Specifications

Elcon heat-resistant anticorrosive enamel has the following technical characteristics:

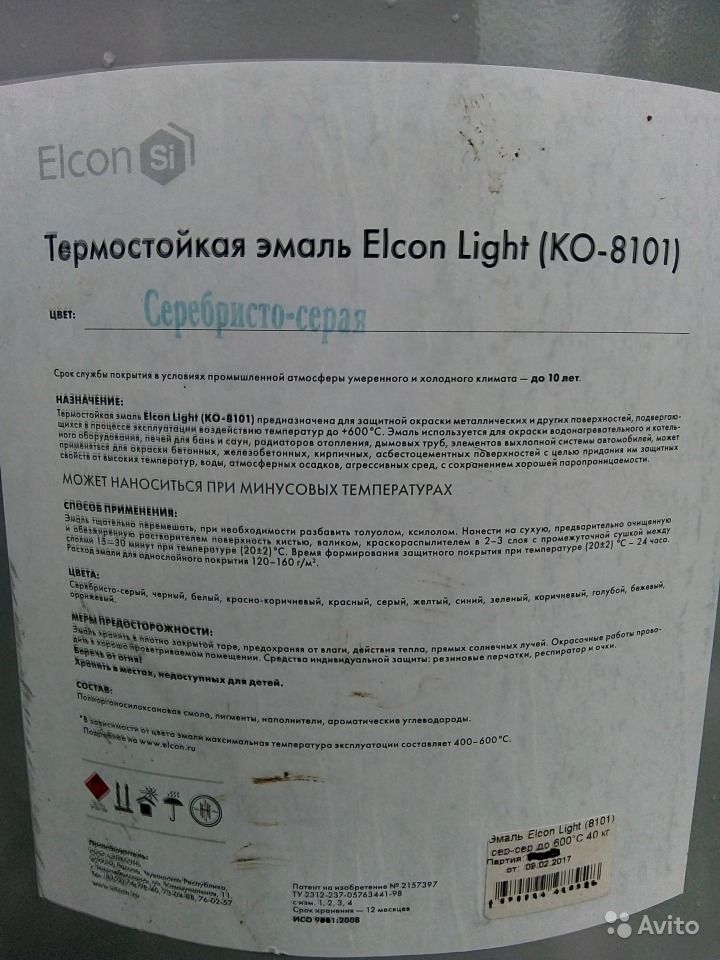

- The chemical composition of the paint corresponds to TU 2312-237-05763441-98.

- The viscosity of the composition at a temperature of 20 degrees is at least 25 s.

- Enamel dries to the third degree at temperatures above 150 degrees in half an hour, and at a temperature of 20 degrees - in two hours.

- The adhesion of the composition to the treated surface corresponds to 1 point.

- The impact strength of the applied layer is 40 cm.

- Resistance to constant contact with water is at least 100 hours, when exposed to oils and gasoline - at least 72 hours. In this case, the temperature of the liquid should be about 20 degrees.

- The consumption of this paint is 350 g per 1 m2 when applied to metal and 450 g per 1 m2 - on concrete. The enamel must be applied in at least two layers, but the actual consumption can be increased by one and a half times. This must be taken into account when calculating the required amount of enamel.

- The solvent for this product is xylene and toluene.

- Elcon enamel has a low-flammability, hardly flammable composition, when ignited, it practically does not smoke and is low-toxic.

Heat-resistant enamels of the KO series - description

Organosilicon paints, varnishes, enamels have a huge advantage over others in heat resistance. Obtaining a refractory material is achieved by creating a macromolecule of an organosilicon compound, in which the bonds between silicon and oxygen atoms are very strong. Also, various targeted additives give the desired properties to the funds:

- anti-corrosion substances;

- acrylic varnishes;

- carbide layers;

- epoxy resins;

- ethyl cellulose, etc.

To achieve the desired color, special pigments are introduced into the composition. Their base is also heat-resistant, so the color does not lose brightness even at high temperatures. Most often, paints are applied to metal, because they provide surface protection against corrosion. But enamels can also be used on concrete, brick, if they are used in an aggressive environment.

Features of enamels are as follows:

- withstand heating up to +600 degrees;

- resistant to steam, moisture, atmospheric precipitation, sunlight, a number of chemicals (chlorine, etc.);

- do not require heat hardening;

- have excellent adhesion to surfaces;

- easy to apply;

- can be used in external and internal works;

- after complete drying, non-toxic;

- provide decorative qualities.

Now such paints and varnishes are widely used by oil and gas production and processing enterprises. They are also used in power plants, marine enterprises, they are used to paint heating pipes, stoves, reinforced concrete structures, fireplaces, ventilation.

How to apply to the surface correctly?

In order to achieve the expected results when applying KO 8101 enamel, it is necessary to take into account some rules that will help to increase the service life of the coating.

Despite all the compliance with GOST, the material must be used correctly:

The main requirement that must be met when applying KO 8101 is a well-prepared surface. The place where the enamel will be applied must be well dried, without plaque and obvious roughness. It is desirable that the surface is free of grease. Be sure to clean the surface of rust and chips, in order to remove the old paint, you can use the manual method

Air humidity should not exceed 80%.

- If the material is applied in cold conditions, the temperature of the surrounding atmosphere and the surface to be enameled should be controlled. The place of application should be at least three degrees warmer than the air. Only then will it be possible to avoid the formation of frost or dew.It is not recommended to carry out work at a time when it is raining or snowing.

- Sometimes it becomes necessary to dilute the enamel. This happens if the composition looks too thick. Xylene can be used for dilution. Experts advise to apply enamel not in one layer, but at least two, then the surface will be uniform, and the heat-resistant film will be twice as strong. The second coat immediately follows the first, wet on wet, with at least 7 minutes between applications. The final dry layer should be only 32 µm thick.

Application methods

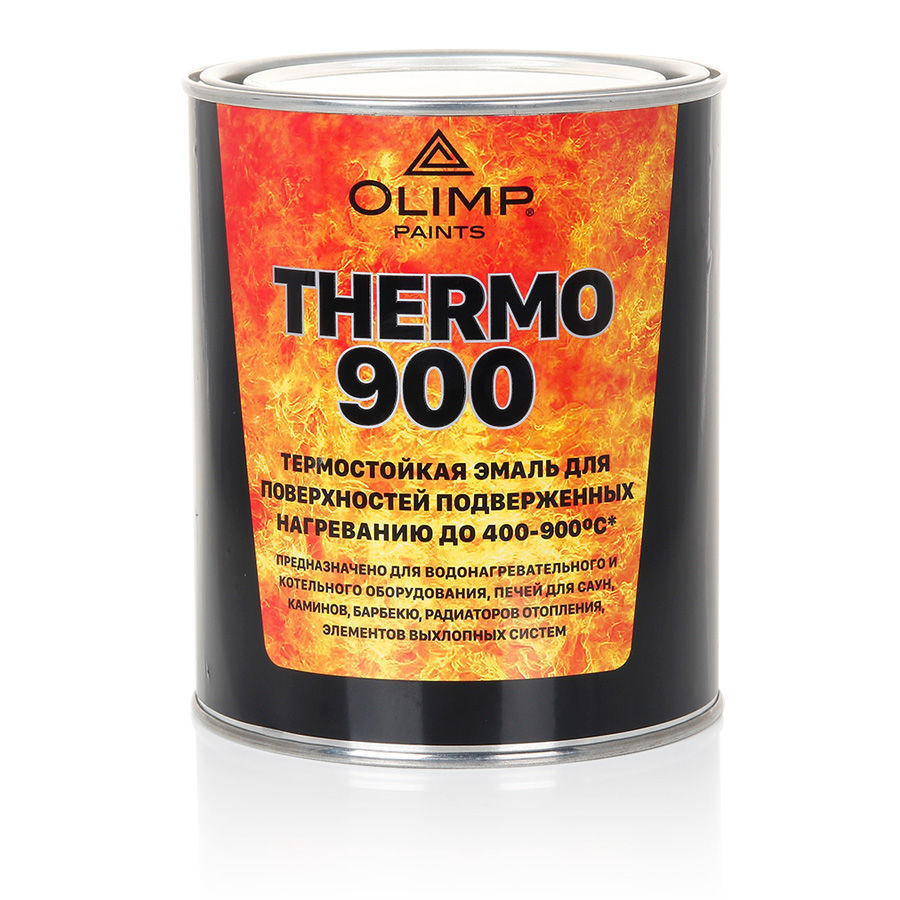

The scope of application of heat-resistant enamels is quite wide. Such a paint and varnish material can be used both in industrial facilities and for household equipment.

Most often, the following are painted with a fire-resistant composition:

- heating radiators;

- gas pipelines;

- heating pipes;

- auto parts;

- industrial drying equipment;

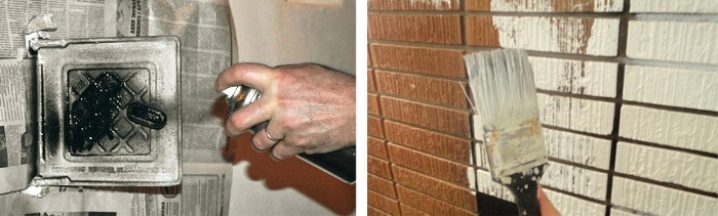

- fireplaces, stoves, boilers;

- gas stoves;

- heating elements of industrial equipment.

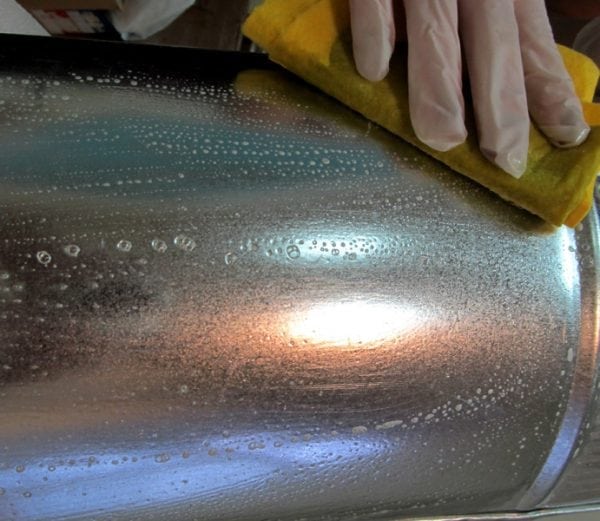

Before applying heat-resistant enamel, the surface must be thoroughly cleaned and degreased with a solvent. Paint brushes, spray guns or rollers can be used to work with paint. You can also purchase a paint and varnish product in the form of an aerosol can. The recommended operating temperature range is -20 to +40 degrees.

For personal safety, it is recommended to paint products with a respirator and gloves. If work is carried out indoors, then it should be well ventilated. The dye mixture is usually applied in no more than three layers.

Helpful hints

When buying enamel KO 8101, you can demand a quality certificate from the seller, this will be the main guarantee that not a fake, but a high-quality material that can serve for 15 years has fallen into your hands. This period is set by manufacturers, but practice shows that the material can last much longer, sometimes this period reaches 25 years, even despite the conditions of an aggressive environment and exposure to ultraviolet rays.

Using this paint and varnish material, you can save a lot, since the application is quite economical and a small amount of paint is enough to cover a large surface, and the second painting allows you to completely hide all the flaws and strengthen the protection.

When using the material, you should be careful, since the enamel is flammable, which means it should not be left near an open flame.

It is advisable to carry out the work with normal air access or good ventilation in the room.

You will learn more about heat-resistant enamel in the following video.

Heat-resistant enamel KO - 8101

Heat-resistant enamel KO-8101 Elcon creates anti-corrosion protection for parts, objects and structures operating at temperatures from -60 ºC to +1000 ºC, withstands the effects of chemical environments: mineral oil, petroleum products, is resistant to alkaline compounds. The material is applied in an electric field.

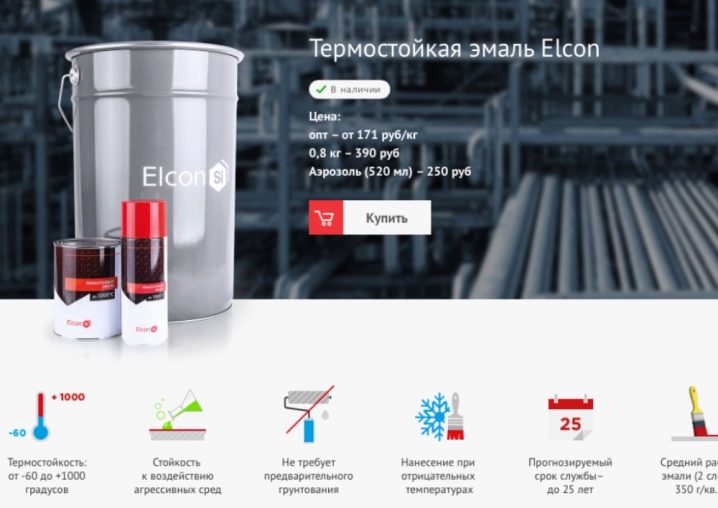

Packing: 25 kg. Price: 242 rubles / kg can of 0.8 kg. Price: from 450 rubles / piece aerosol 520 ml. Price: 300 rubles / piece color "gold" can of 0.8 kg -price RUB 950 / pc

More about the material:

Heat-resistant enamel KO-8101 can also be used for painting surfaces indoors, after drying it does not emit toxic fumes. The material has gained wide popularity as an anti-corrosion and heat-resistant enamel for stoves and pipes, as well as for fireplaces, grills and chimneys.

The material has good adhesion to metal, concrete, reinforced concrete and can be used as waterproofing to reduce water absorption.

When used on brick and asbestos surfaces, heat-resistant enamel KO-8101, along with the fact that it significantly improves the decorative appearance of the object, while maintaining the vapor permeability of materials.

Heat-resistant enamel KO-8101 has different heat resistance up to 400, 600 and 1000 ºС, depending on the color.

Heat-resistant enamel KO-8101 is a unique material that can be applied in winter, at low air temperatures, namely down to -30 ° C, and create a high-quality anti-corrosion coating. No priming is required due to the high content of effective anti-corrosion additives and corrosion inhibitors in the enamel composition.

Consumption: 120-200 g / m² per layer. Recommended: 2-3 coats. One layer 40-50 microns. Thinner: xylene, toluene. Drying time for heat-resistant enamel KO-8101: up to degree 3, at a temperature of (20 ± 2) ºС, - no more than 2 hours; at a temperature of (150 ± 2) ºС, - no more than 0.5 h.

Colors: silver-gray, black, gray, white, etc. by agreement. Packing: 25 kg, 0.8 kg, aerosol 520 ml.

Requirements for applying heat-resistant enamel KO-8101: the prepared surface must be dry, free of ice, application can be performed from -30 ° C to + 40 ° C and relative humidity of no more than 80%.

The manufacturer's warranty is 15 years for a coating made in compliance with the application technology.

2 Features of applying paint and calculating the required amount

Compliance with the manufacturer's recommendations guarantees a long service life of the coating:

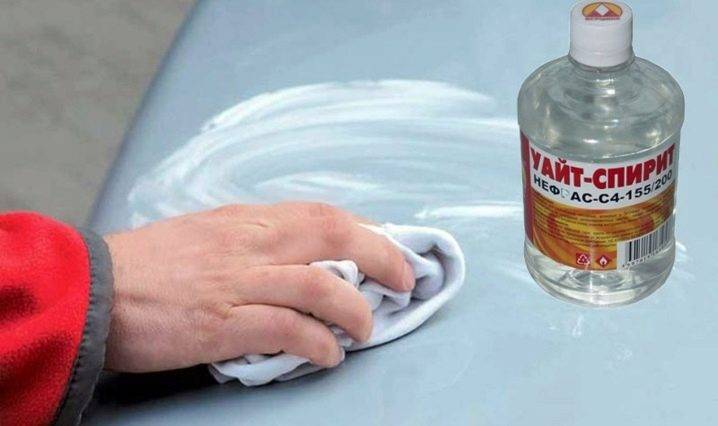

- Prepare the surface by removing dirt, rust and old paint. After this, it is necessary to degrease the element.

- Prepare the enamel - stir for a few minutes. With a strong enamel density, it is proposed to dilute it with a solvent, in an amount of 30% by weight of the composition.

- Painting can be done with a brush, rollers and spray. Drying time for each previous layer is 2 hours.

One square meter of metal surface requires 350 grams of composition, and one square meter of concrete surface requires 450 grams of composition. The calculation for the area of your product to be painted should be proportional.

Other Elcon enamels

In addition to heat-resistant paint, the company's product range also includes several products used for industrial and personal purposes:

- Organosilicate composition OS-12-03. This paint is intended for corrosion protection of metal surfaces.

- Weatherproof enamel KO-198. This composition is intended for coating concrete and reinforced concrete surfaces, as well as metal surfaces that are used in aggressive environments such as salt solutions or acids.

- Emulsion Si-HP. It is used for impregnation of residential and industrial premises. Designed to protect wood from inflammation, as well as mold, fungi and other biological damage.

Surface preparation

For all described paints, there is a general instruction for the preliminary preparation of surfaces. To improve adhesion to the base, the following preparatory measures are carried out:

- to clean the painted product from dirt, dust, salts, grease and other contaminants;

- remove all existing rust, as well as paint that is poorly adhered to the surface (all or some areas);

- purification to the degree of St3, SA2-2.5 according to the standards;

- before painting, degrease the base with solvent or xylene, start painting no later than 6 hours in an open area, in a day - indoors.

The main condition for a high-quality result is the presence of a completely dry and clean base, then the material will lie flat and have good adhesion.

Specifications

Elcon entered the market of finishing materials in 1998 and managed to win the favor of major equipment manufacturers. The color palette offered to customers is quite extensive and allows you to choose the best solution for a particular surface.

Also, the manufacturer declares the following technical characteristics of the enamel:

- does not require prior application of a primer;

- operating temperature from -60 to +1000 degrees Celsius;

- dries to touch in two hours after application;

- adhesion to the surface is estimated at 1 point, the surface is smooth, without flaking pieces;

- impact resistance - 40 cm;

- withstands exposure to water up to 100 hours, oil and gasoline - from seventy-two at a liquid temperature not higher than twenty degrees;

- consumption per square meter - within three hundred and fifty grams for metal and one hundred grams more - for concrete;

- slightly flammable;

- hardly flammable;

- not smoky;

- low toxic;

- application temperature - not lower than three degrees Celsius, without surface icing;

- complete drying time - at least three days;

- resistant to humidity and temperature fluctuations;

- requires at least two layers of application;

- service life - at least 20 years;

- will dissolve with xylene and toluene.

Elcon enamel is versatile and can be applied on different surfaces, be it metal, concrete, brick or wood.

Elcon KO-8101 is a one-component anticorrosive organosilicon enamel. It is used to paint metal devices operated in high humidity conditions. Scope: in baths, saunas, for outdoor barbecues. Application temperature - not lower than -30 degrees Celsius.