Installation of VS

The lining is installed vertically or horizontally. Both installation options are used for interior work. When cladding facades, the profile is installed horizontally. Before finishing the fences with clapboard for wooden panels, a support base is prepared.

A lathing from a bar is attached to the walls and ceiling. For this, lumber is used with a section of 30x30 mm, 30x40 mm and 40x40 mm. A larger cross-section of rails is used for significant amounts of work on one plane. The beam is tied with mounting metal corners. The corners are fixed to the walls and ceiling with dowels, to the timber - with screws.

The joints of the cladding to the floor and ceiling are closed with plastic or wooden skirting boards. For vertical external and internal corners, polymer profiles are used for plastic panels.

Nails or screws

The bottom flange of the groove is fastened. Small carnations are hammered at an angle with a hammer with an extension into the bottom shelf of the groove. With a drill, screws are screwed in with the head. Installation of horizontal panels is carried out from top to bottom. This method requires skill and dexterity from the employee.

Pneumatic stapler

The tool does not have to be purchased, it can be rented. The stapler allows you to quickly "shoot" the lining to the crate. This method is only suitable for cladding fences inside the house. Horizontal installation is also done from top to bottom. The vertical installation of "Calm" starts from the corners.

Installation of VSh on kleimers

The most progressive method of VSh mounting is fastening panels with clamps. The mounting part is a bracket that has a shelf with holes and a curved toothed platform (tooth).

Installation begins with the bottom row of the lining with the groove up. It is attached directly to the timber with screws. Then the clamps are immersed in the groove with their toothed ends. The fastener pads are nailed with nails, screwed in with self-tapping screws or shot with a stapler to the crate.

The next row is inserted with spikes into the grooves of the lower panels. The upper lining is punched with a rubber hammer until the protrusions fit tightly into the grooves. The process is then repeated until the finish is finished.

Clapboard classification

The dimensions of the elements of the profile of the Kolkhoz woman's lining are determined by the state standard. In the regulatory document, wood products are classified according to several criteria. The main one is the degree of processing of the source material.

Wood is very popular among finishing materials. According to the degree of wood processing, products of several varieties are distinguished:

- Higher (Extra class);

- First (class A),

- Second (class B),

- Third (class C).

The surface of the planks is even, smooth, without knots and tar stains.

Class I panels have no more than one knot, blind crack or resin pocket. Boards of the second grade have no more than two defects of each type. Products of the third class have no more than four defects.

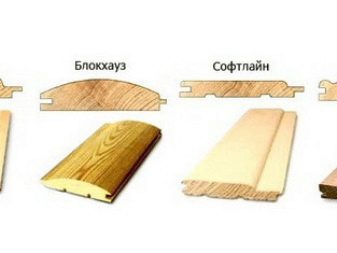

In addition to the known to us "Kolkhoznitsa", the standard provides for the following types of panels:

- "Euro lining";

- "Calm";

- "Landhouse";

- "Soft-line";

- "With a double-sided profile",

- "Block house";

- "American".

The profile of the Euro-lining type panels has a straight inclined bevel at the base of the ridge. A wide seam is formed between the connected panels. The large gap makes it easier to maintain the paneled surface.

Products of the "Calm" type do not have a chamfer at the base of the ridge. The panels are connected with a large seal, no gap. The edges of the planks are curved. The covered surface resembles the laying of a wall with a bar.

Profile elements of the "Landhouse" type have a curved outline. The chamfer at the base of the ridge is rounded.Various patterns are applied to the surface of the panel using wood burning.

For your information. Many people confuse the profiles of Shtil and Kolkhoznitsa. With great external similarity, these types of profiles have some differences. In the first profile, the edges of the panels have a rounded shape. The edges of the lining of the Kolkhoz woman are straight lines.

The "Soft-line" profile has radius curves. Curvilinear outline allows for increased streamlining of forms. Smooth, even surface makes wood maintenance much easier. Smooth transitions between panels prevent the appearance of various damages on the surface of products during operation.

Products with a double-sided profile have flat, smooth surfaces. There are no ventilation ducts on the back of the panels. Both sides of the plank are front. It is used in the construction of internal wooden partitions.

The front side of the "Blockhouse" type panels has a convex surface. The reverse side of the products has ventilation cavities. The covered surface resembles the laying of a wall with logs.

Products of the "American" type have a rectilinear inclined surface. The cladding surface resembles a siding joint.

Classification

Lumber is produced in several varieties. The grade is determined by the quality of the processing of the front surface of the panels, the structure of the wood, the type of wood, the correct geometry of the profile.

The "Calm" lining is made of the following grades:

- Extra;

- Prima;

- A;

- AB, BC.

Extra

This class is assigned to panels without defects. HS of "Extra" class has no cracks, chips, distortions and rotten knots. The profile is made by splicing from several boards. Due to this, the front surface of the lining is smooth. The highest grade VS is considered elite, which is reflected in its high price. The products are delivered to the retail network in vacuum packaging.

Prima

Lining "Prima" is made of larch. Lumber is used for facing facades. The boards are durable, they tolerate sudden changes in temperature well. The facade clad with "Prima" creates an imitation of wall decoration with profiled timber. Larch panels are used to cover the interior surfaces of living quarters.

A

The lining of class "A" is a product of the 1st grade. For different manufacturers, VSh 1 grade is in no way inferior in quality characteristics to panels of the Extra class. The technical conditions of production allow subtle cracks no more than 90 mm long, light knots ø no more than 15 mm.

AB, BC

The lining of classes "AB", "BC" with reduced requirements for the quality of the material are rejected boards of the highest grades or products from low-quality wood. Usually, lumber is used for wall cladding, ceilings in utility rooms.

Production

Lumber is made by processing unedged or edged boards, depending on the woodworking equipment. Six-spindle machines process boards from four sides, forming a front surface, radial longitudinal chamfers with grooves, protrusions.

On the back side of the profile, two longitudinal ventilation ducts are cut with milling heads. Ventilation of the space between the cladding and the fence takes place along them. This prevents moisture from accumulating.

Four-, two-spindle equipment: tenons and grooves are cut in pre-planed wood. This operation can be performed by masters on a milling cutter adapted for this.

Decorative coating

To obtain an attractive appearance of the lined surface, the lining is processed in different ways. For this, different means are used:

stain;

The boards are impregnated with stain. The liquid is used as an antiseptic. The treated surfaces acquire a sophisticated look with an accentuated wood structure.

furniture varnish;

The panels are opened with varnish after staining. The tool gives the lining a gloss, creates a protective layer.

tinting;

Tinting fluids are added to wood stain or varnish to give wood a noble shade. Using the color matching method, you can create an imitation of valuable wood species.

coloring;

The outer cladding of the facades is painted with enamels. Painted boards create a beautiful interior for dining rooms, kitchens, hallways.

brushing.

Special attention is paid to such treatment of "Calm" as brushing. The technology of the process is that the front surface of the panels is cleaned with metal brushes.

This can be done manually or with a power tool.

The soft fibers of the wood are removed, leaving a harder wood structure. The result is a relief that imitates the aging of a tree. Brushed panels are additionally treated with stain, varnish or tinting.

Properties

Cedar lining is a high quality finishing material most often used for finishing steam baths.

On the territory of Russia, only a few enterprises produce real elite lining. Such a finishing material has unique properties.

The cedar panel, impregnated with oil wax, looks like a very noble and refined material, the cedar lining has such an original texture.

It strikes with a variety of color nuances from a sunny light yellow to austere dark coral. Entering a room decorated with cedar panels, you can feel the unique atmosphere of coziness and comfort with the aroma of cedar needles.

Profile types

The ceiling in the room is finished with Altai cedar

The lining of wood can be classified by the type of coniferous wood, by the type of wood and by the type of profile.

Let's highlight the most popular coniferous materials in the production of lumber.

This includes lining made of Canadian cedar, as well as Siberian and mountainous Altai.

Classification by wood type is made according to the number of knots and natural defects present on the cedar panels. There are several varieties or classes of lining: the highest quality "extra", middle class A and B, lower quality board of grade C.

The most common types of profiles are eurolining, softline and calm.

Euro lining has the deepest groove and the largest spike, as well as special grooves for ventilation on the back of the board.

The lining of the "softline" profile, respectively, has a spike and a groove less deep, but the board itself is somewhat wider, which creates a smoother and less dazzling surface when finished with such a profile.

The lining "calm" is characterized by the absence of a shelf that continues the spike from the back of the board. The clapboard trim of such a profile is distinguished by an inconspicuous connection of the panels and looks like a homogeneous surface without seams.

Video - exclusive work (not done by a specialist):

approximate cost

Decorating premises with cedar clapboard is not cheap, but the price is justified by the high wear resistance of the material and its excellent characteristics.

This material does not shrink, does not crack, does not deform, and is heat resistant.

The price of the lining is optimally correlated with its quality. Consider the approximate cost of one cubic meter of various types.

- Siberian "calm" of extra class, size 110x14mm, length 2-4 m: price 1350 rubles / sq.m

- Siberian "softline" of extra class, size 110x15mm, length 2-3 m: price 1350 rubles / sq.m

- Siberian cedar of class AB, size 140x14mm, length 3-6 m: price 550 rubles / sq.m

- Siberian extra class, size 96x14 mm, length 2-4 m, price: 950 rubles / sq.m

- Top-class Canadian cedar, size 90x12.5 mm, length 2-3 m: price 2117 rubles / sq.m

Video - rules for buying:

When buying a lining, it is necessary to check the integrity of the packaging, this is important to preserve the moisture content of the material and its appearance. The board emits a specific coniferous aroma, it is difficult to confuse it with the smell of other types of wood

The color of the board ranges from light yellow, pinkish to dark brown shades.

Varieties

Lining "calm" by its quality is divided into grades.The grade is determined depending on the class of raw materials used, the appearance of the front side, the number of knots per 1.5 running meters of the surface, the type of wood. There are 4 varieties.

- Extra grade boards are characterized by excellent quality, high thermal conductivity and good appearance. Knot-free spliced lining is a material of this kind. In this case, the wood material does not contain a single knot, the surface is smooth, clean, and there are no defects at all. The color and texture of the wood are stable. Board length up to 5 meters.

- Grade "A". In this class, 1 knot is allowed per 1.5 running meters. Often, boards of this type of certain types of wood (pine, larch) may not differ from the top class. The length of the board is up to 3.8 meters.

- Grade "B". There can be up to 4 knots and 2 resin pockets per unit of length. The length of the board is up to 5 meters. Most often used for flooring.

- Grade "C". This grade is economy class lumber. There may be knots, cracks, blue spots. Used in utility rooms, utility rooms, technical buildings. For lining "calm" such material is used extremely rarely.

What it is?

Lining is a profiled board for indoor and outdoor wall cladding, covered with antiseptic compounds.

Lining panels differ in several ways.

- By wood material. The lining is made of coniferous or deciduous wood. The strength, color, texture, durability of the panels depend on the type of wood.

- By wood class. Class "A" is considered the best, the material for the manufacture of boards in this case does not contain defects, areas of high humidity are absent. In class "B" these flaws may be present in small numbers. Class "C" is low quality wood with areas of decay, knots and cracks.

- By profile. There are several types of profiles: ordinary, euro-lining, American, block-house, lining under a log house, under a bar, "calm".

"Calm" - a profile of lining panels for cladding, which quickly and easily allows you to mount an almost perfectly flat wall. Such facing material looks beautiful and will harmoniously fit into any interior. The solidity of the surface is achieved due to the butt joint of the panel and the rounded chamfer at the edges of the product. The connecting shelf, in contrast to the usual lining, is absent.

Along the entire length of the panel, a special groove is provided in the “calm” lining to ensure free air access. This allows you to get rid of excess moisture in the wood due to the formation of condensation by airing. During operation, such a lining shows itself better.

Specifications

The dimensions of the "Calm" lining are different. The material of a domestic manufacturer is generally from 9 to 15 cm wide. The length of the panels is up to six meters. Variations in the thickness of the panels vary from 1.2 to 2.5 cm.The width of the foreign-made material ranges from 8 to 14 cm.The boards are thick from 1.25 to 2.1 cm.The length of the panels is the same as that of the domestic manufacturer - up to six meters.

Unlike the classic variations of the lining, "Calm" has varieties with other parameters. For example, the width of a domestic material can be from 120 mm to 140 mm, and the thickness of the profile can be from 1.5 to 2.5 cm.

The lining "Calm" of foreign production is identical to the dimensions of other types of materials. Calm is characterized by differences in the length of the finishing board. For example, it ranges from 2 meters to 6 meters. This variety allows for fewer butt joints on the cladding surface. The finish is smoother and more solid. The most widespread are the "Extra" and "Premium" classes. They belong to the higher quality species.

The appearance of wooden products differs depending on the class.Classes are divided depending on the presence of knots on 1 meter of the panel. The fewer there are, the better the quality is considered. The scope of the lining is interconnected with the type of base. For example, pine or spruce panels are suitable for covering verandas and loggias. The structure of the needles is characterized by increased resin content, thanks to which the lining acquires good water-repellent qualities. Coniferous lining is not suitable for finishing steam rooms in saunas. Since, due to the high degree of tar content, such a lining begins to exude a pungent and unpleasant odor.

Hardwood panels do not emit resin, and therefore are allowed in the decoration of steam rooms. Such cladding will have a positive effect on the human body due to its subtle healing scent. Expensive types of wood, for example, cedar lining, can only be used for finishing small decorative elements. The highest cost panels are often made from rare wood species.

Lining "Extra" class can only be used for interior decoration. The quality of the material is very high. The class is divided into varieties: A, B, C. Here it is worth considering in more detail the nuances of choosing a particular variety, depending on the qualities of the variety. Variations on sale imply the presence of varieties with characteristics: AB, BC.

Manufacturing materials

Linden, alder panels are deciduous types of material. Linden, birch, aspen, oak, alder, and other options look like wooden flat panels about 70 mm wide with rounded edges and a missing shelf on the spike side. The panels are in demand due to the unique qualities of hardwoods. This wood is characterized by excellent strength and density. The panels will not lose their original appearance even under the influence of various external conditions.

These species do not rot or mold. Any hardwood materials should be treated with an antiseptic. The processed lining is suitable for cladding and the outside of buildings. Clapboard facades look presentable and amazingly beautiful.

Conifers, for example, pine, cedar, and other conifers, can also serve as the basis for the production of Shtil lining. "Calm" from Angarsk pine is the best fit for cladding rooms inside. This breed is characterized by a unique surface pattern. The panels are suitable for finishing not only the attic or veranda, but also the living room and other rooms in the house. You can diversify the design variations by coloring the wood, as well as by choosing combinations of various types.

Lining made of pine, birch or linden is an inexpensive finishing material. Cedar products are an elite grade of decoration that can only be used to decorate some interior parts of a room.

Cedar lining is used not only for home interiors, but also for executive offices, facing bank halls, shops.

Advantages and disadvantages

Like all building materials made of wood, the "calm" lining is characterized by all the features of this natural material. These are strength, ecological naturalness, durability, aesthetic beauty and expressiveness.

The lining of the "calm" profile has advantages that are achieved due to its design features and processing.

- The surface of the cladding is smooth, due to this, the scope of application is significantly expanded.

- A wide range of product sizes (width and length), which makes it possible to use them for finishing both entire premises and sections of walls or ceilings. In this case, the number of joints can be minimized due to the elongated and widened board.

- The installation process is easy and fast due to the low weight of the material and the ready-made tongue-and-groove fastening system.

- Natural wood texture, choice of shades, no need for painting.

- The strength of the finished structure, resistance to deformation processes.The fixation of the elements is reliable and there is no possibility of their disconnection during operation.

- The assembled cladding retains its original appearance for a long time, the lining panels do not diverge, no gaps are formed.

- Thanks to a special profile recess, moisture and condensation drainage is provided sufficiently well, which helps the material to resist decay.

- The walls do not need to be leveled or primed before cladding.

- Lining "calm" is used for both vertical and horizontal surfaces.

The main disadvantage, like all high quality wooden finishing materials, is the cost. The price per square meter of calm lining is higher than the cost of the usual version.

What it is?

The cost of natural materials is high, everyone cannot afford to buy them. The use of Shtil lining is an excellent choice from the whole variety of products on the market. What it is, and what parameters are characterized by this method of finishing, we will consider.

The lining looks like classic boards used for cladding, made from natural raw materials. Pine, cedar, birch, linden, and other wood bases are used for the manufacture of Shtil lining. This finish differs from other varieties in the absence of grooves along the edges of the panel. To connect the parts of the cladding, there are provided “tongue-and-groove” fasteners. The technology makes it possible to embody a flat and smooth surface decor with an accurate imitation of solid wood.

Lining "Calm" is a high-quality sawn timber. One finishing panel is a clean-cut, dried board with defined dimensions. The technology for the production of the board is similar to the methods of manufacturing the Euro profile. The distinctive features of the lining are a thinner profile. And during assembly, there is no parting between the panels, since there are no deepened grooves. The fastening of the panels is invisible to the eye. The material is allowed for use both in interior and exterior decoration.

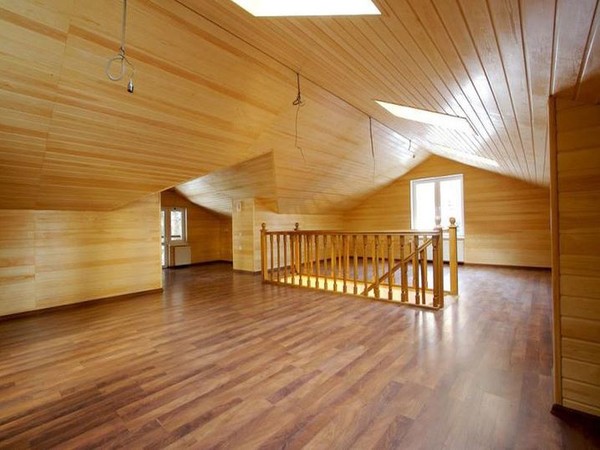

Beautiful examples of sheathing

Decorating the inside or the facade of buildings with "Calm" clapboard is one of the inexpensive ways to transform a home. The panels are manufactured using modern technologies, which increases the performance characteristics. Some types of panels do not require any maintenance or treatment with fungicidal agents. Wood paneling is always in fashion.

Classic lining made of boards is an ecological material. It will fit well with most trendy interiors. However, if this material is used everywhere, then a kind of dacha effect arises. Therefore, the lining should be used selectively, for example, for decoration and creating fashionable accents.

Wood panels can be present in the interior decoration of the walls, on the ceiling, in other interior details.

- The ability to paint the lining is a positive decorative advantage of this material. For example, white lining is well suited for the embodiment of a Scandinavian interior.

- Painted lining is often used for cladding facades, street elements, such as gazebos. The painted lining inside the gazebo will retain its original qualities for a long time.

- Today creature manufacturers have diversified the clapboard assortment. In addition to classic planking boards, in stores you can find good and interesting materials from the point of view of the designer. For example, the facing of the boards with an overlap imitates the lining "American".

- A block house can easily cope with imitation of a log laying.

- Choose lining options in accordance with the conceived design. As you can see, standard boards can be supplemented with other types of designs.

You will learn how to quickly attach the lining in the following video.

Advantages, disadvantages of "Calm"

Among the advantages are the following:

- the decoration of the VSh fences has an aesthetic appeal;

- the absence of a relief surface creates the impression of an integral cladding area;

- ease of installation of panels;

- environmental friendliness of the material;

- high strength of products.

The disadvantages of the profile include high cost. Spruce and pine panels are not used for outdoor use. When exposed to direct sunlight, the wood begins to exude resin, which leads to cracks and disruption of the geometry of the panels. At low air temperatures, the negative consequences are aggravated, which sometimes leads to a complete loss of the functionality of the cladding.

Scope of use

In order to live in the cozy atmosphere of a wooden house, it is not necessary to build a house from a bar or to put a log house. It is enough to cover the walls and ceiling with clapboard. The wall, lined with "calm" clapboard, has smooth transitions at the joints of the panels and an even appearance as a whole. The inner lining looks like an almost complete canvas, so this lining is often called "wooden wallpaper". The evenness of the resulting surface and ease of installation make it possible to use this material on ceilings, especially if the finishing result is to be of the highest level.

In the interiors of residential buildings, wood is one of the favorite finishing materials because of its comfort. And for many premises, it is excellent in terms of operation and design (baths, summer kitchens, interiors in eco, ethno, country styles, etc.).

Nuances of choice

Perceptible advantages of grade A lining:

- wide panel, which allows you to sheathe the premises quite quickly, without much physical effort;

- the ability to mount both horizontally and vertically;

- the tongue-and-groove system ensures very simple installation;

- there is little waste that is inevitable when working with other varieties;

- the presence of special ventilation slots.

Differences in the appearance of the varieties:

- A - rare knots without rot and areas with visible resin are visible;

- B - the presence of a larger number of knots, as well as areas with visible resin;

- C - blue is allowed in places with visible resin, knots falling out.