Top 7 refractory paints for metal up to 1000 degrees

To protect the heating radiator, metal stove or other objects from corrosion and aggressive external influences, they are covered with heat-resistant paint and varnish enamels. The paintwork can withstand up to 1000 degrees C. The enamel not only protects, but also gives an aesthetic appearance.

It is difficult to make a choice in favor of this or that paint. A fresh coating will give the items a new look. We have compiled for you a rating of the most popular paints and varnishes. All submitted candidates have been verified by operational practice and experience.

Tikkurila termal silikonimaali

Country of origin Finland and Russia. Used for painting metal products. Based on silicone resin. Suitable for indoor and outdoor use. Resistant to high temperatures up to 400 degrees. This property provides protection for chimneys and dampers. Used for painting a car muffler. Black color. After drying, a semi-matt sheen is formed. Protects the structure of the metal.

Apply by brush or spray. The time of complete drying at a temperature of +230 C is exactly 1 hour. You can use the surface cleaners after one month. One liter of enamel is designed for 16-20 square meters. If the paint is applied in one layer. The price matches the quality. The only negative is heat treatment after application for complete drying.

Celsitus-600

Black paint. Withstands exposure to temperatures up to +600 degrees. High degree of protection when using metal under the influence of high temperatures and moisture. Resistant to the influence of petroleum products, oil, gasoline. It is used for painting: electric motor, transformer, household heating appliances, bridge, tank, metal structure, railway tanks, calipers. Can be applied to reinforced concrete, asbestos-cement, brick, plastered surfaces. The enamel is applied in three layers. The color is black, the surface takes on a matte shade.

Certa KO-85

Certa is used for items that operate at temperatures from -50 to 900 degrees C. Heat-resistant enamel. It tolerates temperature changes well, including high temperatures. Protects against aggressive environments and high humidity levels. Prevents corrosion, moisture ingress. It is applied at minus 30 degrees Celsius. Transparent paintwork material. Used instead of varnish for covering bricks, concrete, ceramics. Apply in three coats to achieve a matte finish. In one layer, the brick acquires a wet effect.

Elcon

To obtain the desired color, it is mixed with a color scheme. At the same time, the pigment contained reduces the level of protection and durability of the painted coating.

The color palette is very rich. Gloss is matte and glossy. The product, painted in classic black color, can be heated up to 1000. And all other colors are not higher than 700 degrees. You can create beautiful patterns on the stenciled walls without involving specialists. In addition to metal surfaces, it protects concrete, brick, asbestos products from the influence of an aggressive environment.

Kudo

The composition does not include toxic components. When used, no harmful substances are released into the air. Can be used inside living space, stove or fireplace, chimney. No primer is required before application. Complete drying time 2 hours. It is considered to be slightly flammable, difficult to ignite. The room temperature is not lower than + 3C. The service life is not less than 20 years.Universal, used on products of different surfaces.

Dali

Matt paint for interior and exterior use. It is used for painting the exhaust systems of a car, chimney, chimney. Black color. Before opening the can, the manufacturer recommends mixing the contents well. Apply by brush or spray. Drying time from 1 to 3 hours. If you want to apply several layers to the product, then the time interval for each layer is 1 hour. Thermal hardening for 2 hours at a temperature of 200 degrees.

Serebryanka heat-resistant Novbytkhim

Heat-resistant universal. Used for glass, brick, concrete, plaster surfaces. The formed layer protects against oil, gasoline, water, and vapors, salt fog in the range from -50 to +600 degrees Celsius. Withstands sudden changes in temperature, but within the range indicated on the package. The enamel is waterproof, dries quickly. No more than three layers are applied. Stir not only before application, but also during application. Prepare the surface in advance. Remove dust and dirt. The composition includes organic substances.

How to Choose Heat Resistant Fireplace and Stove Adhesive?

Fireplace

The hearth heats up to low temperatures, especially if used infrequently. But the furnace structure, during continuous operation, requires compositions that can work with constant heating.

Accordingly, the type of heat-resistant glue is selected depending on the operating conditions.

- For cladding a fireplace, heat-resistant adhesive mixtures are sufficient. The outer surface of the hearth does not get too hot to require more heat-resistant options. They use both cement-based compositions with polymer additives, like Cerezit, and special synthetic mixtures.

- For lining the furnace, the composition of the same category is most often used, but more durable. The structure not only heats up more, but also operates longer: one bookmark of firewood is enough for a day of work. Accordingly, all this time, the cladding must accumulate heat and give it to the room. The heat-resistant tile adhesive must withstand the constant heat action, that is, be heat-resistant.

-

The laying of the stove structure, in particular the firebox, requires the use of much more serious adhesive

mixtures. Constant heating up to +1000 C allows using only heat-resistant refractory mixtures. But using the same composition for laying tiles is economically unprofitable.

- Another application of heat-resistant glue is electric ovens and gas ovens. A rather fragile part of them is glass, or, more precisely, the junction of glass and metal. Despite the not too high heating temperature of the oven - an absolute maximum of 240 C, the sealant at the junction evaporates over time. To update it, you need a heat-resistant adhesive - Moment, for example. Can be used for glass and any heat resistant sealant for higher reliability.

Extra options

In addition to resistance to heat, adhesives for tiling or brickwork must meet some more characteristics:

coefficient of thermal expansion - under the influence of temperature, the volume of the material increases. If the coefficients of the adhesive and the material are very different, the joint will quickly fail. Complete coincidence of indicators is impossible, however, it is possible to achieve sufficient elasticity of the seam;

solution viscosity - adhesive properties. A mixture that is too high does not hold the tiles to the surface. If the viscosity is too low, the tile slides along the vertical surface;

gas tightness - combustion products should not enter the room, which means that the resulting seam must have high performance;

composition for dishes should differ in special parameters

It is important that the glue is not only heat-resistant, but also food inert.Mixes for food plastic containers are selected especially carefully.

Glue components

The specified properties of the glue are ensured by the selection of the proportions of its components: filler, binder and plasticizer. The dependence of the properties of the glue on their ratio is nonlinear; manufacturer researchers are looking for some optimum. Therefore, it makes no sense to "improve" the ready-made mixtures, adding, say, to increase the fire resistance of the "missing" component: in the end, the glue will be either bad or completely unusable.

In ready-made stove / fireplace adhesives, the base is composed of a trace. component:

-

Clay-cement binder,

sand filler, mineral plasticizer - chamotte fiber. The cheapest, strongest, fire and heat resistant, but weak adhesion. Mainly heat-resistant masonry adhesive for stoves and bases of solid fuel household heating appliances. Can be used for finishing horizontal and flat surfaces. The main drawback, from the point of view of a beginner, is that a brick or tile must be put in place right away. If you crawl with it, adjusting it along the liquid glue, the strength and gas tightness of the dried seam will decrease several times. Limiting heat resistance - 1200 degrees. -

Binder - heat-resistant aluminosilicate cement and kaolin,

filler quartz sand, mineral plasticizer - liquid glass. Somewhat more expensive than clay-cement-fireclay, but have good adhesion. Refractory glue on aluminosilicates and kaolin holds up to 1360 degrees. The main disadvantage is the service life of up to 20-25 years. Liquid glass is nothing more than old silicate stationery glue; it gradually loses its plasticity and crumbles into powder. For the same reason, the initial plasticity of the dried aluminosilicate glue is low, but it is quite suitable for finishing with tiles or porcelain stoneware on stove bricks. -

The binder and filler are the same, but the mineral plasticizer is talcum powder.

Talcochlorite, also known as steatite, soapstone, stove or pot stone, is widely used in stove business. Aluminosilicate kiln glue with talcum chloride is universal, it has excellent adhesion, high joint strength, heat resistance up to 1500 degrees, almost full compliance with TCR with kiln and ceramic finishing materials. An additional advantage is the ideal ratio of heat capacity and thermal conductivity, because steatite perfectly re-radiates hard thermal (infrared, IR) radiation into soft. The main disadvantage is the high cost, approx. RUB 1000 per bucket and more.

Due to their high cost, there are few adhesives for fireplaces and stoves with soapstone; mostly Finnish ScannMix

and german Mixonit

... The latter is of general purpose. In the directions for use, there is even a bonding of fibrous insulation, but not a word about the construction of furnaces. Mixonit holds the cladding on them without problems, but it's still not worth using it as a masonry without a manufacturer's warranty.

Advantages and disadvantages

High consumer demand and a wide range of applications are due to a number of indisputable advantages of heat-resistant glue.

- The availability and reasonable cost of the formulations make the glue even more popular in the consumer market.

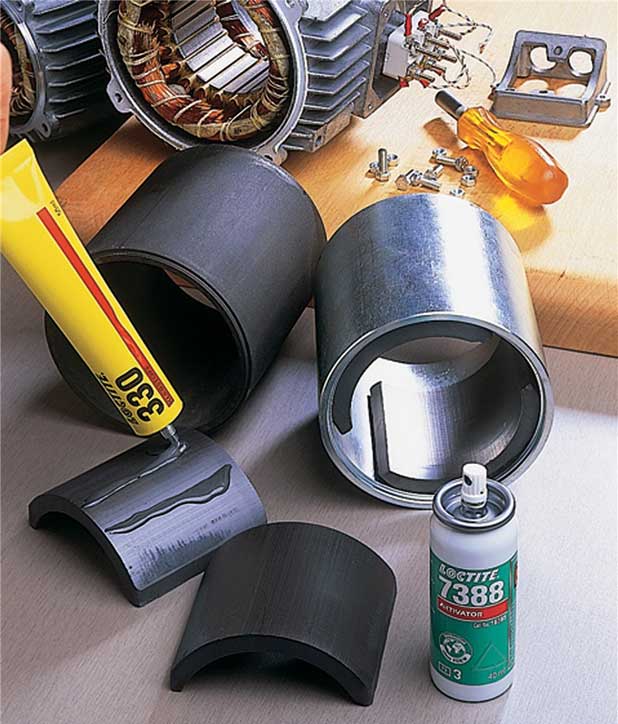

- For gluing parts by cold welding, professional skills and special welding equipment are not required.

- The ability to carry out repair work without removing and dismantling the repaired parts.

The quick time of complete drying of some models allows you to carry out repairs on your own and in a short time.

Unlike traditional welding, the compositions do not have a thermal effect on metal components, which is convenient when repairing complex mechanisms and sensitive assemblies.

The high quality of the connection guarantees the continuity of the fastened elements even under the influence of mechanical stress.

With the help of hot glue, a refractory and heat-resistant seam is formed

This is important when repairing metal structures that operate at temperatures exceeding 1000 degrees.

- No need for additional seam treatment such as sanding and leveling. This is the advantage of this group of glue over electric gas welding.

- Possibility of bonding metal with rubber, glass, plastic and wood products.

Automotive adhesives

The selection of adhesives required for automotive plastics is based on the intended use of the substance. Popular brands WEICOIN constraction, Power Plast, AKFIX, Moment. Some formulations involve working with simple parts, while others are used to restore complex mechanisms.

Many adhesives come in convenient packaging for easy application

When using, attention should be paid to the setting and polymerization times. The composition can begin to act in minutes, and complete polymerization and hardening occurs in a few hours

You should also pay attention to the application temperature. Most brands should not be heated to temperatures above 100 ° C, that is, the heat resistance is conditional here.

Advantages and disadvantages

Among the obvious advantages of hot melt glue for metal are the following:

- increased strength indicators, resistance to vibration loads;

- weather resistance;

- good adhesion rates, including when gluing surfaces of different textures;

- the ability to withstand high-temperature exposure - for some types of work over + 1000 ° C;

- ease of use, the ability to abandon the use of welding;

- the ability to glue to metal not only metal, but also ceramic, glass and other elements;

- high indicators of wear resistance and durability, which makes the composition universal;

- environmental friendliness - suitable for interior work in residential premises;

- anti-corrosion protection.

Among the shortcomings, it is worth noting that in terms of the quality of fastening, the glue is still inferior to the fixation that cold welding gives. If the part is subjected to active dynamic loads, then gluing is only a temporary measure. In the future, it is necessary to provide better repair or replacement of damaged parts. Many thermal compositions are not very easy to use, since for the final polymerization of the glue, heating of the parts to be glued at rather high temperatures is necessary, which requires the use of special ovens, since other heating methods usually lead to deformation of the parts.

Features of the choice of paint for the oven

You cannot paint a stove with simple paints: the highest temperatures that they can withstand are 45-55 ° C. During the first firebox, this coating will swell, change color before our eyes, bubble up, and also spread “aromas” and smoke. Therefore, special formulations are definitely needed that can withstand elevated temperatures.

The degree of heat resistance required will depend on the type of oven. If it is a metal stove, then it can heat up to more than 700-900 ° C: the temperature is higher in the combustion zone, but taking into account the design, the outer walls may not heat up so much. For the outer surface of the brick, higher values are not required - 300 ° C is quite enough.

An important requirement is refractory paint for metal for the oven must be suitable for interior painting. It is best for sauna stoves that it still protects against high humidity.

Thermal paint terminology for metal

For painting surfaces with elevated temperatures, refractory, heat-resistant and heat-resistant paints are suitable. Do not use fire retardants. Although it has a similar name, the purpose of this paint is completely different: when heated to a certain temperature (about 150 ° C), it bubbles, blocking the access of oxygen to the structure, thus preventing its destruction. Quite a useful effect, but not in the case of the stove.

- Heat-resistant paints, as a rule, have a field of application up to 700 degrees. These compounds can be used to paint metal elements of fireplaces and brick stoves, metal heating stoves. It is undesirable to cover the body of metal sauna stoves with these paints, since in some places the temperature rises to 900 ° C. For them, there are heat-resistant enamels that can withstand temperatures up to 1000 degrees.

- Refractory paint for metal can withstand open fire. Their operating temperature is even higher, however, for domestic use, these formulations are unprofitable, since they are quite expensive.

- There are also high-temperature paints that are used to paint heating system radiators. As a rule, they behave normally if they do not heat more than 250 ° C. They can only be used for brick ovens - they are perfect for tinting surfaces or painting joints.

- There are also heat-resistant varnishes. They normally tolerate temperatures up to 300-350 ° C. If a brick is treated with such a varnish, then the surface will become brighter, acquire color and shine.

Application for various surfaces

In order to decide which paint to paint the oven, you need to pay attention to which surfaces this composition is intended for. Often the scope of application is indicated on the packaging in large letters.

For example, refractory paint for metal. If the scope of use is extensive, then it is designated in a smaller print, but it must be on the package, like the brand name. If these data are not available, cancel the purchase. Most likely, this is a fake, and the combination of high temperatures and dubious quality is dangerous to health.

In addition to temperature resistance, paint for a metal bath stove must protect against high humidity. In this case, it will hold on for a longer time.

Color selection

Heat resistant paint is usually found in silver, gray and black. The rest of the shades must be looked for, but they also exist: red, white, blue and green. The coating can be glossy or matte.

Usually matte black thermal paint is found, however some manufacturers have different shades and colors.

Manufacturing form

Thermal paints are made in cans or cans. Accordingly, they can be applied from cans with rollers, brushes or sprayed using special equipment, and sprayed from cans.

Heat resistant spray paint typically has a volume of approximately 500 ml. In cans, usually packing is 0.4-5 kg. There is a larger package in barrels and buckets.

What is more convenient? It's a matter of habit. With dexterity, the layer comes out more even from the can. In this case, the consumption may be less than when using a brush or roller.

Heat-resistant glue - what are its features

Heat-resistant glue can be sold ready-made or in powder form; before work, the second option requires dilution. The components can be of synthetic or natural origin. Most often, the base is epoxy resin, modifiers, plasticizers and other elements are also added that can improve the properties of the flame retardant glue.

Heat-resistant glue can be sold ready-made or in powder form.

Scope of application

High-temperature adhesives designed for certain materials can be produced: wood, metal, rubber, tiles, plastic and others. Separately, the use of heat-resistant glass and metal as an adhesive, instead of welding, is highlighted. They can be used for gluing the following products:

- When laying underfloor heating;

- As a heat-resistant sealant for closing gaps in the chimneys of stoves and fireplaces;

- Cladding with ceramics and other tiled materials of stoves and fireplaces;

- For laying bricks in the construction of furnace structures;

- For joining glass in the oven;

- For repair and installation work of automotive heating parts;

- For gluing plastic and graphite products;

- Renovation work with oil radiators and central heating systems.

High-temperature adhesives designed for certain materials can be produced: wood, metal, rubber, tiles, plastic and others.

High-temperature adhesives designed for certain materials can be produced: wood, metal, rubber, tiles, plastic and others.

Advantages and Disadvantages of Heat Resistant Adhesives

The use of heat-resistant glue for metal and other types of material has both positive and negative sides. The pluses include:

- High strength of the resulting seam. The adhesive can withstand moisture, temperature and deformation loads;

- Quick drying, the first setting takes about ten minutes, the final drying, depending on the type of solution, lasts a maximum of a day;

- Does not shrink and does not crack;

- Ease of use, no devices required. Hot melt glue for metal can be used instead of welding.

The cons are:

- Handles only a small amount of work. It is used only for pasting small defects;

- It is required to carry out preparatory work with surfaces;

- The seam is inelastic.

The adhesive can withstand moisture, temperature and deformation.

The adhesive can withstand moisture, temperature and deformation.

How to work with glue

Each type of glue has its own operating characteristics. However, there are general recommendations, the implementation of which will ensure a reliable connection and repair.

- Preparation of parts. Surfaces should be cleaned before applying the adhesive. Old rust, dirt, previous composition is removed. When facing work, the surface is primed.

- Some mixtures can be applied to wet items. But if this is not indicated on the packaging, the parts should be well dried.

- The solution is usually spread in a thin layer over both elements. Liquid products set quickly. Therefore, there is no more than 2–5 minutes to correct the position. Dry mixes for finishing works can be changed up to 15–20 minutes.

- The details are pressed against each other. If possible, they should be left in a secured state for an hour.

- After final setting, the surfaces can be painted.

When self-mixing the solution, strictly adhere to the manufacturer's recommendations. Technological deviations can affect the quality of the connections.