Mode of application

As with many other types, when working with glue 88, you need to carefully prepare the surfaces to be peeled, i.e. they must be cleaned of dirt and dust and degreased well.

Generally there are two ways when working with 88 glue: "cold" and "hot". With the cold method, it is necessary to apply a thin layer of glue on the surfaces to be glued, hold for 10-15 minutes. After that, you should once again apply a thin layer on the surface, hold for about 5 minutes and press them strongly together for a couple of minutes. Strength is critical, not duration of pressure. The maximum strength of the product to be pecked is reached after 24 hours. With the hot method, the glue is applied in a thin layer to the material and dries for half an hour. After that, the surfaces of the parts are heated to 80–90 ° C and pressed tightly together for several minutes. Maximum strength with this method is achieved after 3 hours. At home, the "hot" method is more difficult, so it is most often used in industries. And if you use 88 glue in the manufacture of models, then the hot method can only spoil the parts to be glued.

Properties

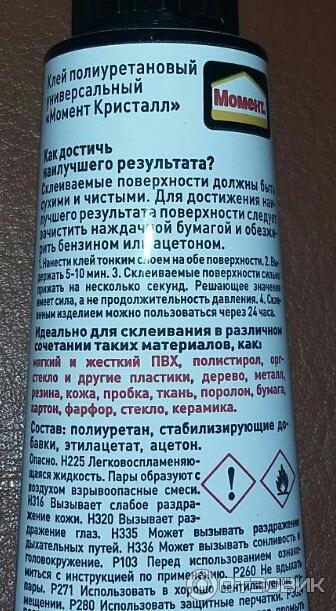

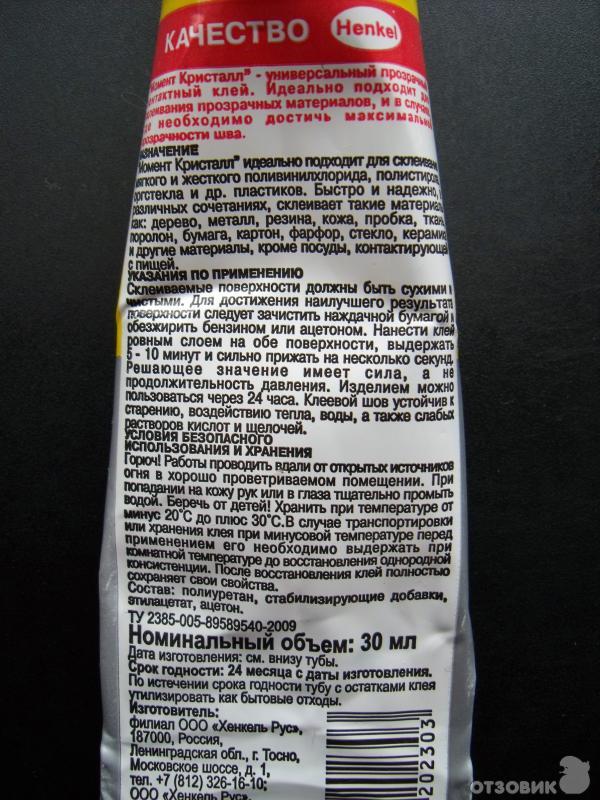

Polyurethane glue is capable of gluing hard and soft materials from polystyrene, polyvinyl chloride and other types of synthetic polymer products. It can also be used for bonding wood materials, natural plant cork, acrylic resin organic glass, metal, ceramic and porcelain, rubber, paper and cardboard.

Main technical and operational characteristics of the product:

- the product is a transparent gel that remains colorless even after hardening;

- suitable for gluing various combinations of materials;

- is a water-resistant composition, therefore it can be used for products made of natural and synthetic rubber (rubber);

- not subject to aggressive alkaline and acidic effects;

- has the ability to crystallize during solidification, provides perfect adhesion to surfaces;

- possesses high strength properties, after processing does not leave dirty marks and stains;

- processed seams are not affected by high and low temperatures (from -40 to +70 degrees);

- you do not need to use solvents to remove excess adhesive - they can be removed mechanically or by rolling them with your fingers.

A feature of the glue is the restoration of its required properties after freezing. It is able to regain its original consistency at room temperature.

The Moment Crystal universal gel can dry out, crystallize prematurely and become unusable only if the package is not sealed. Storage of the product provides for an average temperature of -20 to +30 degrees for 24 months.

There are two main limitations in the use of glue:

- it cannot be used for gluing utensils used for food;

- it is not suitable for repairing PP, PE and Teflon products.

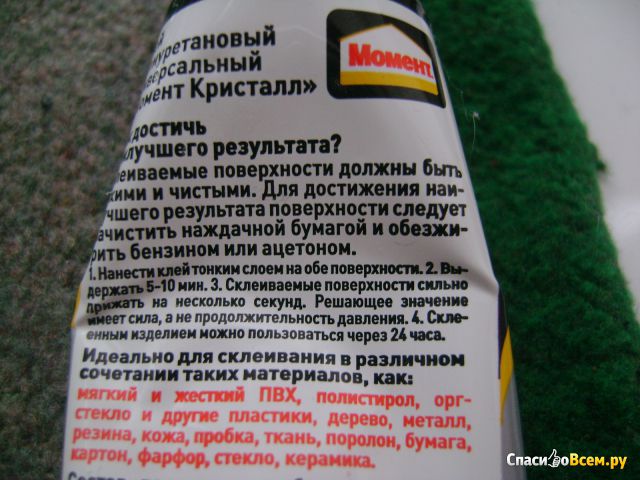

Instructions for use

The adhesive, having maximum adhesion, sets instantly, because the composition is recognized as the highest quality and most durable among analogues. However, before use, as stated in the product description, the surfaces to be joined must be prepared. If it is metal, it should be cleaned of scale, rust, dust and dirt. After that, it is advisable to grind the coating with any abrasive and wipe it off, removing small particles. Then you can degrease the material with acetone or gasoline.

The composition is applied in an even layer only on dry clean surfaces and left until a thin but noticeable film forms on them (for 20-25 minutes). With high porosity of the processed products, the glue can be absorbed well, so it will have to be applied again.

Before bonding the coatings, make sure that the transparent film is in the correct consistency. If it does not stick to your hands, then you can connect the sections. This must be done quickly, with strong pressure - the strength of the seam depends on it. The closure should be uniform over the entire surface area so that air bubbles do not form.

For maximum strength, it is not the duration of the pressure that is important, but its strength, therefore, the gluing must be done as carefully as possible. It is worth pressing the surface for 5-7 seconds. After that, it will no longer be possible to make adjustments. To create optimal uniform pressure during gluing, professional craftsmen recommend using an ordinary rolling pin or bottle. You can use the product after repair a day later, when the polymerization of the adhesive is completely completed.

Usually, the glue does not stain, but sometimes it is necessary to remove residues that have accidentally fallen on the surface. This must be done quickly. Fresh dirt can be removed with a clean finger. Dried stains can be removed with gasoline or acetone (with the exception of fabrics that have to be taken to dry cleaning).

Safety measures

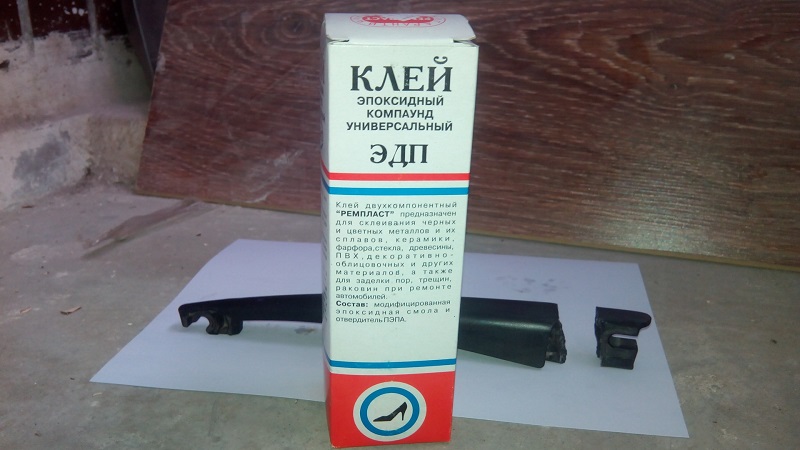

When working with a line of epoxy adhesives, you should not only carefully adhere to the attached instructions, but also observe safety measures. Given the harmfulness of the substance, it is imperative to adhere to these rules. They are as follows:

- Do not allow resin to come into contact with unprotected skin. In addition to serious allergic reactions, the contact of glue on the skin, given the speed of polymerization, brings painful sensations. If the resin comes into contact with the skin, wash it off immediately with soapy water.

- For protection from dust and harmful toxic fumes, use a respirator mask with a charcoal filter.

- All work with glue is carried out in a well-ventilated area.

- Use rubber gloves when mixing resin with hardener.

- Do not mix resinous substances in a container that will later be used for food or food storage.

- If the paste or glue is difficult to squeeze out of the tube, the tube can be slightly warmed up under hot running water. Do not use a water bath, microwave oven or ovens for this purpose, otherwise the resin will boil and become unusable.

The main features of the substance

Fast curing epoxy adhesives cure quickly after adding a hardener to the base composition. The hardened mass has the following qualities:

- frost resistance (the mass can easily withstand temperatures up to -20⁰С);

- heat resistance (temperature limit at which the glue keeps gluing: up to + 250⁰С);

- good ductility and elasticity, which provides a high level of bond strength;

- resistance to aggressive media (acids, alkalis, oils, petroleum products, household chemicals);

- low shrinkage;

- water-repellent properties and high waterproofing performance;

- excellent interaction with almost all materials.

But you should be aware of some of the disadvantages of such glue. For example, not all surfaces lend themselves to gluing - epoxy cannot connect Teflon, silicone and polyethylene. Take into account the accelerated polymerization time, so if there are blemishes during gluing, it will be very difficult to remove them later.

Adhesive does not work with all materials

Adhesive does not work with all materials

Where is used

Due to its high technical qualities, versatility, epoxy glue is actively used in various branches of modern industry. Namely:

- in construction, to connect reinforced concrete structures, panels, cracks and potholes in concrete are filled with glue, with its help, tiles are laid;

- shipbuilding uses an adhesive substance for the installation and assembly of ship parts made of fiberglass, plastic and metal, the substance is also used to improve the waterproofing qualities of materials;

- aviation (design), used for gluing various parts, manufacturing and installing batteries, additional fixation for thermal protection;

- mechanical engineering uses epoxy glue for mounting accessories, fastening brake pads and various parts when assembling machines, for carrying out various repairs.

Varieties of glue

Experts distinguish two large groups of epoxy adhesive. It:

- Liquid. Packaged in tubes. This form of release is convenient and easy to use.

- Plastic bars. Its consistency is similar to plasticine or dough. Also available in tube packaging. After squeezing out, the mass is slightly moistened with water and softened by hand.

Various modified formulations can also be found on the market. The temperature regime of polymerization of such modifications ranges from + 60–120⁰С. These adhesives are used for bonding various materials that are resistant to solvents, petrochemicals and oils.

In household, home use, several brands of epoxy glue are common. They are recognizable and familiar to almost everyone:

- universal glue Moment;

- Contact designed for sealing pipes, repairing plumbing;

- cold welding glue is used for gluing metal products.

Is epoxy glue harmful to health

When working with an epoxy-based adhesive, you should be aware that it is a health hazard. When working with her, it becomes mandatory to use personal protective equipment: gloves, a respirator mask and glasses. If the glue mass enters the stomach, a person runs the risk of serious poisoning, and contact with the skin leads to the development of allergic reactions.

Views

Adhesive polymer mixtures differ among themselves in some components that are part of their composition.

All modern formulations are divided into three main groups.

- Adhesives based on urea-formaldehyde resins, polyurethane and epoxy resin.

- Water-based mixtures. This glue can be thinned with water. This group includes PVA and bustilate (synthetic latex wallpaper adhesive).

- Compounds that can be diluted with organic solvents. This type includes nitrocellulose (nitroclays), rubber glue and a mixture based on perchlorovinyl resin.

Depending on the technical characteristics of a particular type of polymer glue, its scope is determined.

Let's consider the main types.

- Indoor mixes. Used for cladding various surfaces.

- Outdoor adhesives. This group includes compounds that are characterized by increased resistance to environmental influences and low temperatures. For outdoor use, only waterproof mixtures are suitable.

- Universal mixes. This composition is suitable for bonding most types of materials and can be used both indoors and outdoors.

- Mounting solution. Differs in high performance characteristics. With this glue, even massive products can be glued to various surfaces.

- Glue "Liquid nails". The composition is characterized by low consumption and fast drying. Bonds a wide variety of materials together quickly and reliably.

- Mix "Cold welding". It is a transparent gel-like mass. The peculiarity of this modification lies in the fact that with the help of such a tool it is possible to neatly and imperceptibly connect the chipped pieces of an object with its base.

Description and purpose of the adhesive

E8000 glue is considered a multipurpose agent.Most often it is used to fix elements of mobile devices. But at the same time it is often used for gluing glass and metal surfaces. The composition is suitable for fixing wood, electrical boards and other electrical fittings.

> Application of the product helps to achieve high adhesion strength. The characteristics of the finished seam can be compared to a cast material. Sometimes it turns out to be stronger than the glued parts. Users note that the use of the composition helps to achieve complete transparency of the contact layer. After using the substance, there are no visible sizing seams. Therefore, the tool can be used to repair expensive products and firmly fix parts made of metal, plastic or glass.

By fixing electrical components, it is possible to achieve a strong contact between conductive surfaces with absolute conductivity. This feature provides widespread use of the substance in the professional repair of computers, mobile phones, laptops and other gadgets.

With the help of glue, it is possible to achieve fixation of such materials:

- metal;

- wood;

- glass;

- fiberglass;

- textile;

- bamboo;

- leather;

- rubber;

- decorations;

- paper;

- electronics;

- nylon;

- plastic.

This glue has many advantages:

- Fixation reliability. With the help of the substance, it is possible to bond glass and plexiglass, which is often used in smartphones.

- Transparency. The composition is absolutely invisible on the surface of the product.

- Resistant to moisture. The components in the glue make it resistant to high humidity.

- Resistance to mechanical damage. The glue is considered to be quite dense, because it is able to withstand even strong blows.

Varieties

Today in specialized stores you can find various types of universal glue.

We will learn about the difference between such means and what individual characteristics each of the types has:

- Of course, fast-drying adhesives are very popular among professionals and not only. They are easy to apply to the surface, completely transparent, have a high adhesion rate and at the same time dry very quickly. Just a couple of minutes - and the product will be ready. Many manufacturers produce just these types of universal products. We will tell you more about brands below.

- Such glue is very popular, which is considered to be not only universal, but also superfast. Usually people call it a second. A small tube with such a substance will help to instantly solve everyday problems and restore the integrity of many objects. The adhesive is easy to apply and dries very quickly.

- Another popular all-in-one product is contact adhesive. This product is suitable for all surfaces, it is completely odorless, easy to apply, does not spread and dries quickly. This tool is, indeed, a universal solution for many everyday problems.

- You can often find wallpaper glue, which is also universal. It is easy to use on both vinyl and fiberglass coverings. Since the composition is universal, it is often used for gluing fabric webs.

- There are universal products that are made on the basis of silicone. As a rule, such glue is used in rooms with high humidity. For example, when renovating a bathroom or kitchen. In the composition of such glue there are already such components that prevent the appearance of mold. This is another significant plus of such a universal glue. The product is transparent, dries quickly and perfectly withstands various temperatures.

- For serious outdoor renovation work, a universal assembly adhesive is usually used, which is highly reliable and durable. This tool does not react at all to temperature changes, it can withstand atmospheric pressure, etc.As a rule, polymers are necessarily present in its composition.

Best adhesives for vinyl wallpaper

Vinyl coverings are divided into three types: heavy, foamed, and dense. For such wallpaper, it is better to choose glue, which contains an equal amount of base and PVC. It is good if such an adhesive mixture is frost / moisture resistant without the content of toxic substances. In this category, there are three nominees who have become the best due to quality.

Quelyd Special Vinyl

This vinyl-based wallpaper adhesive is also suitable for textile flooring. It is presented in a standard cardboard package, has a specific adhesive smell and is easily soluble in water. The shelf life of this product in a sealed package is unlimited, and in finished form it can be stored for up to two weeks. The base holds firmly even on heavy wallpaper, but the consumption of Kveled is not economical, a package of 300 grams is enough for 150 sq / m. It is noteworthy that it is possible to apply Special-Vinyl on the wall even without a preliminary primer, and its antifungal components will protect against mold.

Dignity

- Fast cooking;

- Leaves no marks or stains;

- Waterproof;

- Suitable for heavy wallpapers.

disadvantages

- High price;

- Dries for a long time.

After using this tool, it takes a lot of time to dry the room, as evidenced by numerous customer reviews. But the adhesion of Quelyd Special Vinyl is excellent, it sticks even to uneven surfaces.

Metylan Vinyl Premium with indicator

Methylane is suitable for vinyl, textile and paper wallpapers, plus it has an indicator. The consumption is standard, one package is enough for a large room, and the preparation of glue is not difficult. The Metylan indicator has a pleasant purple or pink color. When dry, it turns pale, becoming completely transparent, and the color tone allows you to adjust the work and remove excess from the wallpaper. Users note that Vinyl Premium does not lose its properties even when stored for a long time in a completely sealed container.

Dignity

- Low price;

- Antifungal properties;

- Fast setting;

- Convenient packaging with a dispenser.

disadvantages

- There is a persistent chemical odor;

- Designed for dry rooms only.

According to the manufacturer, the composition contains only modified starch, dye, antimicrobial components and PVC. The shelf life of the funds is limited to 4 years.

Best putties

Kleo Smart Vinyl

Cleo glue for vinyl wallpaper can be called universal. It will work with all types of vinyl, even light and super heavy. It dissolves rather quickly, has antiseptic properties, and is safe for humans and animals. Buyers praise the Kleo Smart packaging, the adhesive is placed in a sealed, tight bag, so even if the box is deformed, the glue does not spill out. Also, it does not leave marks on the wallpaper, regardless of their shade, and after drying it becomes completely transparent, without a glossy shine.

Dignity

- Possibility of adjustment upon application;

- Non-toxic

- Doesn't smell;

- Good adhesion properties.

disadvantages

- Short shelf life ready-made;

- Not an economical expense.

For heavy vinyl wallcoverings, buyers recommend applying the product to the pre-treated surface. This will improve the grip, the edges will not come loose, but the glue consumption will increase significantly.

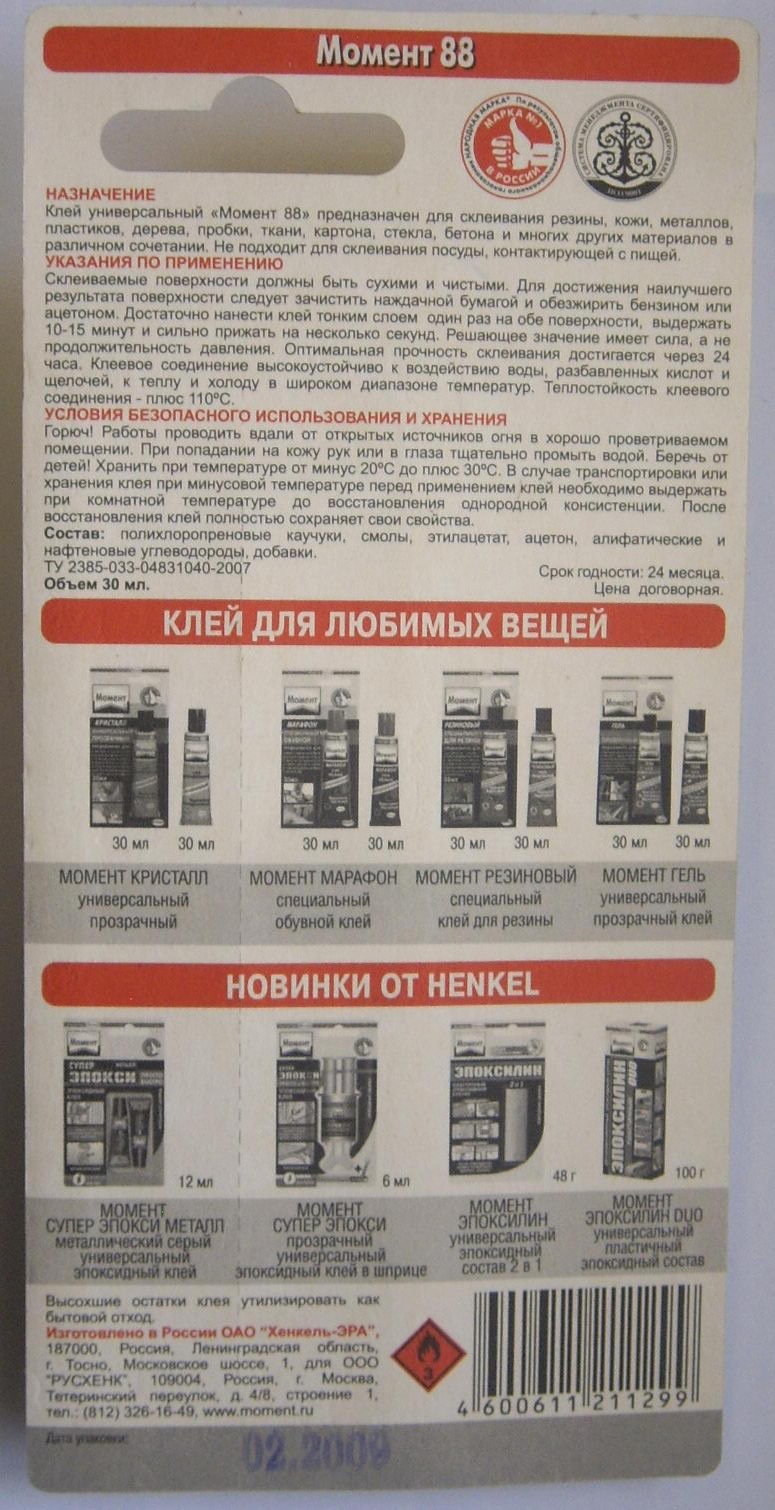

How to use glue 88: detailed instructions

Adhesive 88 is water resistant, versatile and has an immediate set. It is intended for joining surfaces made of metal, wood, polymer-synthetic materials, plastic, glass, ceramic and porcelain products. This article contains helpful tips on how to use 88 glue.

Glue 88 glues the skin

Views

- Glue 88-CA has the following characteristics:

- tensile strength indicator above 11 kgf / cm kV;

- the expense of the product is 300 g / m2.

This type has established itself as a quality tool that can provide durable connections for building materials such as metal surfaces, foam rubber and many other materials.

- Glue 88-NP has the following characteristics:

- tensile strength indicator above 13 kgf / cm2;

- increased level of resistance to fresh and salt water.

This type has a fairly wide range of applications. For example, it is used when gluing plastic coatings in the construction of cars, and the same in industrial and private construction, when it is required to glue rubber to a surface made of metal, glass, concrete, genuine leather, etc.

- Glue 88-M has the following characteristics:

- tensile strength indicator above 15 kgf / cm2;

- resistance to temperature fluctuations in the range from -40 to + 70 ° С.

This type is analogous to 88-CA and 88-NP, but significantly surpassed them in terms of strength and water resistance. Mainly used in construction for bonding rubber with metal, glass, concrete, natural leather, wood, etc. It is also actively consumed in the process of repairing cars and motorcycles, as shown in the photo.

Specifications

This tool is a solution of a mixture:

- rubber;

- phenol formaldehyde resin;

- ethyl acetate;

- and nefras.

Glue 88, we drag the ceiling of the car

In consistency, the solution is viscous and homogeneous. Its color ranges from gray-green to beige. According to the instructions, precipitation is allowed.

Application

This adhesive is a high quality product for use on a production scale. The fast-setting property has made it widely used in the footwear industry. This product is also appreciated for its ease of application to a surface of any temperature:

- As mentioned earlier, glue 88 in construction is used to make joints by cold applying rubber based on general purpose rubber to surfaces made of metal, glass, concrete, wood, etc .;

- In everyday life, the tool has found its application for gluing leather and textile products in the process of manufacturing and repairing shoes, as well as for joining foam rubber products with metal, wood and reinforced concrete surfaces.

Glue 88 is produced on an industrial scale in containers of 25 kg, as shown in the photo, with a warranty period for the invariability of technical parameters for 1 year. However, the guarantee remains only if the conditions for the correct storage of the product are met: the container with the substance must be tightly closed with a lid and be kept in a room with a temperature regime of +10 to + 25 ° C.

The product arrives on store shelves completely ready for use, and its high quality is guaranteed by the manufacturer.

Application methods

- Cold. According to the instructions, this adhesive is applied to the surface of the material in an even thin layer and dried for a third of an hour. Then the procedure is repeated one more time.

After this, the surfaces must be firmly connected to each other for a couple of minutes and left for another day in a resting position;

- Hot. According to the instructions, this adhesive is applied to the surface of the material in an even thin layer and dried for half an hour, as shown in the photo.

The surfaces need to be heated to 80-90 ° C, and then firmly connected to each other for a couple of minutes and left for 3 hours.

Let's summarize

Adhesive 88 is distinguished by its versatility and the ability to firmly bond difficult-to-bond surfaces. The most common brands are Lux, NP and CA, as seen in the photo.

All of them are characterized by a unique adhesive ability and are used in different temperature conditions.

Their constituent components are produced by the most experienced companies, which ensures the high quality of the adhesive composition.

Precautionary measures

In the process of polymerization of VK-9, phenols and formaldehydes, harmful to health, are released. Even slight vapors can cause an allergic reaction in people with weakened immune systems in the form of itching, rash, rhinitis. If glue gets on the skin, if it is not removed, it can cause a chemical burn, which takes a long time and is difficult to heal.

Splashes of epoxy that have got into the eye cannot be removed on their own. You will need an urgent appeal to an ophthalmologist. The manufacturer's instructions indicate that it is not recommended to work with resins for persons under the age of 18.

To protect against vapors and skin contact with resins during mixing and handling, it is necessary to:

- Respirator. Type: gas mask. Filter element: activated carbon, oxygen cartridge.

- Safety glasses.

- Overalls.

- Gloves.

This degree of protection is necessary when pouring large areas, when harmful emissions can have a pathogenic effect on the liver, heart, and stomach. For small jobs, latex gloves and glasses are sufficient.

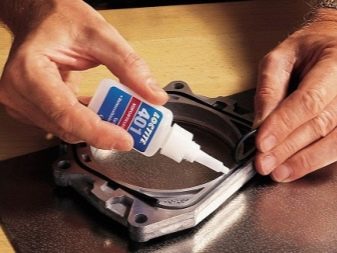

Instructions for use

All tips for working with glue are indicated on the packaging. To obtain a high-quality glue seam, the base must first be prepared - cleaned of dirt, sandpaper with fine grain. To remove grease stains, oil film, both bonded surfaces should be degreased. For this purpose, it is best to wipe them with alcohol, acetone, which will also help remove the remnants of paintwork. You can also wash products with household detergents.

Further tips for working with glue are as follows:

- apply glue to one of the surfaces, if they are homogeneous, and to both, when dissimilar materials are glued;

- if the bases are porous, repeat the application of the glue after a couple of minutes;

- press the products together from the center to the edges to prevent air from accumulating, fix in any convenient way;

- if possible, it is allowed to use a special roller for rolling parts;

- stand for 10-20 minutes;

- until full operation, leave the product for a day (to build the strength of the glue seam).

You can make adjustments to the position of parts only immediately after they are attached to each other. Separation of objects with immediate re-bonding is allowed. After 5-7 minutes, it will be impossible to do this, you will have to clean the bases from the glue and repeat all the manipulations. The manufacturer does not recommend gluing in rooms with high humidity. Despite the moisture resistance of the glue seam, at the time of connection, it is worth excluding the effect of liquid in one form or another.

Sometimes it happens that the glue gets on clothes, other objects, and hands. You can remove already dried glue with acetone, gasoline. It is better to give the fabric to dry cleaning or try to wash it with powder, detergents, wipe with alcohol. The glue is removed from the tools with gasoline, in which they are soaked for 1-2 hours.