Features and purpose

The oversized washer is a standard flat fastener that has a large outer diameter and thickness. Basic information about such parts can be found in GOST 6958-78. It describes the design of these washers, their dimensions, weight, and technical requirements. In addition, many requirements for the quality and manufacturing process of such elements are listed in the special standard din 9021. Unlike the standard flat model, which has an outer diameter slightly larger than the diameter of a bolt or nut, reinforced fasteners are large and heavy. The ratio of the diameters of the outer and inner parts for the enlarged views is 1: 3. These parts are most often not used as a separate fixture, they are used as an auxiliary fastener.

Oversized washers can be made from different materials. The most popular option is considered to be models made from a steel base. The diameter of such samples most often varies from 12 to 48 millimeters, although models with a lower indicator are currently sold. These types of fasteners, as a rule, belong to the accuracy class A or C. The first type belongs to the group of increased accuracy levels. Models related to it have a larger diameter value compared to group C.

Reinforced models will be the best option for bolting, because they contribute to the most even distribution of the total load over a large area. As a result, the pressure on the supporting surface is reduced, the reliability and safety of the finished structure is ensured. Sometimes these parts are used together with studs, spring elements, nuts. Such washers should be purchased if you are going to work with thin, fragile or soft materials, since in these cases it is not always possible to take other fasteners, including bolts.

All washers have their own specific geometric meanings. These include the indicator of the inner and outer diameter, as well as the thickness. Fasteners are marked according to the metric diameter of the structure

Before purchasing a suitable set with reinforced washers, make sure that their surface is not scratched, chipped or otherwise damaged.

Dimensions (edit)

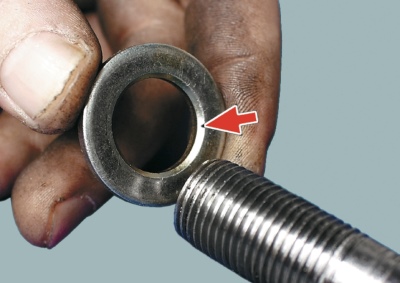

The inner hole diameter of the reinforced washer is slightly larger than the thread size. The outer diameter is approximately three times the inner diameter. The washer is available in a wide range of sizes and can accommodate threads from M2.5 to M36. For example, the inner diameter of the M3 washer can be 3.2 mm, the outer diameter is 9.0. For M6 - 6.4 and 18 mm, M24 - 25 and 72 mm. The weight of a thousand pieces of M6 washers made of S1008 steel is 2.5 kg, M24 is 121 kg.

| Ramer | Inner diameter (mm) | Outside diameter (mm) | Thickness (mm) | Weight 1000 pcs. (kg) |

| Reinforced washer М-6 | 6,40-7,00 | 18,00-19,00 | 1,50-1,70 | 2,52 |

| Reinforced washer М-8 | 8,40-9,84 | 24,00-25,00 | 1,90-2,10 | 5,85 |

| Reinforced washer М-10 | 10,50-12,00 | 30,00-31,00 | 2,40-2,60 | 11,58 |

| Reinforced washer М-12 | 13,00-15,00 | 37,00-38,00 | 2,90-3,20 | 20,33 |

| Reinforced washer М-14 | 15,00-17,00 | 42,00-43,00 | 2,90-3,20 | 29,38 |

| Reinforced washer М-16 | 17,00-19,00 | 50,00-51,00 | 2,90-3,20 | 37,32 |

| Reinforced washer М-18 | 19,00-21,00 | 54,00-55,00 | 3,20-4,00 | 73,13 |

| Reinforced washer М-20 | 22,00-24,00 | 60,00-61,00 | 3,90-4,20 | 83,47 |

| Reinforced washer М-24 | 26,00-27,00 | 72,00-73,00 | 4,90-5,20 | 121,63 |

Comparison

Basket

Materials (edit)

Various types of metals can be used to make enlarged fasteners of this type.

Steel. A carbon, alloy and corrosion resistant steel base is a suitable option for making washers. This material is considered the most durable and reliable, in addition, it does not corrode. As a rule, in the manufacturing process, fasteners are additionally coated with a special galvanized coating, which provides better protection of the washer from mechanical stress, improves its reliability and durability.Galvanized steel is absolutely safe from an environmental point of view.

Installation rules

In order for the washer to be able to provide the most reliable and strong fixation, it is necessary to install it correctly. First you need to calculate that the diameter of the outer part is equal to the diameter of the inner part, which has been multiplied by three. During the installation process, the washer with an increased field is tightly fixed in the place between the mount and the part that will be connected. After that, it is necessary to tighten the entire fastening structure with effort.

When installing, it is worth remembering the following important nuances:

- do not forget, when it is possible to create a bolted connection on a soft surface, it is still better to use a reinforced washer, since it is such fasteners that will allow you to form a large supporting area;

- the increased support area makes it possible to evenly distribute all the pressure that has arisen on the surface, this makes the connecting structure more durable and resistant;

- if during the installation process you screw a nut, then it is better to use such a washer as an additional protective element, because when installing the nuts, there is a lot of friction, which can lead to surface damage; an enlarged washer in this case will help prevent scratches and other damage to the structure.

The following video describes the installation of oversized washers.

Washers material and features

Reinforced washers are made of various materials. The most commonly used galvanized structural steel. They can also be made from carbon and mild steel, stainless steel, brass, copper, aluminum, non-ferrous alloys and plastic. Hot and galvanized zinc coating, chemical oxidation, yellow chromating are used. The washer can meet various GOST and DIN standards. The most widespread flat washer is enlarged DIN 9021. Most often it is made of stainless steel A2 or acid-resistant austenitic steel A4. Also, hardware of this type, made of galvanized steel S1008, is quite common. Other types of reinforced or oversized washers are produced according to DIN 440, 1440, 1052, 6340, 7349, 7989. DIN 440 and 1052 washers are most widely used in woodworking and furniture production, 7349 is used with bolts with heavy spring pins, 7989 - for joining steel structures. Washer hardened standard 6340 is made of high-strength alloy steel and is used for increased loads.

Reinforced washers are made of various materials. The most commonly used galvanized structural steel. They can also be made from carbon and mild steel, stainless steel, brass, copper, aluminum, non-ferrous alloys and plastic. Hot and galvanized zinc coating, chemical oxidation, yellow chromating are used. The washer can meet various GOST and DIN standards. The most widespread flat washer is enlarged DIN 9021. Most often it is made of stainless steel A2 or acid-resistant austenitic steel A4. Also, hardware of this type, made of galvanized steel S1008, is quite common. Other types of reinforced or oversized washers are produced according to DIN 440, 1440, 1052, 6340, 7349, 7989. DIN 440 and 1052 washers are most widely used in woodworking and furniture production, 7349 is used with bolts with heavy spring pins, 7989 - for joining steel structures. Washer hardened standard 6340 is made of high-strength alloy steel and is used for increased loads.