of a domestic sample are not regulated by GOST, due to which manufacturers sometimes themselves select the parameters of the material being produced. Today on the market you can find wall paneling with the following dimensions: the thickness of the bar is from 12 to 40 mm, the width is from 76 to 200 mm, the size of the spikes is within 4 - 5 mm. Length in meters - from 0.2 to 6. Errors are not included in the usual lining, however, such shortcomings sometimes occur.

Euro lining has more accurate parameters, and when purchasing such a facing board, you can find only a few of its types: lining thickness - 13, 16, 19 mm, width 80, 100, 110, 120 mm, length: 0.5 - 6 m. vary from 8 to 9 mm. Strict requirements are also imposed on possible errors in the dimensions of the lining of a foreign sample. They can have the following parameters: thickness - 0.7 mm, width 1 mm, length - 5 m, spike - about 0.5 mm.

The largest range is found in the length of the board. Its direct purpose depends on this parameter.

Long lining is widely used in almost all cladding works, when the shortened version is only suitable for hemming roof eaves or for forming a small wooden box masking communications. A short board is several times cheaper. Such material, in fact, is a waste of the main production. This is usually due to the fact that in longer bars during the facing stage, so-called dead branches can be encountered, which are necessarily cut out. "Dead" are those who do not hold well and can fall off the board. "Living" do not break the structure. According to domestic and European quality standards, the latter are allowed to be left in products of grade "1" or "A". For this reason, the lining of small length begins its marking from the second grade. It is often completely unsuitable for serious interior work. In order to get small, high-quality boards, you need a long wooden board for sawing.

Price

Regardless of the grade of the timber, the size of the lining will directly affect its cost. However, the final price of wood cladding also depends on the shape of the product, as well as the type of wood. If we talk about standard bars 6 m long with grade "1" or "A", then you can roughly decide on the cost of 1m2:

- Regular. Such material also has the popular name "kolkhoz woman". The width of the lining is a quarter of a standard board. Products of the first grade will cost from 300 to 500 rubles. Linden and cedar are the most expensive. 1 m2 of "kolkhoz woman" made of such wood will cost the buyer up to 1000 rubles.

- Block house. Width - about 15 cm. The budget option is pine and alder - from 250 to 500 rubles. for 1 m2. Standard lime and larch bars - from 1000 to 1500 rubles. Cedar - up to 2500 rubles.

- American. Usually it is not produced in bulk and is made only to order with a bar width from 14 to 16 cm.The price is about 1000 rubles per 1 m2

How to properly prepare a room for clapboard decoration

Before facing the premises with pine clapboard, the following work is carried out:

- Insulation laying;

- Vapor barrier device;

- Installation of the lathing.

- We install thermal insulation

Thermal insulation is used to protect the premises from the cold. Wooden bars are sewn onto the walls and ceiling. The extreme bars on the ceiling are installed at a distance of 10 centimeters from the wall. The extreme bars on the wall are installed at a distance of 10 centimeters from the corner of the room.

The bars on the ceiling are fixed along the long sides of the room. Wooden racks on the walls are fixed perpendicular to the floor. The installed bars are aligned along the cord line. After checking, they are sewn to the walls with self-tapping screws.

After installing the outermost bars, the intermediate bars are attached. They are attached with a pitch of 400 to 500 mm.The position of the bars is carefully checked using measuring instruments. Installed slats are sewn with screws or nails.

A layer of thermal insulation is placed between the installed bars. Mineral wool slabs or roll material are used as insulation. Insulation in rolls is cut into sheets of the required length.

Experts recommend using basalt insulation. The material has high thermal insulation, fire resistance, durability.

Canvases on the ceiling are sewn with self-tapping screws with wide hats. The thermal insulation on the walls is fixed with twine. The rope is pressed tightly against the slabs. The ends of the rope are fixed on the racks.