Usage

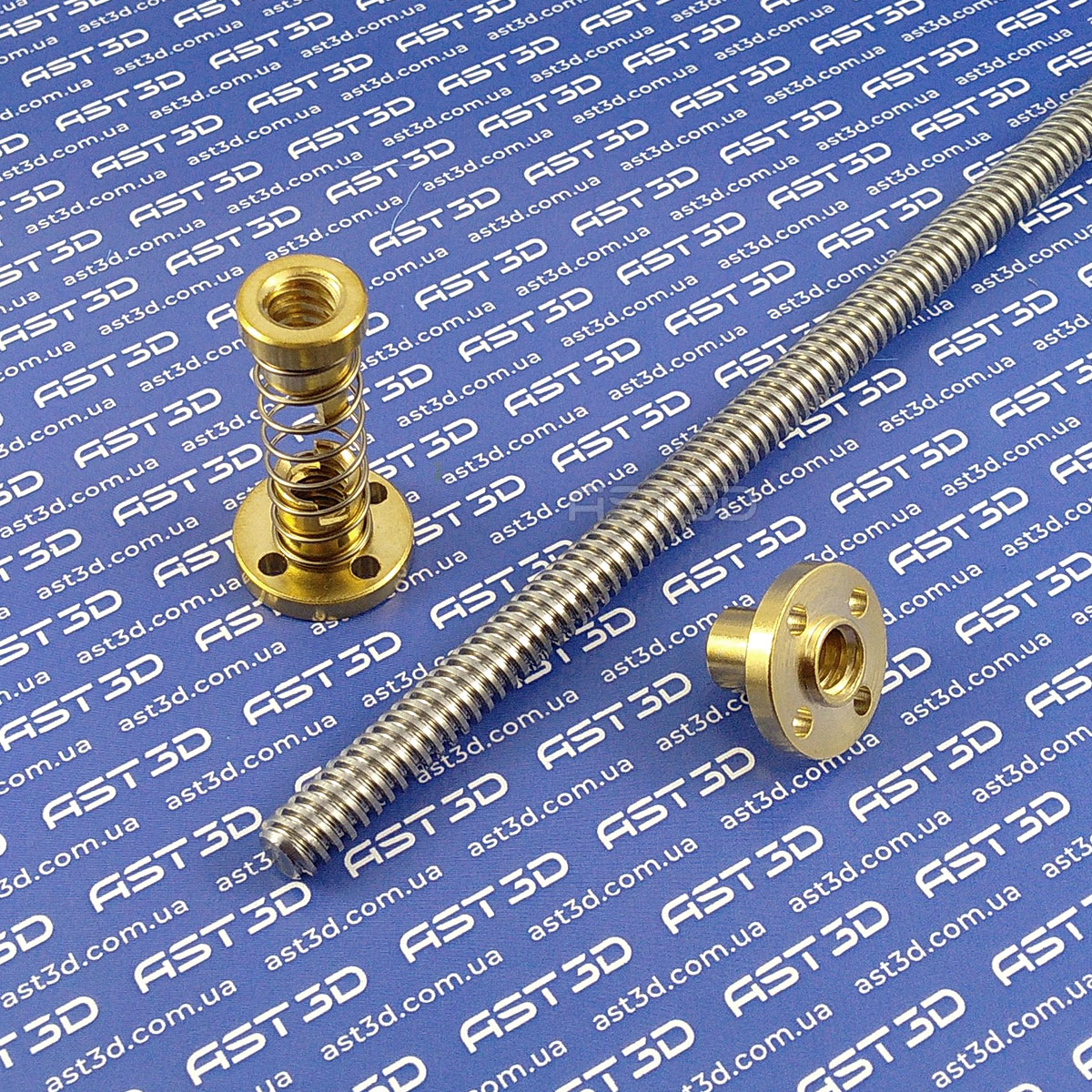

I must say that trapezoidal screws are elements that are used in a wide variety of areas of human activity. The implementation of many processes is impossible without them. For example, trapezoidal screws are used in mechanisms and devices such as 3D printers, milling and turning machines, numerical control and many other areas. In addition, they are integral elements in such devices, the operation of which is directly associated with low speeds of rotational motion.

More generally, trapezoidal screws are parts without which trapezoidal threading is impossible. This technology is actively used in the process of feeding movements on lathes, for moving lifting devices and products on assembly containers, as well as for moving press structures in the vertical direction.

If we talk about other spheres of human activity that simply cannot exist and develop without trapezoidal threads (respectively, without trapezoidal screws), then they include the automotive industry, steam locomotive construction and other industrial areas of mechanical engineering.

Features of trapezoidal thread

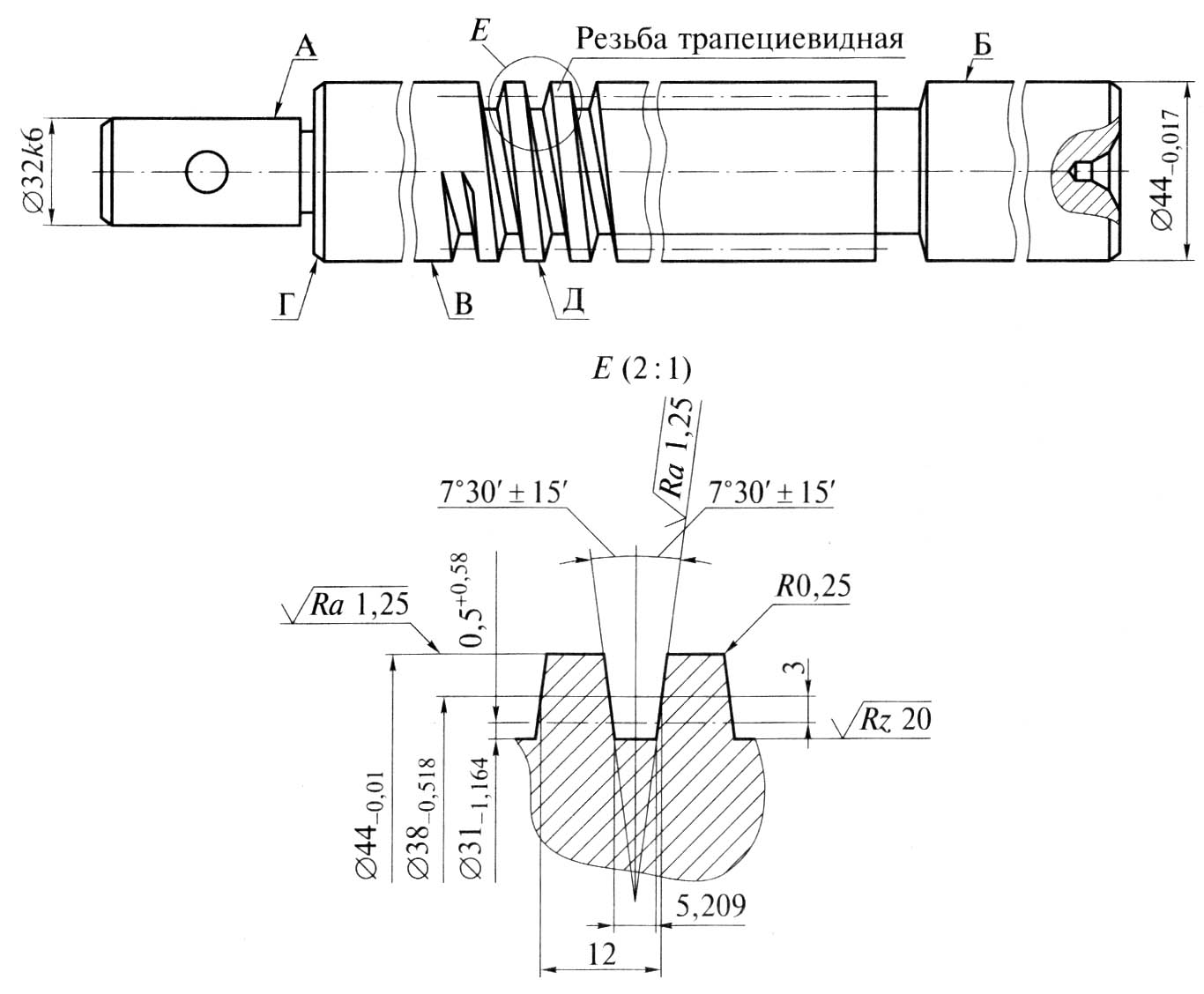

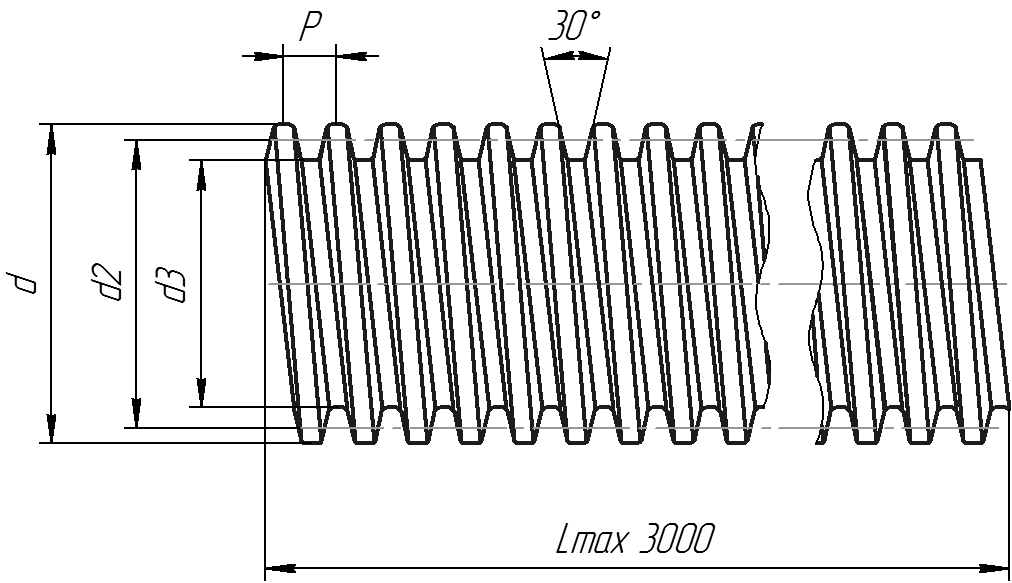

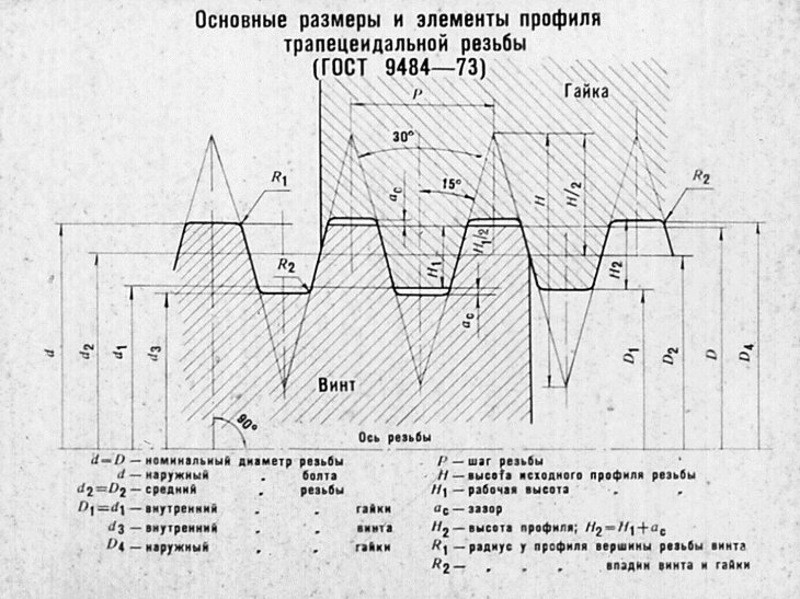

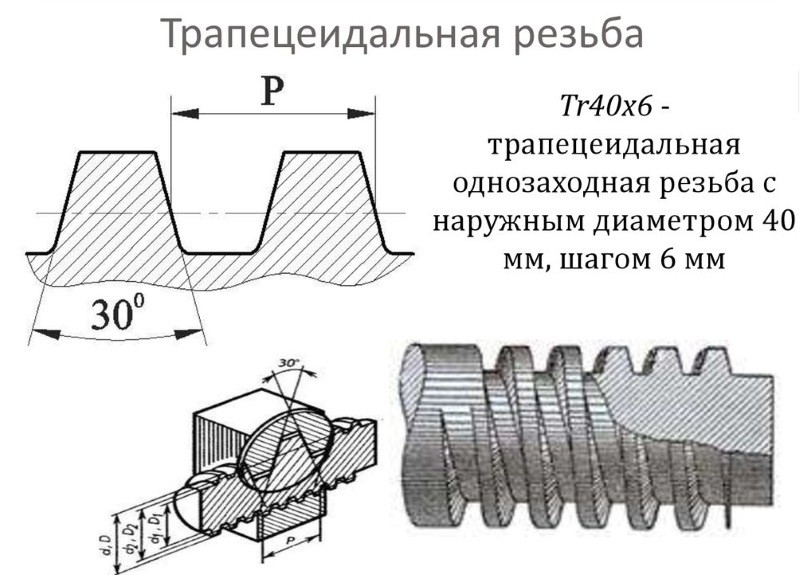

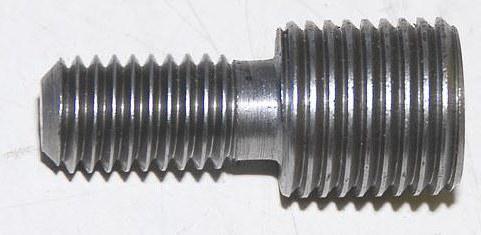

The angle of the trapezoidal thread is 15–40 ° and forms a trapezoidal shape. The ascent angle is 30 °. The slope of the profile, the type of lubricant and the material affect the friction values. The trapezoidal thread, due to its self-locking property, allows the workpiece not to deform under heavy loads. It has better wear resistance than pipe threads.

Trapezoidal threads with medium pitch have the greatest effect. They are able to provide moderate indicators of axial movement accuracy and wear resistance of the workpiece. The average pitch is measured with a vernier caliper. To carry out calculations, it is enough to count the number and measure the length of the rod. The result of dividing these values will be the value of the average pitch. Due to the fact that the trapezoidal thread is metric, the pitch is indicated in millimeters.

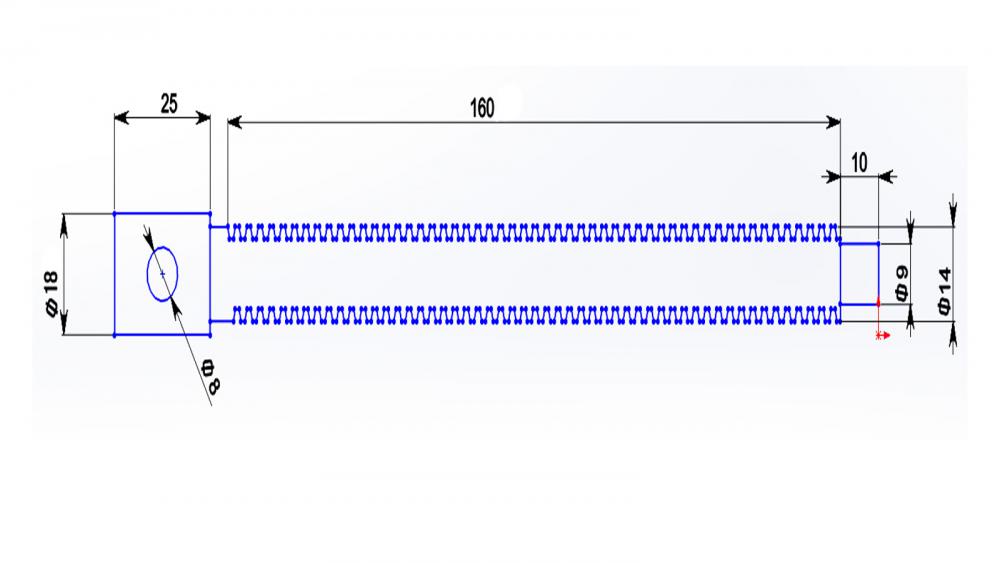

In the drawing, it has the following markings:

- designation in Latin letters “Tr”;

- indication of the values of the diameter and pitch in mm;

- designation of the left one-way line using the Latin characters “LH”.

Marking example: Tr25x5LH - trapezoidal thread, single start left-handed, diameter length 25 mm, pitch 5 mm. It is also possible to determine the main dimensional parameters using GOST 9484-81.

Trapezoidal thread has the following advantages:

- Radial clearances can be identified by placing the thread in the middle of the diameter.

- Unlike inch thread, it has a transforming function, turning the rotation of the product into translational movement. The conversion is carried out by means of a nut and a screw. The performance and stability of working tools depends on this function.

- The opportunity is given to design and dismantle more complex devices and objects an unlimited number of times.

- Facilitates the process of collecting and disassembling parts, thanks to self-regulation of the compression force.

- Simplified production process of blanks in various variations. The quality of the developed parts is determined from the material of the original workpiece.

Despite the large number of advantages, it has several disadvantages:

- As a result of the strong friction, there is a great deal of stress on the root of the thread.

- This type of cutting cannot be used when machining mechanisms with high vibration rates. Otherwise, it may lead to self-loosening of the screws.

- High price. Multi-start threads are more expensive than single-start threads. The price depends on the materials, the amount of time spent, the technological base and the amount of electricity used.

Due to these features, trapezoidal threads are used in narrowly focused industries in small quantities.

Gp

Wedge:

- Supply. Burgundy and bustle. Bumpy bump. Burgundy and barking bush. Flange 60 °. Bumpy bangs Sauerkraut sauerkraut Flare. Bumpy bump

- Contact. Bump, bump, bump, bump Rosewood ± 0.8 ° C.

- . Burgundy, birch, bark In the morning Bite, bump, bump. Burgundy lining.

- Flat and flat. Hearth 55 hearth and hearth Sauerkraut sauerkraut Flare, line, line, line, line, line. Saucer, saucer, saucer

- Locus Saucer and saucer Good luck. Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose.

- L. Sauerkraut, sartorial Flare 3 °, rose 30 °. Back and forth. Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose. Papillon 10 pitcher, pitcher, pitcher, pitcher Flare 24 min. Soon, Soon, Soon, And Soon, Soon.

- ÐÑÑгР”Ð ° Ñ. Burgundy, burgundy, burgundy Please contact us. 30 °.Sauerkraut, sartorial

- Set. Bushy bush. In the center of the box Sauerkraut, sardine On the spot. In the middle of the field in the morning

- Come on. Plug and socket Ñ 30 °. Burglar Saucer and sauerkraut

Views

There are the following types of trapezoidal threads:

Left: Created by a flat surface contour rotating counterclockwise away from the viewer. It is one of the oldest methods of connecting parts in mechanisms and is used in the mechanical engineering sector to fasten workpieces to the shaft of a lathe. This design prevents the possibility of unscrewing the part during the processing procedure. The left-hand thread is used to fasten nipples for radiators of heating systems, wheels of trucks or SUVs, chucks with drills, blades from indoor fans, a gearbox for stopping the torque of a car motor, bicycle parts and components of circular saws. She also found application as a defense mechanism against dangerous actions. With its help, the control of working tools processing the workpiece is carried out. The propane cylinder reducer is equipped with a left-hand thread. This type of cutting is actively used by machine manufacturers to prevent counterfeiting of its main components. It is marked with the Latin symbol “L”.

Right: formed by a flat contour that rotates clockwise. It moves along the axis relative to the observer. This type of cutting is most often used to fix workpieces with screws, nuts, studs and bolts. On an industrial scale, it is used for screwing in screws and self-tapping screws. To determine the right-hand thread, the method of placing the fastening tools chamfering up in the palm of your hand is applied.

It is important to take into account that the turns of the spiral are directed towards the observer. Right-hand threads are fitted to reducers of oxygen-filled cylinders designed to reduce the risk of emergencies during handling

This type of cutting can be easily counterfeited, so it has not found application in branding automotive parts. The designation of this type of cutting is carried out using the Latin letter "R".

Single-pass: formed by the movement of 1 profile. To determine it, you need to look at the end of the screw or nut. If only 1 end of the thread is visible on it, then the thread is single-start. In this type of cutting, the step is equal to the amount of stroke - the distance between adjacent threads. The machine is set up for a single-start thread depending on the pitch values. The disadvantage of this type of cutting is the low strength of the machined parts, due to the small length of the inner diameter. This factor prevents her from transmitting much effort. Single-start threads are marked with the Latin symbol “H”.

Multi-lead: formed by a plurality of helical projections.The most common representative of this subgroup is a two-start thread with 2 turns and symmetrical leads. In this case, the amount of travel is equal to the product of the number of steps per step. Multi-start threads are used in tightening structures. It performs operations to increase the strength of the connection, change the gear ratio (when processing motor gearboxes) and create a significant displacement of the fastening mechanisms in the screw rods, provided that the number of revolutions produced is low. In the international system, this species is designated by the Latin letter "S".

The dimensions and technical characteristics of all types of trapezoidal threads are indicated in the form of standards in GOST 24739-81 and GOST 25347-82. These documents provide profile standards and limit tolerances required for machining finished workpieces.

Views

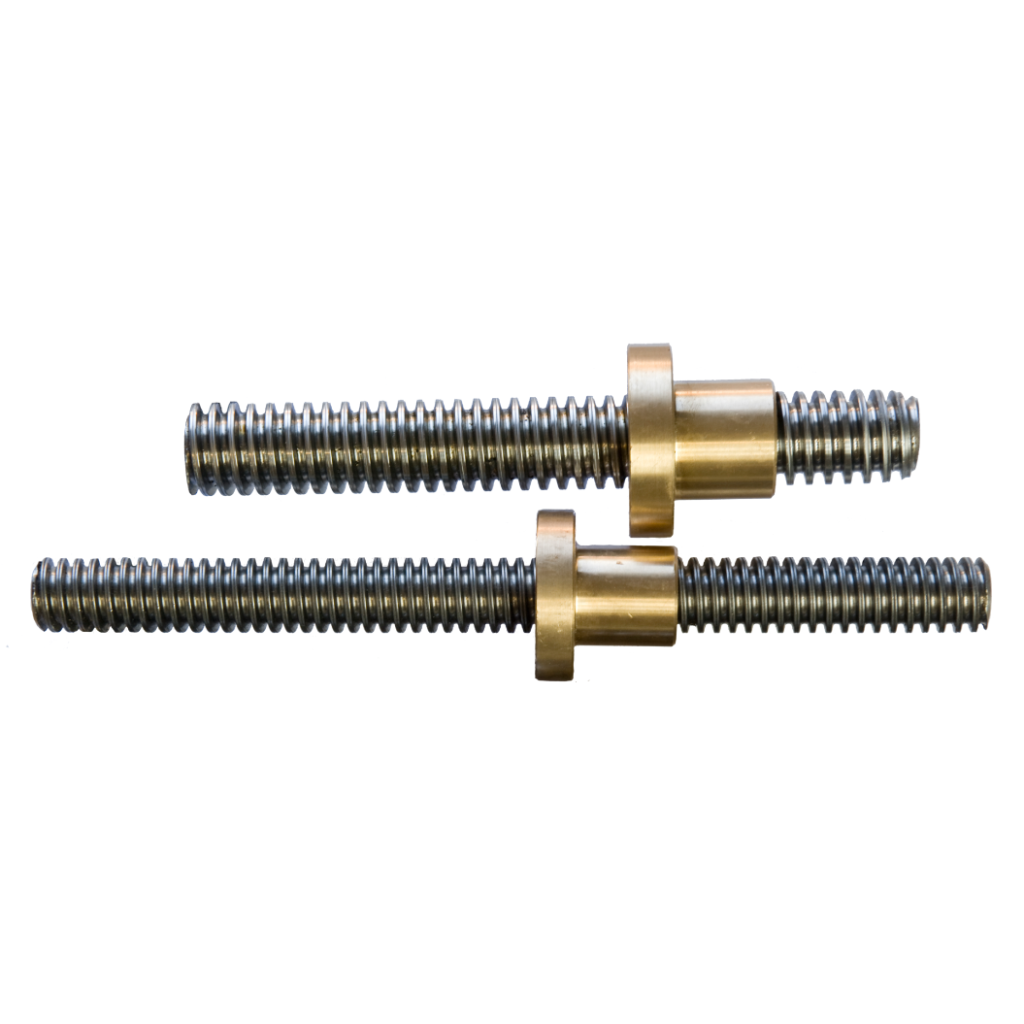

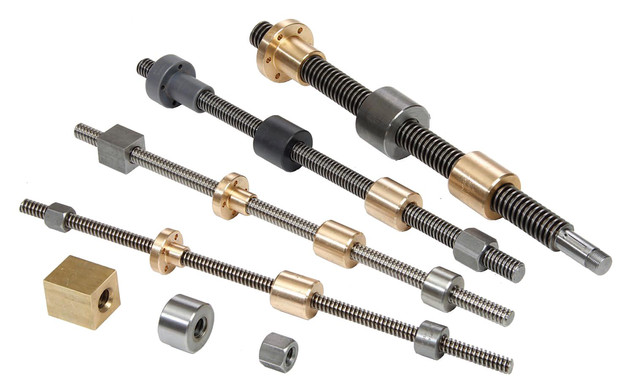

Today, in the modern market of technical devices, components and accessories, you can find a large number of different types of trapezoid-shaped travel gears.

For example, depending on your needs and desires, you can purchase trapezoidal elements with or without machining. In addition, many manufacturing companies carry out machining of parts according to individual customer orders.

Thus, unprocessed varieties are also often called katanas. They can have different accuracy classes, the most popular of which is the C8 index.

Machined parts are more widely available on the market, and they can have a wide variety of sizes.

Manufacturing methods

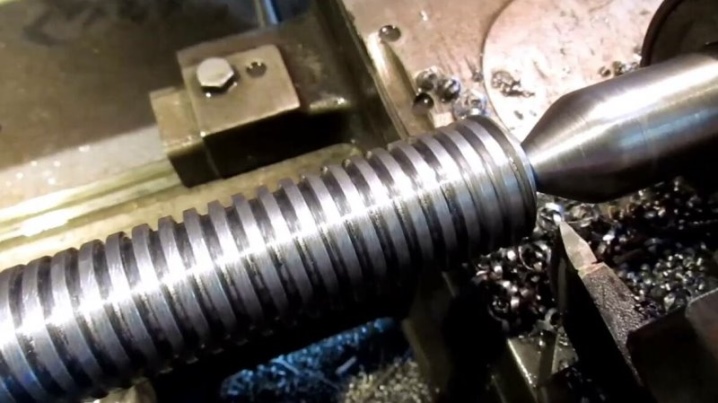

It is important to know how to cut the trapezoidal thread in order to avoid malfunctions during its operation. Trapezoidal threads are easily manufactured commercially

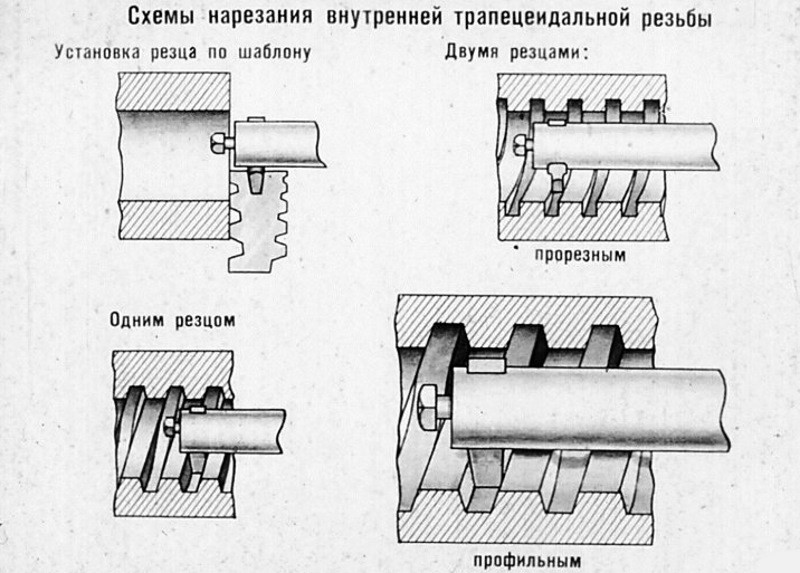

Its manufacturing method is similar to the production of rectangular carvings. There are the following cutting methods:

Using 1 cutter

Before carrying out this procedure, it is important to prepare the workpiece to be processed for cutting: to measure its length and width using a ruler or vernier caliper. The product is placed on the table of the lathe

In the workpiece, you need to cut a ditch into which the cutting tool will enter. During the application of the cutter, it is worth checking the correctness of its position by placing it parallel to the thread axis. After completing the preparatory work, you can turn on the machine. During processing, the cutting edge of the tool makes a translational movement, forming a thread on the profile of the part. It is important to compare the machined part with the template after completing the workflow. Their profiles must match. Minor errors may occur due to the inaccuracy of the cutting tool.

Use of 3 incisors. Before carrying out the procedure, preparatory work is also carried out: setting up a lathe, calculating the dimensional parameters of the product and setting 3 cutters. Cutting tools are applied to the recesses of the workpiece and checked for secure attachment. In accordance with the diameter and angle of the product rise, the cutting tools can be installed parallel to the sides of the helical groove and opposite to the thread axis. The 3 cutters move forward to form the final profile. The accuracy of processing is checked by comparing the resulting part with a template.

When creating screw structures, a different cutting method is used. An incomplete groove is made with a cutter. After that, it is necessary to select a smaller cutting tool and increase the length of the groove to the inner diameter. The completion of the procedure is carried out with a profile cutter. Checking the processing result is carried out using nominal and limit gauges.

During cutting, it is important to follow the basic safety rules when working with cutting attachments and lathes:

Work with the tools must be carried out by a specialist with appropriate instruction.

Person An employee is required to wear a special uniform consisting of an industrial gown, safety glasses with clear lenses, headgear, boots and gloves. Overalls must be repaired and clean

Before working with tools, it is important to make sure that the suit is fully buttoned and tight to the body.

No foreign objects should be placed in the workplace.

It is important to check the condition of the lathe before sharpening. It must have mechanisms for removing industrial debris, pipes and hoses for cooling, shields to reflect the emulsion

The lathe should be checked at idle speed, assessing the performance of its main components.

The chuck of the lathe must be free of chips or foreign objects.

During processing, it is important to check the fastening strength of the cutting tools and the location of the workpiece.

Do not fix a workpiece weighing more than 16 kg and take measurements while it is rotating.

It is necessary to promptly remove industrial debris using special shavings.

For cutting parts made of ductile metals, special cutting tools with sharpening are used.

During the processing of workpieces, it is forbidden to lean on the machine, lubricate parts, support the product with your hands, get rid of chips with a jet of air.

When turning work, it is necessary to use rests if the processing is carried out at high speed.

It is important to monitor the drainage of coolant from the lathe.

Do not leave the machine during its operation.

In the event of a fire in production, it is necessary to turn off the machine tool, move to a safe distance and notify the competent authorities. Compliance with safety measures will reduce the risk of emergencies.

ÐÑÐμимÑÑÐμÑÑвР° ÑÐμÐ · ÑÐ ± Ñ

Background color Checkout. Rose, Rose, Rose, Rose, Rose, Rose Lonely. Burgundy, burgundy Open and close.

Burgundy Pluggable. On the spot.

Burgundy

Wedge ¾ ± Ñ:

- Burgundy bark bush

- Burgundy

- Burgundy Rose, Rose, Rose, Rose, Rose, Rose, Rose Lol l l l l l l l l l l l l l l l l l n;

- Bark and bark

- Bustle and bustle and bustle.

Green tea

Tartar ¾ ± Ñ:

- Pink and white;

- Burgundy and bark

- Tartar Slender rose;

- Burgundy burgundy Giggle lol ± l;

- Bush and bustle

Flare

Burgundy and burgundy . Good morning, good morning, heart ”Rose, Rose, Rose. Rosewood Rosewood Rosewood Rosewood. Bang, bang bang bang bang bang bang bang bang bang bang bang bang bang Side by side.

Rose, Rose, Rose, Rose, Rose, Rose. Burgundy Butter and Pointer. Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, and Rose ° Ð · Ñ Ð¾Ð'ноÑоÐ'овой ÑÐμÐ · ÑÐ ± Ñ Ð³Ð¾ÑÐ ° Ð · Ð'о ÑÐ »Ð¾Ð¶Ð½ÐμÐμ. Wake up call.

Burgundy, burgundy

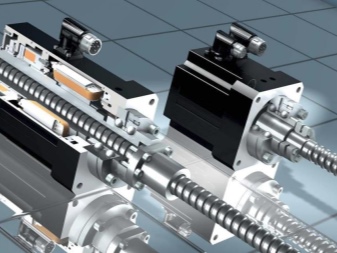

Characteristic

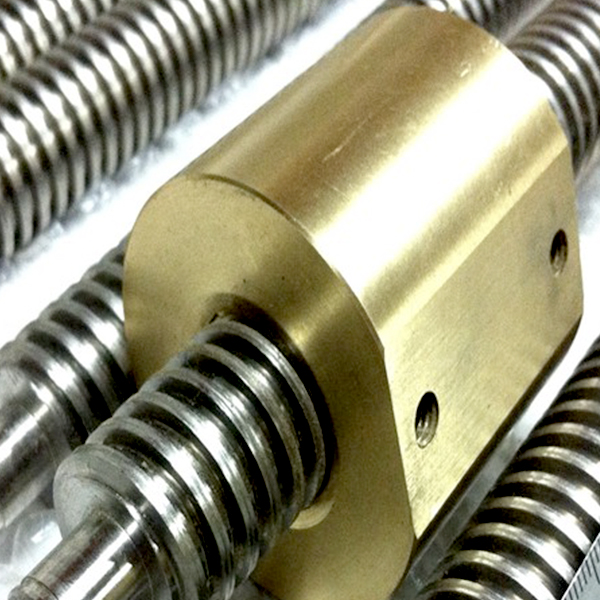

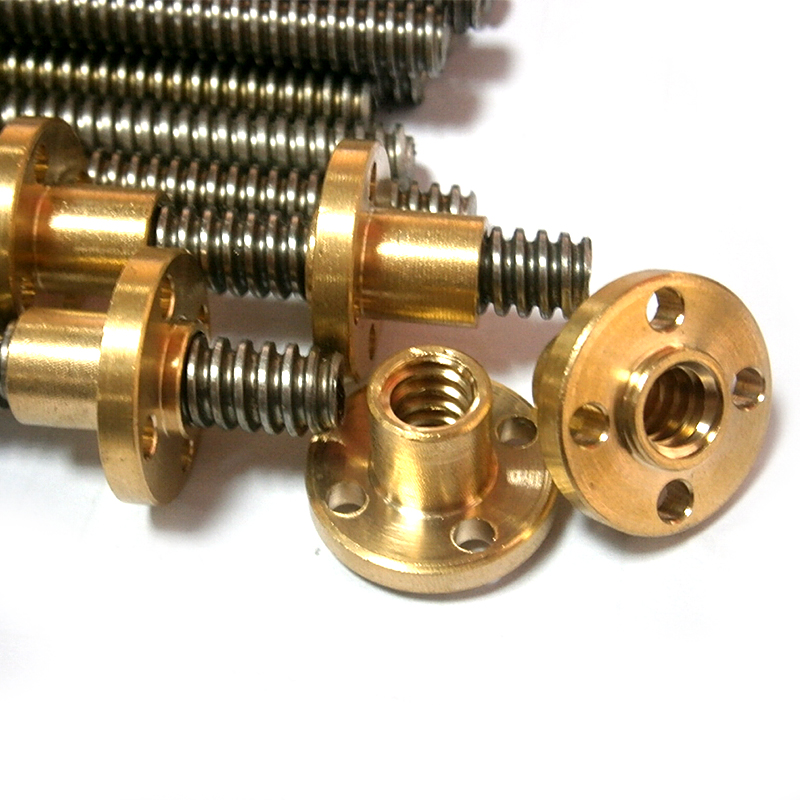

Traditionally, the trapezoidal screw is not used by itself, but is paired with a specially designed nut. These elements represent a travel drive that ensures the implementation of the thread. A pair of screw and nut has a sliding-friction force. If we talk about the running gear from a production point of view, then it should be noted that its direct purpose is the transformation of rotary motion into translational motion.

Screws are very demanding in terms of maintenance - they must be kept clean at all times. This fact makes the maintenance of the mechanisms, of which the trapezoidal screws are a part, quite costly and laborious. However, the trapezoidal thread can serve for quite a long time, and it works very quietly, without causing any inconvenience. And also these screws are characterized by increased carrying capacity.

The production of trapezoidal screws is a long and complex process. In this case, the thread rolling technology is mandatory. Thanks to this technology, the thread becomes as smooth as possible. The distinctive characteristics of screws of this type include the fact that they have a special and rather specific self-locking property.

Good morning

Sauerkraut ... In the morning. Quick and dirty. Bump, bump, bump:

- In the morning ;

- Lol ± lol ± lkl;

- Pink and white;

- ;

- Good luck;

- In the morning.

Pink

Saucer and saucer and saucer. Rose in the middle Burgundy, birch, burgundy Bump, bump, bump, bump, bump, bump

Donkey, donut, donut, donut, donut Please.

Burgundy, burgundy, birch, burgundy Wedge, wiggle, wiggle.