Views

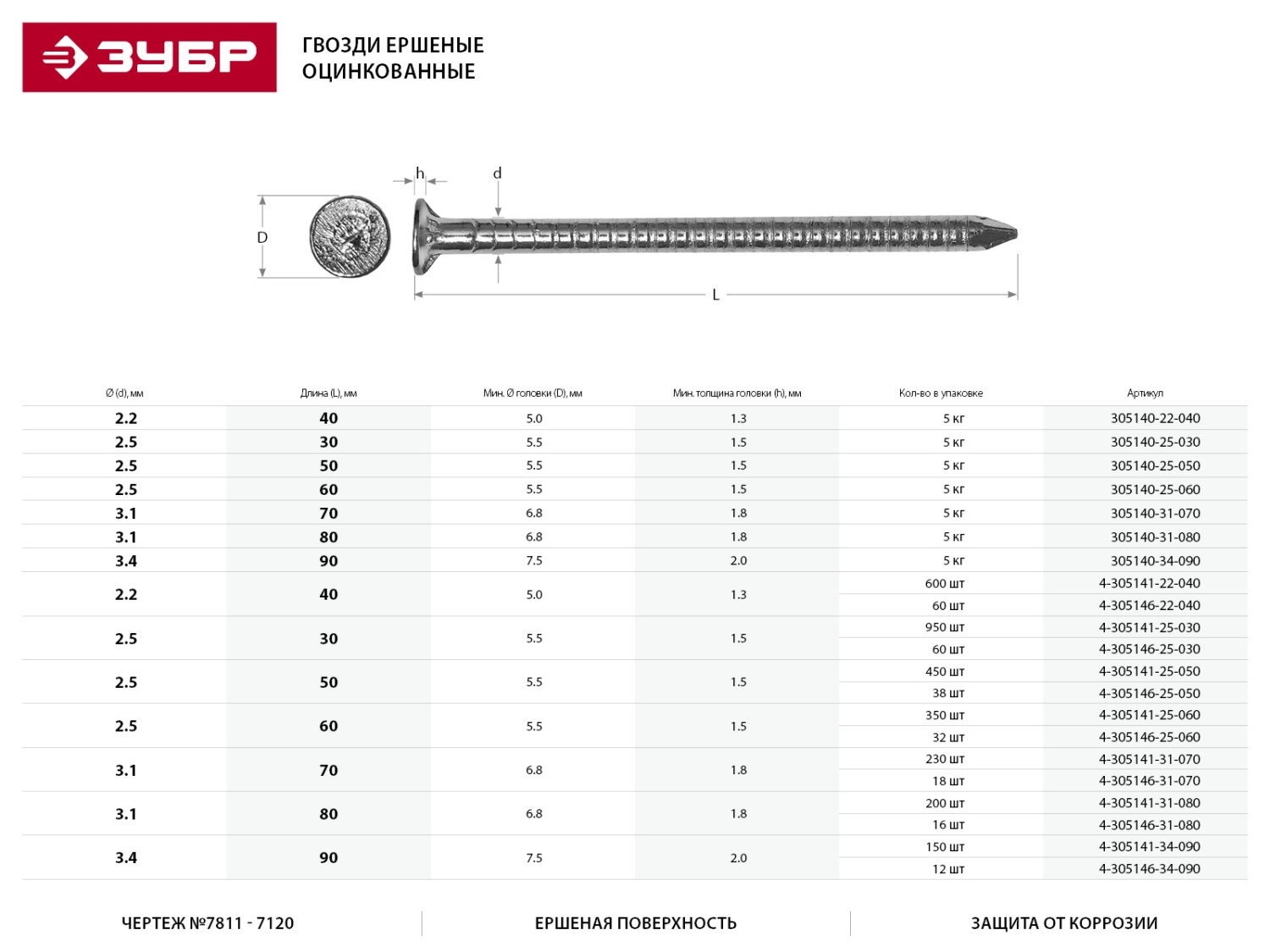

Serrated nails can be made using steel wire. It is of the light-drawn type or is applied with a zinc layer by diffusion. The second option allows you to increase the protection against destruction and extend the service life. The length of brushed galvanized nails can be 2-10 cm. Their cross-section varies from 0.2 to 0.45 cm.

But not all such hardware is equally in demand. Many people buy diffusion-galvanized products with dimensions of 6.5x0.335 cm. They are needed to attach 22 mm wind braces to roof trusses and to perform other carpentry work. Nails based on light-drawn metal (5x0.265 cm in size) are also widely used. Such products are used to fasten sheet finishing materials to the floor.

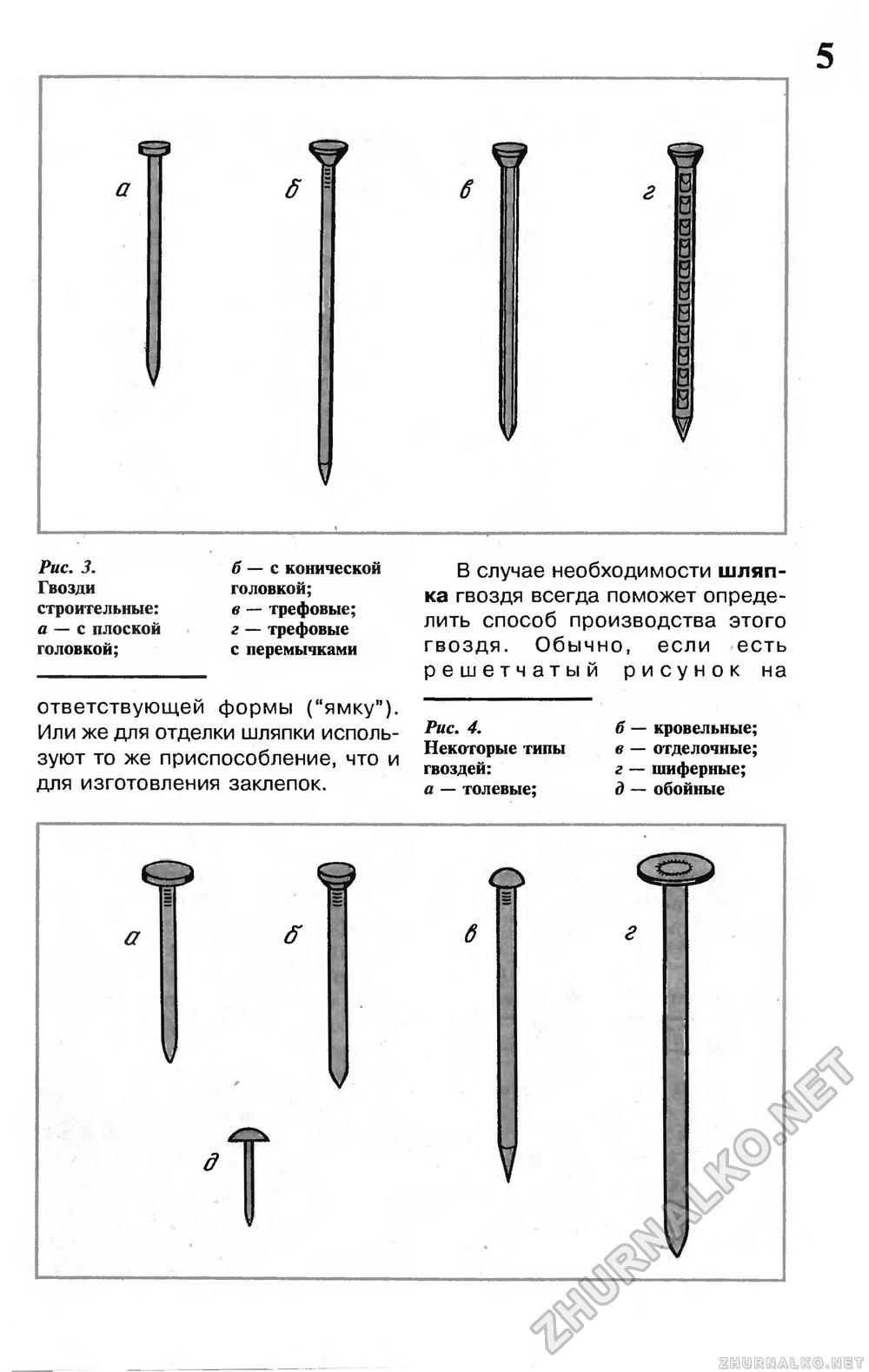

Also worth mentioning is the division into:

- marked;

- having a cone-shaped head;

- pallet variety (nail with a flattened head);

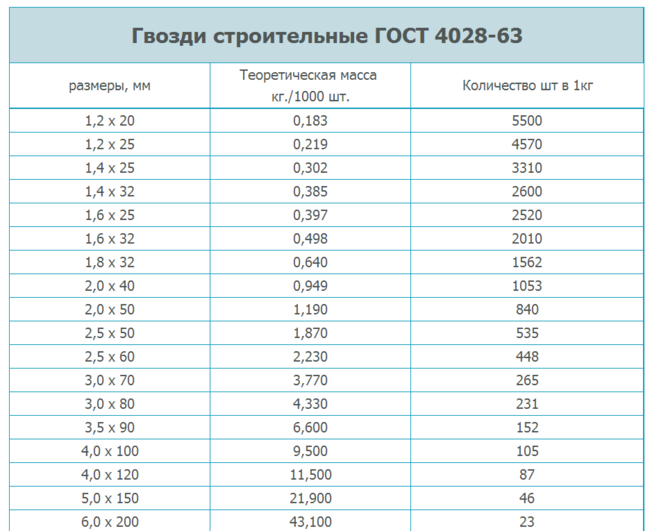

- cassette type of nails.

The latter type is located in the compartments of the plastic tape. It is not used by hand and is only intended to be operated with an air gun. As for roofing brushed nails, they allow you to fasten not only sheet metal and roofing material.

1 Main characteristics of construction nails

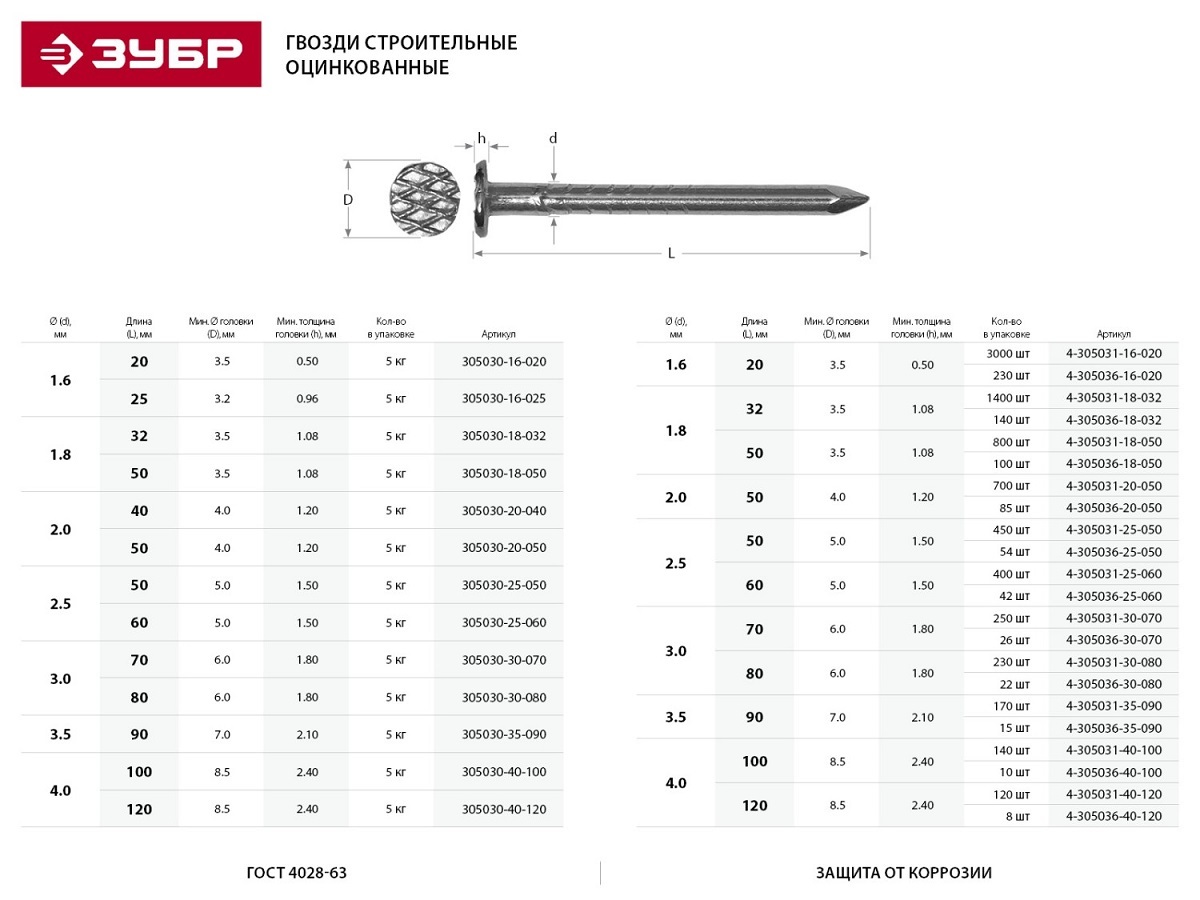

Construction nails are fasteners made in the form of a rod, one end of which is pointed, and the other has a corrugated head (head). Both the shank and the head can have a variety of shapes and sizes, which ultimately determine the purpose of a given nail.

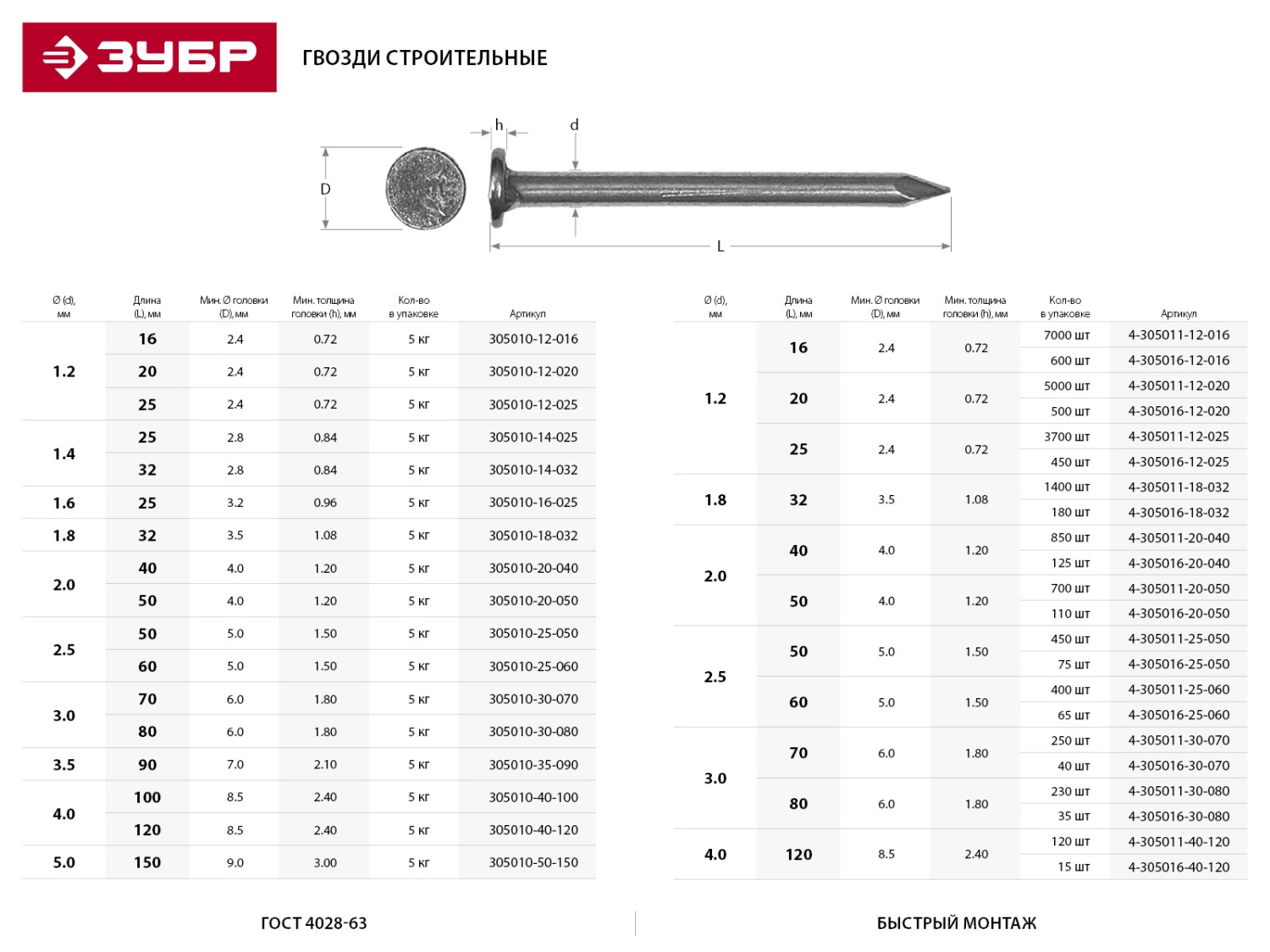

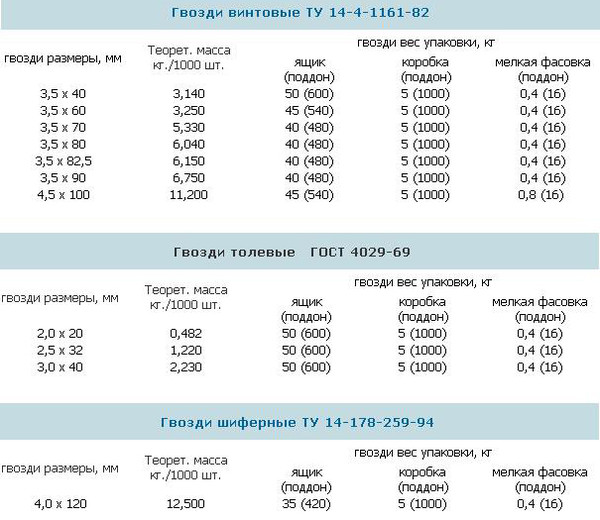

Since the times of the Soviet Union, there have been standards for the production of such a product as construction nails GOST 4028, they are still in effect. In particular, GOST 4028-63 for this kind of fasteners involves the production of black nails, uncoated, and GOST 4028-80 indicates galvanized construction nails, i.e. coated with a thin layer of zinc to prevent corrosion.

As a rule, nails are made from low-carbon steel wire of round and sometimes square cross-section, without heat treatment. However, for special cases, nails made of copper or steel with acid-resistant properties are launched into production.

Construction nails

Construction nails

In the all-Russian classifier of products, OKPD, construction nails are designated by the code 28.73.14.111 and occupy the first place in terms of the frequency of requests.

Standard specifications are subject to slight differences. Thus, nails with a flat head are characterized by a smooth surface of the head and a maximum shank diameter of 1.6 mm, while nails with a conical head have a corrugated surface and a shank diameter of more than 1.6 mm. Thus, the diameter of the head for a flat head nail is approximately two times the diameter of the shank. The standard edge angle is set at forty degrees.

Table 3. Thickness of wood, depth of face and permissible load on nails.

| Sizes of nails, d x l, mm | Minimum wood thickness, mm | Minimum bottomhole depth, mm | Permissible shear load N1, H | ||||

| without pre-drilling | pre-drilled | 12d | 8d | for softwood | for oak and beech | ||

| without pre-drilling | pre-drilled | always pre-drilled | |||||

| 2.2 x 45 2.2 x 50 |

24 | 24 | 27 | 18 | 200 | 250 | 300 |

| 2.5 x 55 2.5 x 60 |

24 | 24 | 30 | 20 | 250 | 310 | 375 |

| 2.8 x 65 | 24 | 24 | 34 | 23 | 300 | 375 | 450 |

| 3.1 x 65 3.1 x 70 3.1 x 80 |

24 | 24 | 38 | 25 | 375 | 460 | 560 |

| 3.4 x 90 3.8 x 100 4.2 x 110 4.6 x 130 |

24 24 26 30 |

24 24 26 28 |

41 46 51 56 |

27 30 34 37 |

430 525 625 725 |

540 650 775 905 |

650 780 930 1090 |

| 5.5 x 140 5.5 x 160 |

40 | 35 | 66 | 44 | 975 | 1220 | 1460 |

| 6.0 x 180 7.0 x 210 7.6 x 230 8.8 x 260 |

50 60 70 88 |

35 45 46 53 |

72 84 91 106 |

48 56 61 70 |

1120 1450 1640 2060 |

1400 1800 2050 2575 |

1680 2170 2460 3090 |

4 How to work with nails correctly

Finally, we bring to your attention a few tricks that will help you easily and effortlessly drive a nail into any surface.

You don't need to hold the nail with your fingers the entire time you hit it with a hammer. It is enough, having put it to the place intended for hammering, lightly knock on the head so that the nail enters 2-3 mm.Then the fingers can be removed and thereby save them from injury. If the nail is bent during driving, you can take it by the bend with pliers and continue driving.

Pliers or a nailer are usually used to remove the fasteners. Moreover, using pliers, it is recommended to make rotational movements in the direction and counterclockwise. When using a nailer, it is recommended to place a thin piece of wood underneath it to keep the wall or floor surface from damage.

Working with fasteners

Working with fasteners

When fastening two parts, it must be borne in mind that for good adhesion, the nail must sink into the lower part at least 2/3 of its total length. The same rule applies to walls.

In order to qualitatively mount the hinged structure, the nail is driven in, slightly tilting its head away from you, so that the structure is held stronger under load. When laying boards on the floor, it will be best to nail the first row of boards, holding the nails straight, and for the second and subsequent rows observe a slight slope so that the nail point "looks" towards the previous row. Thus, it will be possible to minimize the gaps between the boards.

When driving a bent nail, it is important to take into account that, when plunging into the wood, it will not straighten, but will continue to move along a curve. Perhaps such a property will be useful for assembling any non-standard design.

But it will not be easy to get it out of the tree afterwards.

For hammering small nails it is better to use a “doboinik”, since it is very inconvenient to hold small nails in your fingers. In addition, this way you will not damage the surrounding material, even if you miss the nail. This is especially true in the presence of expensive plaster or wallpaper.

Installation features

Roofing nails are widely used, but they are especially in demand during the season of roofing or construction works. For decoration, hardware with a large hat is unsuitable, as it can spoil the appearance of the product. As for the installation of the roof, such hardware is used as follows:

when choosing the length and diameter of the nail, the thickness of the roofing material must be taken into account; it is impractical to choose the longest nails, since at the time of their hammering with a hammer, the hardware rod can bend, distracting the master for dismantling and replacing the fastener, but the worst thing is that at this moment the surface of the waterproofing roofing material can be damaged;

the most popular sizes of roofing nails among roofing masters are products with a diameter of 7 mm and a length of 25 mm; to mount the roof on the ridge of the roof or its ribbed lags, it is enough to take a nail 30 mm long with a head diameter of 10 mm.

The process of installing the hardware is simple - it is driven into the roof structure until the cap is in full contact with the roofing material. Hardware should be placed in a strictly vertical position at an angle of 90 ° relative to the structure of the lathing.

The following video will show you how to properly drive nails into a board.

What is it and what is it for?

The technical characteristics by which roofing nails are made comply with GOST standards. But these standards also allow some deviations from the prescribed execution regulations, namely:

- small errors in the diameter of the products are allowed, the parameters of which depend on the length of the nail;

- the deviation along the length of the nail cannot exceed the indicator of its diameter;

- the central position of the axis of the rod relative to the head should not exceed standard norms, for example, for hardware of 3-4 mm, the deviation of the axis can reach 0.4-0.5 mm;

- the surface of the outer side of the head of the nail should be even and flat;

- the sharpening of the tip of the working rod of the hardware should not exceed an angle of 40 °;

- a certain degree of deflection of the nail rod is allowed, depending on its diameter, for example, for hardware with a diameter of 90 mm, the deflection should not exceed 0.5–0.7 mm.

At the manufacturing plant, a finished batch of hardware is tested under laboratory conditions for compliance with the tolerances of deviations from GOST, and the smoothness of the head, the central position and the deflection of the rod are analyzed. As for the shape of the cap and its smoothness, as well as the height - these parameters are not subject to research in the factory laboratory. Hardware intended for roofing work depends on the materials with which they interact. Roofing can be smooth or wavy. Shingles, roofing felt, bitumen-coated membranes are considered smooth materials. Corrugated material is a corrugated type of roofing slate made of asbestos cement.

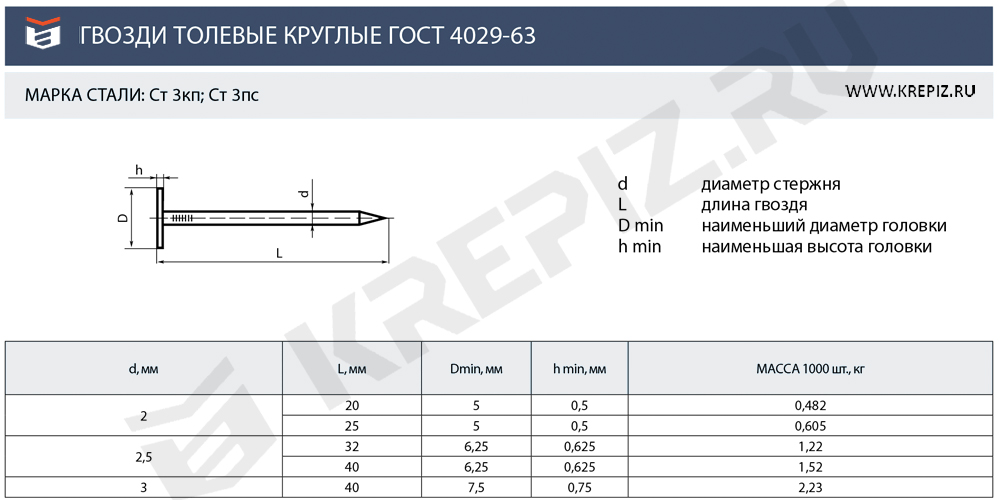

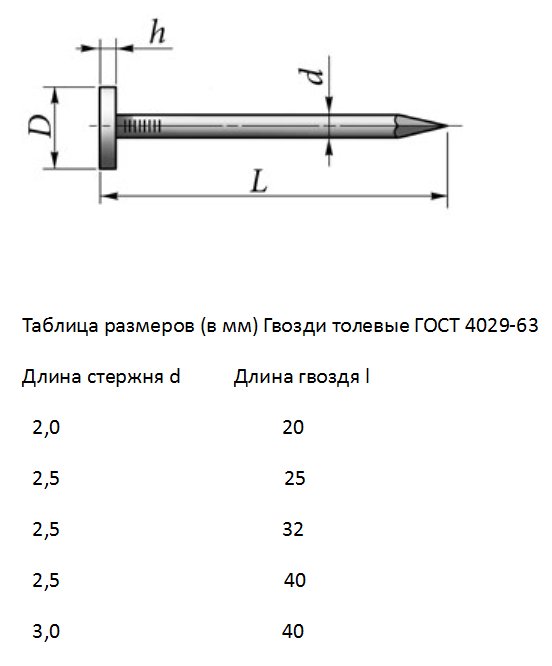

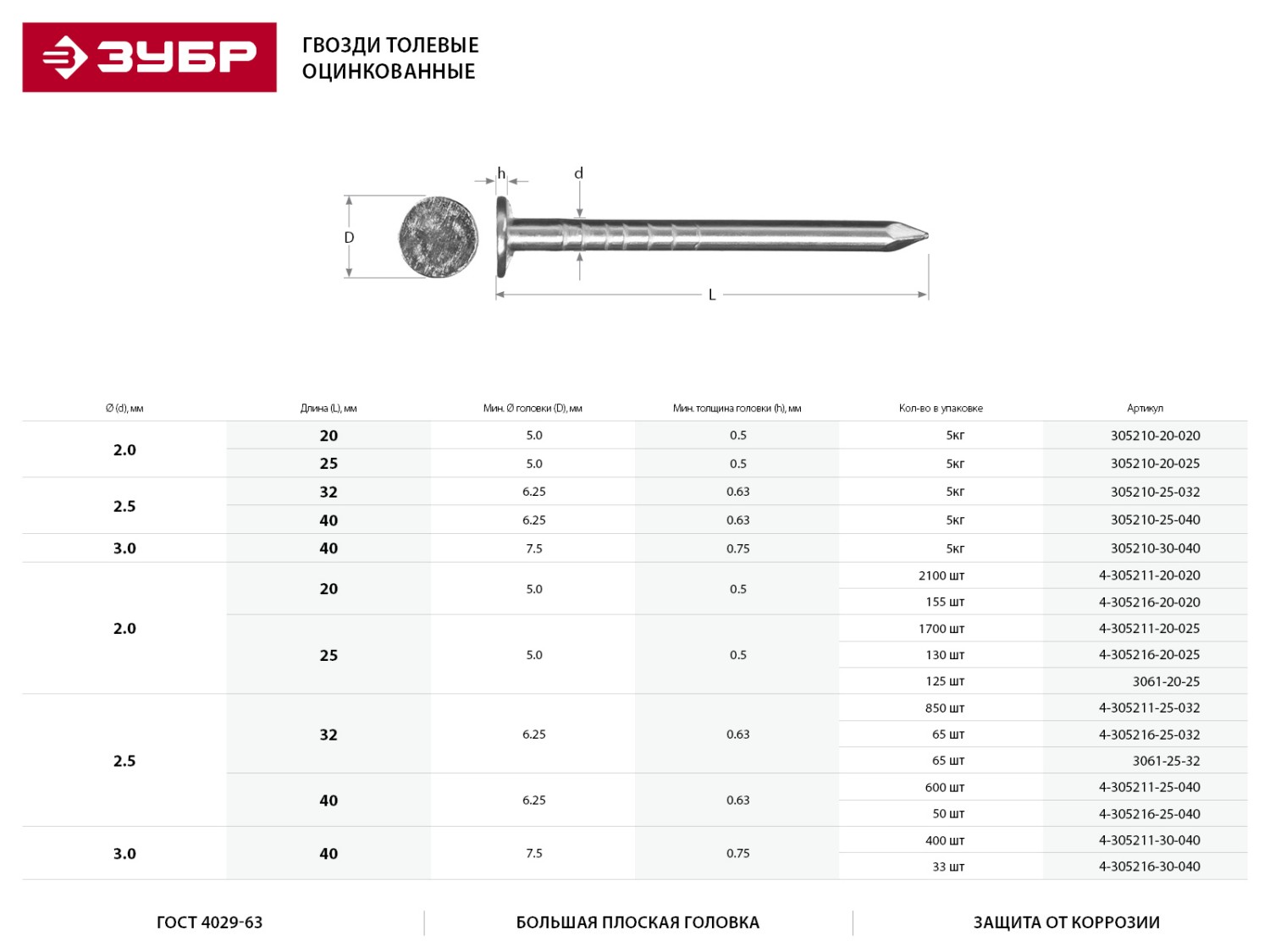

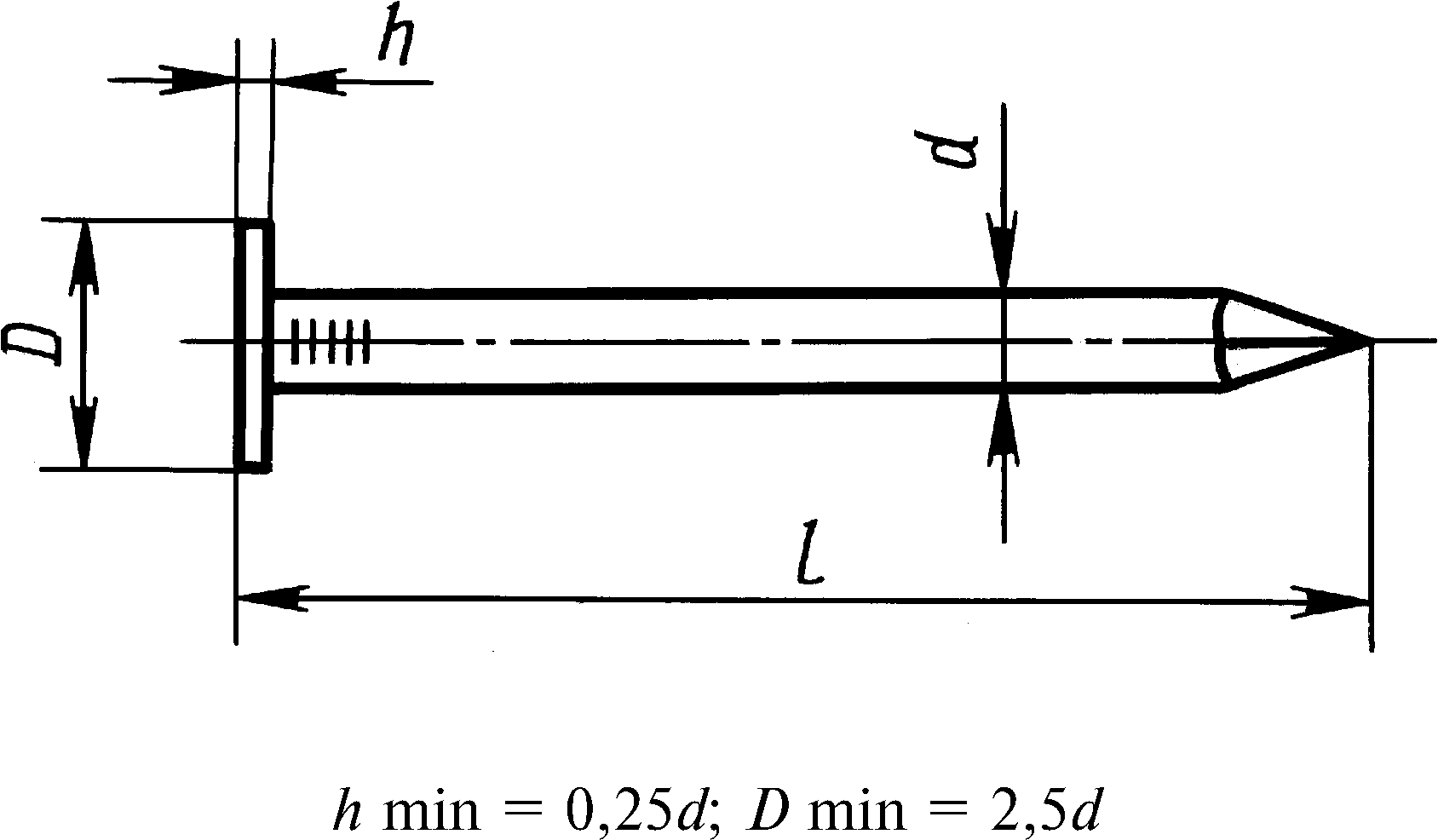

The performance characteristics of roofing nails are as follows:

- the nail shank does not have a groove, it is sharpened and its standard length is from 20 to 40 mm;

- the head of the nail is round, flat and smooth, its diameter is proportional to the diameter of the nail and is its size multiplied by a factor of 2.5;

- the height of the head cannot be higher than ¼ of the shank diameter.

The similar structure of this hardware makes it possible to use it for fastening a soft roof without fear that the material will be perforated or damaged. The wide, flat head of the nail holds the layer of material securely when it acts as a pitched surface.

The use of roofing hardware today is very diverse, namely:

- fixing soft roofing materials on the roof surface;

- reliable fixation of asbestos-cement plates;

- for the assembly of component parts of cabinet furniture;

- when joining chipboard or plywood sheets that do not have an upper protective layer.

The use of roofing hardware is advisable only when the thickness and density of the material are small. For this reason, these hardware cannot be suitable for finishing because of their large hat.

Applications

Galvanized brushed nails, as already mentioned, are in demand by carpenters, builders and repairmen. They are much better suited for rigid structures such as:

- prefabricated pallets;

- scaffolding and flooring on construction sites;

- rough and front floors;

- assemblies from a wooden base and a perforated metal part;

- roof lathing.

They are also required when performing the following tasks:

- preparation of packaging containers;

- decoration of walls and ceilings;

- installation of slopes at windows and boxes at doors.

Nails for a nailer differ in their area of application - and this is expressed primarily in different lengths. Frame hardware can be up to 9 cm in length. For cladding hardware, this figure is up to 6 cm. And fasteners with large caps go to the roof. For a pneumatic pistol of a drum type, drum nails are intended; these hardware are held together by wire or plastic sheath.

The need to use brushed nails when assembling wooden containers is understandable. It will inevitably be thrown at some stage, pushed by the loaders, if only because they have to do the job quickly. And only reliable fasteners help out in such a situation. Where a sharp nail is driven in, the total bond strength will be 5 times higher than with standard fasteners.

In the next video, we will look at one of the options for using a roughened nail for attaching perforated fasteners.

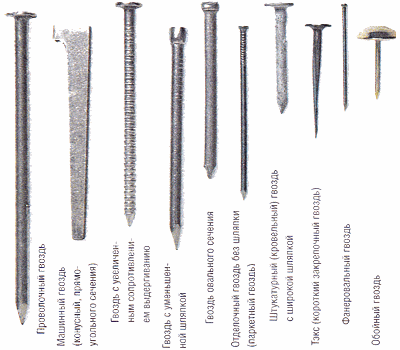

Species overview

Even before starting the construction of the structure, it is worth deciding on the number and type of construction nails, without which it is impossible to do in this matter. Currently on the market you can find a wide variety of hardware of this type. Often found black, flat-headed, tapered, and others.

Construction nails are of the following types.

Slate.As mentioned earlier, these hardware are used during the installation of slate and its fasteners to a wooden surface. The nail has a round cross-section of the rod, as well as a flat rounded head with a diameter of 1.8 centimeters. This device is characterized by a diameter of 5 millimeters and a length of up to 10 centimeters.

Also, this type of product is divided into the following types, according to the material of manufacture.

- Stainless.

- Galvanized.

- Brass.

- Plastic.

Peculiarities

Ruffled nails are usually called a special category of hardware. Along their core is a specially made transverse notch. This component of the nail helps it provide a fairly reliable bond even in loose and unstable materials. Since hardware is coated with a zinc layer in production, it turns out to be quite reliable. The low cone-shaped head helps to further improve the efficiency of the connection.

Even the combined effects of shock, vibration and shrinkage are perfectly tolerated by a ruffled nail. Ordinary hardware, for comparison, even under the influence of one of these factors, can lose its supporting qualities. Ring-shaped "ruffs", entering the tree, repel the fibers. The force of inertia makes them tend to return to their original position.

The cone-shaped head mentioned above sinks into the wood without any problems. After that, pulling out the nail becomes much more difficult. Attempts to pull it out will result in a breakage of the cap or the hardware itself. Summing up, it is worth noting that such products:

- stable and reliable;

- operated for a long time;

- resistant to corrosive effects.

Applications

Construction hardware is used not only for the construction of a frame house, but also for many other procedures. They are often used to connect various wooden and plastic elements. Some types of this device have a decorative function, since after fastening it does not stand out from the tree. Also, the use of a construction nail is relevant during the fastening of parts that are in the open air.

The slate nail is used for direct installation of the roof, fastening the slate sheet to the wooden frame.

They prevent the formation of rust and thus keep the roof intact for a long time. The furniture construction nail has found its application in the furniture industry. It is distinguished from its congeners by its thin diameter section and small size.

With their help, thin furniture parts are attached to each other, for example, the back of the cabinet. Decorative hardware is a thin and short product with a convex head. Such a device can have both copper and brass surfaces. According to experts, nails should be used strictly in accordance with their intended purpose. Otherwise, the fasteners will not last long.

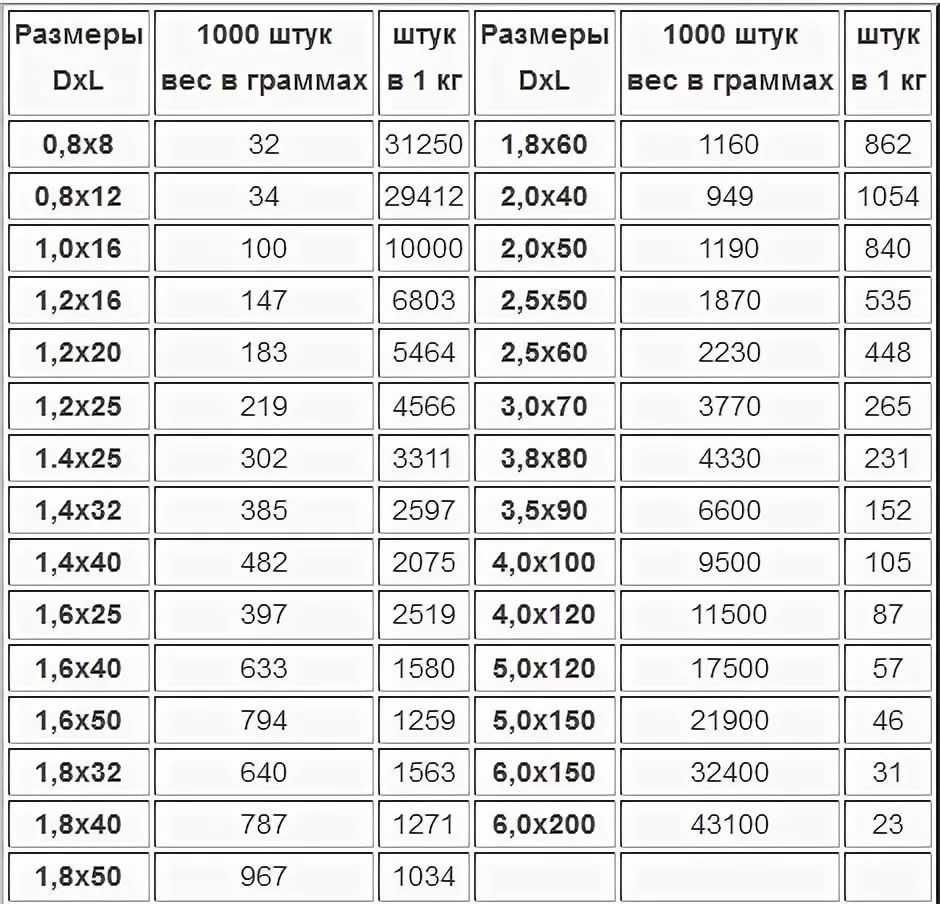

Dimensions (edit)

The sufficient variety of areas of use of such fasteners forces manufacturers to offer a variety of dimensions. The marking must indicate the length of a particular nail and the cross-section of the rod. It should be borne in mind that the latter indicator is 10-16% inferior to the thread diameter. The best way to present the main parameters will help this table:

|

Overall dimensions |

Pieces per 100 g |

Weight 100 pcs, kg |

|

3.4x40 |

41,7 |

0,2341 |

|

3.4x50 |

33,9 |

0,2739 |

|

3.4x60 |

28,5 |

0,3662 |

|

3.4x70 |

24,6 |

0.4278 |

|

3.4x80 |

21,7 |

0,4893 |

|

3.4x90 |

19,3 |

0,5508 |

|

3.8x100 |

12,9 |

1,1203 |

With a size of 3.9 by 90 mm, 100 grams will weigh 14.3 such nails, 100 pieces of them will "pull" 1.007 kg

Important: galvanized products will be heavier just due to the insulating anticorrosive layer. Basic technical parameters are controlled according to GOST 283-75

It provides information about the required precision for parameters and custom properties. Although the standard was adopted back in 1975, it remains relevant.

The regulation prescribes the use of wires made from low carbon steel. Additional heat treatment is not recommended. The finished wire is square.

The nails are checked on random samples from each batch. A party is recognized as fit if the sample contains no more than 0.5% violations. Most often they try to focus on the following properties:

- misalignment with respect to the bar - by diameter;

- the range of cross-section and length values - according to the standards of GOST 3282-74;

- violation of the roundness of the cap - in accordance with the diameter (for example, if the cross-section of the nail is 3 mm, the deviation from the perfectly round shape of the cap can be no more than 0.4 mm);

- obligatory smoothness of the head part;

- taper angles (on the edges of the tip) - maximum 40 degrees;

- deflection corresponding to the length of the nail rod.

Varieties

There are several types of such fasteners. There are screw, construction, zinc, roofing, wire nails. Their use is determined by the purposes of the work during construction, as well as by the material.

In its form, such a building element is as follows:

- pyramidal;

- conical;

- in the form of a parallelepiped;

- in the form of a cylinder.

Additionally, it is customary to distinguish nails depending on what materials they were made for.

- For decoration and furniture production, it is customary to use aluminum and copper parts.

- If the humidity in the room is too high, then acid resistant nails will do.

- Copper models and elements with a brass element are practically not used in construction. The main reason is that they are too expensive. Often used as decorative elements.

- Galvanized nails are convenient in that virtually no corrosion process occurs on them. They are used for both interior and exterior work.

- Black details are only applicable as a temporary option. In construction, they are subsequently replaced with more reliable analogues.

Before carrying out construction work, it is recommended to determine the nature of the varieties of products.

- Conventional fasteners are used to connect wood products. This is a classic option that is more popular when choosing building materials.

- Screw nails are available in black and galvanized. In the first option, it is an exclusively temporary solution, in the second, it is rather a solution to practical problems. Such elements are in the price category available to the average buyer (both individuals and legal entities).

- Galvanized slate nails are used exclusively for fastening slate. To ensure the most snug fit to the material, the product has a matching cap. The galvanizing method is electroplated, it is able to protect against rusty streaks.

- Cliff nails are needed to secure soft roofing and roll materials. They perfectly hold wood due to their structure.

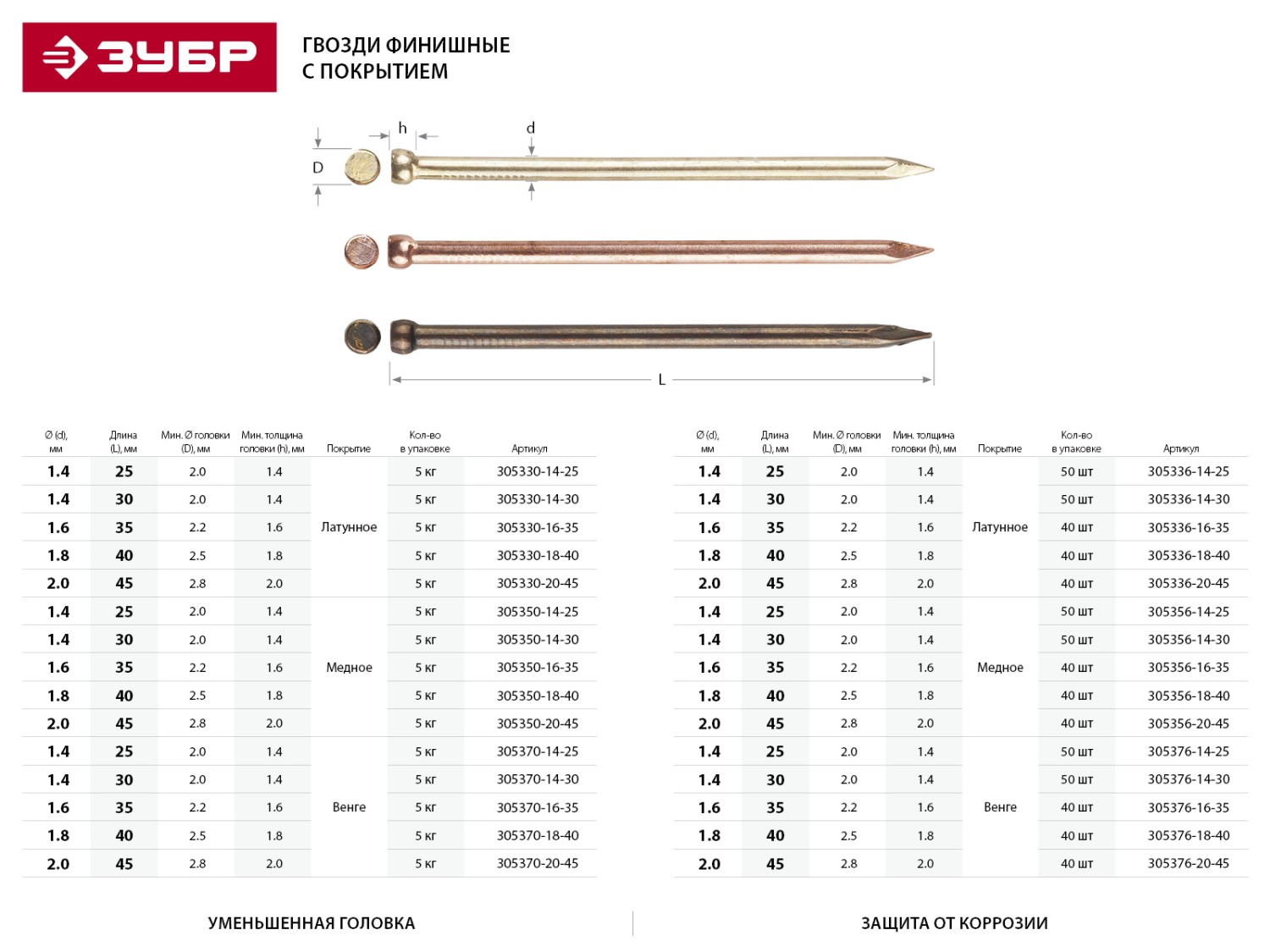

- Finishing elements are used exclusively for fine fixing of the finish. The main feature is that it is one of the most durable methods for fastening materials.

Usage Tips

The main recommendation when choosing building products comes down to the fact that it is better to first have a scheme or plan of construction work, and only then calculate and purchase the goods. The desired characteristics are immediately prescribed, depending on what material they will be applicable to, what shelf life is expected from them, and also whether they should be protected from rust.

Nails are chosen depending on their direct purpose or aesthetic appeal. If they are more of a technical function, then the first option is preferable.

Additionally, it is customary to highlight roofing, wallpaper and finishing nails. First of all, they will differ in their price and technical characteristics. On sale there are building elements for drywall, plastering, packaging, molding, boot, with double and closing caps.

Watch the related video below.

Peculiarities

No matter how improved construction technologies, nails remain one of the most demanded elements for fastening. Construction nails are a rod with a pointed tip, at the end of which a head is located. The shape of the rod and the head can have a different shape and size, which determines the purpose of the hardware.

For construction nails, there is a valid GOST 4028, it regulates the manufacture of these devices. The material for the production of hardware is usually low-carbon steel wire with a round or square cross-section, without heat treatment.

Specifications:

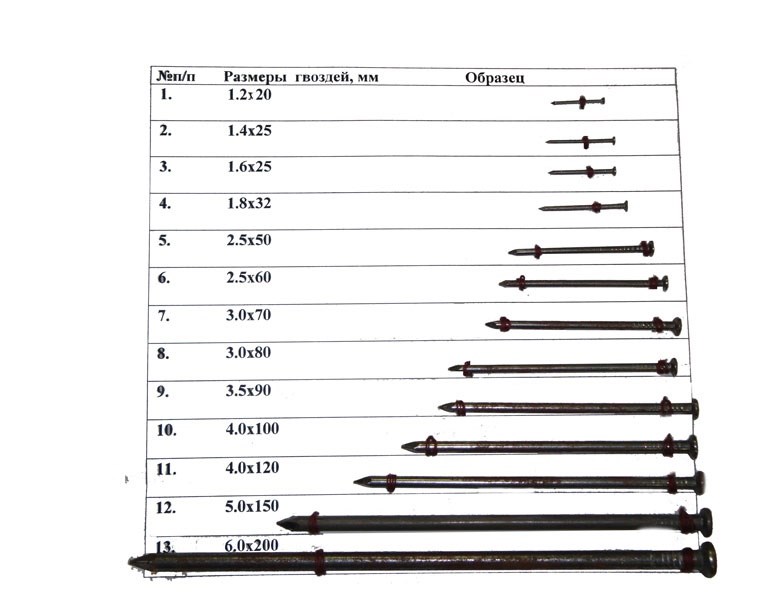

- the core of the product can have a diameter of 1, 2 - 6 mm;

- the length of the nail is 20-200 mm;

- indicator of one-sided rod deflection 0, 1 - 0, 7 mm.

The sale of hardware for construction is usually carried out in batches, each of which is in a corrugated cardboard box weighing from 10 to 25 kilograms. The package contains only one standard size of the nail, each unit of which must be marked.

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

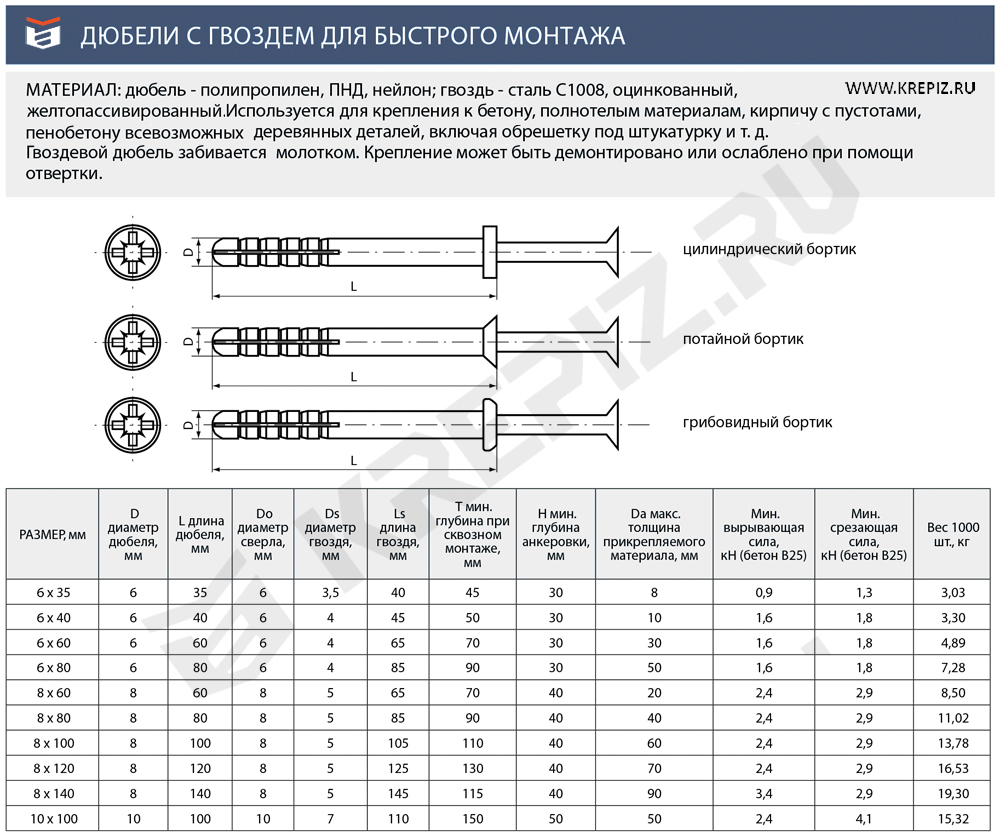

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

Species overview

The design of roofing nails is simple, but the classification of hardware is not very diverse, since these products, intended as fasteners for roofing felt, have a very specific application.

Galvanized nails are made from low carbon steel wire. After cold stamping, the nails are coated with a thin layer of zinc. The thickness of the coating does not exceed 6 microns, but this layer protects the hardware from the effects of a humid environment and prevents the development of corrosive processes. Galvanized nails with flat round heads can be safely used for outdoor use. Zinc ensures durability of the hardware, the fastener made will be strong and reliable for many years.

- Uncoated nails are regular black nails made from steel wire rod. Since the hardware does not have a zinc coating, their cost is much lower than that of galvanized counterparts. But such hardware quickly rusts and spoils the appearance of the roof with rust stains. Therefore, it is advisable to use black nails for internal work in order to assemble furniture or when assembling chipboard joints.

- An ugly shank surface is the most common option where the nail shank has no notches or threads.

- Carving on the surface of the rod - this type of hardware is used in areas with difficult climatic conditions, where strong winds constantly blow. The thread on such products is made in the form of knurling and during installation. It provides a strong connection between the roofing material and the roof structure.