What product can be called transport?

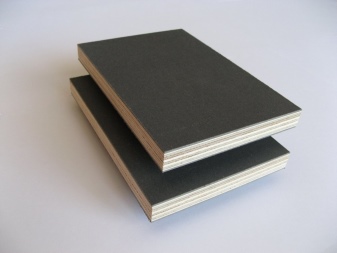

In the automotive industry and applications, transport film faced plywood plays an important role. The first criterion for directionality is thickness.

It is from him that further branching into certain types occurs, which have their own direction, for example:

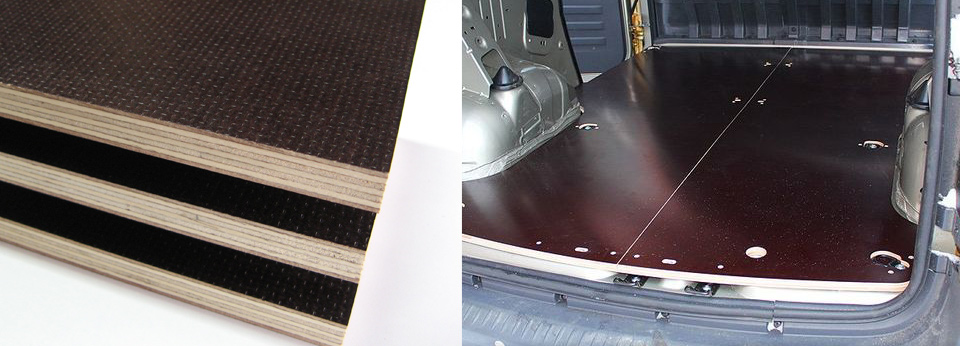

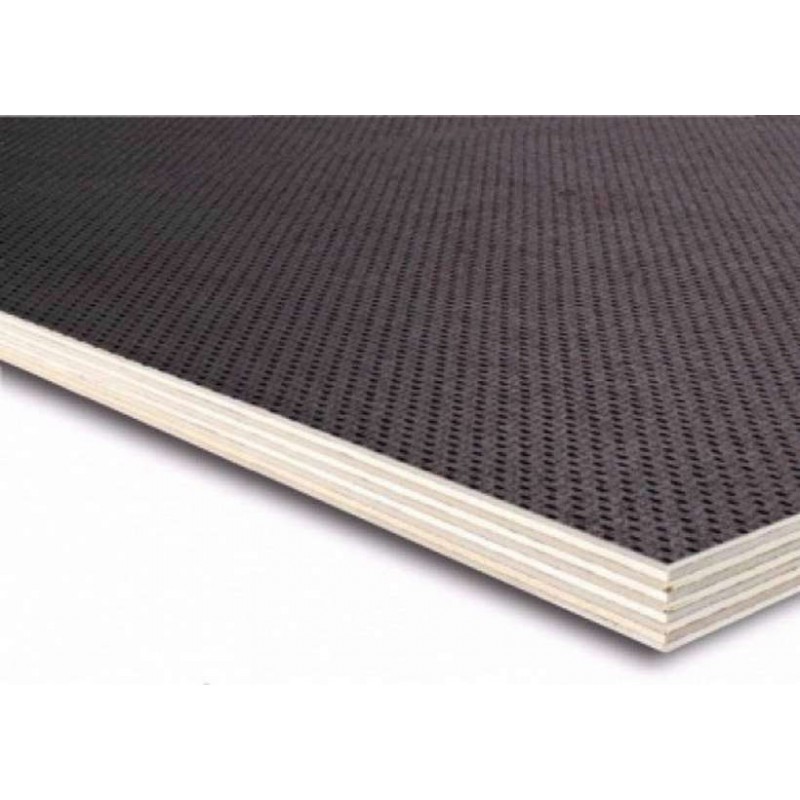

- For finishing floors and doors in vans, it is accepted to use products from 24 to 27 millimeters thick. What exactly the thickness of these parameters is suitable in one case or another depends on what kind of metal frame is in the van. The moment in processing is also important, for example for floors, in order to reduce friction to a minimum, mesh plywood is used. For finishing other parts, plywood is used with laminated layers on both sides of the sheet.

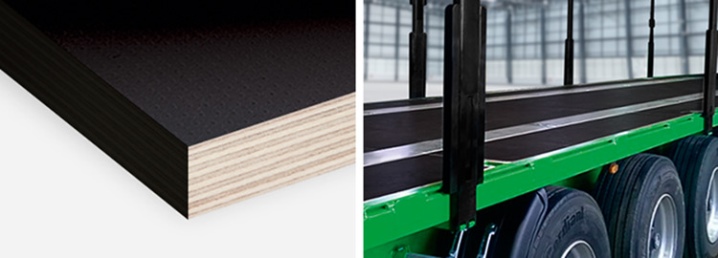

- For semi-trailers, due to the lack of need, less thick materials are used. Usually 15 - 21 millimeters are sufficient for light and commercial trailers.

- Also, often for light vehicles, transport plywood is used with a thickness of 9 - 12 millimeters. Additionally, many manufacturers use it in light boats.

What makes the material transportable

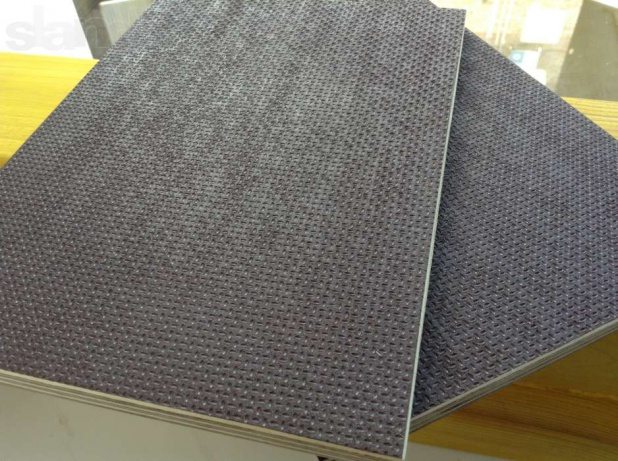

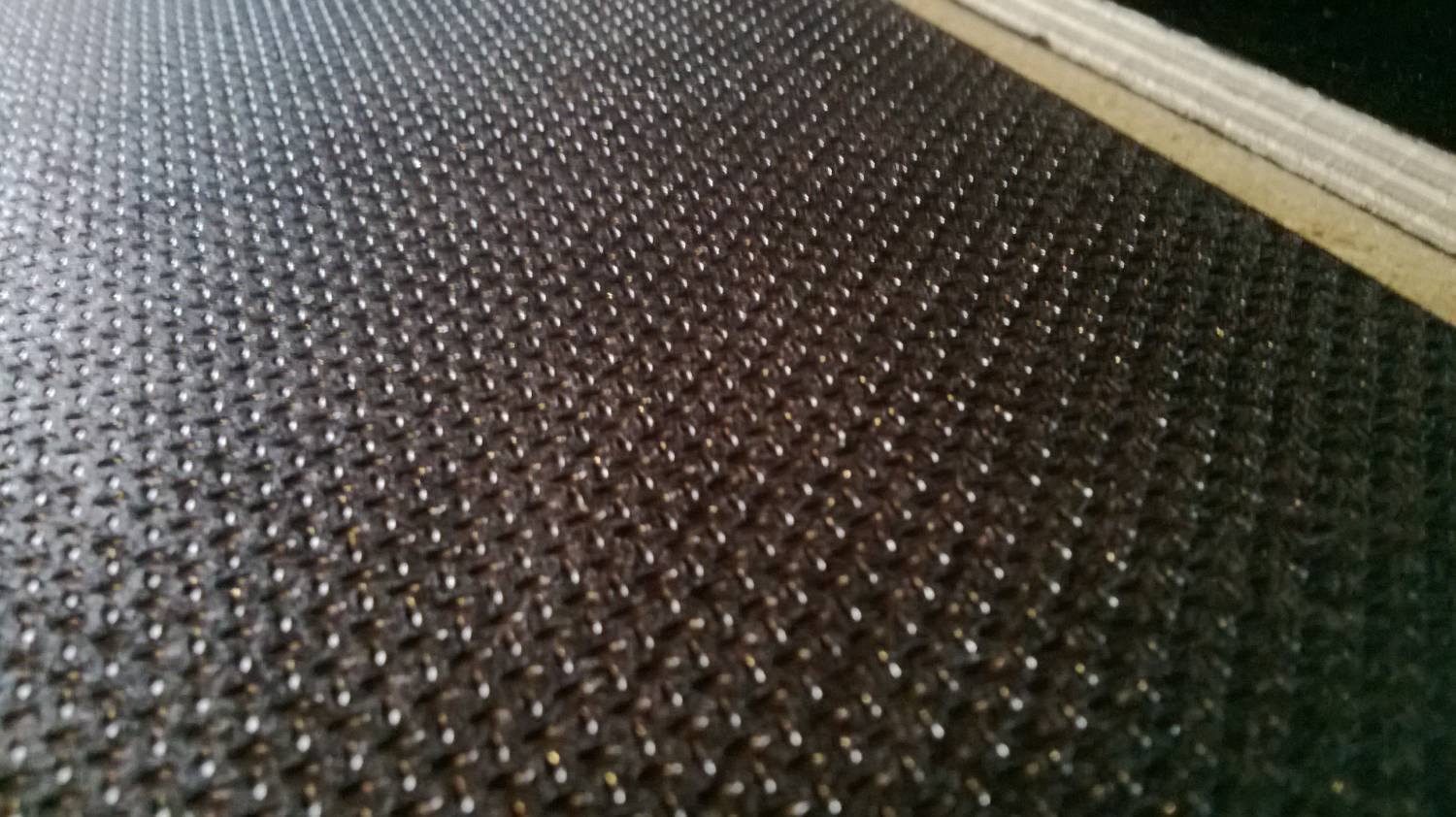

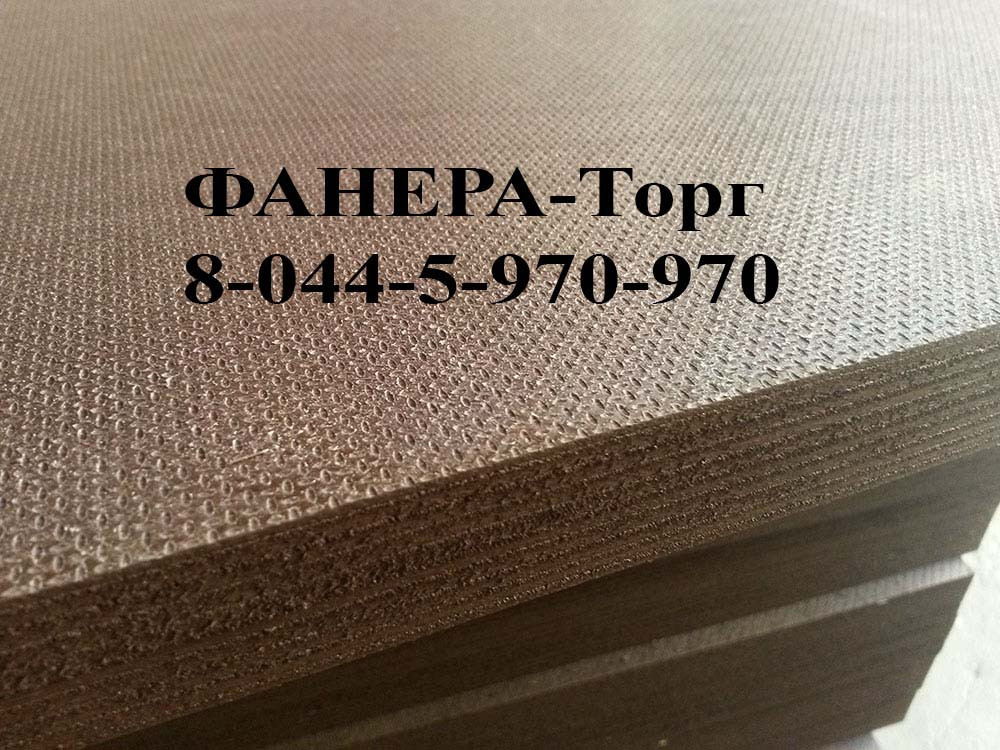

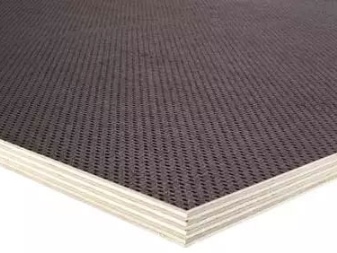

This is the main feature - the grid.

This is the main feature - the grid.

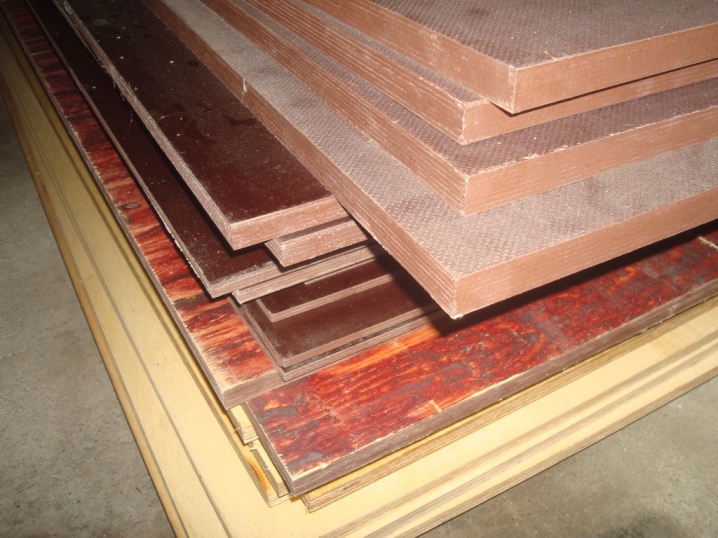

Everyone knows that plywood as a material is a puff of peeled veneer of birch or coniferous wood. For the sake of objectivity, I would like to mention that not only birch, but also other types of hardwood can be successfully used in the manufacture of plywood, while the technology does not change and adjacent layers are superimposed on each other with the intersection of the fibers at an angle of 90 degrees.

Let's omit all the technological stages of preparation and move on to the main thing:

It has been observed that impregnation can give the material water resistance and, in some cases, greater strength. But she alone is not able to solve the issues of resistance to such unpleasant moments as bending and twisting. The solution to this problem was found quite quickly, the fibers were glued at different angles, ranging from 30 to 60 (an interesting effect when gluing layers at a fiber angle of 45 degrees);

A bit of history

Everything came from Finland.

Everything came from Finland.

Few people know that at one time the film faced plywood, which was imported into the territory of our country, then still the USSR, from Finland. That is why it got the name of Finnish plywood.

At that time, it was a high quality material made from birch and only birch veneer using phenol-formaldehyde glue and a thin plastic film. Then this technology was poorly understood, but the reviews were impressive.

Gradually, the scope of the material began to expand:

- In construction - reusable film faced plywood for formwork construction, especially in cases of on-site installation of panels;

- Lining of the bottom of the body, sides in trucks and road trains;

- Shipbuilding - interior decoration.

From history to today

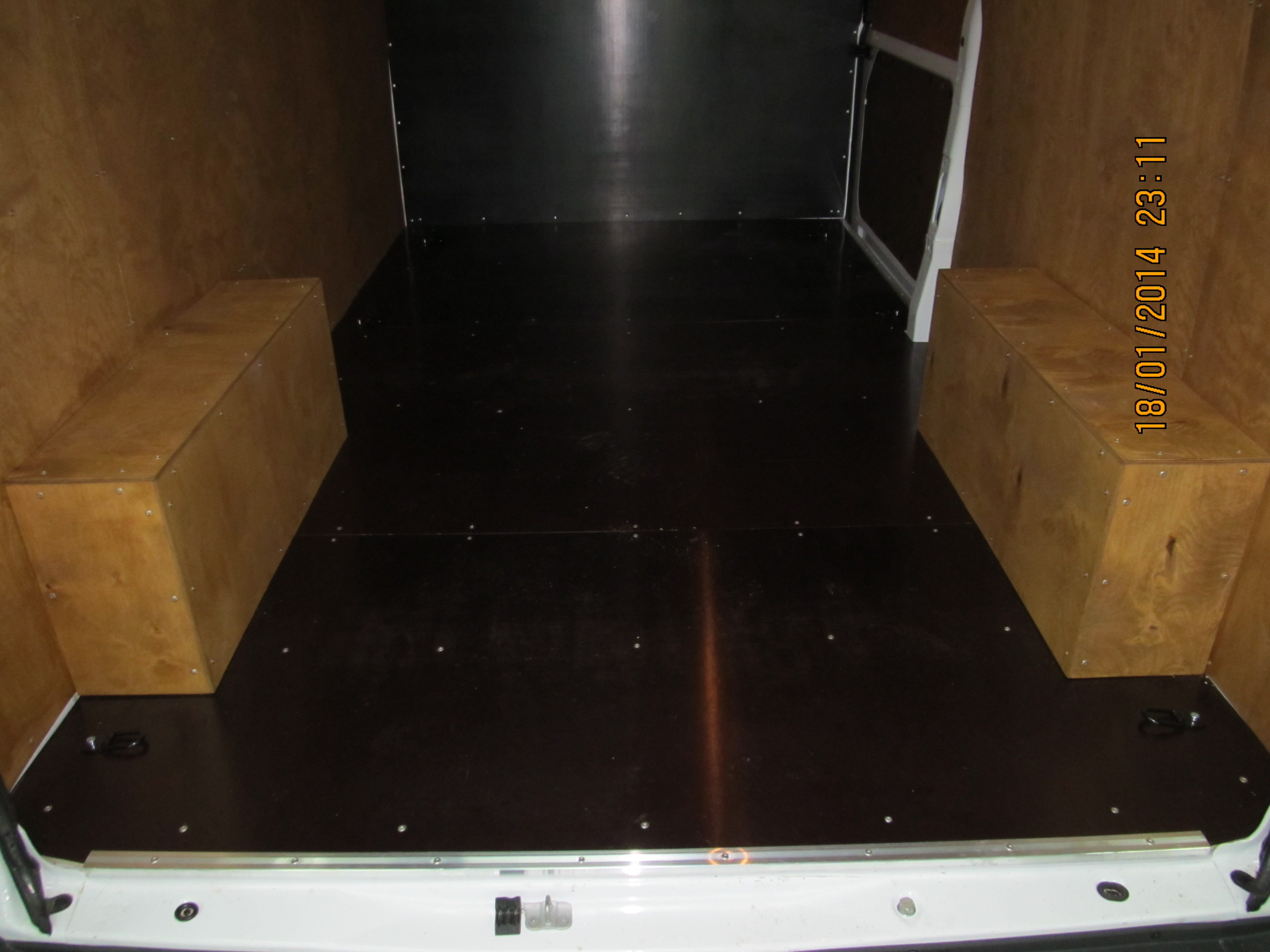

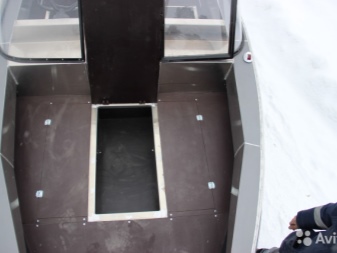

Interior decoration of the minibus.

Interior decoration of the minibus.

For the sake of objectivity, I would like to note that practically nothing has changed. For the needs of road transport, transport film faced plywood with a mesh layer is also used. Product characteristics: high strength, moisture resistance and no sliding effect are in demand and are used.

And although the main characteristics of plywood have not changed:

- Sheet sizes 1220x2440, 1250x2500, 1500x3000 (all dimensions are in mm);

- Sheet thickness from 4 to 30 mm;

Not all sheet types are used in the automotive industry.And the main criterion here, of course, is the thickness of the product.

So:

- If you do not plan to overload your semi-trailer with an excess of cargo, then there is an even more budgetary option for laminated "mesh" - from 9.5 to 12 mm. This type of transport is suitable not only for semi-trailers, but even for home-made boats and boats. The products will perfectly cope with the load from their weight and from 2 to 4-5 people.

- And another dimension that will make a difference in the automotive industry is 6.5mm. Let's just say it's not for the bottom of the van, it's for the walls. It is he who goes to the lining of the walls of the van, as well as the thermal van, industrial refrigerator, to the technological laminated walls (see also the article Sheathing the van with plywood or how to protect the metal from dents and corrosion).

Types and special properties

For bonding birch veneer, thermosetting phenol-formaldehyde resins and bakelite varnishes can be used. The latter, when impregnated with plywood sheets, give them the highest characteristics in terms of moisture resistance and wear resistance.

The manufacture of such a material, or rather its individual layers, takes place using high temperatures and pressure. Such a parameter as increased moisture resistance is achieved by the same type of cooling, that is, under high pressure. In conclusion, the products are treated with solutions, water and alcohol.

Subject to the entire technological process, the output is high-quality transport plywood with a number of positive properties, including:

- Maximum resistance to mold and mildew.

- Excellent strength and moisture resistance.

- Transport plywood sheets are, by definition, fireproof.

- They have increased performance at any temperature and climatic conditions.

- These sheets are practically immune to acidic, alkaline and other influences.

Also, transport types of material have a different distribution, which is based on their characteristics:

- For interior decoration of residential and office premises, as in the automotive industry, it is customary to use the types of material FBS - F and FBS 1 - A. The fastening of these sheets is carried out with coumarone and rosin mastics.

- For external use in the structure of boats, boats, cars, the laminated structure FBS1 is used. These products are not as high quality as the previous ones and therefore they are not allowed for interior decoration.

Due to bakelite resins, transport plywood sheets provide products with excellent strength characteristics, in some cases, which exceed those of steel. For these reasons, the application of products occurs in a wide variety of industries and the automotive industry is a prime example of this.

Application

Floor plywood with a thickness of 24 or 27 mm is rarely used. Basically, it is needed to sheathe walls and doors. Theoretically, it is considered that the layer should correspond to the applied profile, however, such parameters fit perfectly into most options. Material with double-sided lamination is used for vertical surfaces. But mesh products are usually used for the floor of a semi-trailer or trailer.

Structures with a thickness of 1.5 to 2.1 cm are more common in semi-trailers, and not in full-fledged trailers. Plywood of this type is unable to withstand significant loads. The bottom part of a conventional passenger semitrailer can also be covered with mesh material. Plywood that is 2.1 cm thick is relatively expensive. For this reason, the bulk of the craftsmen use it precisely as a floor covering, the sides are trimmed with thinner materials at an affordable price.

The transportation of the lightest cargo usually allows the use of a sheet with a thickness of 0.95 - 1.2 cm. Such designs are applicable even for boats and boats. They will help you cope with the workload of 2-5 people. In some cases, plywood with a thickness of 0.65 cm is used for the walls of vans.Such a product is even suitable for equipping isothermal vans and mobile refrigerators on wheels.

The load on the floor must be taken into account. This is not about the absolute loading of the transported goods, but about the load created by the actions of the loaders in the semitrailer. Normally, the floor is calculated for the value of such a load from 7100 to 9500 kg (in terms of one axle). However, a competent calculation is only possible when taking into account the existence of even heavier loaders.

A separate topic is the use of transport plywood in a gazelle and other small minibuses. You can even make a floor made of laminated material with your own hands, without resorting to professionals. A simple laminated product is better than a specialized one (designed specifically for cars) already due to a much more affordable price. Also this coverage:

allows you to get excellent strength and wear resistance;

cut into exact dimensions without problems;

flexible enough (which is important when wall cladding);

does not swell and does not suffer in any other way from moisture;

not prone to delamination;

relatively resistant to fire.

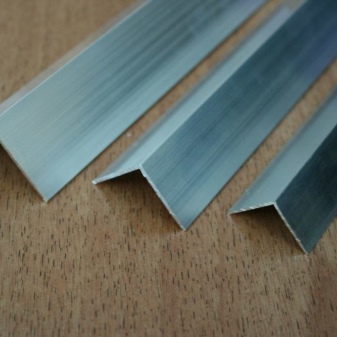

In addition to plywood, you will need:

- frame slats;

- composition for corrosion protection;

- mastic for plywood materials;

- metal fasteners;

- aluminum corners on the threshold;

- strip in the form of the letter T (for joints).

First of all, a slatted crate is created. Already on it and screw the flooring. Thick plywood strips can serve as a replacement for the slats. The frame can be attached by making holes in the body. These places are certainly treated with a composition that inhibits metal corrosion. Next, the slats are fixed to the floor, the wheel arches can be closed with a frame, although this is not necessary.

Plywood preparation is greatly facilitated by using a pattern. It is carefully transferred to sheets. Shaped cuts are usually made with a small-toothed file. Usually the sheets are fastened using self-tapping screws. But for the greatest reliability, aluminum blind rivets can be used.

A homemade floor for a truck body can be mounted on small hinges and self-tapping screws. Some people choose sheets with a thickness of 0.5 cm for a truck (for a cargo van), where it is planned only to walk, but not to roll any heavy carts.

It is also recommended to take:

- for floors - plywood F / W;

- on the front wall - F / F grade with a thickness of 2.4 - 2.7 cm;

- for wall cladding - smooth plywood F / F 0.65 cm thick.

Where did this material come from?

In those days, plywood sheets with such quality were almost impossible to find. In addition, the manufacturing technology in the USSR was practically unknown.

Today, the use of transport plywood has taken on a broader perspective.

In addition to the main type of focus in the automotive industry, it is used:

- In construction. Such plywood sheets become unique and indispensable for formwork construction. A particular advantage in this area is achieved by the fact that the formwork is assembled at the direct work site.

- Often, it is used to decorate interior residential and office premises.

- Lining the floors and finishing the boards in boats, yachts, boats.

What then what today, Finnish plywood sheets are produced in several versions. One of them features completely smooth laminated surfaces. The second type is performed using a mesh structure on one side, and smooth on the other. For this reason, the material was nicknamed transport.

Choice

Picking up automotive plywood is not as difficult as it sounds. In most cases, bodies are formed from FSF. Birch specimens are preferred; coniferous blanks are occasionally used. Additional lamination is carried out for situations where special water resistance and an attractive appearance are required. It must also be understood that laminate may not withstand constant walking and handling, so it is better for walls than for floors.

In extreme cases, a FSF is placed on the floor with the grid up.The dimensions of the plywood are matched to the dimensions of the vehicle. The most common choice is 4/4. But at the same time, in constantly exposed places, it is preferable

It is important - according to GOST 3916.1-96, predominantly sheets are produced with a thickness:

- 3;

- 4;

- 6,5;

- 9;

- 12;

- 15;

- 18;

- 21;

- 24;

- 27;

- 30 mm.

For information on how to sheathe the cargo compartment with plywood, see the next video.

Views

The best quality option for transport plywood is birch veneer. Its parts are held together using thermosetting compounds based on phenol-formaldehyde resins. Bakelite varnishes are also sometimes used. The second option guarantees excellent resistance to moisture and mechanical wear. Film faced mesh and smooth plywood with a thickness of 0.6 cm is quite widespread.

A typical solution like this:

- has a formaldehyde emission category not worse than E1;

- resistant to moisture;

- has a natural moisture content of 5 to 14%;

- has a specific gravity from 640 to 700 kg per 1 m3;

- processed from the ends;

- has a thickness difference of no more than 0.06 cm.

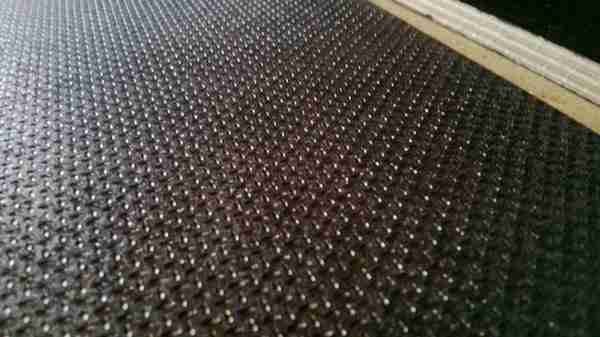

Sveza Titan hard-wearing plywood with anti-slip notch is popular. This grade of material is of high quality. Thanks to the non-slip surface and a special abrasive coating, both people and goods will be completely protected from possible problems. The outer coating includes corundum particles, which reliably protect against mechanical damage.

The abrasion resistance of good transport plywood with mesh is at least 2600 Taber revolutions. The rolling resistance of the roller propellers of hand unloading carts and similar equipment exceeds 10,000 cycles. Determination of sustainability takes place according to the SFS 3939 standard.

Characteristic

Before dealing with the types, use and choice of transport plywood, it is necessary to carefully study its general features. Of course, this material is close to that which is used for the arrangement of the floor, the construction of partitions and other similar applications. However, there are still noticeable differences. Transport plywood differs from ordinary transport plywood by the presence of a moisture-resistant laminated layer.

Basically, such a product is placed on the floor in self-propelled vans and trailers. However, there are a number of other important areas of its use. Specific types are distinguished, first of all, by size (more precisely, by thickness). The doors and the floor are laid out from the inside with the plywood that matches the applied frame. The maximum permissible thickness is 27 mm.