What it is?

Sealing washers belong to the fasteners, the use of which can significantly strengthen and make the bond between the parts even stronger.

In addition to sealing the attachment point, the product contributes to:

- reducing damage to fasteners;

- preventing self-unscrewing of elements;

- an increase in the area of the supporting surface.

A washer is made in accordance with regulatory documents, and this is GOST 19752-84 “Sealing gaskets. Design. Technical features". According to him, the product is characterized by:

- nominal and inner diameter;

- outer diameter;

- thick.

Sealing washers, which guarantee high tightness, are widely used in various industries:

- chemical;

- oil and gas production;

- engineering;

- construction.

The assortment of sealing washers is varied. This makes it possible to select a product for a specific type of work, for example:

- for fixing polycarbonate;

- forest layer;

- fuel systems, etc.

What are they?

There is a wide selection and assortment of washers with gaskets from various manufacturers on the fastener market today. This is due to the fact that recently new building materials have been appearing more and more often, which are made from modern raw materials, and for each of them you can choose a special sealing washer.

There are several basic classifications of washers. For example, they are divided according to the material of manufacture.

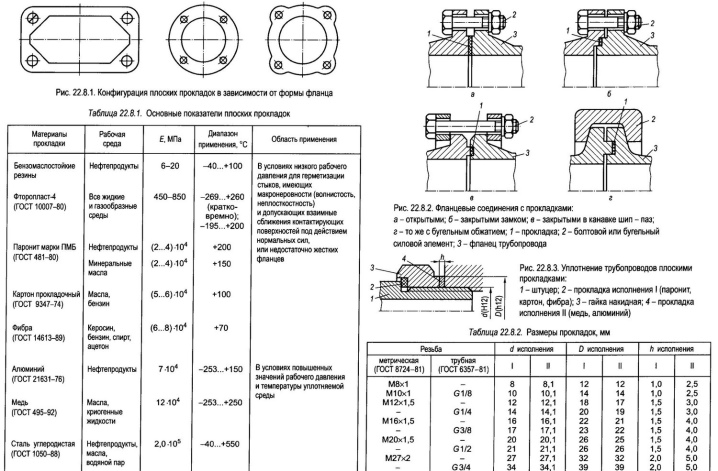

Rubber. Basically, such a model is used in the process of installing roofing structures and facade elements to a wooden or metal crate. Also, a rubberized product is often used when laying and connecting a pipeline.

Any type of installation and construction work is accompanied by the use of O-rings. Currently, manufacturers use another material for the manufacture of sealing washers - polycarbonate. Such a product is called a thermal washer.

In addition to the material, the products differ in size. Today, the greatest demand is for seals in sizes M6, M8, M10, M4, M12. For those who have doubts about the exact size of the product, a set, which includes products of different sizes, is ideal.

How are they used?

Earlier we have already written that O-rings are widely and often used in various types of work to create a tighter and more sealed joint. They are used in the process of attaching parts to a metal, stone, brick, plasterboard base.

There is no need to list where and when to use the washer. An O-ring is an essential part of absolutely any fastener. Construction, repair work cannot be fully and correctly performed if they were carried out without an O-ring. The main thing is to choose the right product. In this case, you need to focus on the material from which the washer is made and on its size.

How to restore copper sealing washers, see below.

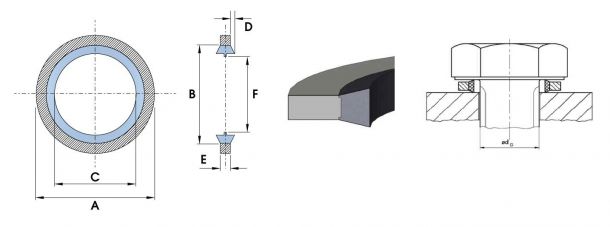

USIT-Ring rubber-to-metal seals

USIT-Ring self-centering rubber-to-metal seals are a combination of a metal washer and a vulcanized rubber sealing lip. USIT-Rings are used to seal a variety of hydraulic connections as an effective replacement for soft metal rings. These O-rings are suitable for use in water, air, mineral oils, as well as HFA, HFB and VDMA 24320 fluids. types of USIT-Rings have significant technical and economic advantages,the main ones are:

- Reliable seal for high and low pressure.

- Stable over a wide temperature range.

- The metal ring protects against over-compression and subsidence.

- Resistant to mineral oils (DIN51524), hydraulic fluid HFAm HFB, HFC (VDMA24320).

- Easy to assemble, allows for re-installation.

Technical data: The maximum pressure against the O-ring depends on the size and version and ranges from 25 to 70 MPa. Operating temperature: from -30 ° C to + 200 ° C. Media: mineral oils, synthetic oils, water, water oil emulsions, gases.

|

Order name |

Ring size Tolerances, mm: -> |

Min burst pressure (bar) |

||||||

|---|---|---|---|---|---|---|---|---|

|

A +0,13/-0 |

B +0,1/-0,1 |

C +0,1/-0,1 |

D +0,25/-0 |

E +0,1/-0,1 |

F +0/-0,2 |

|||

| USIT-R1 / 8 ″ | 1/8″ | 15,88 | 11,84 | 10,37 | 0,25 | 2,1 | 8,56 | 1500 |

| USIT-R1 / 4 ″ | 1/4″ | 20,57 | 15,21 | 13,74 | 0,25 | 2,1 | 11,45 | 1550 |

| USIT-R3 / 8 ″ | 3/8″ | 23,8 | 18,75 | 17,28 | 0,25 | 2,1 | 14,96 | 1260 |

| USIT-R1 / 2 ″ | 1/2″ | 28,58 | 23,01 | 21,54 | 0,25 | 2,1 | 18,64 | 1150 |

| USIT-R5 / 8 ″ | 5/8″ | 31,75 | 24,97 | 23,49 | 0,25 | 2,5 | 20,60 | 1250 |

| USIT-R3 / 4 ″ | 3/4″ | 34,93 | 28,53 | 27,05 | 0,25 | 2,1 | 24,13 | 1060 |

| USIT-R 1 ″ | 1″ | 42,83 | 33,89 | 33,89 | 0,25 | 2,5 | 30,3 | 870 |

| USIT-R1.1 / 4 ″ | 1.1/4″ | 52,38 | 45,93 | 42,93 | 0,25 | 2,5 | 38,96 | 690 |

| USIT-R1.1 / 2 ″ | 1.1/2″ | 58,60 | 51,39 | 48,44 | 0,25 | 2,5 | 44,86 | 690 |

| USIT-R 2 ″ | 2″ | 73,03 | 63,63 | 60,58 | 0,25 | 2,5 | 56,67 | 700 |

| USIT-M4 | M4 | 7 | 5,4 | 4,5 | 0,3 | 1 | 3,4 | 1770 |

| USIT-M6 | M6 | 11 | 8 | 6,6 | 0,3 | 1 | 4,7 | 1680 |

| USIT-M8 | M8 | 14 | 10,4 | 8,7 | 0,3 | 1 | 6,4 | 1550 |

| USIT-M10 | M10 | 16 | 12,4 | 10,7 | 0,4 | 1,5 | 8,56 | 1350 |

| USIT-M12 | M12 | 18 | 14,4 | 12,7 | 0,4 | 1,5 | 9,73 | 1250 |

| USIT-M14 | M14 | 22 | 16,4 | 14,7 | 0,4 | 1,5 | 11,38 | 1510 |

| USIT-M16 | М16 | 24 | 18,4 | 16,7 | 0,4 | 1,5 | 13,41 | 1400 |

| USIT-M18 | M18 | 26 | 20,44 | 18,7 | 0,4 | 1,5 | 14,76 | 1275 |

| USIT-M20 | M20 | 28 | 22,5 | 20,7 | 0,4 | 1,5 | 16,76 | 1150 |

| USIT-M22 | M22 | 30 | 24,4 | 22,7 | 0,4 | 2 | 18,74 | 1100 |

| USIT-M24 | M24 | 32 | 26,4 | 24,7 | 0,4 | 2 | 20,11 | 1050 |

| USIT-M26 | M26 | 35 | 28,4 | 26,7 | 0,4 | 2 | 22,3 | 1050 |

| USIT-M27 | M27 | 36 | 29,4 | 27,7 | 0,4 | 2 | 23,3 | 1060 |

| USIT-M30 | M30 | 39 | 32,7 | 31 | 0,4 | 2 | 25,7 | 860 |

| USIT-M33 | M33 | 42 | 35,4 | 33,7 | 0,4 | 2 | 28,7 | 820 |

| USIT-M36 | M36 | 46 | 38,4 | 36,7 | 0,4 | 2 | 31,1 | 760 |

| USIT-M42 | M42 | 53 | 44,4 | 42,7 | 0,4 | 2 | 36,5 | 690 |