Manufacturers overview

Many companies are trying to break into the field of heat-resistant enamels. But it is better to use those that have already won trust. Among them are "Certa", "Elcon" and "Termal".

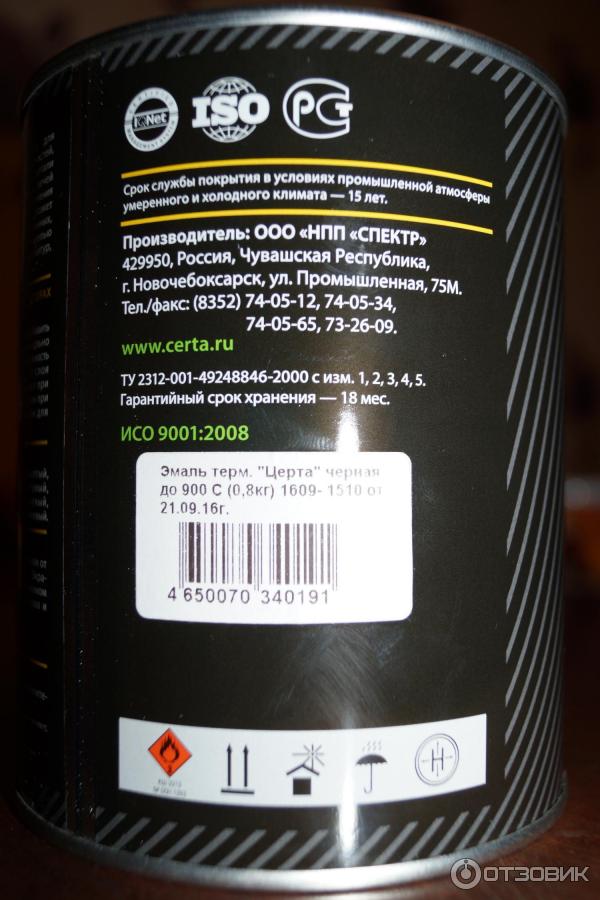

"Certa"

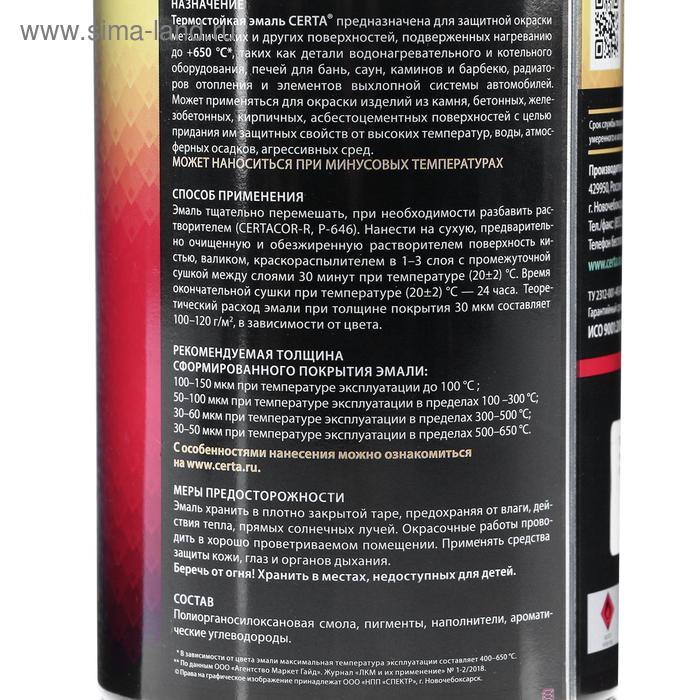

Excellent paint, which is produced by the Russian company "Spectrum". Heat-resistant enamel "Certa" is delivered both in small containers and in large cans. There are options that come in aerosol form. The maximum temperature at which the heat-resistant enamel "Certa" retains its properties is 900 °. At the same time, it is ready for the fact that the surfaces on which it will be located will cool down to -65 °. There are 26 colors to choose from. The most stable of these is black. Other options are capable of withstanding heating up to 500 °. The minimum price for 800 gr is 300 rubles.

"Elcon"

Heat-resistant enamel "Elcon" is a product of the Russian company of the same name, which started producing its products back in 1998. Many large equipment manufacturers choose the products of this particular company. Individual samples of paint formulations can easily withstand temperatures up to 1000 °. There is a wide range of colors available to help you find the best solution for any metal surface. The minimum temperature that the paint can withstand is -60 °. At the same time, she does not lose her qualities with sudden changes. For a can of 800 grams, you will have to pay 390 rubles.

"Termal"

Heat-resistant enamel "Termal" is produced by a Finnish company. It belongs to the alkyd type, that is, resins serve as the basis. In the assortment, the manufacturer has black and silver options. Often purchased for use on sauna stoves and barbecues. Its cost is much higher than the two previous options and for 330 grams you will have to pay about 600 rubles. The composition has its own characteristics for application. For normal drying, it is necessary to warm up the surface to 230 ° and hold for a time in accordance with the manufacturer's instructions.

"Hammerite"

Hammerite is a very renowned manufacturer with a wide range of solutions for painting all types of surfaces. Heat-resistant paints from this company are designed for metal surfaces. It is also a primer at the same time, so there is no need to make efforts to remove rust. The disadvantage of such enamel is its fear of gasoline and various oils. Withstands temperatures up to 600 ° and is applied in one layer.

"Kudo" and "Bosny"

Heat-resistant enamel "Kudo" is produced in Russia, its main component is organosilicon components. There are 20 different shades to choose from. The composition is resistant to temperatures up to 600 °. Supplied in aerosol cans. Approximate the cost starts from 150 rubles... Bosny-branded formulations are manufactured by R.J.LONDON CHEMICALS INDUSTRIES Co. Ltd. She has been producing various formulations for over 40 years. Heat-resistant aerosols can be purchased for temperatures of 650 and 200 °. Suitable not only for use with metal, but also other surfaces. The cost of products starts at 450 rubles.

Note! You can make your own heat resistant paint. The video tells you how to do it.

Criterias of choice

According to temperature groups, enamel is divided into the following types:

- heat resistant;

- heat resistant;

- fireproof.

Note! Fire retardant paints are not the same as fire retardant paints. The task of the latter is to create at a certain stage a protective film that blocks the access of oxygen to the surface.

Heat-resistant paints include all types that can withstand temperatures up to 600 °. They can be used to paint stoves, for example, in saunas or for some car parts. If you need to protect a surface that can be heated to 800 °, then heat resistant paint options are suitable.Refractory paints may be needed for surfaces that are, for example, near open ovens or other sources of fire. They have excellent stability, but they will also have to pay a round sum. Therefore, most often such compositions are purchased by various companies that are engaged in production on an industrial scale.

To save money, you can purchase high temperature paints. They withstand operating conditions where the temperature does not exceed 200 °. Most often, such compositions are used for household heating systems and boiler rooms. These enamels are used to cover the seams of brick ovens. High temperature varnish can be an excellent solution for the outer walls of the fireplace. It perfectly tolerates heat up to 350 ° and gives the surface finish and shine. A great way to apply high temperature paints is to coat your barbecue.

Features of the composition

Organosilicon enamel has properties that allow this type of product to be used wherever it is necessary to ensure the best quality and maximum durability of the painted surface. The enamel has a water-repellent effect, and is also immune to temperature extremes, so it can be used in conditions of maximum and minimum temperatures.

The composition is also not afraid of the sun's rays, even with prolonged exposure, the initial shade of the surface and its inherent technical characteristics do not change.

Enamels are produced synthetically on the basis of air oxygen and silicon. This composition gives special strength and reliability to the structure. In the composition of organosilicon materials there are special impurities to prevent corrosion, which improves the quality and resistance of the painted surface to adverse factors.

By adding acrylic resins and cellulose ethyl ester to the composition, manufacturers have achieved rapid drying of the painted surface. Carbide layers in the paint provide sufficient coating hardness, they also prevent mechanical damage to the surface. Thanks to the compounds of enamel with epoxy resins, resistance to the negative effects of chemical agents has appeared.

The color range was expanded by pigments, which are also part of the enamel. They can withstand ultra-high temperatures up to 150 degrees without losing their original shade. Organosilicon enamels, in addition to their inherent unique properties, have advantages and disadvantages in comparison with other types of paints and varnishes.

The main advantages include:

- thermal and frost resistance;

- resistance to high humidity;

- moisture resistance;

- fire safety;

- resistance to ultraviolet radiation;

- resistance to chemical reactions;

- wide color palette;

- low consumption in the painting process;

- the ability to work at subzero temperatures;

- corrosion protection.

Disadvantages of the material:

- the release of toxic gases when the composition dries;

- with prolonged contact, they negatively affect the body.

Safety requirements

When working with paintwork materials, the following safety conditions must be observed:

- Apply enamel or paint outdoors. If this is not possible, then it is necessary to open the windows and ensure a constant flow of air and the ventilation process;

- Prepare fire-fighting equipment in case of fire. This type of coating is fairly easy to ignite when sprayed, so any source of ignition must be excluded.

It is necessary to use rubber gloves, a respirator with gas and dust protection properties.

Do not smoke in the area where these works are performed.

Do not smoke in the area where these works are performed.

If you use these recommendations, then with the help of this type of paintwork you can get a high-quality coating from black to white, taking into account 100 possible chromatic shades.It will have high mechanical strength and heat resistance.

Composition and properties

The composition of heat-resistant enamel is more complex than that of conventional coloring mixtures. As a basis for such a material, an organosilicon varnish is used, which is mixed with polymers, dyes and various fillers. The technical characteristics of refractory enamel depend on its composition, which may differ from manufacturer to manufacturer. To designate certain properties of heat-resistant mixtures, special markings are used.

It is worth considering the most common coating modifications:

- KO-811. This enamel is used for painting aluminum, steel and titanium structures. The composition of the paint and varnish material does not include toxic substances, therefore this paint is considered environmentally friendly. This enamel has good resistance to high levels of humidity and sudden temperature changes.

- KO-813. The paint is intended for application to metal products. It has anti-corrosion properties and can be operated at temperatures from -60 to +500 degrees.

- KO-814. This enamel is most often used for painting steam lines. The operating temperature range is from -60 to +400 degrees.

- KO-8101. The modification is intended for application to metal structures that are exposed to temperatures ranging from -60 to +600 degrees. The enamel has not only high anti-corrosion properties, but also resistance to the negative effects of petroleum products, mineral motor oils and salts.

- KO-8104. This paint can be used to paint steam pipelines, vehicle exhaust systems and ovens. The enamel has anti-corrosion properties. The operating temperature of the coating can be from -60 to +600 degrees.

- KO-8111. Enamel provides reliable protection against rust, and can also be used to paint products that are used in an aggressive environment.

Varieties

All types of paints that are used for surfaces heated to high temperatures can be classified according to three parameters:

- packing method;

- storage duration;

- method of application.

The choice of packaging for heat-resistant enamel will depend on what specific purposes it will be used for and what area needs to be covered. Aerosol samples are available commercially. They are available in cans with a capacity of up to 0.5 liters. If a larger volume is required, then you should opt for samples that can be purchased in cans, buckets or barrels with a maximum weight of up to 40 kg.

Note! To cover an area of 1 m2, you will need about 250 grams of coloring composition

The minimum shelf life during which the paint retains all its properties is 7 months. Usually the manufacturer indicates a specific number on the product label. The easiest to apply are paints that are supplied in aerosols. There is no need to purchase additional items. It is enough just to spray the enamel onto the surface. For other options, you can use a brush or roller. With good fluidity, it is allowed to use pneumatic atomizers that operate in tandem with a compressor. In this case, the stability of the final layer will be the same in any of the application options.

Note! When spraying paint from an aerosol or from a spray gun, the consumption per 1m2 slightly increases compared to a roller or brush

Range

The assortment line of paints and varnishes includes the following options:

- Thermal paint Certa, able to resist changes when heated up to 1000 ° C;

- Thermo-enamel Certa has anti-corrosion properties. Operation allows temperature conditions up to 1000 ° С;

- Thermal enamels used for ovens in cans.Comfortable to apply as it does not require a brush or roller. It is easy to store even when it is started and has already been covered with surfaces. There is no need to think about how to seal the container with paint. This type of enamel is able to withstand low temperatures down to - 60 ° С;

- Metal paint, packaged in cans and used as an aerosol coating. It can be used not only for metal, but also for concrete, brick, plastered walls, and other types of coating.

Comfortable to apply as it does not require a brush or roller.

Comfortable to apply as it does not require a brush or roller.

How to use it correctly?

To prepare the surface for painting, it should be cleaned of dirt, rust, old paint, oil or grease. Mechanical or manual cleaning can be carried out. Surface treatment is carried out to grades St 3 or SA2-SA2.5. The letters St indicate that it is cleaned manually or mechanically, using a brush. Before cleaning, all rust should be scrubbed off the surfaces, the residues of oil products and dirt should be removed. After all contaminants have been removed, dedusting is carried out.

Blast cleaning is indicated by the letters SA. The SA2-SA2.5 grade assumes a very thorough cleaning of the surface. During the inspection, there should be no residues of oils, rust, paint or other contaminants.

After how the surface is completely cleaned, it should be degreased with a solvent; for this, "Solvent" or "Xylene" may be suitable. Degrease the surface before work. You should not keep the product after processing without degreasing for more than six hours outdoors and more than a day indoors.

Preparatory stage

After opening the jar, stir the enamel thoroughly until the sediment disappears and wait ten minutes until the bubbles disappear. You can measure the viscosity of enamel with a special device VZ-246 viscometer, it is designed to determine the conditional indicator, that is, the expiration time of paintwork materials. Using "Xylene" or "Solvent", you can dilute the paint to the desired consistency, but not more than 30%. At the end of the work, the jar is tightly closed and left for storage.

Coloration

The paint is applied to the surface with a roller or brush. It should be applied in a thin layer, it depends on how well the organosilicon film and metal adhere.

When using Certa spray paint in a can, a very even coating is obtained, but many toxic substances get into the air. It is better to use this option for coloring not very large objects, such as a brazier, barbecue or a muffler.

It is important to carry out work in the fresh air, using means to protect against toxic substances

Many heat-resistant materials do not require pretreatment. The consumption of paintwork materials will depend on the conditions in which it is used. When painting the walls of the chimney, two layers of enamel should be applied; when painting braziers or barbecues, one is enough. On a brick or plaster surface, 2-3 thick layers are applied.

How to use correctly

Certa paint requires correct processing. Therefore, in order to ensure a long service life, it is necessary to adhere to all the recommended steps.

Certa paint requires correct processing.

Certa paint requires correct processing.

Surface preparation

Surface without fail:

- It is cleaned from rust;

- Degreased;

- All dirt is removed from it;

- It is also necessary to clean the old paint;

- All manipulations can be carried out both in manual mode and using special tools, for example, a cord brush.

All manipulations can be carried out both in manual mode and using special tools.

All manipulations can be carried out both in manual mode and using special tools.

Preparation of material for application

Before applying Certa enamel to the surface, it is important to stir it. This is done to eliminate sediment.

With this manipulation, air bubbles enter the mass. Therefore, you need to wait until they disappear.

Using a special device for measuring viscosity, determine this parameter for paintwork materials. If necessary, you can use Solvent or Xylene. With their help, the paint is brought to the desired level of viscosity.

It is important to remember that it can be diluted to a concentration of no more than 30% solvent and 70% paintwork materials.

It is necessary to understand that all solvents are toxic, which is why Certa heat-resistant enamel is not recommended for use inside living spaces.

Before applying Certa enamel to the surface, it is important to stir it.

Summary

It is not possible to review all available manufacturers in one article. Therefore, before buying paint from a brand that is not listed here, you should carefully evaluate its composition and take a trial batch so as not to invest your funds in the wrong product. As it became clear, a good look can be given not only to ordinary surfaces, but also to those that are constantly heated to high temperatures. This means that metal stoves do not have to look primitive, periodically getting rusty.

-

Tikkurila for indoor and outdoor use

-

Parquet board varnish

-

Red paint

-

How to choose a heat-resistant varnish

1 Main features

The coating of this company is manufactured by the Russian company Spectr. The composition is packed in jars weighing from 0.5 to 20 kilograms. Some types of enamel are sold only in aerosols. Temperature limits at which the enamel can be applied is from -60 to +900 degrees. The enamel color palette has about 26 options. One of the most persistent shades is considered to be the black tone of Certa enamel. The composition is distinguished by a high rate of heat resistance, it can be used on heating mains, gas pipelines, and also during the operation of furnaces. The quality of the products is backed up by certificates, which specify the technical properties of the coating. The composition of the paintwork is more complex than the composition of standard paints, it contains various ingredients.

Properties

The paintwork has an excellent anti-corrosion indicator, it is not subject to rust, and also demonstrates resistance to temperature extremes, retains its original characteristics in any conditions. Pleases and its plasticity, the coating does not crack when heated. The paintwork is perfect for indoor use, giving the product durability and a beautiful appearance.

Among the key characteristics of this product, one can single out the need to prepare the base for staining, as well as in a bitch under high temperatures. To achieve the desired result in coloring, it is necessary to apply the product several times - this is about 2-3 layers. It takes 2 days for the product to fully dry and the temperature is in the range of 20-25 degrees. Based on the testing of the product, its shelf life reaches 25 years.

Release form

Most often, Certa heat-resistant paint is available in three basic shades - black, gray and white. You can also find other colors that look great as decorative finishes. These funds are slightly more expensive. As for the gloss index, the paint can be matte or glossy. The paint and varnish mixture is produced in the following variations:

- aerosol cans - the ideal solution for painting complex structures;

- cans or buckets with the mixture ready for application - this form is characterized by the minimum consumption of the product.

Varieties

It is customary to classify enamels based on organosilicon into limited heat-resistant and heat-resistant.

Limited heat resistant

They have found application for the decoration of facades. The limitation in enamel is imposed due to the content of pigments in the composition, which impart the necessary shade to the paint and varnish product. Many pigments cannot withstand exposure to high temperatures, therefore they are called limited heat resistance.

Limited heat-resistant enamels include: KO-983, KO-174, KO-198, KO-168, KO-42, KO-5102.Coatings based on such materials have high physical and mechanical characteristics, lack of water absorption, moisture resistance, good adhesion to metal, ceramic, glass surfaces, resistance to sunlight, thermal stress and environmental friendliness.

Enamel does not form a sediment during long-term storage and transportation, it is easily applied to the surface with any tools. The main advantage of limited heat-resistant formulations is the ability to apply at sub-zero temperatures. Moreover, their service life in a harsh climate is up to 10 years.

Organosilicon enamels are produced in the form of a suspension of pigments and fillers with a solvent in an organosilicon material. It is convenient to transport the products in any way in accordance with the norms for the carriage of goods at temperatures above 0 degrees.

Also, do not forget to treat the surface with a special compound to give strength and prime it. All irregularities are eliminated with a putty, and after drying, the surface must be primed again. Coloring is carried out at a temperature not exceeding 20 degrees. The enamel is applied in several layers with drying of each layer for 15-20 minutes.

Heat resistant

Enamels are incorporated into anticorrosive paints intended for painting surfaces exposed to high temperatures and high humidity. Heat-resistant compounds are often used in construction and renovation, for painting chimneys, fireplaces and stoves.

Heat-resistant enamels on an organosilicon base include: KO-8111, KO-8104, KO-8101, KO-814, KO-868, KO-870, KO-813, KO-818, KO-83, KO-88, KO- 89, KO-84. All of them have long-term heat-resistant properties (up to 600 degrees). They are used for application on metal and other surfaces: for painting fireplaces, chimneys, barbecues and other structures that are exposed to prolonged exposure to high temperatures.

Heat-resistant compounds are often used in the oil industry: for painting pipelines with superheated steam, oil pipelines, gas pipelines, chimneys and other structures exposed to high temperatures and corrosive environments with oils, oil products, and salts.

The enamels are available in different colors: silver, gray, white, brown.

Consumption per 1 m² is 100-130 grams at high temperatures, and at atmospheric conditions and low temperatures - 140-180 grams. The shelf life of heat-resistant enamels is 1 year.

Also in the industry they use KO-811 anticorrosive enamels to protect titanium and steel surfaces. They are available in green, black and red. The enamel formulation includes resinous-asphaltene substances, special fillers to preserve all the positive properties of the paint during storage.

Anti-corrosion compounds can withstand temperatures ranging from -60 to 400 degrees. Coating KO-811 has increased protection against atmospheric agents and resistance to corrosive substances.

When applying such enamel, it is not necessary in a preliminary primer, but the staining process is carried out under strict factory conditions, including at sub-zero temperatures. Apply the composition with a spray gun in two layers. Enamel consumption per 1 m² is 100-130 grams. Solvent, toluene, xylene are used as diluents. Expiration date - 1 year.

3 How to use it correctly

It is important to be thoroughly prepared before use. The container with the product should be carefully opened and the composition should be mixed so that the sediment is gone

Next, leave the paint for a couple of minutes to remove bubbles that will interfere with the coloring process. To dilute the material, use 30% solvents. At the end of the staining, close the container tightly.

Use a roller or brush for easy application.The layer should be thin, which will increase the adhesion of the composition to the surface. When using an aerosol or a special spray bottle, the coating comes out even. Aerosol spray is not suitable for large surfaces. To protect yourself from poisoning and headaches, work should be done outdoors. Get a protective mask before you start working on enamel.

The number of layers will depend on the type of surface being painted. To paint the brazier, one layer is enough; to process the chimney, you will need two layers. Brick surfaces require three coatings. In industrial conditions, it takes 40-45 minutes for the product to completely dry; at home, the material will not dry out during this period of time. after painting, it is allowed to transport or install equipment after three days.

Metal parts require three cross coats of paint. It will take at least two days for complete drying, provided that the temperature is in the range of 18-22 degrees. Heat-resistant paint for metal Certa up to 900 degrees is considered to be one of the most demanded and popular ones.

The saturation of the solution depends on the pigment; you can find a white or black shade or other color scheme.

Safety requirements

Heat-resistant Certa enamel contains solvents and a pungent odor

That is why it is so important to be careful when using it. Only with the correct use of the coloring agent can the safety of human health be ensured. The best option is to carry out work in the open air

If the room is closed, it is worth opening the windows

The best option is to carry out work in the open air. If the room is closed, it is worth opening the windows.

Gloves and a respirator are required to work with enamel. Remember also that it is highly flammable, so there should be no open flames nearby. Smoking is also prohibited in the area where the staining is carried out.

Observing all safety measures, you can avoid unpleasant consequences in the form of poisoning and headaches.

Whenever possible, prioritize outdoor work rather than indoor surface treatment. You may also need a protective paste, which must be purchased in advance.

Similar:

| Professional standardCleaning and preparation of the surface for the application of protective coatings, performance of work on the application of enamel, paints and varnishes, various ... | Instructions for the application of organosilicon varnish ko-85 and organosilicon enamel ko-814From up to + 400 ° C. Enamel has increased atmospheric, moisture, salt, oil, petrol resistance | ||

| Instructions for use: Acrylic paint, high-pressure vac-s "Special"The instruction is intended for specialists in the application of paints and varnishes. | Instructions for the use of fire retardant thermally expanding paint "astra-m"The instruction is intended for specialists in the application of fire retardant materials. | ||

| Instructions for use. Instructions for applying corundum anticorrosiveCorundum anticorrosive specially formulated for coating poorly prepared metal substrates | Step-by-step instructions for applying gel polishDo not forget that you need to remove the film from the retractable bottom of the lamp because there is a mirror coating! | ||

| Instructions for use The polypropylene bag is fixed inside ...Bags are made of heat-resistant polypropylene film for waste disposal in an autoclave or microwave installation, with increased ... | Instructions for use (prizma) prismOne-component decorative paint "prizma" is ready for application, it does not need to be diluted with anything. Applied to the paint and varnish surface…. | ||

| Technical instruction for fire retardant paint vd-ak-121O 1This technological instruction applies to the production of work on the application of fire retardant paint vd-ak-121O to the surface ... | Instructions for applying gel polishUse a 240 grit file to shape the free edge as desired. With a thin or weakened nail plate, the free edge should be left ... | ||

| Instructions for the preparation and application of fire retardant intumescent composition "endotherm xt-150"The composition and coating intumescent fire retardant "Endotherm xt-150" are produced according to tu u 13481691. 01-97 in accordance with the technological ... | Magnetic Paint Application InstructionsFor good adhesion to glossy and semi-gloss surfaces, you need to wipe them with sandpaper, or use deglosser ... | ||

| Standard for Specialized Medical Care in Suspended ... | Technological instructions for applying Technogrip 200B to floorsBefore processing the entire surface, we recommend that you carry out a trial processing in a small area in order to determine the exact ... | ||

| Instructions for applying ultra-thin thermal insulation armor classic armor classicFrom up to +200 ° C (in the peak short-term mode up to +260 ° C). The armor fits well on all types of surfaces. Insulation work can be ... | Terms of Reference Requirements for the technical characteristics of goods No.Summer suit made of heat-resistant anti-electrostatic fabric with flame retardant properties to protect against thermal risks of electric ... |

Instructions, instructions for use

Range

Popular paints from Russian manufacturers have found their application in many industries. Most often they are used in the chemical industry and mechanical engineering, they cover parts of furnaces and heating devices with them.

This type of paint has certain specifics:

- contains a toxic solvent;

- before starting work, the surface is prepared;

- dry the Certa enamel at high temperatures.

It should be borne in mind that under industrial conditions Certa dries for 45-50 minutes; in home use without toxic accelerators, this time will not be enough. After painting, installation or transportation of equipment should be carried out only after three days. When painting metal parts, apply 2-3 cross layers.

The most popular can be called Certa heat-resistant metal paint up to 900 degrees. Pigment is responsible for the color saturation of paintwork materials, more often you can find white or black enamel, but you can find other shades if you need to maintain a certain color range.

The most commonly used paint is black, semi-gloss black, silvery gray and graphite. Other colors are also chosen, among them yellow, copper, red, brown, blue, blue and green. In addition, unique novelties have appeared - gold and copper colors.

This paint will protect the material from corrosion, fire and moisture. Anti-corrosion paint is easy to apply, it is applied to metal, concrete and cement surfaces, after painting it dries within half an hour. After drying, the enamel forms a uniform film without wrinkles and irregularities. If the paint is applied to a weld seam or other hard-to-reach places, they are painted with a brush, passing several times over this area.

Paintwork materials are produced in different modifications, nickel, chromium or aluminum in powder can be added there. Spectrum produces Certa enamel in 400 and 800 gram packs, as well as 520 ml aerosols for coating rough cast iron, forged and cast steel surfaces. After testing with paint, the coating has been confirmed to have a shelf life of up to 25 years.

You should pay attention to the novelty - this is Certa Patina enamel, which is used to decorate metal products. Patina allows you to give products an aged effect

When applying patina to a metal surface, you should:

- stir the paint;

- dip the brush;

- grind excess paint;

- lightly touching with a brush, you should go over the selected areas without overlapping the previous layer.