Where is it applied?

The main direction of application is the reinforcement of reinforced concrete structures. The fiber is laid on those sections of the structure, which have the greatest stress.

What grounds for strengthening building structures can be distinguished:

- physical aging of the object, actual wear of the material and individual structural elements (floor slabs, columns, etc.);

- such damage to the concrete structure, which has reduced its bearing capacity;

- redevelopment of the premises, in which adjustments are made to the bearing structural units;

- situations when there is a request to increase the number of storeys in buildings;

- reinforcement of structures dictated by the emergency and its urgent resolution;

- ground movements.

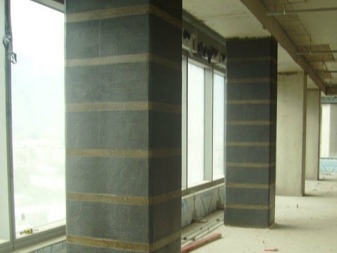

But carbon fiber interacts so well not only with reinforced concrete. The same applies to metal structures that have a modulus of strength and elasticity related to carbon fiber. You can also work with stone structures, such as pillars, brick walls of houses.

Wooden floor beams also need to be reinforced if the condition of the beam system requires intervention, if the bearing capacity is obviously reduced.

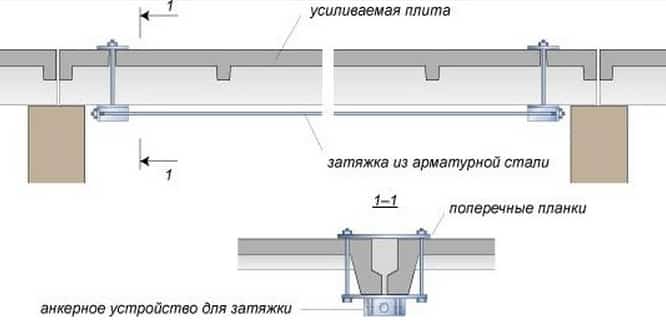

Methods for strengthening (strengthening) the main types of slabs

A variety of types of slabs are used in construction. They can be monolithic, ribbed, hollow. Depending on the degree and type of destruction, the method of strengthening the floors is also selected. Before starting work, the necessary calculations are carried out and a technical project is created.

The calculations take into account the presence and location of compressed reinforcement located along the width of the reinforcement bars. Reinforcement of slabs should be carried out by experienced workers.

Hollow core slabs

Such slabs are restored by filling technological voids. This method is much more effective than installing an additional monolith. First, clean the slab from the screed. Then a furrow is made in it, up to 100 mm wide, along the slab above the voids. At the next stage, the surfaces are blown with compressed air.

Next, a vertical reinforcing frame and a horizontal reinforcing mesh are made. Then special slats are exposed, the voids are filled with concrete.

2 ways for monolithic floors

The most common reinforcement method is to create another monolithic slab, which is superimposed on top of the old one. However, many experts believe that this method is not always effective. In some cases, it is possible to prove by calculations that the old coating, on the contrary, is loaded even more.

Strengthening the ribs is safer to carry out with corners, having previously processed them, removing fat from the surface. The size of such a corner is 100x100 or 120x120 mm. It is led under the edge of the slab. A gap is prepared in the supporting parts, up to 120 mm deep.

This is done so that there is where to put the bottom shelf of the corner. It should be directed towards the inside of the unit. In the second method of reinforcing monolithic blocks, overlap fragments are replaced.

U-shaped plates

This type can be enhanced in two ways. The first method has already been described - with the creation of a new concrete array. The second way is to use a channel. It helps redistribute loads, most of which will be on floor beams and load-bearing walls. A corset made of welded beams gives the same effect.

Ribbed slabs

For the repair of such floors, three methods have been developed:

- They use the same technology as for the repair of monolithic slabs.

- Support columns are installed.

- Truss fittings are used. It is laid along the diagonal of the slab, thereby forming 2 stiffeners, thus strengthening the slab.

Carbon fiber reinforced concrete slabs

This type of amplification is considered the most progressive. In this case, the carbon tape is glued directly to the RC plate itself.

What to do if the columns are overloaded

Many specialists who have had to deal with the restoration of slabs believe that such methods in most cases do not completely solve the problem. They can be used when reinforcing compressed columns that coincide with the projection of the working reinforcing bars of the frame. In this case, the columns are wrapped with bundles in several layers.

The harnesses are made from carbon fiber. If there are no harnesses, use strips of the same fabric. When applying a set of these measures, the bearing capacity of the entire structure increases.

The slabs of any building are constantly energized. They are acted upon by mechanical, statistical and dynamic forces. Additionally, they are destroyed by adverse environmental conditions, exposure to various chemicals. Therefore, examining their condition and determining the method of amplification is a responsible job.

Benefits of Composite Materials

Reinforcement of load-bearing structures with carbon fiber is a progressive and modern method that has a number of advantages due to the properties of the material itself:

- In order to carry out reinforcement work, you do not need to attract special equipment with a large carrying capacity, since the material is lightweight.

- The technology of external reinforcement of reinforced concrete structures using composite materials allows performing these works up to 10 times faster than using other technologies.

- The material allows you to achieve a fourfold increase in the bearing capacity of the structure compared to the same indicator when using other materials.

- Structural load does not increase

- Carbon fiber is not affected by corrosive processes and negative environmental factors

- The service life of the material can be over 75 years

- Carbon fiber is by far the least costly and most effective way to correct errors in design and preliminary construction work.

The effectiveness of this technology can hardly be overestimated. Its use helps to avoid serious operational problems in case of damage to structures as a result of natural wear and tear or mechanical stress. Strengthening will allow not only to minimize the consequences of the damage received, returning the structure to its previous bearing capacity, but even to significantly increase it. In addition, the dense and waterproof composite material will protect the concrete from moisture and prevent corrosion in the reinforcement.

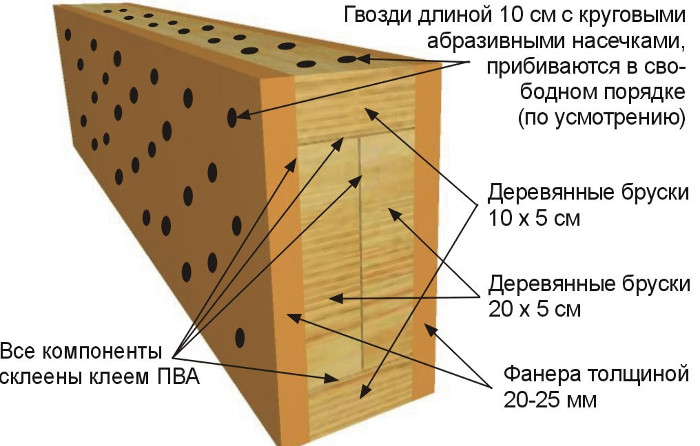

Applying overlays

The use of overlays for strengthening and repairing floor beams is used when there is damage in a certain area. The meaning of the restoration work is to install wooden plates on both sides of the problem area, which are attached to whole parts of the timber with bolts complete with nuts and washers.

Moreover, the overlays can be placed both from the sides of the beam, and from above and below. However, in any case, for repairs, it is necessary to use dried wood treated with an antiseptic or antifungal solution.

If a section of the floor beam is damaged to such an extent that practically nothing is left of it, the overlays must be installed along the entire length of the beam: from one wall to another. At the junction points, metal profiles should be used. In particular, a steel prosthesis, which is a metal strip bent under 90º or a metal rod of the corresponding diameter.

Calculation of reinforcement of reinforced concrete structures

The calculation of the reinforcement of reinforced concrete structures (walls, floors, foundations, columns) and other building systems presupposes responsible and complex work that can be performed exclusively by highly qualified professionals. It is not unambiguously recommended to carry out calculations on your own. Usually, the task is entrusted to entire departments of design organizations - it will not be difficult to find specialists within Moscow and distant regions.

What data is needed to calculate the reinforcement of reinforced concrete structures:

- The results of the examination, examinations of those building structures that are planned to be strengthened - without them, calculations cannot be carried out.

- Detailed photos of the surface are highly desirable.

- Detailed explanations of what and how to do.

Usually, calculations of the reinforcement of structures are carried out within 1-5 days, but it is desirable to clarify, since the period may depend on the amount of work, the workload of specialists and other equally important parameters.

Reinforcement of concrete with carbon fiber is a modern and effective method of increasing the bearing capacity of structures, eliminating the consequences of accidents, reconstructing old elements and strengthening new ones.

Preparation of components.

Carbon materials are supplied coiled and packed in polyethylene

It is very important not to stain them with dust, which will be very much after grinding the concrete, otherwise the carbon fiber will not be impregnated with a binder, i.e. you get a manufacturing defect

Therefore, the blank area should be covered with dense polyethylene and the required length of carbon material should be unwound along it. Cutting of carbon tapes and nets can be carried out with a clerical knife, or with metal scissors, and carbon lamellas - with an angle grinder with a cut-off wheel for metal.

As a rule, two-component adhesives are used - i.e. it is required to mix two materials in a certain proportion. It is necessary to strictly follow the manufacturer's instructions and use scales or measuring instruments when dispensing. Mixing of the compositions takes place by gradually adding one component to another with constant mixing with a low-speed drill. Dosing errors, or improper mixing of one component with another, can cause the adhesive to boil.

In recent years, most manufacturers have supplied adhesive in kits - i.e. in two buckets with already dosed volumes of components. Thus, you can simply mix the contents of one bucket into another (the bucket is specially supplied with a larger volume (half empty)) and get a ready-made adhesive composition.

Polymer-cement adhesives (for carbon nets) are supplied in bags and can be sealed with water according to the instructions, like any repair material.

It should be remembered that the adhesive has a limited lifespan - about 30-40 minutes and it decreases sharply when the temperature rises above 20 ° C, therefore the volume of the prepared adhesive should not exceed the physical capabilities of its production.

Installation of carbon fiber materials.

Depending on the type of carbon fiber material, the technology of its installation is significantly different:

Installation of carbon tapes can be carried out by "wet" or "dry" method. In both cases, a layer of adhesive is applied to the base, but with the "wet" method, the carbon tape is first impregnated with adhesive, and then rolled to the base, and in the "dry" method, the tape is rolled onto the base, and then impregnated with a layer of adhesive from above. Impregnation of carbon tape is carried out by applying a layer of adhesive to its surface and pressing it with a paint roller or spatula, ensuring that the upper layer of the binder penetrates deep into the carbon fiber, and the lower layer of the binder comes out.Carbon tapes can be stacked in several layers, but when glued to a ceiling surface, it is not recommended to carry out more than 2 layers in one shift - the material begins to "slide" under its own weight.

It should be remembered that after the adhesive has polymerized, its surface will be smooth and it will be impossible to apply a high-quality finish to it. Therefore, it is necessary to apply a layer of coarse sand on the "fresh" element of reinforcement.

When installing carbon lamellas, adhesive is applied both to the structure and to the reinforcing element. After that, the lamella is rolled to the base with a paint roller, or a spatula.

Installation of carbon mesh is carried out on a damp concrete surface. First, the first layer of the polymer-cement composition is applied. It can be applied both manually and mechanically - by shotcrete. A carbon mesh is rolled over the "fresh" layer of polymer cement with a slight indentation into the composition. It is most convenient to do this with a spatula. Then it is necessary to maintain a technological pause before the start of the setting of the composition. The setting time depends on the selected composition and ambient temperature, but the required state - polymer cement is hardly pressed with a finger. After that, a covering layer of polymer cement is applied.

Basic methods of reinforcing concrete objects

Reinforcement with carbon sheets is based on two methods:

Innovative - a method that has been mentioned more than once in the text (it is divided into "dry" and "wet" method). It consists of using a composite material (carbon fiber, carbon fiber or Kevlar) using adhesives for a strong bond. By fixing, as a rule, with cement materials.

Combined - by the very name it is clear that it combines several methods. Of these, innovative and traditional. The second method is to build up the level of strength by using materials other than carbon fiber. Such materials are less convenient in construction, since they have a relatively higher weight. Thus, the combined method is to use carbon cloth and other reinforcing materials. This method is usually used in areas of increased stress.

What to look out for when creating a reinforcement project:

First of all, attention should be paid to the results of the analysis and examination of the structure. Such an analysis is carried out in the case of visible defects, with a decrease in the level of strength.

What is the duration of the building

Old buildings are more susceptible to destructive processes.

It is necessary to collect information about the soil on which the construction of the facility is planned

It is important to indicate whether there are water bodies that could create flooding, other existing natural features (aggressive impact of external factors)

Information about emergency situations, positions. It is necessary to indicate the existing defects.

The actual characteristics of all materials used (concrete, steel, etc.)

etc.).

Information about previously reinforced parts.

Data on possible magnifying loads.

Carbon fiber reinforcement

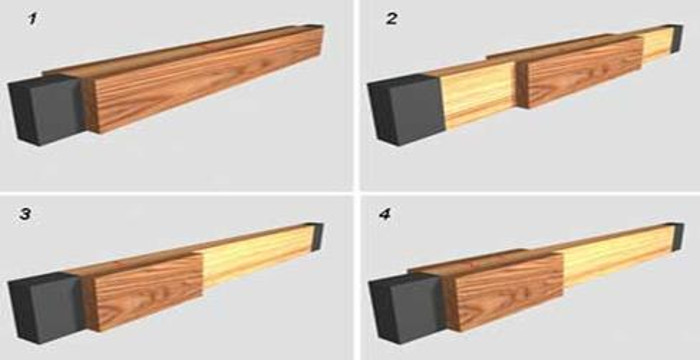

Carbon fiber reinforcement is a method of strengthening wooden floor beams, which is not entirely traditional, but is used in cases where the room has a small area or for other reasons when the above methods cannot be applied.

Carbon fiber is an innovative material that perfectly copes with any mechanical stress, including bending stress.

Carbon fiber elements are produced in various modifications, including plates, sheets, threads, ribbons or simply in the form of fabrics.The very process of reinforcing beams with carbon fiber consists in applying layers with glue (epoxy resin) on top of each other until sufficient rigidity of the beam is obtained.

After the glue hardens, the layers are a monolithic coating, which is not inferior to metal in its characteristics.

We apply modern technologies

Recently, there have been experimental attempts to replace metal reinforcement when reinforcing the overlap with carbon fiber or carbon fiber reinforced plastics. Indeed, materials, mainly tows and fabrics based on carbon fiber or "Kevlar" used in the manufacture of body armor, have even higher tensile strength than traditional metal reinforcement.

Where is it better to apply

The use of such materials must be subject to certain requirements:

- the surface of the building element must be perfectly (to a fraction of a millimeter) leveled;

- the glue must be selected so that it creates the necessary adhesion (adhesion) between the surfaces to be glued and is chemically neutral to their structure;

- ensuring reliable protection of the structure during subsequent operation (materials such as carbon fiber are difficult to tear, but easy to cut).

Installing Carbon Fiber to Reinforce Concrete

Strengthening of structures is a necessary stage for the construction of a durable and high-quality building. The main purpose of using amplifiers is to increase the strength of the bearing characteristics. Such technologies are necessary for the construction and restoration of structures after exposure to external stimuli.

In particular, in case of local damage, it makes no sense to dismantle the structure and erect a new one. It is much easier to fix the situation by knowing how to use carbon cloth.

In the photo above, you can visually reconstruct the complete picture of all of the above. Installing carbon fiber is easy enough to even do it yourself. The main thing is to know the installation methods and basic principles before performing the installation:

- Before installation work, it is necessary to level the surface to be repaired, then remove the upper layers of dust from it.

- Remove all visible dents, cracks, or other defects on the work plane. Covering them tightly with cement compounds.

- Align, smooth out all protruding irregularities.

- It is recommended to draw a line for neat and easy adhesion.

There are two installation methods

- "Dry method". Materials with adhesives are used as an adhesive. The first step is to mix binders for installation. The carbon fiber is cut to the required size. The adhesive is applied to the surface to be repaired. The cut fabric is glued to the adhesive composition, a covering layer of the polymer-cement composition is applied on top. Sand if desired for better grip.

- The "wet method" is somewhat different from the first. After mixing the binders for installation, the fiber is cut in accordance with the required dimensions and shapes. The adhesive is applied to the surface to be repaired. In addition, it impregnates the canvas from both sides. After that, the canvas is carefully glued, sprinkled with sand. The final stage is the application of a protective coating with a polymer-cement composition. Carry out final finishing.

Reinforcement of structures with carbon fiber is used to improve the strength of buildings constructed from different materials. Suitable for strengthening concrete, reinforced concrete buildings, structures made of wood, metal, stone materials.

The strengthening method can be used to strengthen structures of any complexity and geometry (arches, columns, load-bearing walls, ceiling openings, etc.).

How to understand in which case the installation of a reinforcing sheet is necessary? There are several main reasons why reinforcement of structures is desirable:

- Miscalculations, inaccuracies in the original design of the building.

- The soil under the constructed object turned out to be prone to mobility.

- The building was erected a long time ago, the first signs of wear of materials and individual parts appeared. Early wear is possible in case of aggressive external factors.

- Redevelopment, which entails changes in load-bearing walls and other fundamental structures.

- An increase in the level of safety is required to avoid unpleasant outcomes of possible accidents.

- The supporting structure of the room was significantly damaged. In this case, it is necessary to increase the level of strength of this element.

- The erection of additional floors and their rebuilding require an increase in the reliability of the lower part of the building.

- For preventive measures during the reconstruction of an old object. The use of carbon fiber reinforcement as the introduction of a new technological method.

- Any accidental damage

Stages of work and types of reinforcing elements

The general principle of reinforcement is the same everywhere - carbon fiber is applied to those parts of the structure where the greatest stress is present. Most often, this is the center of the structure span along the lower edge. And to solve specific problems, you will need to decide which type of reinforcing elements is best suited - ribbons, lamellas or mesh.

Tapes and slats

Reinforcement of building structures with carbon fiber strips and lamellas occurs in a similar way. For this, the same or similar adhesives are used, and the installation is carried out according to general principles. This is why they are often used together.

The use of carbon mesh in almost one hundred percent of cases excludes the possibility of using tape and lamellas, since its installation is associated with the performance of "wet" work.

How is the work carried out?

Initially, the main thing that needs to be done is to determine the very sections of the structure that are experiencing the greatest loads, and, therefore, need reinforcement. After that, the structure is marked out and preparatory work begins, during which the areas on which the composite will be glued are thoroughly cleaned of finish, dirt, etc. Cleaning takes place using special grinding equipment.

Grinding

How well the concrete surface was prepared for gluing the composite reinforcement directly affects its effectiveness, since the joint work of the concrete and the composite in terms of load distribution depends on it. Grinding must be carried out in compliance with the technology. The ingress of moisture on the surface to be sanded must be completely excluded, and dust and dirt should be completely removed after sanding.

Components

After the surface of the reinforced concrete structure has been prepared, it is the turn of the preparation of the reinforcing components. Carbon fiber is supplied rolled up in its original packaging. In order to start working with the material, prepare for this a special area on the construction site, covered with polyethylene. This is done in order to exclude the ingress of concrete dust on the material, as this will lead to marriage. You can cut the carbon cloth using an ordinary construction knife, metal scissors. Lamella cutting can be done with an angle grinder.

For stickers, two-component adhesives are most often used. It is not difficult to purchase the ingredients, but you should strictly follow the manufacturer's instructions when mixing them, and accurately calculate the dosage using the scales. This should not be a problem, since many modern suppliers of building adhesives offer them already packed in special buckets.Add the adhesive gradually to prevent boiling during the mixing process.

Mounting

The installation of the carbon tape is done "dry" or "wet". The difference between them is that in the first case, the tape is first applied to the base, after which it is impregnated with an adhesive, and in the second case, impregnation occurs first. The composition is carefully applied to the surface of the reinforcing component so that it penetrates deep into the material and comes out from the side of the concrete base. Lamellas are mounted in a similar way, only the binder in this case is applied both to the base and to the element itself. And the carbon mesh is always mounted on a slightly damp concrete base surface.

Types of slabs used in construction

Reinforced concrete floor slabs are mainly of the following types:

- prefabricated, which are used in coatings and ceilings of residential, industrial and public buildings, laid on reinforced concrete frame elements - beams, girders, trusses, as well as on brick walls; their types:

- ribbed, up to 12000 mm long - with massive longitudinal trapezoidal shelves, in which the main working reinforcement is located, and thin (up to 50 mm thick) shelves reinforced with meshes, in addition, such plates have small transverse stiffeners on the bottom side, located with the same pitch ...

- hollow, with a length of 3000 to 6000 mm - rectangular cross-section with extended longitudinal channels (up to 6 pcs.), while the voids can be either ideally round or oval in shape.

- a monolithic floor in most cases is made in the form of a so-called "beam cage", constituting a single whole with the beams on which it rests. The longitudinal and transverse beams at the crossing points are also monolithically connected and connected by reinforcement with pre-fabricated columns with a given span and pitch. In some cases, prefabricated building frame elements can be used to support monolithic floor slabs.

- In ancient buildings of the late 19th - early 20th centuries, floors with load-bearing I-beams (more often - with ordinary rails) are found, the space between which is filled with concrete on broken brick. In order for these beams not to "move apart" during concreting, they were pulled together by metal strips by forge welding.

Protective coatings

The epoxy resin adhesive is flammable. Under ultraviolet exposure, it also risks becoming very fragile. Therefore, it is necessary to use such compositions with the provided fire protection of objects that are to be strengthened.

In general, the strengthening of a structure with carbon fiber is a progressive, from many points of view, an economical way to strengthen the structure and its elements. Composites used for reinforcement are much lighter and much thinner than more conventional materials. In addition, external reinforcement is a versatile modern technique. It is used both at the stage of building construction and during repairs, during restoration work, that is, in order to strengthen the structure, in many cases it is not even necessary to suspend its operation.

Carbon fiber reinforces elements of residential and industrial buildings, architectural structures, transport and hydraulic facilities, and even nuclear facilities.

But those who believe that the use of new materials and technologies is always more expensive than traditional solutions are a priori mistaken in their calculations. The strength of the structures increases significantly, the building does not cease to be used during the repair (and this could cause financial losses of a more serious size), such repairs are very fast in time.

You can learn how to reinforce boards with carbon fiber in the video below.

Beginning of work

Each such case is carefully studied by specialists.Diagnostics of the condition of load-bearing walls and.

The parameters of the slab are necessarily studied: its width, cross-sectional value and span. After removing the protective layer of concrete, a working reinforcement is installed. Concrete condition analysis is carried out. Examine the existing defects.

Before starting work, it is necessary to carry out preparatory measures, which are as follows:

- Under the emergency overlap, supports are brought in, which are large diameter logs and spacers made of metal pipes. This is necessary to reduce and redistribute the load on the slabs.

- To clearly see the whole picture of damage, layers of whitewash, plaster and paint are removed. All crumbling areas of the concrete layer are cleaned. The metal rods are cleaned from traces of rust. Then the reinforcement is treated with a converter for corrosion.

- Equipment is removed from the top of the slab, the floor is dismantled.

- Dust is removed from the places where a new layer of concrete will be laid, and the areas themselves are degreased.

We identify the violation

The main signs of destruction are cracks and delamination of concrete elements located in the lower part of the slab section. Floor defects are accompanied by the appearance of cracks and delamination of the screed. Problems can be caused by deflections and sagging of structures, the appearance of cracks in the central part of structures and in places of supports. An alarming call may be the appearance of areas with darkening or, conversely, lightening of the surface.

Based on the results of the survey, a tactic for solving the problem is developed. First of all, the bearing capacity of the structure is restored.

For this, a method of additional amplification is selected. All these efforts will be ineffective if the causes that caused the destruction of the slab are not eliminated.

Rebuilding the ribbed platform

If adjacent ribbed slabs are destroyed, all defects in them will be the same. When reinforced, the adjacent corners and the formwork, made in the form of a board pressed from below, create a tray. It is filled with fresh fine-grained concrete, then vibration treatment is carried out using a needle vibrator head with a flexible shaft.

It is better to use “expanding” non-shrinking cement to strengthen the floors. The corners will later become an additional part of the reinforcement. It is also required to carry out treatment with anti-corrosion protection and staining with red lead.

We restore old floors

Structures made of I-beams and concrete, which is based on broken brick, rarely have to be repaired. The reason for this is a large margin of safety. During the construction of floors of this type, strength is laid that is 3 times higher than the required one.

Damage to such an overlap can only occur after prolonged penetration of water and the resulting corrosion of metal parts. Floor cracks become visible damage to such slabs.

Transverse cracks pose no threat. Damaged areas during restoration are removed and replaced with monolithic reinforced concrete.

Modern technologies

Now more and more attempts are being made to replace metal rods with carbon fiber. For this, harnesses and plastic fabric are made. These new materials are superior in strength to metal reinforcement. If you describe the properties of such fabrics, they are identical to Kevlar, which is used for the production of body armor.