Glass surface care

The surface of the fireplace door or the hob of a gas stove is not particularly demanding for care, in fact, caring for fire-resistant glass is not much different from caring for a regular window or a transparent table. In addition, self-cleaning glass goes on sale, it is not susceptible to contamination, therefore it does not require efforts to maintain its cleanliness.

The surface of the fireplace door or the hob of a gas stove is not particularly demanding for care, in fact, caring for fire-resistant glass is not much different from caring for a regular window or a transparent table. In addition, self-cleaning glass goes on sale, it is not susceptible to contamination, therefore it does not require efforts to maintain its cleanliness.

Even if the glass cannot boast of self-cleaning ability, keeping it clean does not require much work. To do this, use common household detergents.

It is important to remember the fragility of the material when starting to clean the surface. You can wash refractory glass only after it has completely cooled down, otherwise it may not withstand a sharp temperature drop

In work, do not use products that contain chlorine and abrasive particles. Such substances are guaranteed to spoil the appearance of the glass and the product as a whole.

Refractory glass - a material that is only growing in popularity

Wanting to bring variety to the interior of your own home, add zest, you should pay attention to it. Fireproof glass in the fireplace doors is a great way to emphasize the beauty of an open fire, it also guarantees the safety of the room and protection against the spread of fire in the fire partition

Fire protection glass marking

Most of the information regarding the characteristics of fire protection glass can be found from its labeling. The letters of the Latin alphabet are used for designation:

- E - resistant to destruction;

- I - has a high resistance to heating up to a critical temperature;

- W - retains heat, does not let heat into the adjacent room.

The manufacturer guarantees the preservation of the declared characteristics for a certain period of time. The time in minutes is indicated after the lettering. For a better understanding, you can consider examples:

- EIW 60 - the product retains resistance to destruction, resistance to heat and retains heat for 60 minutes.

- EI 60 - resistant to destruction, prevents heating for 60 minutes.

- EI 30 - resistant to destruction, prevents heating for 30 minutes.

Which refractory paint to choose for the oven

Paint for metal ovens should be chosen with a temperature threshold of 600 ℃ or more. Here are some of the most famous brands with a brief description of each.

Heat-resistant enamel brand Certa (CERTA), produced by the domestic manufacturer Spectrum. It is designed for use in the temperature range of 65-900 ℃, and it can be applied even in frost -30 ℃. The consumer is offered a total of 26 shades of paint, including such as turquoise, blue and yellow. True, not all colors can withstand the same high temperatures. So, the most heat-resistant is black (up to 900 ℃). Behind it are white, gold, brown, copper, red-brown, green, blue, blue and turquoise (all of them withstand up to 750 ℃). All other shades can be used at temperatures no more than 400-500 ℃. Such paint is produced in cylinders, cans and buckets of different sizes.

Termal paint from the Finnish manufacturer Tikkurila. It is made on the basis of alkyd resins and produced in black and silver colors. It is able to withstand the heating of the metal at the stage when it turns red. When using such paint on sauna stoves, it does not crack and does not peel off for about 3 years.

Please note that if the painted surface is heated to 230 ℃, it will dry in 1 hour. This is a prerequisite for its polymerization.

Hansa heat-resistant metal furnace paint is available in 16 colors and can be used at temperatures up to 800 ℃ to paint stainless steel. It goes on sale in barrels, cans and cans.

The Russian-made Kudo heat-resistant paint is an organosilicon enamel for metal products. It is designed for surface heating up to 600 ℃ and is available in 20 shades, including white, black, red and silver. Sold in 520 ml cylinders.

Aerosol paint Bosny. Available in two versions - for heating up to 650 ℃ and up to 200 ℃. It fits well, does not change color for a long time and does not crack. This brand of thermal paints is used for painting metal, plastic, ceramics and glass, wood and fabrics

Pay attention to this brand, as paint on glass is rare. The cylinder capacity is 400 ml.

Hammerite heat-resistant paint for metal has one peculiarity. It can be applied even over rust without first cleaning the surface. However, beware of contact with diesel fuel, gasoline and grease. The paint can withstand heat up to 600 ℃ and is available in 250 ml cans. It is applied with a brush.

ELCON anticorrosive heat-resistant enamel is able to withstand temperatures up to 800 ℃, including its sharp drops. It is used for painting concrete, brick and metal. Available in cans in a wide variety of colors. There is also an aerosol version of ELCON paint in 520 ml cans - it is designed to warm up to 700 ℃.

Paint for metal and other surfaces KO-8111 "Thermika" withstands up to 600 ℃. In addition, it has a protective effect against stray currents, salts, chlorine, solutions, oils and corrosive substances. It is used for painting fireplaces and stoves. It is better to use the KO-8101 brands and KO-8104 soil from the same manufacturer in the baths. In addition to heat resistance, this paint is also moisture resistant.

Heat-resistant paint Rust-Oleum is designed for very high heat - up to 1093 ℃. In addition, it protects against gasoline and oils. Release form - aerosol can. It comes in matte white, gray, black and transparent.

All of these options are successfully used for painting brick and metal heating stoves and boilers. Some are also suitable for sauna stoves.

Wholesale trade

About glass for the fireplace, protective screens for the fireplace

The fireplace combustion chamber poses a certain threat to the room due to the large number of sparks, coals emitted by cracking wood and hot ash. Closing the opening with a steel or cast-iron flap is inconvenient, in addition, all the beauty of the flame disappears and heat transfer decreases.

Therefore, in modern fireboxes, glass is used for the fireplace, which is strong enough not to scatter when closed, and heat-resistant to withstand the thermal head of the flame.

GLASS FIREPLACE DOOR DEVICE

Today there is no alternative to the use of a glass valve:

- Fireplace doors made of heat-resistant glass do not expand or deform from heat, like cast iron or steel, thanks to this, it is possible to obtain minimal gaps and high quality sealing between the frame and the edge of the door;

- Fire-resistant glass for a fireplace does not burn and does not oxidize, retains its original appearance throughout the entire period of operation;

- The main thing is that a fireplace door with glass allows you not only to enjoy the play of fire, it is the only possible way to control the combustion process so that the flame does not turn into smoldering with the formation of carbon monoxide.

For a small country house and summer cottage, a cast-iron fireplace with glass is most often chosen. In addition to the beautiful appearance, this choice has a purely practical advantage - heat-resistant glass for the fireplace provides faster and more uniform heating of the room. The champion in terms of heating efficiency is a round fireplace with glass, which is able to heat and illuminate the room at the same time.

MAIN VARIETIES OF HEAT RESISTANT GLASS

- Quartz glass options, one of the most heat-resistant and refractory;

- Borosilicate glasses;

- Cerium oxide coated laminated glass sheets.

Pros of processing bricks with varnish

Paintwork materials (paints and varnishes) for bricks are currently the most widely used. All thanks to their properties. They can be used outside and inside the home for vertical, horizontal and inclined surfaces. In its own way, paintwork for bricks is universal - it is not only widely used, but also does not cause difficulties in application. It also does not roll or deform.

Under the influence of moisture, a brick that has not been varnished quickly loses its properties and begins to collapse. It is mainly the walls outside the house that suffer from this. With the help of brick varnish, you can several times reduce the negative impact of snow, rain, hail on the facade of the house, thereby prolonging the life of the brick, and avoiding major wall repairs.

Another noticeable advantage of the lacquer coating of bricks is its resistance to high temperatures. This is especially noticeable on fireplaces and stoves. To cover them, a heat-resistant brick varnish is used.

A fireplace or stove treated with varnish takes on a completely different appearance and looks very beautiful.

Varnish can also protect your home from salt and dust stains. Having processed the facade of a house or a fence with varnish for bricks, you can be one hundred percent sure that they are protected from such untidy phenomena as salt, accumulation of dust and fungus.

The variety of paintwork materials is very wide. Varnishes with enhanced shine will effectively emphasize the facade of the house against the background of other buildings, or simply make it look like a tower from a fairy tale. The varnished walls look very impressive.

Scope of application

Heat-resistant glass grades are widely used in enterprises, the production process of which is associated with high temperatures. The use of transparent material with good heat-resistant characteristics makes it possible to ensure the continuous operation of units and assemblies, while guaranteeing the safety of the operating personnel. Installing fireproof glass in doors and partitions separating production facilities significantly reduces the likelihood of a fire breaking out and spreading.

This material is indispensable in everyday life, where there is a high temperature, and it is impractical to use metal. A prime example is glass fireplace doors. This comfortable, beautiful and functional fireplace will perfectly complement the interior of a residential building, it will also create an atmosphere of warmth and comfort. The fireproof glass door is beautiful and practical. It will not block heat radiation, while protecting the room from smoke and soot.

This material is indispensable in everyday life, where there is a high temperature, and it is impractical to use metal. A prime example is glass fireplace doors. This comfortable, beautiful and functional fireplace will perfectly complement the interior of a residential building, it will also create an atmosphere of warmth and comfort. The fireproof glass door is beautiful and practical. It will not block heat radiation, while protecting the room from smoke and soot.

Fireproof glass can be found in the kitchen, among other things: kitchen apron, transparent doors for ovens and microwave ovens. These solutions allow you to control the cooking process without having to open the door. Separately, you can recall the cooking surfaces of gas stoves, they allow you to evenly distribute the heating, thereby helping to save energy.

High temperature resistant glass is also used for making glassware. Transparent kitchen utensils are great for both open fire and oven cooking. Moreover, transparent dishes can be used in the microwave. An additional plus - the glass surface is easy to clean.

Varieties and properties of heat-resistant materials

Stove and fireplace protective screens

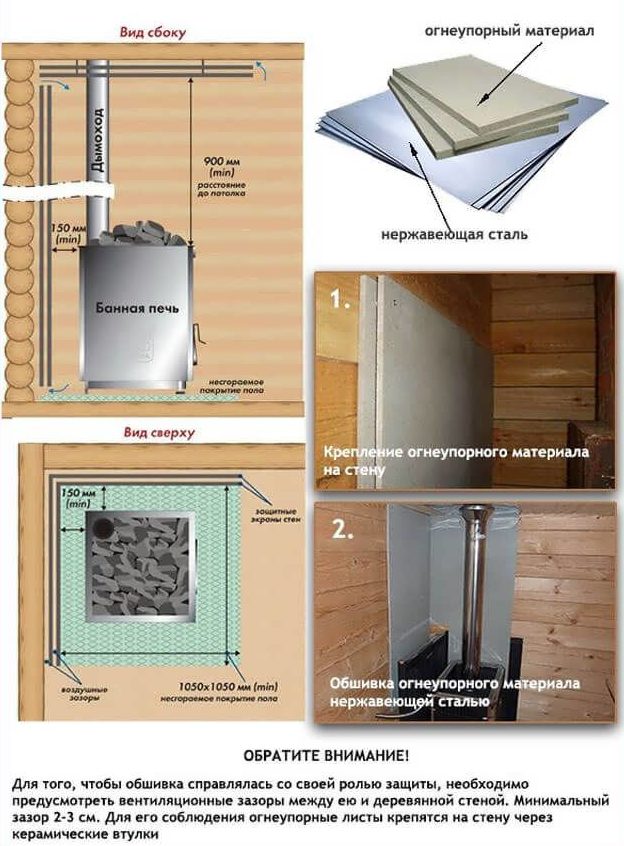

Most often the screens are made of sheet steel to protect the sides around the stove. Their installation is done by no more than 5 cm. from a heating source. Their installation allows you to lower the temperature near the furnace to 100 ° C. There are frontal and lateral types. The screens are fixed to the floor with special legs.

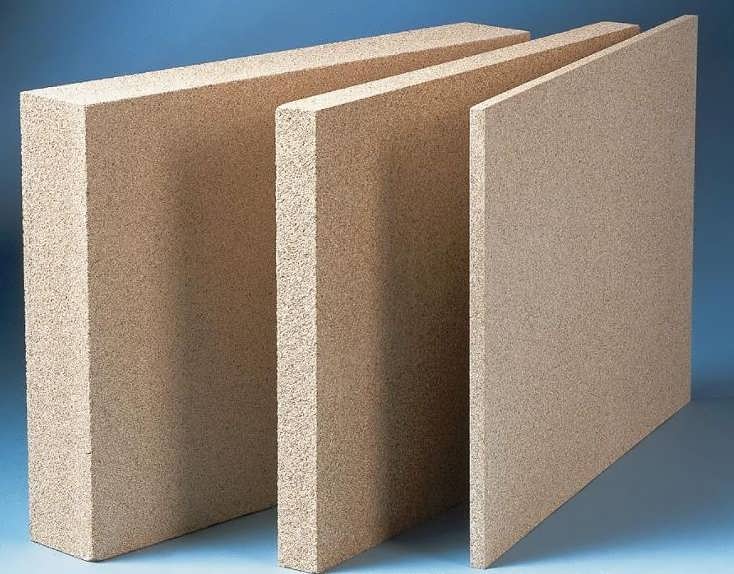

Wall cladding with vermiculite panels (PVTN)

Popular heat-resistant panels for wall cladding near the oven are vermiculite panels. Due to their reliability and long service life, they are installed at nuclear and oil refineries. During operation, high fire resistance, sound and heat insulation, environmental friendliness and aesthetics are achieved.

Very rarely, a non-combustible sheathing sheet is visually attractive. But vermiculite has a beautiful texture. Lining is used for stoves and fireplaces, other fire hazardous objects. Their installation is simple, so you can do it yourself.

Reflective sheathing

Heat-resistant materials with a reflective texture have good characteristics. The panel consists of wood, to which thermal insulation is attached and sheathed with a sheet of metal. The metal sheet is made of galvanized or stainless steel. It is advised to purchase from stainless steel, because the zinc alloy releases harmful compounds from heating.

To increase the strength, the slab is polished to a mirror image. This method allows you to reflect the rays of heat and contribute to less heating. The wall can be sheathed with three materials:

- asbestos sheet - insulates heat well, serves for a long time and is durable;

- minerite - strong fireproof protection for stoves, steam rooms, fireplaces;

- basalt cardboard - consists of basalt fibers. Allows you to isolate heat and sounds.

The cladding will line up like this:

- Room wall;

- The gap from ceramic bushings is from 2cm. up to 3cm.;

- Thermal insulation from 1cm. up to 2cm.;

- Metal sheet.

This installation procedure is universal and allows you to make the safe distance up to 38 cm. But if this distance cannot be achieved, then you need to make two layers of thermal insulation for safety. A gap is also made between them.

Sheathing with cladding

Not all fireproof panels are visually attractive. To refine the panels for the walls, they are lined with ceramics. Porcelain stoneware tiles do not burn, but they transmit heat well. Therefore, it is impossible to install from one. For cladding, a gap of 2 cm is left after the wall. up to 3 cm., put a refractory layer and lay tiles.

The following refractory materials are used as refractory materials:

- Magnesium glass sheet - it has sound and thermal insulation, resistance to sudden changes in temperature and humidity.

- Refractory drywall - fiberglass is added to the composition, which allows the product not to ignite or deform.

- Minerite - it is heat-resistant, moisture-resistant, not prone to decay and destruction.

When mounting, do not reduce the clearance distance. It keeps the wall cool and makes the room safe.

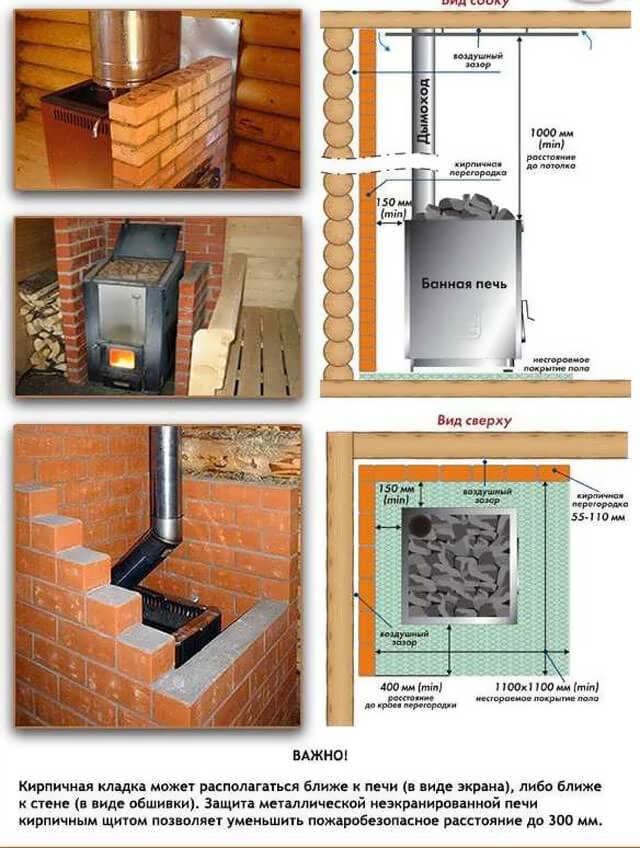

Chamotte

Fireclay is a self-made brick screen with the addition of cement. Installed fireclay is resistant up to 1300C °. Hardware stores offer ready-made adhesives, mastics, coatings used for additional processing based on chamotte fibers. The stove can crack from high degrees and fireclay putties are sealed. It will not be superfluous to coat the entire surface of the stove, then overheating will be less.

Selection of material at the place of use

Around the stove

Previously, asbestos sheets were used to protect the walls behind the stove. But it turned out that it is harmful, so other types were invented. Plasterboard boards with a fire-resistant composition are considered one of the best. It is not only heat-resistant material, but also easy to handle. Often, porcelain stoneware tiles of various colors and textures are mounted on it.

The positive sides of drywall tiles are:

- not flammable up to 1 hour. after the appearance of a fire source;

- fire resistance up to 30 min. with direct opposition to the flame;

- at the ends, everything is processed with a docking chamfer;

- convenient size of tiles 120x250x1.25;

- installation in various ways - with self-tapping screws or glue solution.

They note stainless steel sheets with good reviews. They are expensive, but they can serve a lifetime.However, one sheet will not protect the wall from heating, so it is preliminarily lined with thermal protective fiberglass. Stainless steel is environmentally friendly, but the material that will not allow the walls to heat up can thin out harmful substances. Therefore, when selecting, make sure that there are no phenolic resins in the composition.

Minirite slabs are distinguished by excellent environmental qualities and heat resistance indicators. It is based on gray and white cement, which makes up 90% of the mass. The other ten include mineral fiber and reinforcing materials.

Other refractory materials for walls around furnaces are also distinguished:

- Superizol - it weighs little, is very durable, and is used for a long time.

- Basalt fiber - it is pressed into rolls and does not change shape up to 900C °.

- Terracotta tiles - despite the shade, the tiles do not contain a dye that releases toxins when heated. Besides heat resistance, the tiles are waterproof.

The selection of heat-resistant fiber depends only on preference. After all, each species corresponds to the main function - non-flammability.

Under the boiler

If you need to secure the place around a steam or gas boiler due to very strong heating, then everything is finished with porcelain stoneware. Porcelain stoneware tiles can withstand high degrees. Fiber panels with gypsum impregnation can also be used.

A good refractory wall is obtained from xylolite fiber panels. They are able to withstand 1000C ° without emitting compounds hazardous to health. And good flexibility allows for tight mounting on curved surfaces. Not prone to decay, mold.

Peculiarities

The most important role of a heat-resistant film is to protect the surface from excessive heat and exposure to open flames. A special cover is required for most decorative and even load-bearing structures of buildings. The advantages of such products are:

-

ease of use;

-

containment of the spread of hotbeds of ignition;

-

an increase in the time that can be spent on saving people and material values;

-

containment of the spread of smoke;

-

prevention of glass splitting into dangerous fragments;

-

strengthening the security function of glass;

-

increase in sound insulation characteristics;

-

reduction of heat losses during normal operation;

-

reduction of penetrating ultraviolet radiation.

Remarkably, all these properties are characteristic of one option - a multifunctional film. All other solutions are far less perfect. Certain modifications to film materials may restrict radio wave propagation

This is very important from the point of view of protection against industrial espionage.

Price

The price range for refractory paint is scattered, it all depends on the manufacturer. So the cost of heat-resistant domestic analogs is much cheaper. The price of the product also depends on the composition and temperature conditions that the enamel can withstand. The more complex components, the more expensive the paint.

The presented material allows us to conclude that heat-resistant paint is a high-tech product that is harmless to human health. It is widely used in various industries and at home, withstands high temperatures and has good quality characteristics.

Review of heat-resistant enamels (3 videos)

The choice of paint for calipers and application technology

Despite the popularity of heat-resistant metal paint in cans due to its low cost, this finish cannot be called the best. Most often, 1 can barely covers the surface of 2 drums. In addition, the technology requires you to carefully close other parts of the car so that they do not get dirty during spraying.

Dye in a can costs a little more than an aerosol can. This mixture allows you to get a clean and high quality finish with a brush. This does not require removing the brake system from the discs.The disadvantages of the formulations in the bank include the long time spent on staining.

Spray paint application allows for even and economical use of the material

Heat-resistant paint kits contain a complete set of products designed for full-fledged painting of metal parts of a car.

Typically, the kit includes the following components:

- a bottle with a liquid for cleaning the surface;

- heat-resistant dye;

- primer composition;

- accessories (brush with stiff bristles, protective gloves).

On average, the dyeing process, along with waiting for the paint to dry, takes about 2 hours.

The dye is applied in the following order:

- The wheels of the car are removed.

- The calipers are cleaned of rust and dirt.

- The dye is applied to the calipers in two layers.

The calipers are thoroughly cleaned beforehand, after which paint is applied

Wait at least 35 minutes before applying the second layer of material. The most popular and demanded dyes in this segment are OMP, Kerry, Motip, Foliatec and Kudo.

Choosing heat-resistant paint for a barbecue or stove: popular manufacturers

Most consumers prefer to buy Cert dye formulations from the Spectrum company. This type of finishing material is in high demand due to its optimal technical parameters. The coating can withstand temperatures ranging from -65 to 900 ° C. The manufacturer offers an extensive palette of colors, including 25 shades.

Cert temperature range

| Shade of paint | Temperature indicator, ° C |

| black | 900 |

| gold, copper, white, green, blue, turquoise, light blue, brown | 700-750 |

| yellow and other colors of the palette | 400-500 |

The color of the material also affects the cost of the dye, which is in the range of 300-550 rubles. for 800 g.

Thermal alkyd dye from the Tikkurila brand forms a coating on the surface of the material that does not peel off within 3 years. Even if the metal heats up to a red glow, the dye will retain its properties and attractive appearance. The cost of a 330 ml can is 600 rubles. The material has one specific feature. The composition polymerization process is possible only if the treated surface is heated to 230 ° C for 1 hour.

The following types of paints are considered no less high quality: Hansa, Kudo, Bosnia, Hammerayt, Elkon. The recommended number of coats, temperature parameters of application and requirements for the painting process are different for each manufacturer.

To get a high-quality result, it is very important to adhere to the instructions on the package.

Beneficial features

Fire protection films are available in several types. The best heat-resistant products are worthy of attention, they combine many positive properties. Multifunctional self-adhesive is capable of:

- prevent the spread of flames and smoke;

- maintain the integrity of the structure;

- eliminate the formation of fragments;

- reduce the likelihood of injury to people;

- to strengthen the protective function of glass barriers;

- increase the sound insulation of the room;

- reduce heat losses;

- reduce the intensity of ultraviolet radiation.

High-quality heat-resistant film can withstand temperatures from -60 ℃ to + 80 ℃; humidity equal to 100%. This means that even if streams of almost boiling water are directed at the glass with a film coating, it will not lose its protective qualities.

How to stick on glass

Protective products are easy to use. No special skills required. You need normal, good hand coordination.

Protective products are easy to use. No special skills required. You need normal, good hand coordination.

First you need to wash the window. It is always good to do this. Then you need to add only 3 ml of baby shampoo to one liter of clean (preferably filtered) water. Choose the most common shampoo for babies, without emollients or any other additives.The liquid mixture should be well mixed by shaking and poured into a spray bottle. After that, the solution should be sprayed with a thin layer over the entire glass surface.

Next, you can glue a heat-resistant film sheet. The non-flammable film must have the exact dimensions of the glass to which it will be fixed. The pattern can be made in advance. To cut it out, it is recommended to attach the top and left edge of the heat-resistant film with your hand, and carefully cut off the excess at the bottom and right with a scalpel.

When the heat-resistant fabric is ready, you need to remove the tread layer from it

This should be done carefully, without touching the adhesive layer. Having applied a heat-resistant film to the glass, you need to spray the same compound on the outside.

Then the damp heat-resistant film should be pressed tightly to the glass surface. For this, it is convenient to use polyurethane rollers or trowels. You need to roll and smooth it until all the liquid comes out from under the film around the edges.

The procedure will be completed in 15 minutes. The final fixation will take place within a few weeks (from 1 to 3). The duration of the formation of an adhesive bond depends on the temperature of the air and the concentration of moisture in it.

Considering that the solution for glass processing consists almost entirely of water, it is not recommended to carry out work in the cold.

Features of the choice of paint for the oven

You cannot paint a stove with simple paints: the highest temperatures that they can withstand are 45-55 ° C. During the first firebox, this coating will swell, change color before our eyes, bubble up, and also spread “aromas” and smoke. Therefore, special formulations are definitely needed that can withstand elevated temperatures.

The degree of heat resistance required will depend on the type of oven. If this is a metal stove, then it can heat up to more than 700-900 ° C: the temperature is higher in the combustion zone, but taking into account the design, the outer walls may not heat up so much. For the outer surface of the brick, higher values are not required - 300 ° C is quite enough.

An important requirement is that refractory metal paint for a furnace must be suitable for internal painting. It is best for sauna stoves that it still protects against high humidity.

Thermal paint terminology for metal

For painting surfaces with elevated temperatures, refractory, heat-resistant and heat-resistant paints are suitable. Do not use fire retardants. Although it has a similar name, the purpose of this paint is completely different: when heated to a certain temperature (about 150 ° C), it bubbles, blocking the access of oxygen to the structure, thus preventing its destruction. Quite a useful effect, but not in the case of the stove.

- Heat-resistant paints, as a rule, have a field of application up to 700 degrees. These compounds can be used to paint metal elements of fireplaces and brick stoves, metal heating stoves. It is undesirable to cover the body of metal sauna stoves with these paints, since in some places the temperature rises to 900 ° C. For them, there are heat-resistant enamels that can withstand temperatures up to 1000 degrees.

- Refractory paint for metal can withstand open fire. Their operating temperature is even higher, however, for domestic use, these formulations are unprofitable, since they are quite expensive.

- There are also high-temperature paints that are used to paint heating system radiators. As a rule, they behave normally if they do not heat more than 250 ° C. They can only be used for brick ovens - they are perfect for tinting surfaces or painting joints.

- There are also heat-resistant varnishes. They normally tolerate temperatures up to 300-350 ° C. If a brick is treated with such varnish, then the surface will become brighter, acquire color and shine.

Application for various surfaces

In order to decide which paint to paint the oven, you need to pay attention to which surfaces this composition is intended for. Often the scope of application is indicated on the packaging in large letters.

For example, refractory paint for metal. If the scope of use is extensive, then it is indicated in a smaller print, but it must be on the package, like the brand name. If these data are not available, cancel the purchase. Most likely, this is a fake, and the combination of high temperatures and dubious quality is dangerous to health.

In addition to temperature resistance, paint for a metal bath stove must protect against high humidity. In this case, it will hold on for a longer time.

Color selection

Heat resistant paint is usually found in silver, gray and black. The rest of the shades must be looked for, but they also exist: red, white, blue and green. The coating can be glossy or matte.

Usually matte black thermal paint is found, however some manufacturers have different shades and colors.

Manufacturing form

Thermal paints are made in cans or cans. Accordingly, they can be applied from cans with rollers, brushes or sprayed using special equipment, and sprayed from cans.

Heat-resistant spray paint typically has a volume of approximately 500 ml. In cans, usually packing is 0.4-5 kg. There is a larger package in barrels and buckets.

What is more convenient? It's a matter of habit. With dexterity, the layer comes out more even from the can. In this case, the consumption may be less than when using a brush or roller.

Alkyd heat-resistant coating

Alkyd heat-resistant enamels can withstand heating temperatures up to 150 degrees. Based on this, they can be used for exterior decoration of stoves in places where there is no risk of fire, or indoors for painting radiators.

It is important to take into account that alkyd compounds have a pungent, unpleasant odor, so they need to be applied to a cooled surface. Among the advantages of this type of thermal coating:

- the ability to use on any surface, a high level of adhesion;

- service life up to 10 years;

- protection of the surface from external influences.

The alkyd compound should be applied to the surface in two coats so that the color is more uniform. It is convenient to use a brush to work with it, but some manufacturers produce an alkyd spray. Although it can be used to quickly paint over hard-to-reach areas, the material consumption in this case increases significantly.

Application

No special skills are required when using heat-resistant foil for the kitchen. It is only necessary to work carefully and thoughtfully, without making sudden movements and jerks. The glass substrate is pre-washed and allowed to dry. Then add 3 ml of the most gentle baby shampoo to 1 liter of water. After mixing the composition by shaking, apply it by spraying it from a spray bottle; you need to apply as thin as possible.

The film must exactly match the dimensions of the surface to which it is applied. It is recommended to make patterns in advance.

The protector of the fire protection film on the glass must be removed carefully so that there is no contact with the adhesive layer. The outer part of the coating is treated with the same composition.

In the kitchen, self-adhesive heat-resistant films can be used near cooking zones. Under them, peeling of laminated chipboard is prevented, the risk of swelling and cracking on the material is reduced. Facade material will also help to mask existing defects. It is worth noting the role of heat-resistant film in agriculture and in the garden. There it is needed when steaming the earth.

An overview of heat-resistant film in the video below.