Views

Before starting finishing work, it is important to decide what types of products to sheathe certain rooms of the bath. The generalized characteristics for all types of lining are as follows:

- Breathable structure. Due to this property, fungus and mold rarely form on the lining, proper ventilation is ensured.

- Ecological cleanliness. This material is completely safe for humans.

- Fastening "tongue-and-groove". At the dawn of the formation of the production of lining, fastenings were "in the tongue". To date, these options are not used, as they quickly fail.

For cladding the bath inside, you can use lining made of various types of wood. Uniform conditions for the material - it must be resistant to moisture, frequent and sudden temperature changes. When choosing a material, it is necessary to rely on the main criteria of the tree species.

The wood species for the lining can be as follows:

- conifers;

- deciduous.

When choosing a material, you need to understand for which rooms of the bath it can be used. The most popular types of lining for a bath are made from:

- cedar;

- alder;

- oak;

- ash;

- linden;

- pine trees.

Linden lining is considered the most suitable for cladding the walls of a steam room. The structure of the material is porous, of low density, the wood does not heat up from high temperatures. Linden has medicinal properties, releasing essential particles when heated. They are useful in preventing many diseases.

Linden wood is characterized by soft shades that do not change their color throughout the entire service life. The only drawback of linden is its porosity - the material absorbs moisture. The room must be well ventilated.

Aspen lining, in comparison with linden, has a denser structure. Despite its hardness, the material is easy to process. The surface of the material does not allow steam to penetrate, does not absorb moisture. Under the influence of the temperature difference, it only becomes stronger.

Wells were used to build wells from aspen. The water in them remained clean for many years. Many craftsmen advise choosing exactly aspen lining for a bath.

Alder lining has good thermal conductivity and excellent water resistance. The material does not undergo deformation at almost any temperature. The color of the alder lining is a pleasant golden orange.

The characteristics of the material make it possible to cover both dry and wet bath rooms. No additional processing is required for alder lining. Alder acts on the human body as a general tonic.

Cedar lining is considered an ideal option for covering the bath space. The products are quite expensive, therefore they are rarely used for covering baths. Cedar wood is durable, moisture resistant. Another positive quality is the respectability of her appearance.

From the medicinal qualities of cedar, bactericidal properties are known, as well as the ability to make the air cleaner. The material does not change its original parameters for a long time. The sauna rooms retain the pleasant aroma of cedar needles.

Another option for the basis for the lining is larch. Its installation is difficult, since the board is fragile and splits during processing. Larch is resistant to moisture. After a while, the finish acquires the required strength, but still requires additional processing. Otherwise, the material will lose its natural shade.

Larch is needles, but it does not emit resin, therefore it is suitable for finishing steam rooms. It can be used for walls, ceilings and floors. The material is universal, it can be used both inside and outside the bath.The medicinal qualities of the material are the same as those of other conifers.

Pine lining is often used to decorate baths inside. The price of the material is affordable, but it cannot be used in all premises. For example, in a steam room, resin will be released from it, which will cause burns on the skin if it gets on it.

However, in the rooms of a bath with a normal temperature, pine lining will create a special microclimate. In rooms with normal humidity, upholstered with clapboard, the aromas of the forest will be present. The appearance of the material will last for a long time. Deformation processes can occur due to some hygroscopicity of the material.

Oak lining is famous for its strength and high density of wood. Oak is a beautiful and rich material. The oak finish enriches the premises with essential aromas that suppress pathogenic microorganisms. Oak has a high resistance to moisture and temperature extremes. Oak is suitable for any room in the bath. The lining from it is very different in color.

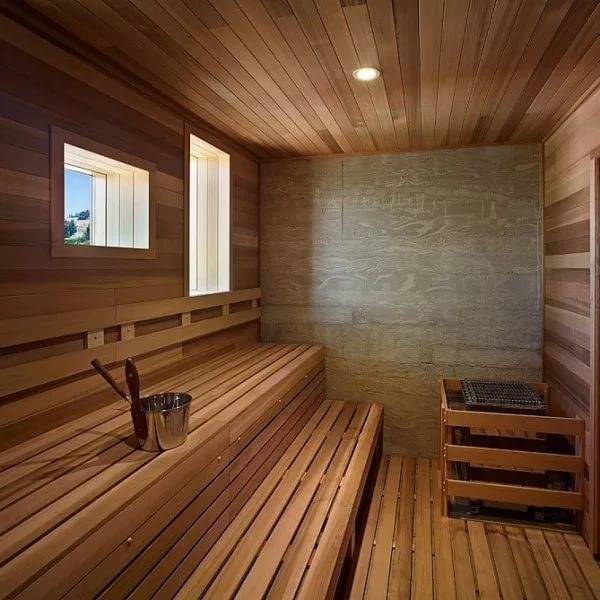

Wood

Despite the large selection of finishing materials, wood has been and remains the most demanded for covering the gazebo. It is versatile and suitable not only for finishing wooden buildings, but also for cladding buildings made of metal, concrete, stone, brick. The main advantages of wood cladding include:

- Ease of installation - no special tools or special skills are required for cladding.

- The beautiful texture, the structure, finished with wood, fits naturally into the landscape design.

- Ease of processing, the ability to produce openwork and carved elements for cladding.

- Thanks to the different coloring methods: staining, burning, throwing, varnishing or oiling, the wood can be given any color, from the natural light to the darkest, if you like, black - all this allows you to use wood to create different styles.

- Good sound and heat insulation properties.

Of course, wood trimming of gazebos also has its drawbacks: it does not tolerate high humidity, biological influences and the influence of microorganisms, but with modern methods of processing with protective impregnations, all the disadvantages of wood sheathing can be considered insignificant.

Lining

Most often, for interior and exterior decoration of the gazebo, lining is used, which is made from different types of wood: alder, linden, beech, cedar, oak, aspen. But usually pine clapboard is used for cladding, since this is the most budgetary option, a deaf parapet and the ceiling of a building are sheathed with it, a convenient thorn-groove connection, allows you to neatly hide the fasteners, and the ends of the rail fit snugly together without forming gaps.

Simple ways of original clapboard cladding

The lining of the gazebo with clapboard can be done in different ways: vertically, horizontally, diagonally, herringbone, in a checkerboard pattern, and it should be noted that the interesting laying of the lath is itself a decoration.

A good idea than sheathe the gazebo outside, photo of clapboard decoration

Timber imitation, blockhouse

The blockhouse is used to decorate medium and large semi-closed and closed-type buildings. Sheathing of the gazebo with imitation of timber, as a rule, is done on the street side of the parapet, less often the ceiling is sheathed with it.

The width of the blockhouse is different, 90-180 mm, thickness, 20-40 mm, which makes it possible to create a finish from an almost graceful paneling to a massive one, like chopped from a log. Decorating a gazebo with your own hands with a blockhouse is no more difficult than clapboarding, a convenient lock and special fasteners-clips make it easier to install the material, and allow you to cope without outside help.

The blockhouse is suitable for covering medium and large gazebos

Rail

The lath for cladding looks like a lining, but it can be different in width, and, as a rule, without a chamfer at the edges. It is ideal if the question arose of how to hem the ceiling in the gazebo, and in addition, a decorative lattice is made from it, with which the parapet and openings of the building are trimmed.

Decorating with a rail is especially important if you do not want to make the building heavier, make it more airy, openwork, or create a French (the rail is stuffed diagonally) or Japanese (fits at a right angle) style.

Decorative lattice - a simple and beautiful solution, how to sheathe a gazebo with slats

Wall insulation or how to insulate the bath from the inside under the lining

I will say right away that in order to answer the question of how to insulate the bath from the inside under the lining, you need to understand that we are talking about a steam room.

But when it comes to additional warming of the steam room in the bath, then with proper organization of ventilation in the steam room and in the bath in general, it is possible to carry out measures to insulate the interior walls and ceilings from the inside.

It is better to insulate the steam room starting from the top and going down below, first the ceiling, then the walls. It is necessary to clean the tree from dirt and fungal formations, if any. You can soak a wooden surface with an antiseptic, while choosing a water-based antiseptic for interior work, it is less toxic.

The procedure for warming the steam room.

We insulate the ceiling

Since the main heat loss occurs through the upper enclosing structures (warm air tends to the upward), then, if possible, insulate the ceiling of the steam room on both sides from the attic and from the side of the steam room.

We insulate the walls

If the walls of the steam room are made of stone materials, then you first need to waterproof them for this, waterproofing on a cement or acrylic basis is suitable, I do not advise using waterproofing on a bitumen basis in a steam room. If the walls are made of wood, then proceed with how to insulate the bath from the inside under the lining and in what sequence.

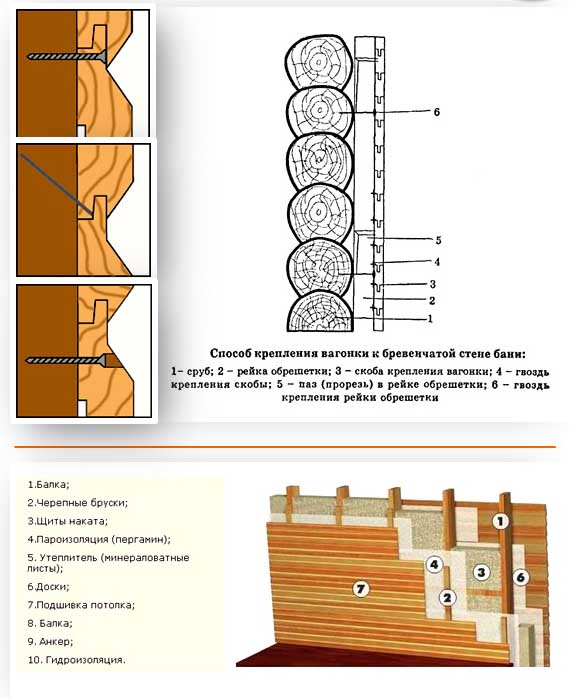

On the walls we fasten vertically bars 50 to 50 at a distance of the width of the stone wool mats, attach the vapor barrier membrane with a construction stapler, wrapping it around all the bars

Between the lathing, place the stone wool tightly in one layer of 5 cm.

If you decide to insulate the steam room in two layers of 5 cm each, then we make a counter crate from a bar 50 to 50 and lay the insulation in a second layer.

Then, from aluminum foil, we make a finishing layer of vapor barrier, fix the foil end-to-end, and close the seams with aluminum tape.

Now you can screw the finishing rail onto the bar to organize the ventilation gap and start covering the steam room with clapboard.

We insulate the floor

Floor insulation will depend on the type of foundation and floors of your bath.

For wooden floors and subfloors, we use stone wool with the organization of waterproofing in the steam room and sink.

Choosing a lining for cladding

Lining

Lining made of wood can be ordinary or euro. The first has a roughness and pile on its surface, the second is perfectly smooth. On the back side of the Euro lining there are ventilation ducts that prevent the accumulation of moisture (condensation) and relieve stress in the material. According to GOST 8242-88, the moisture content of wooden products is allowed within 12 ± 3%, however, ordinary lining can be made of wood with a moisture content of up to 25%, which can lead to deformation during the operation of the bath. Based on this, we will choose a suitable wooden Euro lining for bathing.

Marking and technical requirements

The lining is made from coniferous and deciduous wood. The best options for a steam room are aspen, linden, cedar, spruce, alder, oak, pine.

| Wood | Colour | Properties | Photo |

|---|---|---|---|

| Aspen | White, takes on a silvery tint. The yellow growth rings are barely visible. | Lightweight, withstands high humidity and temperature well. Over time, it hardens so much that it is difficult to drive even a nail into the aspen panel. Does not emit tar, does not heat up. |

Aspen lining, Extra |

| Linden | Light, brown, less often reddish shades. There is a matte sheen. | The fibers are homogeneous, the surface heats up a little, and in the steam room it releases aroma components that are beneficial to health.Upon contact with linden wood in a humid environment, iron oxidizes and rusts, streaks appear. |

Linden Euro lining |

| Linden Cedar Canadian or Siberian | Brown with a pink tint. | One of the most expensive and healthy species of wood. Does not rot, withstands mechanical stress well, does not crack. |

Canadian red cedar lining |

| Pine | Beige, brown with red tints. It gets dark with time. Pronounced pattern of growth rings and resin canals. | Good mechanical properties, toughness, moderate warpage. Does not cause difficulty in processing. It releases resin when heated, so it does not go around for covering those surfaces in the steam room with which tactile contact is possible. It is not suitable for covering the ceiling of the steam room, or repeated heating of the steam room is required, followed by the removal of the resin that has come out (repeat the procedure until all the resin comes out of the lining). For a bath, it is better to choose an Extra-class pine lining. |

Pine |

The following table lists the classes and their descriptions. It is worth knowing that wood with a large number of knots heats up faster and can burn. The markings are the same for all types of wooden lining.

| Class or grade | Description |

|---|---|

| Extra | No cracks, knots or other defects. The surface is perfectly smooth and even. |

| A or 1 | The surface is smooth or slightly rough. There are 1 healthy knot per 1 running meter (knot diameter no more than 1.5 cm). There may be cracks: hairline - no more than ½ of the panel, blind - less than 9.5 cm long (the exit of cracks is directed to the end of the panel), which have appeared when drying - no more than the width of the panel. There may be tar and resin pockets of 2 pcs. by 1 lm |

| B or 2 | There are many knots, of which there can be no more than 2 falling out. by 1 lm There can be through cracks up to 1 mm wide and up to 15-30 cm long, hairline cracks are allowed along the entire length of the board. The presence of wormholes (3 pcs. Per 1 lm) and rot (no more than 1/10 of the panel) is allowed. Lining of grade B is suitable for staining. |

| C or 3 | The quality is poor. Many different defects. This lining is suitable for upholstering technical rooms or rough work. |

Marking

Lining marking

The norms of defects according to GOST are indicated in the table below.

Norms of defects according to GOST

Lining defects

It remains only to select the profile of the lining, because each has its own nuances of installation.

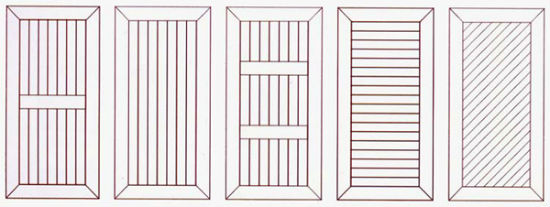

| Profile | Description | Scheme |

|---|---|---|

| Standard | It looks like a classic quarter-board lining. Has a tongue-and-groove connection, and the tongue is shorter than the groove to prevent deformation. |

Lining Standard |

| Calm or Kolkhoz Woman | It differs from the previous one with rounded edges and the presence of channels on the reverse side to prevent the accumulation of condensate. |

Calm |

| Euro | Manufactured in accordance with DIN 68126. It has an elongated spike. After the installation of the lining, the surface of the wall is ribbed. |

Euro |

| Soft-line | Soft-line or soft line is a symbiosis of Euro and Calm lining. Soft rounded corners, elongated spike, embossed wall texture after panels assembly. |

Soft-line |

| Block house | It is used for finishing external walls and rooms. Stylized as a rounded log. There is a thorn-groove connection, the front side is usually rounded, and the back side is even or with channels for ventilation. |

Block house |

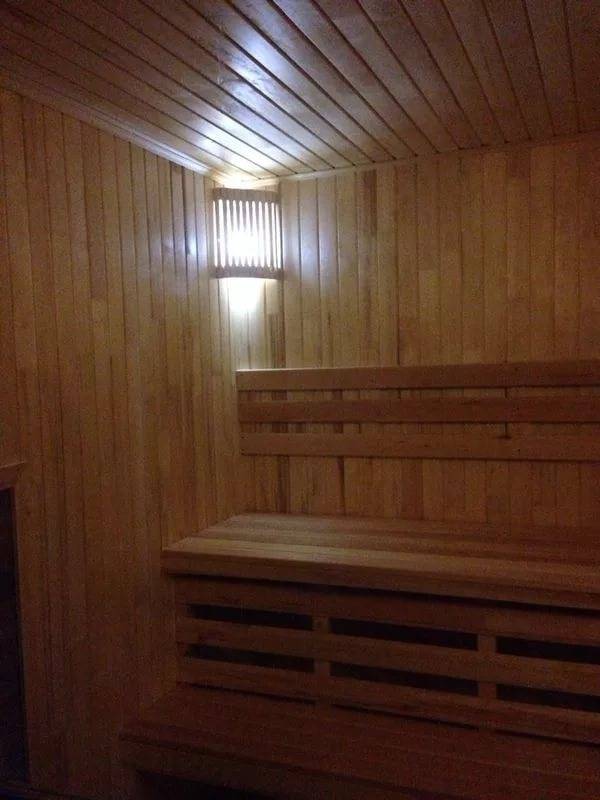

Which tree is right

After all the rough work has been completed, you can proceed to the interior decoration. How to sheathe the ceiling in the bath? For the steam room, only wood should be used. The rest area and washroom can be finished with other materials, but traditionally wooden slats are used. Each of the presented wood species has its own advantages and disadvantages. Before purchasing building materials, it is best to familiarize yourself with the parameters of each of them.

- Linden;

- Aspen;

- Larch;

- Oak;

- Cedar.

The wood species for finishing the ceiling in the bath will differ not only in color, but also in price.It is impossible to say clearly which tree will be the most optimal - it all depends on financial capabilities and personal preferences.

Linden

Linden is distinguished from others by a noble white shade that will not darken throughout the entire period of operation of the bath. Perfect not only for decorating the steam room, but also for the entire bath room. Of the advantages, one can note the absence of odors even at high temperatures and low thermal conductivity.

Lining the ceiling in the bath with linden clapboard should be carried out only after preliminary treatment of the surfaces with antiseptic compounds. Tools can be pre-treated with an antifungal solution, since linden promotes the formation of mold and mildew without treatment with special compounds. Linden is easy to process and install.

Information. Linden has a noble creamy shade that does not darken over many years of use.

Aspen

The color of the wood is noble white, the structure of the fiber is fine. The wood is easy to work with - it can even be bent without fear of breaking. Additionally, it is not required to process aspen with special compounds, since it is least susceptible to rotting. A distinctive feature of aspen is moderate drying, the tree will last for more than a dozen years, will not crack and will retain an excellent appearance throughout its entire service life. Aspen lining has excellent thermal and moisture resistance properties. How to sheathe the ceiling in the bathhouse inside? Choose aspen - it perfectly combines reliability, durability, beautiful appearance at a relatively low cost.

Larch

Larch is distinguished by its high strength and resistance to thermal and mechanical stress. The breed is not subject to rotting and insect attack due to the release of resin. Not afraid of high temperatures and humidity. Due to the constant exposure to moisture, it only becomes stronger, an excellent option for those who do not know how to close the ceiling in the bath.

The raw materials can be used not only for finishing the ceiling in the steam room and washing room, but also for the ceiling in the sauna rest room. The color of the larch wood is red-red, the structure of the tree is uniform, and does not need additional processing.

Information. Larch has a beneficial effect on the human body and has antiseptic properties.

Oak

Ceiling boards in oak baths are the most durable, have low thermal conductivity and are not at all afraid of moisture. Throughout the entire service life, it does not deform and does not change color. The wood has an original texture and various shades.

Among the disadvantages are the high cost and high weight. Oak baths are rare today, but they can boast of their durability. Oak wood is perfect for the ceiling in a washing bath, the material is not afraid of moisture at all.

Cedar

From cedar, you can not only build a rough ceiling in the bath, but also sheathe it from the inside. If you decide to use coniferous wood, cedar is the best option. The color of the wood has a variety of shades, ranging from light beige to dark coffee. Of the advantages, it is possible to note high resistance to moisture and high temperatures, durability in use.

To prevent the formation of mold and mildew, the wood must be treated with antiseptic compounds. Among the disadvantages are the high cost and the ability to release resin. But this can be solved by processing with a special impregnation. The release of resin can go away on its own after several years of using the bath.

Restoration of varnished panels

The quality of the coating will depend on the degree of opacity required for the walls. If you do not need to completely cover the wood structure, it is better to sand off the varnish and rub in the coating. An impregnation can be used to preserve the texture of the wood.

Attention

If you do not need to preserve the structure, then you do not need to clean anything.Acrylic paints with high adhesion fit well on all surfaces and quickly tint in any shade

You can use polyurethane tinted enamel, but walls with such a coating will be very shiny, so this method is not for everybody.

The better

Let us clarify that processing in our understanding is a preventive measure to prevent the appearance of further rot, mold, blue stain, infestation by wood-boring beetles and other similar misfortunes. Or medicinal, if infection has occurred. There are also compounds to reduce the flammability of wood.

Let us clarify that processing in our understanding is a preventive measure to prevent the appearance of further rot, mold, blue stain, infestation by wood-boring beetles and other similar misfortunes. Or medicinal, if infection has occurred. There are also compounds to reduce the flammability of wood.

In the first two cases, we are talking about antiseptics - substances that kill fungi (fungicides) and insects (insecticides). In the third case - about fire retardants, which slow down the fire or make wood non-combustible.

Do I need to process the lining in the bath with these compounds? Optional. They are good for the prevention of infections, they will keep the bath from complete combustion, but they have restrictions on their use in the steam room.

It is also possible to pay attention to impregnated wood

How to process in the steam room

Since we are talking about this, then there are a couple of tools that can be used in a steam room too. However, their effectiveness is very limited.

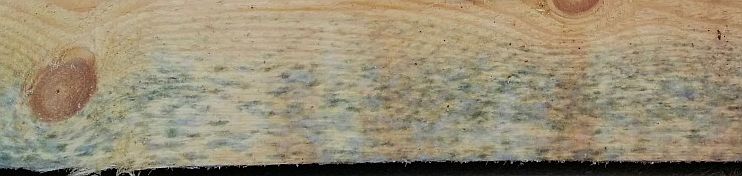

For example, if you treat the lining in the steam room of a bath with Whiteness or its analogs, you can quickly get rid of the blue stain - this is the name of the fungal infection of the tree, with which wood is often sold, since it does not affect the strength, only spoils the appearance of the lumber.

Fungal lesion - blue

BY THE WAY! Why Whiteness? Because there are a number of different wood preservatives, which contain nothing but sodium hypochlorite, just like in "Whiteness". Well, maybe the concentration is different and the price.

After using and achieving the result, "Whiteness" is washed off and ventilated (! More about ventilation in the bath in a separate material). You can use the bath when the smell is no longer felt.

As a close analogue of chlorine, you can use hydrogen peroxide, which is also a strong oxidizing agent that prevents fungi from living.

For mold, you can use boric acid or borax, but now boron compounds are considered poisonous, and from the number of cumulative poisons, that is, accumulating and not excreted from the body. The only good news is that the poison is weak, it takes a lot to get poisoned.

But it is not worth living with mold either, they die from it faster than from boric. If it starts up, then there is no time for it, whether it is a steam room or not a steam room, it is necessary to start a struggle. Until you are exhausted, you cannot use the bath.

However, this applies to all infections - the more serious they are, the more serious the means. It is better to treat the lining in the bath with a professional antiseptic that fights your problem, and then wash everything, than to change the entire lining. But it is better to change the entire lining than to risk your life because of black mold. With wood-boring beetles, the same strategy - while it makes sense to fight - we fight, if there are too many of them - we burn the affected tree.

Processing inside other bath rooms

In this case, there is only one difference from the steam room: in other rooms, prophylactic agents can be used. That is, not to wait for the problem, but to prevent its appearance, poisoning the life of the pests in advance.

Since there is no steam room heat in other rooms, all these poisons will not evaporate and be inhaled by humans.

Therefore, you can safely use antiseptics and fire retardants, whatever you like. In the washing room, you will want to use non-washable compounds, but look at the label: if it says there that this is for the exterior, and not the interior, then it’s better not. Better to update from time to time.

IMPORTANT! Antiseptics can be found on sale not only in the form of separate compositions, but also in the form of primers, which precede the application of varnish, glaze or paint.If you are going to paint with something, choose the right primer and you will not need to use an antiseptic separately.

What absolutely cannot be used to decorate the steam room?

It is impossible to decorate the bath from the inside with linoleum, wood boards, chipboard, fiberboard, mineral wool, because they absorb moisture, are fire hazardous and their manufacturers often sin using harmful and toxic substances, the effect of which can increase significantly with a significant increase in humidity and temperature, which, in in turn, can negatively affect the sensations, comfort and health of the bath visitors.

However, all of the above materials are applicable for finishing the dressing room, since the temperature and humidity there are no longer so high.

We insulate the walls and ceiling in the bath

To make the steam room airtight, thermal insulation in it is performed using mineral insulation and aluminum foil. Foil is used to protect insulation from moisture and high temperatures. The edges of the foil are fixed with special tape. The film is definitely not suitable for these purposes, as it can deform or even melt.

To make the steam room airtight, thermal insulation in it is performed using mineral insulation and aluminum foil

To make the steam room airtight, thermal insulation in it is performed using mineral insulation and aluminum foil

The ceiling is made of boards 20-30 mm thick. The boards are fastened to the beams with nails. For ventilation, it is advisable to round the edges of the boards and leave small gaps.

Preparing walls for decoration

The technique of finishing the bath with clapboard is simple and, if desired, anyone can master it. The first step is to bring the lining into the bath, so that the material undergoes mandatory adaptation to the microclimate of the room. Then they begin to level the walls. After alignment, a crate is made.

Installation of a wooden frame-lathing

Installation of a wooden frame-lathing

You can, of course, without it, but the risk of getting wavy walls at the same time grows at times. For in order to fasten the lining to the walls without lathing, they must and must be perfectly flat.

Sheathe the walls

After all the preparatory work, they begin, in fact, to the wall cladding. Nails, as fasteners, in this case will not work here, because they are prone to corrosion and can then leave ugly stains and rusty streaks on the walls. The lining is cut to the height of the bath walls and attached to the crate or directly to the wall with special brackets or finish nails.

How to properly fix the lining in the bath

How to properly fix the lining in the bath

Finishing the floor in the steam room

The very first thing to do when finishing the floor is to raise its level by 15-20 cm. This action is necessary for better heat conservation and protection from drafts. The floor in the bath is made of planks or ceramic tiles. Again, regular nails are not used here.

Arrangement of a dressing room

The walls of the dressing room can be sheathed with clapboard or pine boards. In the dressing room, the temperature will be lower than in the bathhouse itself, and thanks to this, pine wood will fill the air of the dressing room with phytoncides and a wonderful pleasant aroma of needles. The dressing room can have both a washing area and a relaxation area. In the washing area, the walls are finished with either tile or panels of fir, pine, spruce, cedar, and tiles with a non-slip surface are usually placed on the floor.

Roof cladding

For finishing the roof in the steam room, it is advisable to use corrugated board. This material is made from high quality galvanized sheet steel. At the production stage, each sheet is processed in roll forming machines. The corrugated board protects the galvanized layer from corrosion.

Stages of building a roof of a bath from a profiled sheet:

- A sling system is installed.

- A crate is mounted, which is covered with an antiseptic composition that protects the product from rotting under the influence of humid air and high temperature.

- Wooden surfaces are coated with fire retardant paint.

- Installation of thermal insulation is in progress. This ensures the protection of the corrugated board from sudden changes in temperature.

- A waterproofing agent is laid on top of the thermal insulation, which protects the insulation from moisture accumulation as a result of the appearance of condensation on the inner surface of the profiled sheet. When choosing this element, you must carefully examine its structure.

Preparatory work for wall cladding

Before quickly sheathe the inside of the bath with aluminum foil and wooden clapboard, it is necessary to insulate the walls. Before laying the insulation, a counter-lattice and a crate are mounted. A layer of vapor barrier is laid on top of the insulation.

Thermal insulation device

Basalt wool is the best material for warming baths. This material has good thermal insulation and a high degree of fire resistance. Basalt wool does not rot. This type of insulation does not burn and does not emit harmful substances. Basalt can withstand temperatures up to 1500 ° C.

Experts recommend using Rockwool Light Butts mineral wool. Mineral wool of this company is of high quality, high density and affordable price.

Large, sharp knives with a high-quality blade are used to cut the basalt wool canvases. When cutting, the knife blade is kept at an angle of 30-45 ° to the surface of the blade. When tilted, the blades dull much more slowly.

The width of the canvas is taken 2 cm more than the distance between the vertical posts of the sheathing. The increased width helps to keep the blades in a fixed position.

Insulation sheets are laid in 3 layers with overlapping joints. The amount of overlap is equal to half the length of the blade.

All layers are laid in height within one span of the sheathing. The laying direction is taken from floor to ceiling. They pass to another span after laying all layers of the previous span.

Laying the first layer starts from the floor. First, the whole canvas is laid. After laying all the canvases of the first layer, lay the second layer.

Laying the second layer also starts from the bottom. For overlapping joints, the length of the first sheet of the second layer is taken equal to half the length of the standard sheet.

At the intersection with obstacles, elements of the required shapes and sizes are cut out.

Before sheathing the bath with clapboard, you should take care of protecting the walls from dampness and decay. Therefore, after the installation of thermal insulation, proceed to the installation of the vapor barrier material.

Vapor barrier device

The vapor barrier layer is designed to protect the walls from condensation and increase the heat-reflecting properties of the insulation.

Vapor barrier laying works are the most important when arranging bath rooms. The efficiency of steam use depends on the quality of the vapor barrier works.

Aluminum foil 50-80 microns thick is used as a vapor barrier. Foil attachment starts from the corner of the room from bottom to top.

The vapor barrier canvases are sewn with metal nails or staples to the vertical posts of the insulation cells. To attach the foil, use a pneumatic gun or a special construction stapler.

The foil is laid with an overlap of 2-3 cm of vertical seams. All seams are sealed with aluminum adhesive tape.

In places of transition from walls to floor and ceiling, the foil is laid with an overlap of 5-10 cm in each direction. The free ends are sewn to the ceiling and floor with nails or buttons.

At the joints of the walls with the ceiling, cracks often appear in the foil. To eliminate these gaps, foil corners are used. To make such a corner, a piece of foil is put on the corner of a table or chair.

The made corner is inserted into the corner and carefully glued with tape.

After completing the work, the quality of the vapor barrier is checked. The detected damage is glued with adhesive tape.

After the device of the vapor barrier, the installation of the counter-lattice is started.

Counter-lattice device

The counter lathing serves as the basis for the main lathing.Designed to provide air exchange in the space between the foil layer and the lining.

For the counter-lattice device, wooden bars with a section of 20x20 mm are used. The bars are nailed to the uprights of the insulation cells. The distance between the slats is taken equal to 400-500 mm. The installation of the counter-lattice rails is carried out according to the level and plumb line.

When installing a counter-lattice, a hole with a diameter of 80-100 mm is drilled in the ceiling for the exhaust duct pipe. A sealing cover (valve) is inserted into the hole. During the bath procedures, the opening is closed. To ventilate the bath after washing procedures, the hole is opened.