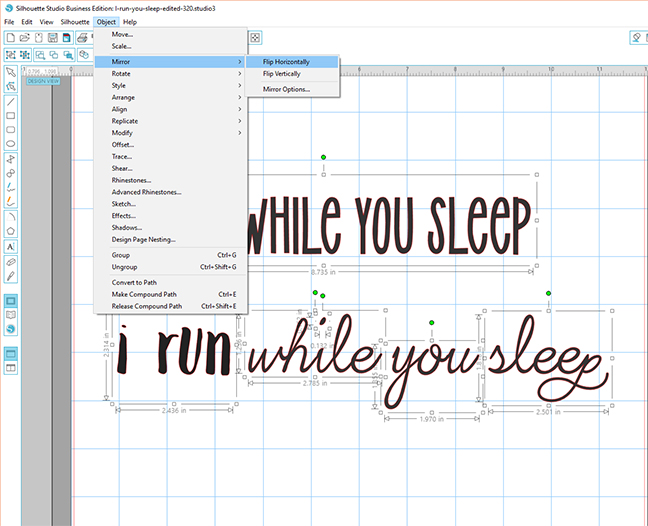

SECOND STEP: SIZE AND MIRROR

Select the text and resize your layout as needed. I try to use the material as rationally as possible and cut the pieces left over from previous projects. For this I use a carry.

MORE: Easier to transfer material to fabric in sections approximately the size of your iron. Plan section sizes in advance so transfer to fabric is quick and easy.

The next step is very important! I even have a reminder sticker on my CAMEO plotter in case I work with thermal transfers.

You need to "mirror" the layout before cutting, otherwise it will be transported back to front.

To do this: select the entire layout. From the Object menu, choose Flip> Flip Horizontally.

Varieties

Thermal transfer films for fabrics are classified according to various criteria.

By thickness

This is a rather serious indicator, and it is important to pay special attention to it, because thermal transfer film is, first of all, a sticker. Image quality will depend on its thickness. The thinner the film, the better the quality of the printed picture.

Thin shell adapts to each material and is easier to cut

The thinner the film, the better the quality of the printed image. The thin shell adapts to each material and is easier to cut.

By composition

The composition of such film materials can be of 2 main types - it is either polyurethane or with a polyvinyl chloride base.

- PVC - these are the most budget films, they are thicker and more inelastic, have a more modest color palette, they are often not equipped with an adhesive backing. They are used on thick fabrics, for cutting and gluing larger parts, often such elements can be seen on overalls. Among the advantages, in addition to the low price, one can note a rather high washing temperature (80–90 ° С).

- Polyurethane (PU) is the best thermal transfer. The material has a complex production technology, therefore, it also has a rather high price. It is thinner and more elastic. It is distinguished by its versatility: parts, both the smallest, medium and large, are perfectly cut out of it. The transfer of images is better. Polyurethane, due to its low thickness, does not leave marks.

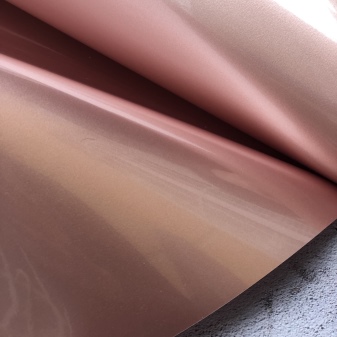

Flex films are quite diverse, they can be classified by color and texture.

- Standard color (these are absolutely all popular colors, however, the palette may vary from company to company).

- Fluorescent (neon colors) - neon orange is most often found, as well as pink, yellow, blue, green.

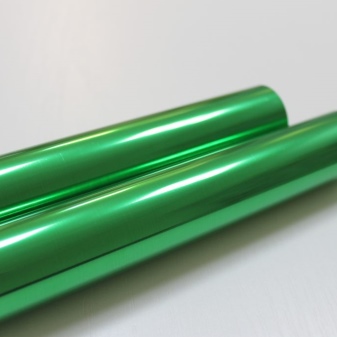

- Metallic - films can be painted in gold and silver.

- Mirror colors are glossy options for gilding and silver.

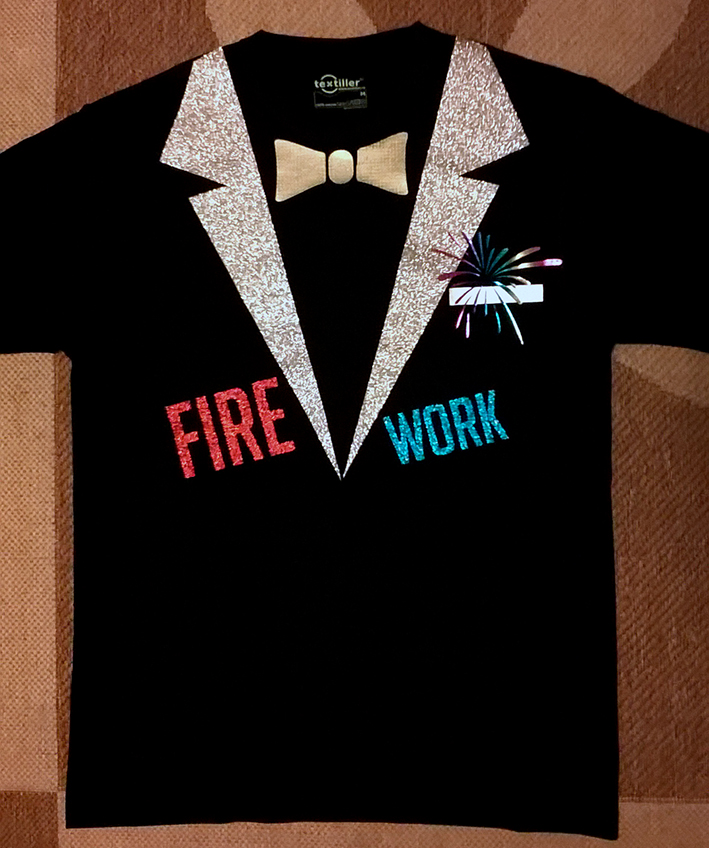

- With glitter - films of all possible shades, characterized by the presence of shiny glitter inclusions.

- Reflective flex. Reflective (aka retroreflective) film contains reflective elements, which in everyday life are called reflectors - this concept is used in colloquial speech. These are, first of all, light strips that distinguish special clothing, for example, traffic police officers, road workers. With its help, any equipment is marked, and it is also possible to use it for advertising and information purposes.

- Light-accumulating thermal film. This unique type of photoluminescent film accumulates energy during daylight hours, and then can glow in the dark for 6 to 8 hours. It is often used for the manufacture of identification marks, used in advertising products. Recently, T-shirts with such images have become fashionable - they are popular with the younger generation.

But that's not all - there are other types of thermal transfer films.

- Thermal films for so-called difficult fabrics, namely: siliconized, treated with water-repellent compounds. As already mentioned, simple thermal films cannot be glued to such a surface. But individual manufacturers have nevertheless developed quite unique products - their films are suitable for transferring designs to similar substrates.

- Films with high elasticity - such developments are used exclusively for delicate, stretchable stretch fabrics. This is a great option to transform your sportswear. The film does not deform even when stretched strongly while running or performing other exercises.

- Bulk thermal films. These products are capable of making a volumetric thermal transfer that will stand out above the surface of the material.

- Thermal transfer flock is an interesting and tactile material with a velvety surface. Products with this finish look exquisite. Fluffy letters or patterns will decorate many products. Flock is produced in a rich color palette. The material has an interesting feature - after the very first wash, the product will be even more attractive, since the villi will straighten out and become fluffier.

- Films with 3D effect occupy a separate niche. They help to create a three-dimensional image that is particularly true.

Manufacturers

In the market of thermal transfer films, a large number of companies are engaged in their release. Italian manufacturers, such as Siser, are considered leaders in the production of quality products. It is also worth noting the Korean company CE-301, as well as brands such as Chemica from France, German Poli-Tape, manufacturers from the USA - CAD-CUT.

Low-cost films are mainly made in the Middle Kingdom. It is believed that Chinese products are slightly worse than European and American ones. But in general, good products are produced in China. For example, we can cite the well-known company Econoflex on the domestic market.

What flock films do we use?

CAD-CUT Premium thermal film for small parts

Elastic and environmentally friendly polyurethane thermal transfer material. Large selection of colors and textures. Plain, foil, fluorescent. Transfer temperature 160C, holding time 20 seconds.

Manufacturer:

Stahls'

Advantages:

For cutting complex layouts and small parts

Elastic, for application on all types of fabrics, cotton, synthetics, mixed.

Specifications:

Roll size - 0.5x30m,

Very thin (90 microns) - for cutting complex layouts and small parts elastic, for application on all types of fabrics, cotton, synthetics, blended.

Does not deform after washing.

Can be applied in several layers, wash resistant.

On a strong self-adhesive backing for easy picking and thermal transfer.

Manufacturer country:

United States of America (USA)

Confusion in terms.

On the net you can often find the opposition of sublimation to thermal transfer, there are even articles with the headings "Thermal transfer vs sublimation." and "Sublimation or Thermal Transfer?" Of course, these headers only make you smile. ))) Moreover, in some publications, thermal transfer is called the film method of applying images, using a classic thermal transfer film and a cutting plotter, in which full color is not possible, and in others, transfer using paper or film on which any image is printed, including ... and full-color and subsequent "welding" of this print on the product (technologies differ from different manufacturers of such media, but in general the process is absolutely the same).

All this is THERMAL TRANSFER!

Of course, all three methods are thermal transfer methods. In all cases, there is a transfer or fixation of blanks prepared by various methods (transfers, applications) onto fabrics, clothes and other products with the help of temperature and pressure, which is provided by a heat press or a calender (calender heat press).At home, many use an ordinary iron, and there can be no question of high-quality transfer and a large transfer area. Therefore, the juxtaposition is, to say the least, incorrect. )) Because in all these cases we have: temperature - thermal and transfer - transfer, but the images themselves (blanks, transfers, applications) are made in completely different ways, materials and equipment, and, accordingly, the physics of penetration or attachment to tissue is different for them ...

Correct classification of thermal transfer.

As a result of the above, it is worth understanding several basic types of thermal transfer transfer of images to various surfaces.

- Sublimation thermal transfer. The ability to transfer full-color graphics not only to textiles (at least 70% polyester), but also to any surface, including hard, curved and cylindrical, provided that there is a layer of polymer (polyester) on the surface. Transferring only to white surfaces, to dark ones is not possible, to colored ones with restrictions, for example, black color is transferred to any colored fabric, except for black, of course. There is no white sublimation ink.

- Film thermal transfer. Technology using thermal transfer films for plotter cutting. The ability to transfer only to textiles of any composition of any color. There are, for example, low temperature thermal transfer films specifically for nylon (POLI-FLEX, NYLON series, 4800).

- Thermal transfer using special media. The ability to transfer to textiles of any composition and color, using special media (film or paper) with a surface designed for printing with various types of inks and toners: for laser printers, including those with white toner, for water, pigment and solvent inks. Currently, carriers have appeared (they consist of a set of two papers A and B), when transferred from which, only the printed image remains on the fabric, without the rest of the substrate, on the product it looks like thermal transfer film or direct printing.

What fabrics are suitable for thermal printing

Thermal film provides complete freedom in the choice of textile material. You can process synthetic or natural, as well as mixed surfaces. Even the color of the material does not matter - the image will retain its original color and will not be corrected. The user can be confident in applying the film to dark and colored fabrics. It is recommended to study the manufacturer's instructions before using the tape - some options have features that should be taken into account when working.

Due to its advantages and low cost, thermal transfer films have practically no competitors.

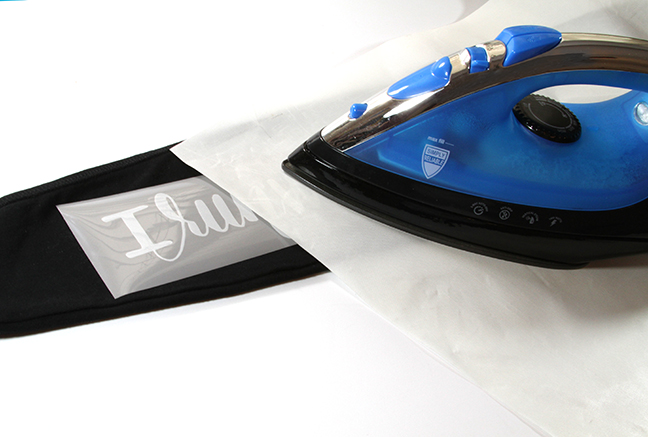

FIFTH STEP - FIXING WITH IRON

Set the maximum temperature on the iron (cotton).

For speed, I use a professional heat press, but this film is made specifically for successful iron transfer.

Place your mockup on the leggings right side up (so it reads well).

Cover the film with a piece of cloth and press with a hot iron for 45 seconds with medium pressure. If the layout is longer than the iron, repeat several times for each section.

Once all the lettering is attached to the fabric, remove the transparent film backing by the tip. (Be careful not to burn yourself!). If the film does not separate from the backing, warm it up for a few more seconds.

So you're done! Let's see what you get!

Missy

Briggs

Thermal transfer films.

The main way to decorate and personalize clothes, both festive, everyday and promotional, as well as sports and workwear, are still thermal transfer films, which can be bought in various organizations selling advertising materials.

The process of making a thermal transfer film and applying it to clothing.

- Preparing a vector layout for cutting on a cutting plotter.

- Cutting thermal transfer film on a cutting plotter, according to the finished layout and removing (sampling) unnecessary parts of the film that do not contain portable graphics.

- Transferring the cut-out thermal transfer to clothing using a heat press.

- Removal of the backing, for different films, can be done hot or cold.

A sample of advertising and decorative thermal transfer.

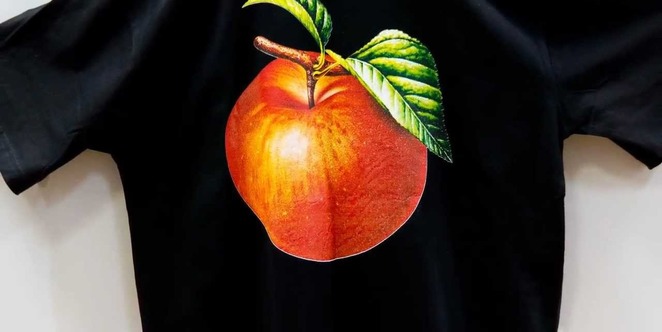

T-shirt and "printing" with thermal transfer film.

Photo 1, women's T-shirt.

Photo 2, men's T-shirt.

Photo 3, reverse side (back).

Samples of applying logos and names on overalls.

Thermal printing equipment

In professional workshops they use:

- plotter cutting, allowing even very small image details to be reproduced;

- heat press. The equipment allows you to easily create multi-color thermal film applications. The mechanism is very easy to use, since the tape is equipped with an adhesive backing. Cutting with a plotter holds the film in place, preventing it from slipping.

Thermal printing

Thermal printing

At home, the equipment is easy to replace with an iron and scissors.

More information about the equipment for applying thermal transfer film and how the application takes place can be seen in the video:

Types of thermal transfer films

Thermal transfer films are classified according to:

- Film thickness - affects the quality of the appliqué. The thinner the material, the better the image will be printed. Thin polyurethane deforms easily to adapt to the material. The film can be cut in any position.

- Composition. Here, the material from which the film was made is taken into account: PVC or polyurethane.

- To the manufacturer. The market is large and many companies are engaged in the production of thermal transfer films. Manufacturers from Italy and Korea are considered to be quality leaders. The Chinese counterparts are slightly worse, but on the whole they represent a good product.

The difference between PVC and polyurethane thermo material:

- PVC film is the cheapest thermal transfer option. It is thick and inelastic - suitable for heavy, coarse fabrics.

- Polyurethane is the best thermal transfer. It is more expensive than PVC, but with it you get better image transfer. The film allows you to work with absolutely any fabric: natural, mixed or synthetic. Polyurethane is characterized by a small thickness, which is why it does not leave marks. The print is so high quality that the picture is wrinkled along with the fabric: the film itself is soft and stretches easily.

Modern manufacturers produce many models of thermal films. The buyer can choose the right one for the material and its design.

Types of thermal transfer films:

- Flex film is a general name for a product. This category includes even the most basic models with a smooth surface and a different color palette;

- Flock films - stand out with an excellent velvety surface that suits different materials;

Flock Thermal Transfer Film

Flock Thermal Transfer Film

- Models with high elasticity - used only for very thin and delicate fabrics;

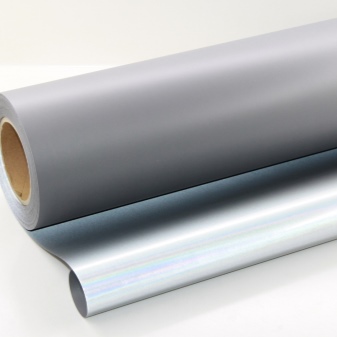

- Models with effects - are considered a variety of assortments and a convenient solution for the embodiment of the desires of designers. They can be metallized, shiny, holographic, etc. Films with a three-dimensional effect occupy a special niche - it helps to achieve image reliability;

Thermal film with three-dimensional effect

Thermal film with three-dimensional effect

Reflective thermal transfer films - used to create markings for special equipment, inscriptions on advertising and information materials;

Reflective Film Plotter Cutting

Reflective Film Plotter Cutting

Light-accumulative films - similar to the previous model, but they emit a glow. During the day they accumulate energy, and in the dark they begin to return it. They are used to form identification badges, advertisements, etc.

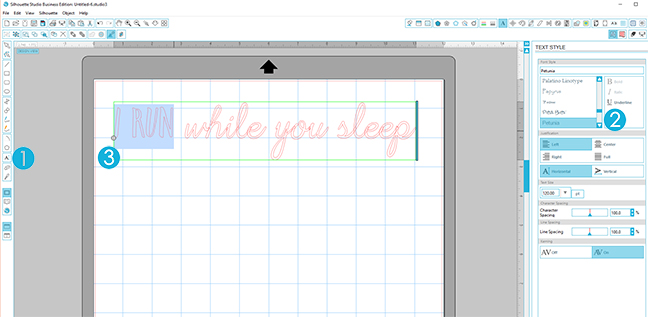

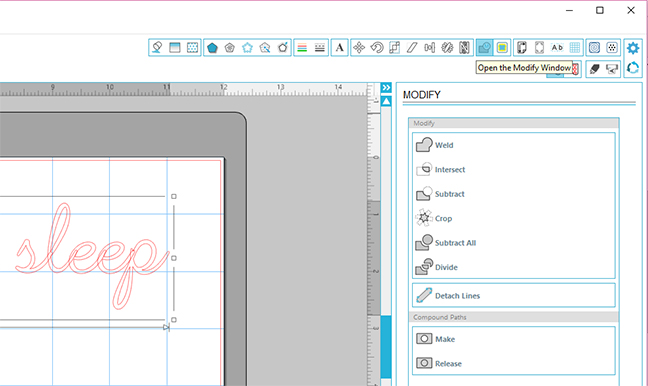

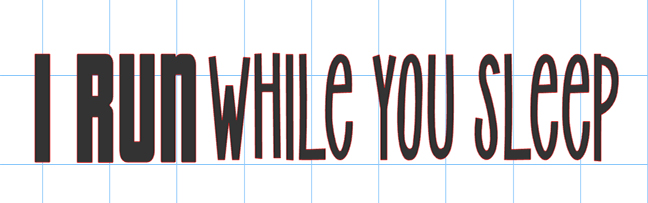

FIRST STEP: LAYOUT PREPARATION

First, create a new layout in Silhouette Studio. I am using the English version.You can also use the Russian version.

Select the Text Tool (1) from the left menu and select a font from the Text Style panel (2).

Select (3) the letters that you want to change to contrasting ones. Select the second font from the dropdown menu.

When using handwritten fonts such as SW Par-Tay Sans, you will need to combine the selected letters (weld) to make them look good.

TO COMBINE: Select the entire word, open the Modify menu and click Weld. It's simple! All letters are now combined and ready to be cut.

How to use?

Thermal transfer printing is not as difficult to work as it might seem to many. However, in the process it is worth adhering to certain rules. The first thing to do is cut out the selected picture or text. There is one nuance here - you need to cut it in mirror image

It is important that the image is transferred to the fabric correctly. For this operation, a plotter is used, after which the so-called selection is made: excess elements are removed - a clean picture (inscription or drawing) should remain, only what will be printed later

The selection can be done with a needle or a clerical knife, doing this very carefully. After that, the thermal transfer film prepared in this way is placed on a backing on a T-shirt, for example

The image should be displayed horizontally in the same way as for sublimation. Then the film is exposed to high temperature. For this, a heat press is used, which heats up to 150 degrees and above.

After that, the thermal transfer film prepared in this way is placed on a substrate on a T-shirt, for example. The image should be displayed horizontally in the same way as for sublimation. Then the film is exposed to high temperature. For this, a heat press is used, which heats up to 150 degrees and above.

Enough exposure for 15 seconds. This happens in professional workshops equipped with special presses. At home, for such a creative process as scrapbooking, an ordinary iron is enough. The glue will melt and firmly adhere the image to the desired location on the garment. After completing this procedure, the backing must be carefully removed.

Some experts do re-burn. It is needed to "tightly" fix the thermal transfer film

It is important to take into account one more nuance - you can remove the substrate when it is cold, but it will be much easier to work with a warm one. At the same time, it is quite simple to distinguish warm from hot: touch it with your hand - if the hand tolerates the temperature, then you can shoot

That's all - you can proudly put on the product, wear it and stand out from the crowd.

For information on how to write on the cover of a notebook using thermal transfer film, see the next video.

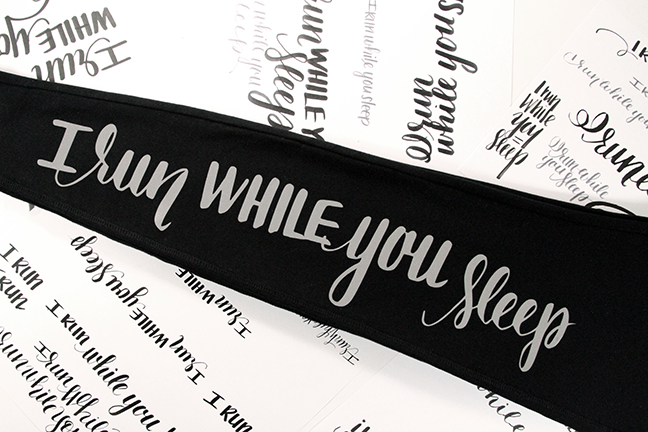

Reflective Fabric for Fabric | Creative leadership

I will be inscribing leggings for my jogger friend. I myself usually sleep when she runs. For application, I use a long lettering that will look like a bright stripe from a distance - especially to improve visibility in the early but dark morning hours.

And if small reflective inserts on clothes from the store only improve visibility, then my wide stripes will make leggings BEST GIFT IN THE LIGHT!

I love to write beautifully myself and use lettering for my projects. Then I store them as SVG files and use them when I need them. For this project I used pre-made fonts from the Silhouette Design Store, but you can try handwriting yourself. You will be amazed at how well handwritten text can work with Silhouette's layouts and patterns.

1. Blocky handwritten (Petunia) and handwritten (SW Par-Tay Thyme)

2. Bold (LW Thick) and thin (LW Simple)

These font combinations contrast beautifully and complement each other. It is useful to print an inscription on a printer before cutting in order to evaluate and possibly correct the layout before cutting on a plotter. My kids are always ready to give me a dose of criticism if the design is bad!

Moving on to cutting and drawing!

Sublimation humor.

Nonsense found on the net. )))

The subject of sublimation thermal transfer is quite simple, but even here, some figures manage to weave such nonsense. ))) On one of the sites, in the chapter "Advantages and disadvantages", I found such a pearl as disadvantages:

Sublimation printers are inkjet printers, if we are talking about printing on fabric, we do not take into account some photo and label printers, there is also sublimation printing, but the source of the dye is polymer tape, these printers have nothing to do with the topic in question! Sublimation printers for printing on fabric are filled with sublimation ink, the printing speed cannot be lower simply physically, the printer does not understand what ink is filled into it, and prints absolutely at the same speed as with native ink. The funny thing is, in the previous paragraph, the authors of this pearl posted a photo of a sublimation printer - *** ValueJet, which is the most direct proof that this printer is an inkjet printer. The most interesting thing is that this statement was made right after that:

The most interesting thing is that this statement was made right after that:

A dumb scene. ))) Who will bring home a printer the size of a desk? And how much should such a printer cost? In general, funny information. )) Although, of course, large format inkjet dye sublimation printers are very popular and widely used, but clearly not at home. )) At home, for dye sublimation printing, inkjet printers of the usual A4 size are great, who wants a larger size, A3, and even an A2 printer can be placed on the desktop.

But that's not all! Also, on this site, a photo with a unique signature is posted:

And this picture is given.

This is NOT a sublimation print on dark!

In the photo, just an example of a thermal transfer paper for dark fabrics or direct printing with white ink pulled from the network, perhaps even silk-screen printing. Anyone who has ever encountered a sublimation thermal transfer knows perfectly well that sublimation on dark, namely black fabrics is NOT possible! The only possible way to apply full color on black textiles, as in this photo, using the sublimation method, is to first apply the image on special thermal transfer film for sublimation (SUBLI-FLOCK 5901, POLI-FLEX 4675), then cut the resulting transfer along the contour, and remove the protective backing, transfer (weld) it to black textiles.

How to choose?

When choosing flex films, it is important to consider a number of criteria.

Manufacturer

There is a rich assortment of thermal transfer films on the market today. Film from European (German, French and Italian) and American manufacturers is in particular demand. And this is not surprising, because they make quality products and supply them to all corners of the world.

Film thickness

Flex films come in various thicknesses (within the range of 60–150 microns), so you should choose the one that suits your specific task. The most popular is considered to be a film thickness of 90-100 microns - such a product is suitable for a variety of jobs.

Adhesive layer

It is impossible to judge the quality of its adhesive layer solely by the appearance of the thermal film. At the same time, this parameter is one of the most important. There is only one way out: first, you can test a small sample of one or another version of the film - this will make it possible to determine the choice and buy the required amount of material of decent quality.A high-quality adhesive layer differs in that the glue does not flow out of it at the time of application to the base, does not stain it, does not melt, while the film itself will be distributed evenly over the entire surface, and after cooling it will not come off.

The cost of thermal films also depends on the materials used. So, if work is not very difficult for you, as well as with a small budget, your choice is PVC film

If jewelry execution of an intricate design or text with small letters is important, if you also need elasticity, wear resistance, a non-standard color for an unusual design, this is certainly a polyurethane film