Features and characteristics

Installed foam insulation is a porous polymer mass. The working solution is applied under pressure to the wall or ceiling, foams upon contact with air and hardens. Numerous gas bubbles provide thermal insulation and protect the premises from street noise and vibrations.

Polyurethane foam, also known as polyurethane foam sealant, is a substance widely used in construction to bond separate parts of the structure to be joined together, heat and sound insulation, seal and fill voids that arise during operation. Usually sold in metal cans, in which the foam itself and a mixture of liquefied gases are under pressure - the so-called. a propellant that acts as a buoyant force for the contents of the cartridge. The versatility of this synthetic polymer makes it an indispensable assistant in many types of construction work and in almost any repair.

Of course, polyurethane foam sealant has its own characteristics and characteristics, which will be discussed below.

High-quality insulation in cylinders: features of polyurethane

PPU is one of the most popular types of thermal insulation materials produced in cans. What else do you need to know about him?

Features and properties of PPU:

- The qualities of this insulation directly depend on its composition and the additives in it;

- With the help of polyurethane, you can quickly and easily insulate a structure of any configuration;

- This material is not afraid of the chemical effects of alkali or acid, is able to withstand dampness, insects and rodents are too tough.

However, as an option, you can use "Ecopen" - one of the varieties of polyurethane foam. With its help, you can safely insulate walls and roofs, and with increased vapor permeability. Eco-foam will show itself perfectly when insulating the ceiling, attic or interfloor ceilings.

But it should be borne in mind that the use of Ecopen is not intended for external insulation of a building without a protective coating, since it is a rather sensitive material to the effects of precipitation and mechanical stress.

Stages of roof insulation with polyurethane foam

When applying the coating, the technology and sequence of work should be observed

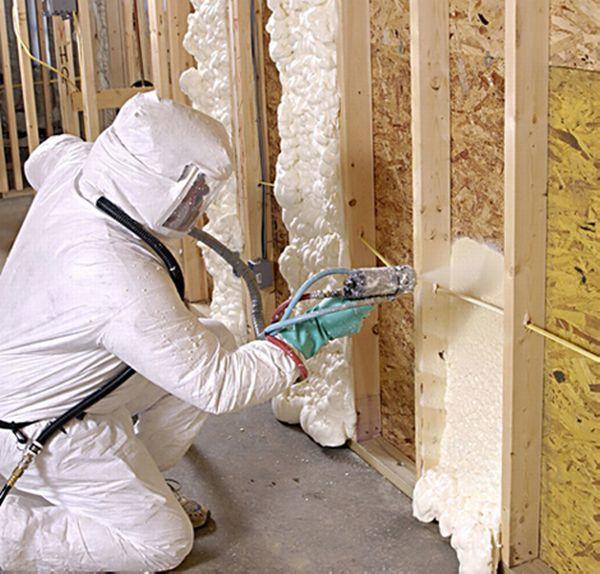

Required tools and safeguards

For work you will need:

- reusable and or disposable spraying machine;

- assembly knife for cutting rolled and sheet materials and removing frozen excess foam;

- measuring tool for marking surfaces;

- protective overalls for the painter with a hood and hands with elastic bands;

- tight shoes;

- safety glasses or face shield;

- respirator;

- gloves.

Preparatory work

During preparation, it is necessary to clean the surface to be treated from debris, dirt and remnants of old coatings.

Next, a crate and a metal profile or wooden slats are installed. Their thickness should match the planned thickness of the foam layer to be applied. In the future, the finishing will be attached to this frame.

The working solution is thoroughly mixed to the consistency required in the instructions.

Spraying the material onto the base

The first layer of foam is applied to the prepared base. It is necessary to achieve a continuous application, close gaps and fill irregularities.

Spraying is carried out from top to bottom. If necessary, after the first layer has hardened, the second and subsequent layers are applied. Each time you need to let it dry and grab the previous layer.

Excess insulation is cut off with a mounting knife flush with the installed crate.

If you plan to close the insulation with a layer of plaster, a polymer or metal reinforcing mesh is mounted on the crate.

Application of fire retardant

Polyurethane foam is highly flammable and emits toxic substances when heated and burned. Therefore, the insulation layer is covered with a fire retardant compound. The composition must be selected specially recommended for use with polyurethane foam. It is wise to choose it from the same manufacturer as the base material. The layer is applied with a spray or roller so that the coating is continuous and all the insulation is protected.

Application

After about 30 cm, stop and see what kind of foam layer is formed. If necessary, apply some more foam over the first layer.

Over time, you will develop an understanding of how much of the solution should be sprayed optimally.

But for pouring, it will be very problematic to correctly evenly distribute the foam throughout the entire space. The fact is that, in theory, you must first pour in the liquid, and then it, expanding, gradually becomes foam.

But the catch is that it is almost impossible to perform this procedure, since you cannot see what is happening inside. That is why it is recommended to install the hose in such a position that it is directed straight downwards, and then start pouring. So, the liquid first fills all the cracks and niches from below, after which, expanding, it will move upward.

Material characteristic

Polyurethane foam (PUF) looks like a homogeneous structure of foam material, consisting of air bubbles filled with gas. Various versions of PU foam are deservedly popular, because they can be made directly at the construction site. The most common method is to spray the material onto the surface. Spraying is used for thermal insulation of houses, industrial workshops, pipelines, and in addition, it is actively used in the interior of premises.

Filling is used if it is necessary to fill the cavity between the walls or the gap between the installed finishing layers.

The thermal conductivity of the material is 0.023-0.025 W / mS. The Teplis heat insulator is lightweight and can be easily applied to surfaces made of any materials (concrete, brick, glass, wood, aluminum, PVC).

Due to the optimal ratio of open and closed cells in the structure, the insulation "breathes". Accordingly, the surface to be treated always remains clean and dry.

Other benefits of the product include:

- resistance to temperature changes;

- environmental friendliness;

- duration of operation (at least 20 years);

- seamless application, excluding the occurrence of cold bridges;

- good sound insulation;

- low flammability;

- immunity to harmful rodents and insects.

Teplis polyurethane insulation is sold in 1 liter cylinders. Included with this product, the manufacturer offers to purchase a mounting gun with nozzles for uniform spraying.

Plinth of a house with sprayed insulation

Features of insulation of various designs

Depending on the surface to be treated, the order of the activities carried out may be different. The advantage of polyurethane foam insulation is that it can be used for both horizontal and vertical elements. Home insulation with foam has a high degree of adhesion to the surface, since the material penetrates into the most inaccessible places.

Insulation of floors

It can be produced both from below and from above. For overlapping over a cold basement, floor insulation from below will be the most competent. Polyurethane foam is practically the only insulation that is convenient to work with in these conditions. To protect the attic floor, polyurethane foam is applied from the cold attic side.

Waterproofing and vapor barrier are not required during operation. It is recommended to carry out the installation in the following order, regardless of whether the insulation is done from above or below:

- removal of dirt and dust from the treated surface;

- to increase adhesion, you can treat the surface with a primer;

- nailing rails or profiles, installing a floor log, between which a heat insulator is sprayed;

- filling the space between the profiles with expanded polystyrene;

- finishing the ceiling or installing a clean floor.

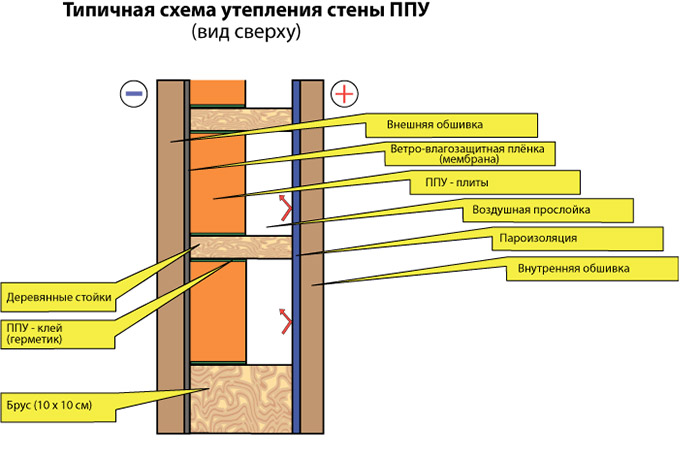

Wall insulation

Wall insulation with foam can be done from the outside and from the inside. External thermal insulation will be a smart solution, but if necessary, internal work is allowed, for example, with additional insulation after the object is put into operation. The differences are only in the finish.

The work is carried out in the following order:

- surface preparation, cleaning from dirt and dust;

- wall marking and installation of vertical battens;

- filling the space between the frame with foam;

- installation of the facing layer.

Mansard roof

Warming the space between the rafters with mounting foam will allow you to choose the pitch of the rafters, regardless of the size of the material, as is the case with mineral wool. The insulation is mounted in the following order:

- installation of elements of the rafter system and roofing;

- cleaning the base;

- spraying polyurethane foam between the rafters from the eaves to the ridge;

- installation of the lathing;

- ceiling cladding, such as plasterboard.

Views

It's no secret that modern insulation manufacturers offer the widest range of sealants to choose from. Let's together try to understand the abundance of types of polyurethane foam and see which types of the required substance will best serve a particular purpose.

Polyurethane foam differs in several ways.

Type

Household

Pros: no special equipment is required to work with household foam. It can be easily distinguished from a professional one by its external type: there is a special valve at the end of the container, on which a lever with a plastic tube is fixed.

Cons: it can only be used to fill small voids or cracks, it is not used for installation, since it almost always requires cutting - the volume of this type of sealant is usually higher than the volume of the space it fills.

Professional

Pros: higher than the previous type, the coefficient of primary expansion, increased elasticity and finer structure. The material flow can be controlled, so it lays down more accurately than household material, evenly filling the required volume. It should also be mentioned that professional polyurethane foam can be easily attached to almost any surface.

Cons: A mounting gun is required to work with a professional look. However, given the versatility and wide scope of application, this disadvantage is very relative.

By temperature of use

Summer

Summer polyurethane foam is recommended for use at positive temperatures - from about +5 to +30. At low ambient temperatures, the release of the useful substance from the cartridge decreases, and the degree of expansion drops significantly. Work at elevated temperatures should also not be carried out due to the peculiarities of the prepolymer, whose viscosity in such cases is significantly reduced.

Winter

It is usually used at temperatures from -10 to +40 degrees. However, there are some types of foam that allow you to work even at -20 - for example, Tytan Professional 65 sealant. After hardening, the winter type is able to easily withstand seventy-degree frost. Suitable for a barrel in which any substance can be stored.

All-season (or universal)

In fact, it has almost the same temperature range as the winter one and does not always stand out as a separate group. Work with it is carried out at temperatures from -15 to +30 degrees.

By the number of components in the can

One-component

It is quite widespread and has a relatively low cost. The polymerization reaction takes place with water. The shelf life does not exceed one year.

Pros: low cost, ready to use immediately after purchase, easy to use.

Cons: short shelf life.

Two-component (structural)

Water does not take part in the reaction. It is replaced by a special component, which is located in a small hermetically sealed container inside the cylinder itself. Its cost is higher than that of a single-component one and, as a rule, it is sold in small containers (usually 220 ml), because the solidification period of the substance after mixing the components is short and is ten minutes.

Pros: Neat void filling.

Cons: high cost, in the manufacture of a polyurethane mixture, it is necessary to strictly adhere to the established proportions.

By the degree of flammability

- Class B1 - fireproof and fireproof. Usually it is pink or bright red - dyes are added on purpose so that when applied, the type of composition is immediately visible.

- Class B2 - self-extinguishing, as the name implies, it does not support combustion.

- Class B3 - combustible polyurethane foam with zero refractoriness. The reviews are mostly positive.

Advantages and disadvantages of this type of insulation

The indisputable advantages of the substance in question, which the manufacturer usually indicates on the packaging, include:

- high degree of adhesion - that is, its ability to firmly adhere to many surfaces. Exceptions are Teflon, silicone, ice, polyethylene and oily surfaces;

- heat resistance (as a rule, it is in the range from -45 ° C to 90 ° C);

- cured polyurethane foam is a dielectric (does not conduct electric current);

- fairly fast solidification rate - from eight minutes to a day;

- high moisture resistance;

- lack of toxicity (of course, after the final solidification);

- a small percentage of shrinkage (no more than 5%) throughout the entire period of operation;

- chemical resistance;

- high strength;

- long service life of the material (up to half a century).

Also equally important characteristics are:

- The total volume of sealant output is calculated in liters and means the amount of foam coming out of a unit of capacity. This characteristic is influenced by the ambient temperature, the degree of humidity and windiness.

- Viscosity - mostly depends on the air temperature. Temperatures above (or below) certain limits specified for each type of foam negatively affect the viscosity of the substance. This is bad for masonry.

- Primary and secondary expansion. Primary expansion - the ability of the composition to expand immediately after leaving the container for a very short time interval (up to sixty seconds). During this short period of time, polyurethane foam sealant is able to increase in volume by 20-40 times. Secondary expansion refers to the ability of a synthetic polymer to expand for a long time before the final cessation of polymerization.

High-quality polyurethane foam has a pleasant light yellow or slightly greenish color, it does not flow down when applied to the surface and is even suitable for roofs. It is not eaten by rodents and insects, it does not harm the environment. When solidified, the substance turns into a durable porous seamless material, which is quite moisture resistant and has excellent insulating properties.

It is important to note that under the influence of solar ultraviolet radiation, this insulating material is subject to rapid destruction - at first it darkens and then becomes brittle. Never forget to plaster the foam-filled area after it has set.

Otherwise, it can simply turn into dust.

Polyurethane foam is suitable for insulating a frame house.It will serve as a special air gap.

Experts' assessments vary, so let's try to draw the line and correlate all the pros and cons.

Dignity

- The porous structure prevents the accumulation of steam inside the penoizol.

- Significant service life - from 50 to 60 years.

- Prevents colonization by microbes and rodents, does not rot.

- Not subject to spontaneous combustion.

- Resistant to hazardous environmental influences.

- Possibility of quick installation.

- Does not release toxic substances after hardening.

- Insulation can be done by hand.

Minuses

- Dries for a long time. Complete drying of a not too thick layer lasts at least two days.

- Harmful formaldehyde is released during polymerization.

- Adheres poorly to dirty surfaces.

- If necessary, dismantling the coating is very difficult.

- In the cold season, working with this material is very difficult.

| Application thickness, cm | Price in rub. per cubic meter, density 36 kg / m3 | Price in rub. per cubic meter, density 53 kg / m3 |

| 3 | 450 | 800 |

| 6 | 900 | 1550 |

| 10 | 1500 | 2600 |

Warming with ready-made sheets:

| Slab thickness. cm | Price in rub. per 1 m2 |

| 10 | 1200 |

| 15 | 1800 |

| 20 | 2300 |

Insulation by pouring:

| Type of work | price, rub. for 1 m3 |

| Pouring on the object being built or into existing holes | 1500 |

| Filling with drilling | 1500 200 per hole |

As you can see, foam is not an inexpensive method of insulation, but taking into account the subsequent savings on heating and the speed of application, you can reduce the total cost of building a building. In addition, the price can be partially covered when doing insulation work with your own hands.

Features of insulation

For self-insulation of a house with foam, a protective suit is required. Foam is usually sprayed from a cylinder onto the entire surface of the facade, it is used to fill the voids between the walls, rafters, and beams.

There are many advantages of this type of wall insulation with foam in the air gap. The main ones include:

- vapor permeability;

- fire resistance;

- the ability to increase in volume;

- resistance to all kinds of mechanical stress;

- the upper temperature limit remains within +80 degrees.

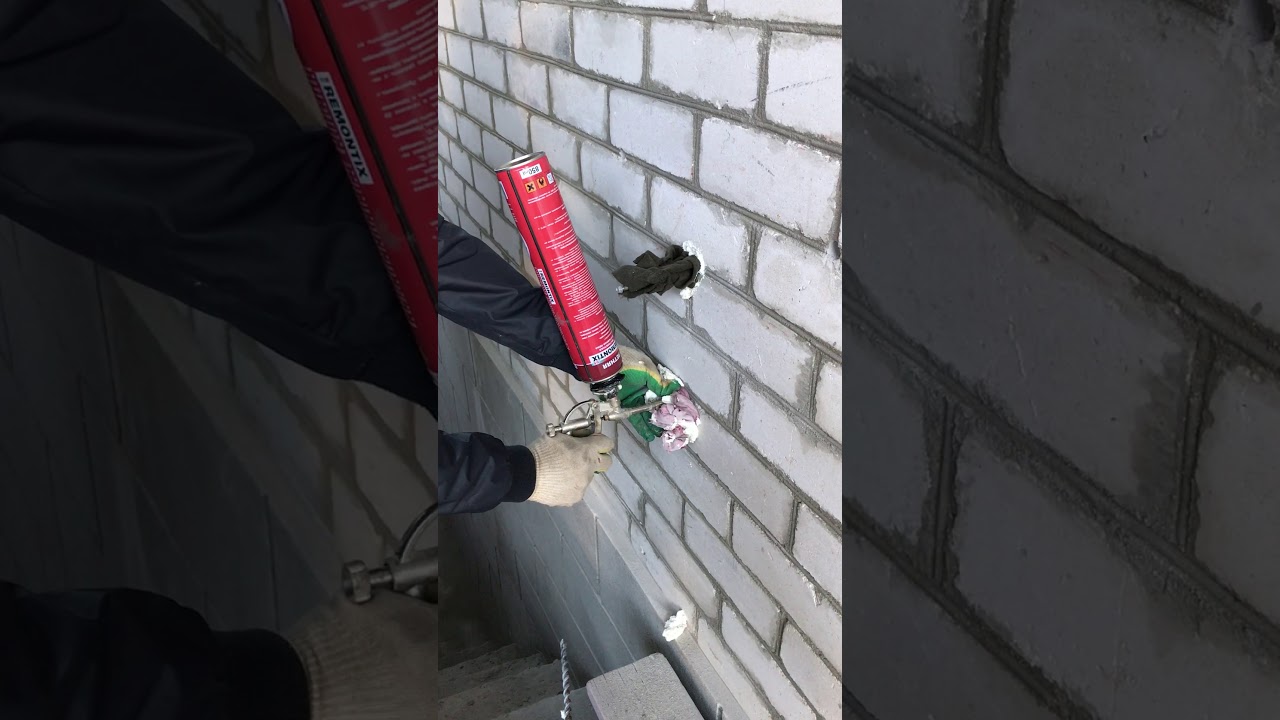

Often, foam is used to seal the gaps that remain after the installation of plastic windows. Due to this, thermal insulation in the apartment also increases. A pneumatic gun is convenient to use for insulating not only windows and outer walls, but also the foundation, loggia and balcony, pipes.

Often, foam is used to seal the gaps that remain after the installation of plastic windows. Due to this, thermal insulation in the apartment also increases. A pneumatic gun is convenient to use for insulating not only windows and outer walls, but also the foundation, loggia and balcony, pipes.

The facade, after being treated with foam insulation for the walls, turns out to be ideal - without visible joints and seams. One container contains an average of 600-700 ml of the composition, which is enough to process a square meter with a layer up to eight centimeters thick. It is very simple to work with such a gun: first, a full cylinder is inserted into it, then you need to direct it to the surface to be treated and pull the trigger. On average, the applied composition hardens within a day.

Types of material and their properties

Foam heat insulators differ in their composition and method of application

Liquid penoizol

This popular material is used to insulate floors and walls. It has the following advantages:

- high-quality adhesion to most building materials;

- a small amount of preparatory work;

- seamless and seamless coating;

- good vapor permeability;

- high penetrating power;

- the ability to fill hard-to-reach volumes;

- resistance to the appearance of fungus, microorganisms and mold;

- environmental friendliness.

The material also has disadvantages:

- linear shrinkage;

- sharp unpleasant odor during application;

- hygroscopicity, additional hydro-vapor barrier is required;

- fire hazard, when heated, poisonous substances are released.

Roof insulation can be done with liquid foam insulation

Roof insulation can be done with liquid foam insulation

Penoizol requires an additional fire retardant coating, it is better to use it for external insulation of the roof of the house.

Polyurethane foam (PPU)

Closed cell polyurethane foam insulation is also popular among homeowners. Experts identify the following advantages inherent in the material:

- applicability over a wide temperature range;

- compatibility with most popular building materials;

- ensuring the tightness of the sprayed coating even with a complex roof configuration;

- low value of the coefficient of thermal conductivity;

- resistance to biological influences: mold, microorganisms, insects, rodents;

- low material density and, accordingly, a small additional load on the roof;

- resistance to solvents and other active substances;

- the ability to withstand compressive and tensile loads;

- low vapor permeability, there is no need for additional vapor barrier;

- minimal hygroscopicity;

- excellent performance in sound insulation;

- long service life, comparable to the service life of insulated structures.

There are PPU and a number of disadvantages:

- high activity of the working composition, harm to open areas of the skin and respiratory organs;

- the need to use protective clothing, masks and respirators;

- vulnerability to sunlight, especially ultraviolet rays, makes it necessary to protect the coating with an additional layer of mastic or plaster;

- emits harmful substances when heated;

- high qualification of the worker applying the coating is required;

- high cost of equipment for applying the material.

The last two factors make it difficult to self-apply polyurethane foam. Even disposable installations, already charged with a certain volume of working solution, are expensive. If the owner of the house does not have experience in their successful application, it is better to turn to professionals and insulate the roof with their help. You will be able to save your nerves, money and time.

Varieties of foam insulation

There are 3 types of foam:

- Mounting room.

- Polyurethane, consisting of 2 substances.

- Liquid foam - penoizol.

Other types, on the packaging of which the scope of application is clearly indicated.

Polyurethane foam in cylinders

This is a one-piece heat insulator. Warming can be done independently.

Types of polyurethane foam:

- facade - having a large temperature range. It can withstand minus and plus temperatures;

- usual - for sealing cracks, sealing seams;

- with extra strength;

- glue foam.

A construction gun is used to apply the material.

Penoizol

Penoizol is similar to polyurethane foam, but it has a different composition. Has a low level of density, does not allow cold, sounds, moisture to pass through. It is most often used to insulate houses.

Applying the material requires equipment, dry warm weather. After the completed work, it takes 5 days for complete drying, only the top is used for finishing work.

Spray polyurethane foam

Polyurethane foam consists of 2 substances. It is the best material for building thermal insulation. For installation, balloon equipment is used. The material on the surface hardens within 10-20 minutes. The structure is closed cells, which have a minimum indicator of thermal conductivity, sound insulation, moisture penetration.

One layer of applied material is 6 cm thick. Sometimes, after complete hardening, a 2 layer is applied for strength.

Is penoizol harmful to health

After testing, Russian manufacturers were convinced of the safety of using Penoizol. There are certificates confirming this. But foam is banned in Canada, it is not used in the United States as insulation. In the UK, there are safety guidelines for the use of carbamide foam as a toxic substance. The problem lies in the concentration of formaldehyde that is released during polymerization. At a high concentration in the air, it causes allergies, tumors in the future

Therefore, it is very important to use high-quality materials and adherence to the pouring technology. In quality products and in the hands of craftsmen, the minimum content of formaldehyde is safe

Which is better - penoizol or polyurethane foam?

In order to understand which material is of the highest quality and strongest, it is necessary to compare them.

Thermal conductivity during installation of assembly insulation.

In this case, polyurethane foam takes the first place, since its coefficient is higher than that of penoizol.

Density.

Foam also wins. Unlike penoizol, it is harder and has a structure of increased density.

Resistant to liquids.

It does not allow liquid to penetrate into its structure, due to the high density of the polyurethane foam material, the first material, on the contrary, is prone to moisture and its absorption.

Resistant to fire.

Penoizol refers to materials that do not ignite at all, and the foam is susceptible to melting and the release of harmful substances.

Life time.

In this category, both materials are equal, and their optimal service life is about 50 years.

Price.

Penoizol is slightly cheaper than polyurethane foam.

Cutting off excess material for further processing.

Warming process

Do-it-yourself foam coating is quite within the power of a home craftsman with initial spray painting skills. Entry-level home appliances are usually handled by one person. When installing the battens and when working with high-performance devices with long hoses, you will need an assistant to carry them, as well as to move containers of components.

Preparing to start work

Before proceeding, it is necessary to prepare the surface for coating. Remove old wallpaper, paint and anything that might prevent the foam from sticking to the surface.

Further, with a step of 50 cm, vertical guides are attached to the wall - wooden bars or a metal profile. They are designed for fastening finishing material - plasterboard, lining or other. If there is no decorative coating, the guides are not installed and the foam is sprayed in a continuous layer.

All work on the laying of communications - electrical and pipeline - must be done before spraying. It is recommended to lay the wires in corrugated plastic or metal sleeves.

Before you start covering the wall with foam, you should also make sure that there are no air bubbles in the hoses and cylinders.

Solid wall covering

Solid wall covering

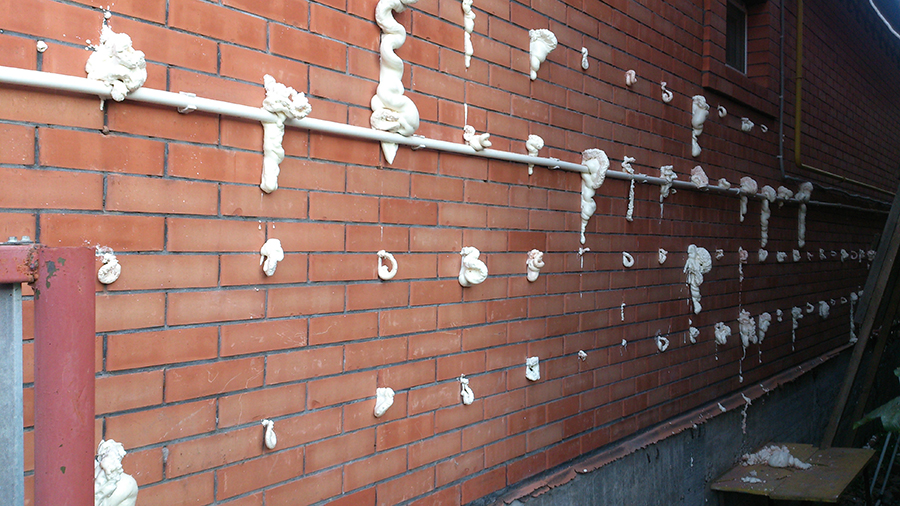

Fill

First, all joints, abutments, cracks and cavities are filled with foam. In this way, you can get rid of unwanted voids left between the structures and the finishing material in the previous stages of construction. When insulating the cavities left between the walls with polymer foam, several holes are made in them. On one side, foam is blown out, when it appears from the control holes on the opposite side, blowing is stopped.

If the lathing is installed, the places of its abutment to the wall are also passed first.

The foam is applied to the wall with even sweeping movements. Vertical surfaces are covered from bottom to top.

Joints and abutments are covered first.

Joints and abutments are covered first.

If pipelines are covered, they must be protected from corrosion before starting work by cleaning, degreasing and applying an anti-corrosion coating.

Next, the spaces between the crate are filled. Assistant transfers hoses of a high-performance unit

Next, the spaces between the crate are filled. Assistant transfers hoses of a high-performance unit

Once the foam has been applied and hardened to the exterior or interior wall, it can be plastered and painted.