Varieties of plastic films

Polyethylene film is made in accordance with GOST 10354-82, shrink cloth - in accordance with GOST 25951-83.

Polyethylene films are produced in different versions for the needs of certain areas where they are used.

By composition

According to the composition of raw materials, polyethylene film can be from:

- HDPE - low pressure polyethylene;

- LDPE - high pressure polyethylene.

Read the difference between these types here.

By the number of layers, PE films can be:

- single-layer;

- multi-layered.

Various additives are added to the polyethylene film to improve its properties. According to the presence of additional "ingredients" in the composition, the canvas can be:

- Normal unstabilized - no additives;

- Light stabilized - the added light stabilizer protects the material from direct sunlight, so it lasts several times longer;

- Hydrophilic (antifog) - additives contribute to the rapid drainage of condensate and rain drops from polyethylene, which prevents the formation of large drops that cause burns in plants and reduce its light transmission;

- With the addition of antistatic agents, they repel dirt and dust particles, which allows the film to remain clean and transparent all season.

Depending on the production technology and composition, polyethylene films can be of different modifications:

- foamed;

- reinforced;

- black, black and white, color;

- from primary or secondary raw materials;

- heat shrinkable;

- technical;

- stretch films, etc.

By release form

Polyethylene film is produced in the following forms:

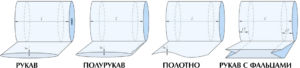

- canvas - a layer of film, without seams and folds;

- a sleeve is a polyethylene pipe wound into a roll. It can be a simple version of a sleeve or a sleeve with folds - folds on the sides;

- a half-sleeve is a sleeve cut on one side.

What is the difference between a canvas, a sleeve and a half-sleeve

What is the difference between a canvas, a sleeve and a half-sleeve

Sizes of plastic films

The standard thickness of polyethylene films is from 20 to 200 microns. Depending on the purpose of the material, the density of the web is selected.

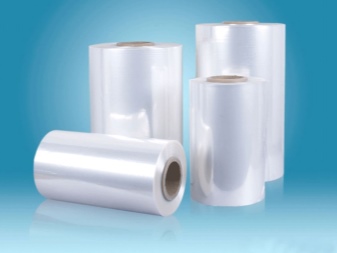

Polyethylene film is sold in rolls with a winding of 80-200 linear meters. Most often, products are sold in a 1.5 m wide sleeve, 3 m in a spread and 100 running meters in a winding. There are also widths of 6, 10 and 12 meters. In hardware stores, they sell polyethylene sleeves at retail in lengths of 1-10 meters. There are narrower or wider fabrics and sleeves, but these sizes are made by manufacturers to order.

What it is?

It's hard to imagine an industry today that doesn't use polymers. Polyethylene turned out to be one of the most convenient, therefore it quickly and firmly entered everyday life. It also transfers its unusual properties to shrink film - the most popular packaging option.

The chemical industry is on a special account, therefore the production of products and materials from polyethylene is regulated by separate norms. The manufacture, use and storage of shrink film is described in the document GOST 25951-83. For example, the composition, temperature characteristics, properties of certified materials, the packaging method of the film itself, and even storage features are described.

The composition of polyethylene affects its density, transparency and strength. The name "shrink" film was given due to its specific temperature properties. For example, it remains stable at + 30º-50º С - it does not decompose or deform. It is to this level that the air is sometimes heated in the hot season.If the film is exposed to a high temperature (shrinkage in industrial conditions is achieved by heating + 120º-150º С), then the material begins to change its shape. It becomes plastic and shrinks or shrinks. With this effect, polyethylene repeats the contours of objects, wrapping them like a dense knitted fabric, and not in contact with these very objects. Thanks to this effect, it is possible to tightly pack goods of various shapes and characteristics.

The packaging has unique properties: it is sealed, resistant to mechanical damage, forms a dense and durable frame, inside which, if necessary, you can securely fix such items as cans, bottles or bags. Through transparent polyethylene, it is easy to see the contents without opening the protective container, to see the marking, color, condition.

The only drawback - long-term decomposition - is compensated by the fact that polyethylene is recycled and reused in production.

Application

Packaging film is a material that specialists from various fields of professional activity cannot do without.

However, if you decide to use film, it is very important to become familiar with the distinctive characteristics of the material, with the properties of the film and with the existing varieties. At the same time, it is especially important to carefully approach the choice of packaging film so that the material performs its functions efficiently.

Packaging film is used in a wide variety of areas of human life.

Trips. With the help of the material, you can pack luggage, suitcases, bags (in this regard, the film is also often called luggage). This is true in the process of moving or traveling. Your luggage will not get dirty, scratched, or open.

Shipping. Transportation of things and furniture is impossible without packing material. It will protect your belongings from mechanical damage, as well as from the effects of various negative environmental influences.

Food industry. Packaging material is very often used in the food industry (both in industry and at home). The material can be used for packaging frozen and fresh food

At the same time, it is important for these purposes to choose a special food variety and in no case use a technical type

SPA. The material is actively used in beauty salons and spas for wrapping and various kinds of cosmetic procedures.

The following video talks about stretch wrap.

Selection Tips

The choice of packaging film is an important and responsible task

In the course of its implementation, it is important to take into account several key characteristics and parameters.

Appointment. Analyze in advance for what purposes you will use the material. The point is that different types of material are used for different purposes. Accordingly, you need to be as careful as possible.

Price. Choose a material that matches the best price-performance ratio. This means that you should not choose the cheapest or most expensive material. It is better to give preference to goods from the middle price segment.

Manufacturer and place of purchase. In this regard, you should only trust trusted companies and bona fide sellers who are respected among the professional community. Thus, you will be able to purchase a film that will comply with generally accepted regulations and standards.

Reviews. It is recommended to study consumer reviews in advance and make sure that all the characteristics that were declared by the manufacturer correspond to the real state of affairs.

Features and characteristics

Packaging film is a material that is produced in accordance with the requirements of GOST.At its core, it is one of the cheapest, but at the same time safe and effective materials for packaging. A number of factors can be attributed to the distinctive characteristics of packaging films. Let's consider them in more detail:

- strength and reliability (meaning that the packaging qualitatively protects any product from the negative influences of the external environment);

- physical protection of the product (depending on your wishes, needs, as well as the fragility of the product, the film can be wrapped around one or another product 1 or more times);

- the possibility of heat shrinkage (this means that, under the influence of temperatures, the material can increase and decrease in size, acquiring the necessary shape for a particular product);

- ensures the tightness of the package.

When packing a product in a film specially designed for this purpose, it is important to keep in mind that the product automatically creates a so-called barrier layer. Material thickness can vary from 15 to 125 microns

Depending on this indicator, it is possible to pack bulk substances, food products or other goods into the film. As for the width, its maximum indicator is 1.3 m.

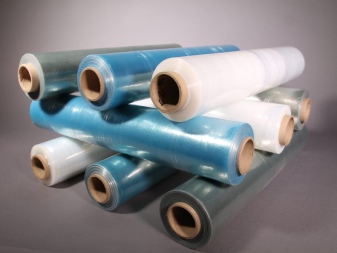

Species overview

A wide variety of packaging films can be found on the market today. It happens:

- in rolls;

- transparent;

- barrier;

- wrapping;

- for winding;

- waterproofing;

- metallized;

- polyethylene;

- water soluble;

- black;

- for vacuum packaging;

- polypropylene;

- industrial.

The product can be thick or thin. Let's consider several main categories of packaging films, as well as get acquainted with the main characteristics of these types.

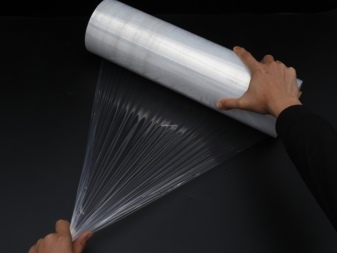

Stretch film

By external mind stretch film (or stretch film) is a transparent material for packaging. Its distinguishing feature is the ability to stretch (or prestretch). This means that the film can stretch and contract back as needed. And also this material is self-adhesive, accordingly, you can fix the free edges of the wrapper without using additional accessories (for example, without tape or glue).

Among other things, the material is very elastic and also has high protective properties. Thanks to this, you can be sure that the product will not be affected by such negative factors as excessive moisture, dust, dirt. With the help of stretch film, piece goods are most often packed, and the cargo is also fastened to the pallet. At the same time, the packaging process can be carried out both manually and automatically (by means of special tables and pallet wrappers).

Air bubble

Air bubble wrap Is a polymer material that consists of several layers. The voids between the layers are filled with air. It should be noted right away that the film does not stretch, therefore it is used for manual packaging of fragile products. As for the distinctive features of the material, they are as follows:

- shock-absorbing characteristics (this is due to the fact that the air gap between the layers of the film significantly reduces the load of mechanical damage on the material itself);

- strength and reliability (the raw material for the production of the film is polyethylene, which is very resistant to tears, stretching, punctures);

- thermal insulation properties (thanks to this, the product is protected from the influence of unfavorable temperatures).

On the market there is air bubble film of the most different density: from 80 to 150 g / m 2.

Food

Already by the name of this material, it can be concluded that it is used for packaging food products. The distinctive characteristics include a small thickness and a high level of pre-stretch, as well as elasticity and strength. The cling film contains only safe elements, therefore, it can be used for any purpose

It is also important to note the following characteristics of the material:

- transparent and glossy surface (thanks to this you can clearly and clearly see the products inside the package);

- protective properties (the film does not allow moisture to pass through and retains odors, which is necessary for the safe storage of food);

- resistance to certain substances (for example, to fats or salts);

- resistance to low temperatures (accordingly, in the process of freezing and defrosting products, the film does not break down).

Other

In addition to the above, there are other types of packaging films. For example, types such as coextrusive, laminated and multilayer films are popular.

As for the coextrusive material, it is made by forcing polymers and forming a large number of layers. In the course of production, only environmentally friendly and safe substances are used. At the same time, the process of making the film itself does not require large financial costs. It is also worth noting the easy process of removing the material, which is one of the essential advantages of this type of film.

To create a laminated film, it is necessary to carefully glue several layers of various materials (and each manufacturer can choose their number at his discretion). Laminate can be used for interlayer printing or foil. The multilayer material is used for packaging goods such as dairy products, frozen foods, fertilizers, feed.