Varieties

All putties are divided into three types, taking into account the grain size of the structure, which largely determines the purpose of the composition and method of applying the solution.

- Starting. It is used for the initial leveling of walls, as well as ceilings, doorways and slopes. Differs in good adhesion, coating durability and long service life. The particles of the main substance in the mixture are quite large, therefore, after hardening, a rough surface is obtained, which is difficult to grind. Serves as the basis for other types of decorative finishes.

- Finish. It is applied before decorative finishing, suitable for thin and light finishing materials. The finishing mixture has a fine-grained structure, due to which the use of the mixture allows you to remove minor defects. When dry, this composition gives a perfectly smooth super-white surface, which resembles polishing and does not need further sanding. The finishing putty is considered to be the coating of the second layer and is applied to the starting one.

- Universal. The manufacturer of universal putties positions its product as “two in one”, that is, in one composition both start and finish. It is commonly used for minor repairs, initial leveling of walls and finishing preparation.

Universal putties are used in a wide variety of finishing works:

- for minor repairs, elimination of cracks, chips, grouting of joints;

- for the initial leveling of the wall, eliminating irregularities and deformations;

- as a topcoat before decorative finishing with paint, wallpaper or slabs;

- for fixing gypsum blocks;

- when forming decorative elements of the interior.

Mixing instructions

After that, you need to prepare a filler "Novol" with fiberglass. Do not dilute a large amount, as after ten minutes it will harden and it will be impossible to use it. It should be limited to a small amount, the application of which will take 6-7 minutes.

Important! Before dilution, the main composition must be thoroughly mixed, since the density of the solvent is higher, and it accumulates on the surface.

Add about 3% of the hardener from the Novol kit to the filler base. This is the optimal ratio and this parameter is indicated in the instructions on the opposite side of the Novol inscription. It can be achieved either with the help of high-precision scales, or by dividing the base several times into equal slides and, visually, determine the required amount. You can use a special easel for mixing, but a metal spatula will work as well. The main thing is that the resulting solution is of a uniform color, and there are no contrasting streaks in it.

Preparatory stage

In addition to the putty, you will need a set of certain consumables and tools:

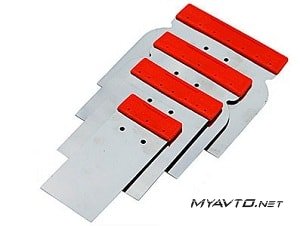

- plastic spatulas of different sizes;

- several metal spatulas;

- solvent for cleaning surfaces and tools;

- abrasive material with grain size from 60 to 240;

- grinding plane;

- masking tape;

- developing powder;

- rubber spatula;

- easel for breeding.

Before starting filling, it is necessary to polish the problem area with high quality. It is best to choose a 120 grit abrasive for the job. This will help level the work surface and improve material adhesion. To avoid problems when applying Novol putty and further painting, it is better to repeat this procedure several times. It is necessary to completely get rid of rust and wipe the slightest chips and scratches as efficiently as possible. You can expand them along the plane, this section will be leveled and reinforced with fiberglass.Next, degrease the work surface with a solvent or white spirit, according to the instructions.

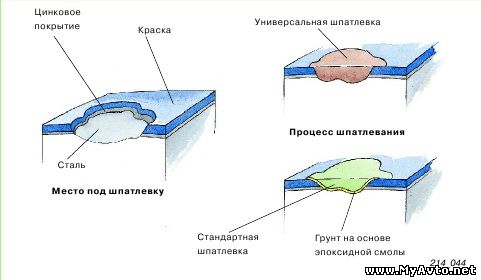

Polyester putty application

The quality of the paintwork begins with the filler. To be painted

metal surfaces must be degreased and sanded. Layer thickness

putties over 400 ... 500 microns are unacceptable.

Rule! The better the filling, the less sanding!

Polyester putty can be applied to bare metal or to a prepared part. On galvanized metal, use

universal or special putty with zinc. Can be applied over epoxy primer.

Before application, the surface must be sanded. If it is bare metal, then the abrasive can be at least P80. If it is an old paintwork, then the finishing abrasive should be P180-P240 before applying the filler.

The putty should never be applied to etching (acidic) soil.

Do not strive to remove all the pits at once, in one step. Apply with a clean spatula. As soon as you notice that the putty starts to “roll off” during the work, finish the work. After a while, it will harden. Basically, auto putty is applied and sanded several times before an acceptable result is achieved.

SKODA RAPID - any ride is a pleasure

Skoda Rapid is the most affordable car from the entire SKODA line presented in Russia, however, it is equipped with the most modern options usually offered for cars of a higher class. The exterior of an expensive European car, the design of which has no random details combined with convenience and functionality, will surpass all your wildest expectations. Everything is thought out - to the smallest detail.

And it's not just the pleasure that you get when passing through a bunch of turns at high speed - although SKODA RAPID will easily provide you with it. A lot of details that can make every trip as convenient and comfortable as possible - this is why ŠKODA cars are appreciated in more than a hundred countries around the world.

In general, he can be called a "city dweller" of the compact class. At the same time, the Skoda Rapid is a family car, its spacious interior and spacious luggage compartment is perfect for traveling with the whole family. Will fit almost anything and even more! And if there is still not enough space, the luggage rack can be easily removed, and the second-row seats can be folded.

Under the hood - there is also something to be impressed with. SKODA RAPID engines are the embodiment of all the engineering power of the Volkswagen auto concern. Their economy and time-tested reliability guarantee you years of trouble-free operation under the most demanding schedules in the most challenging road conditions.

A family car should be truly comfortable, and not only in the first row, but also in the second. Indeed, in a real family, everyone should be equally comfortable. SKODA RAPID fully meets these requirements, because it is a car in which everyone will find a convenient and comfortable place for themselves. Even on the longest trip.

Correct filling of the work area

After receiving the solution, apply the filler with fiberglass to the working area with even movements. The mixture should fill all cracks and depressions, which can only be achieved after a few repetitions. Do not rush, it is better to take ten-minute breaks between applications. After complete processing of the defective area, you need to give the putty time to dry completely. This usually takes about two hours, after which the sanding period begins again. For this we need a grinding plane and a developing powder. We process the working area with powder in order to clearly distinguish all the irregularities and rub them with an abrasive material. The optimal powder consumption can be checked by consulting the instructions.

Important! In order not to damage the site outside the repair area, it should be pasted over with masking tape.

If metal appears under the layer to be rubbed, it will be necessary to reapply a layer with fiberglass, so excessive zeal is useless here. Fiberglass putty is much softer than paint or metal and is much easier to wipe off.

Having obtained the desired result, apply the final layer. It is best to choose a special Novol finishing putty or liquid, if you have a special sprayer at hand. Compared to fiberglass, the finish should be thinner. This layer is sanded with a 240 grit abrasive. This way, you can get rid of coarse marks and transitions that would spoil the result of the work after painting. The area to be rubbed must also be treated with a developing powder in order to detect problem areas.

Important! The finishing putty from Novol, according to the instructions for use, is subject to the action of a solvent, so you should not use it for degreasing.

Having received a smooth and even surface, you can proceed to the priming and further painting according to the instructions for applying paints and varnishes. A well-done work on applying Novol filler with fiberglass will hide all defects after painting and allow you to enjoy the perfect look of the car for a long time.

- How to change silent blocks on a VAZ-2107

- Removing scratches from a plastic bumper

- How to change the oil in a Kia Rio

- Car varnish restoration

Preparing and mixing the putty

You can prepare the putty on a piece of organic glass or buy a special "easel" for mixing the putty. Basically, many people use two spatulas, one large the other smaller. Clean the tool immediately after finishing work, before the residues have hardened. After the filler has hardened, it is necessary to sand the surface from the smallest irregularities. The spatula can also be cleaned with a universal solvent.

During storage of the putty, solids settle and the resin forms a film. Therefore, before use, it should be thoroughly mixed to ensure an even mixing of the resin and solid filler. Otherwise, it is impossible to achieve the desired ratio when adding the hardener, since the filler will not participate in the reaction. Only a clean tool should be used to remove the putty from the container. Residues of putty or hardener on the tool will react with the contents of the container, causing the remaining putty to become unusable.

The putty is applied to the surface with spatulas. The stores sell special sets of spatulas, made of thin steel or stainless steel. There are also plastic and rubber spatulas, which are very convenient to use in certain situations. For filling large and even areas, such as door panels, you can use a building facade trowel for finishing work. It is also suitable as a ruler to control the shape of the sanded surface.

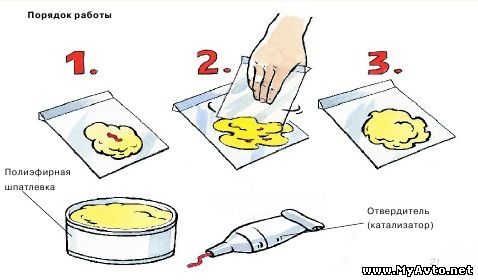

Polyester putty consists of two components, which should be

mix immediately before use: resin and hardener

(catalyst). The hardener should be added in the proportion indicated

manufacturer; usually from 2 to 3 g per 100 g of putty (2 ... 3 percent

by weight). Mix the red putty and hardener

spatula until traces of red hardener are visible. Learning to dose the hardener correctly comes with experience.

"Spaklyu" should be applied with a thin layer. With a thick layer, it is impossible to obtain a high-quality coating.

Prepared car putty should be used within 5

up to 10 minutes. The putty layer should be applied quickly and accurately. Do not mix more putty than required. It loses the qualities necessary to obtain a quality layer.

- Too little

hardener (catalyst).The putty does not harden in due time. Grinding is difficult, lumps into lumps, there are

scratches and risks. - Too much hardener (catalyst). From this "shpaklya" does not harden faster. In it

an active hardener remains which reacts with the resin and

filler and paint pigments. The consequence is defects: unevenness

coloring, the formation of spots and clear contours of the painted areas.

Universal putty brands

- Kreizel 662 is a product of a German manufacturer, a composition based on cement and lime. Additional additives increase resistance to mechanical stress and vibration. The mixture is not limited in terms of moisture level. The technical process determines the applied layer of at least 3 mm to ensure the absence of cracks. The price of a universal mixture is around 350 rubles per 25 kg bag.

- Knauf Multi-finish is a German-made plaster mix with a mineral filler. Polymeric modifiers are present, it is especially plastic, dries quickly, and is easy to sand. When processed, it gives a surface according to the Q4 standard. Excellent aesthetic appearance, used for decorative finishes. The price of such a mixture is approximately 370 rubles per 25 kg.

- Holzer Feinspachtel is a ready-made universal polymeric putty. It is distinguished by high vapor permeability, average moisture resistance. It is easy to sand and can be applied in a layer up to 3 mm on various types of surfaces. Can be used to create embossed decorative coatings. Price for 28 kg. a bucket ranges from 960 to 1100 rubles.

- Well-known manufacturers also include Novol Uni, Axton and VGT. The products of the brands are especially popular with the masters.

For information on how to putty the walls under the wallpaper, see the next video.

Advantages and disadvantages

The universal putty has a number of undeniable advantages.

- It can be used as an adhesive base when installing drywall or gypsum fiber in a frameless way, and this is its difference from the finishing putty, which does not show fixing characteristics.

- This mixture is popular with consumers due to its strength, durability and high plasticity. The composition is resistant to high humidity, temperature fluctuations and other adverse environmental influences. The coating is wear-resistant, resistant to mechanical damage. Universal fillers are used for both interior and exterior finishing works.

- The main criterion that makes it possible to classify a building mixture as a universal type is considered to be a complex of composition characteristics in an extended range of applications. This means that its performance remains unchanged in a wide variety of conditions. In practice, there are not so many materials that meet this requirement and fit the definition of "universal" in the construction market. As a rule, these are multicomponent formulations and at the same time are by no means budgetary.

- The universal putty is very popular among non-professionals who have started repairs on their own. It is very convenient when all the necessary work can be carried out using the same mixture.

Builders prefer specialized putties, arguing that the quality of the universal composition is not enough for the standard technology using layers of leveling and finishing coat.

Minuses:

- Among the disadvantages of such a mixture, the greatest layer thickness is distinguished. According to consumer reviews, with a large number of irregularities up to 10 mm deep, the universal mixture should not be used as a starting one. Otherwise, you will not achieve a perfectly even coverage.

- Another significant disadvantage of the mixture is the high price.

Putty Novol

A very important building material, without which no repair work can do, is putty. One of the most popular is Novol putty, which is very often used by professional builders.Novol putty is used to fill in scratches and irregularities before applying paints and varnishes. It is characterized by a high level of elasticity, resistance to high temperatures, and ease of application. Novol putty has good adhesion to various types of substrates, although it is not recommended for use on galvanized steel.

Putty Novol instruction.

The material can be used to work with the following surfaces: aluminum, acrylic two-component primers, steel, lacquer coatings.

Attention! Novol putty is not applied on reactive primers, one-component nitrocellulose and acrylic products. Novol putty is mixed with hardener in a 3 to 2 ratio

It should be applied within six minutes after cooking at a temperature of about twenty degrees above zero. Novol putty dries no more than half an hour at room temperature, and in case of high temperatures - ten minutes

Novol putty is mixed with a hardener in a ratio of 3 to 2. It should be applied within six minutes after preparation at a temperature of about twenty degrees above zero. Novol putty dries no more than half an hour at room temperature, and in case of high temperatures - in ten minutes.

During the preparation of the mixture, the components are mixed until a homogeneous consistency, observing all proportional ratios. In this case, special dispensers are used, which allow you to take exactly the amount of material that is needed to obtain high-quality material. The Novol putty is applied with a spatula, in a layer not exceeding three millimeters thick. The material is recommended to be applied at temperatures not lower than ten degrees Celsius.

One of the most frequently used materials of the trade mark is Novol uni putty. It has a beige color and is a versatile material. In most cases, it is applied by spraying, but there are also cases of using a spatula. After working with Novol uni putty, tools are not cleaned with water, as with most putties, but with a special solvent for nitrocellulose materials.

Store Novol uni putty in dry rooms with low temperatures, away from sources of heat and fire. It is necessary to protect the material from direct sunlight. The putty has a shelf life of no more than a year. The hardener is stored for six months longer.

Criterias of choice

In order to choose the right universal putty suitable for specific needs, it is worth considering a number of basic factors.

It is important to find out:

- internal or external walls of the building are finished with it;

- the type of surface to which the mixture should be applied;

- resistance to aggressive influences on the finished surface (humidity, temperature drop, mechanical damage);

- the qualities that the finishing surface should have (smoothness, plasticity, strength, color);

- whether further finishing work will be carried out or the putty will be the face of the wall.

There are optimal types of putties for some finishing materials.

If this material is the front surface, special attention should be paid to color. The timing in which the work will be carried out matters

Dry putties are stored for a long time, ready-made without special additives have a strictly limited shelf life. Finishing work budget is one of the main factors.

The starting putty should:

- it is good to level even significant wall irregularities up to 10 mm or more;

- be plastic, otherwise cracks form after drying;

- have good adhesion: stick to the surface material at the molecular level, otherwise peeling from the surface is possible;

- be durable.

The basic requirements for the finishing putty are as follows:

- the surface must be flat and smooth;

- it should give in to grinding;

- the material should have an aesthetic appearance (if the putty will be the face of the wall without further finishing), especially with regard to color.

The special point is strength. Strong universal putty with good resistance to mechanical stress. It is advisable to use it in gyms, children's rooms, entertainment establishments, entertainment centers and places of active human activity. It is more difficult to grind, which complicates further finishing work.

Another subtlety is the choice of finishing materials of the same brand. For example, one manufacturer's primer and filler were developed and tested for step-by-step co-application. The interaction of such materials with each other will be guaranteed of high quality.

Additional specific criteria may be put forward:

- moisture resistance;

- resistance to temperature;

- environmental friendliness of the composition;

- biological inertness;

- fire safety;

- acid resistance.