How to fix

This type of fastener has a hole into which you need to insert a self-tapping screw. It also attracts the thermal washer to the metal frame. In this case, the leg of the thermal washer is abutted against the structure frame in such a way that the self-tapping screw itself does not damage the polycarbonate panel.

Installation profiles

To do the joining of sheets of material with each other, you will need to purchase connecting profiles. Their thickness is selected based on the panel parameters. It is quite difficult to work with such details, so it must be done with special care.

Depending on the color of the panels that are joined, you can buy a split or one-piece profile. The first slats are suitable for attaching two sheets of different colors side by side, and one-piece ones are relevant for single-color panels.

The most expensive option is considered to be an aluminum profile due to its increased waterproofing ability and special attractiveness. Therefore, with a high consumption of materials and a meager budget for construction work, it is worth completely abandoning the purchase of this type of finishing panels.

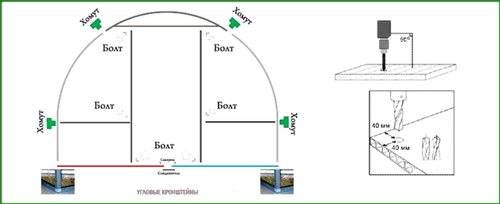

To fasten the panels at an angle of ninety degrees, for example, for the construction of a canopy to the utility block, you will need corner profiles. You can see with your own eyes the attachment of polycarbonate to a metal frame in the video below. This material will help you fasten polycarbonate panels to a metal frame of such buildings as a greenhouse, garage, and the like.

Fasteners

Installation of polycarbonate can be carried out using various elements: self-tapping screws, washers, special designs. They are chosen based on the purpose of the future structure and materials for creating the frame.

Washers and screws

How to fix polycarbonate - different fasteners can be used for this. The most popular are carpentry or galvanized self-tapping screws from 19 to 50 mm. Their choice depends on the following factors:

- washer size - decorative models 3-15 mm thick, standard silicone up to 5 mm thick;

- installation diagram - for wooden lathing fasteners 50 mm, in the fastening without overlap, 19 mm self-tapping screws are used, with an overlap - 25 mm;

- thickness of slabs - when using a window structure, the thickness of the side slabs is 6-8 mm, for the roof 10 mm, for a standard frame, the thickness of the material is not more than 10 mm.

For the main methods, a universal hexagon self-tapping screw with a drill at the end is used. Designed for aluminum structures. It can also be used for wood, but the strength characteristics are lost. On the opposite side, ordinary carpentry screws can be used.

Washers for fastening

The only type of fastener for all types of polycarbonate is a screw with a large washer made of durable plastic or a self-tapping screw. Washer screws are used to create decorative designs. Not suitable for greenhouses due to centering sleeve. The simplest version of tight fastening of sheets is provided by a snap-on split profile. The boards are placed on the assembled profile and snapped into place with an overlay foil. Bolts with nuts can also be used, but they are not very convenient to use - the work takes more time and you can destroy the plate by overtightening the nut.

How to attach polycarbonate to a metal frame:

- Experts recommend using fasteners with washers and plugs that have an O-ring and bulged washers.

- They are recessed in the holes with a leg.

- The panel is pressed tightly, harmonious appearance, moisture does not get inside.

Self-tapping screws or other similar items must be purchased separately. Polycarbonate washers are produced in different colors, stronger, thermal washers are transparent.

Washers with plugs

Polypropylene washers consist of a plug, a cover (different colors) and a seal. They have no UV protection, quickly fade and lose strength. Not recommended for indoor use and on shaded roofs. Their main advantage is the price.

Metal washers are mainly used for metal frames and large areas. They do not loosen, provide high-quality fastening. They are concave, a gasket is placed in the mold, fastened with bolts or self-tapping screws. Washers with gaskets provide maximum tightness, prevent moisture from penetrating into the canvas.

Metal washers

For fixing plastic under a canopy or indoors, you can use self-tapping screws with a gasket or a thin washer. In the most optimal cases, the washers can be completely abandoned. It is imperative to put on an additional gasket under the washer for outdoor structures.

Profile

The connecting profile allows you to attach sheets with a frame and between themselves.

The profile is made of identical sheet material and can have a thickness of 4-16 mm.

A thermal gap of 3 mm is left inside between the profile and the sheet.

During the installation process, a perforated or sealing tape is used, which is attached to the ends.

Then the plastic is installed directly in the profile.

The profile itself is of several types:

- connecting;

- one-piece;

- end;

- detachable.

All options have their own characteristics and characteristics that must be taken into account when choosing a type of construction.

Plates can be mounted in aluminum, plastic or polycarbonate profiles. The profile itself has a different cross-section and is marked with Latin letters. Plates installed in the grid can be fixed with a sealant. But in strong winds it will be a weak connection

It is important to choose a quality sealant that will retain its elasticity and strength for several years.

To know how to properly attach polycarbonate to a greenhouse, you need to remember several important rules:

- the sealant is used only on the upper slopes;

- avoid any curvature of the sheets when using thermal washers - this leads to the appearance of holes and loss of tightness of the structure;

- arched structures from below are attached with perforated tape, which will protect against air release, breaks and damage to the sheets themselves;

- metal profile is used only for structures larger than 2 m;

- aluminum is a good hermetic agent and is a base, rubber seals.

What are polycarbonate washers for?

It is worth taking into account the fact that the correct process of fastening the material can be carried out only if thermal insulation washers are used. Washers for attaching polycarbonate are used for the following purposes:

Washers for attaching polycarbonate are used for the following purposes:

Insulation - in cases where it is necessary to observe the temperature regime in the structure being erected

It is important to understand that coping with such a problem is much more difficult in winter, when even a microcrack can have a significant impact.

Increased service life - if only self-tapping screws are used during the construction of a structure, then there is a high probability that moisture will enter through the holes made and remain in the polycarbonate cavity, thereby having a negative effect on the material. When using cellular polycarbonate, you will have to disassemble the entire structure, remove water and blow it with compressed air.

Attractive appearance - despite the fact that this item may seem insignificant, it is worthwhile to understand that many people put this aspect in the first place

If necessary, attachments can be selected in the same shade as the main building material.

Corrosion protection - the use of plastic products allows you to protect self-tapping screws from corrosion during operation, as a result of which the service life will be significantly increased.

Thermal compensation - even if the building material is properly fixed, it is impossible to predict how polycarbonate will behave during temperature fluctuations. That is why it is recommended to choose thermal washers that can change with the material used during the heating process.

As you can see, the help of the washers is undeniable, in addition, they are able to extend the service life of the erected structure.

Installation features

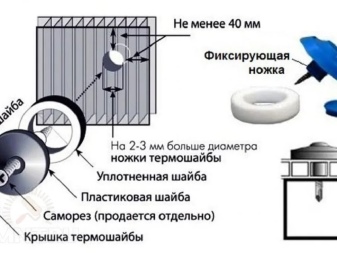

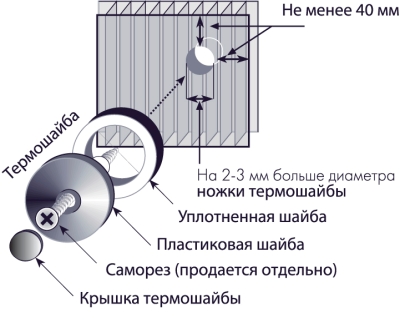

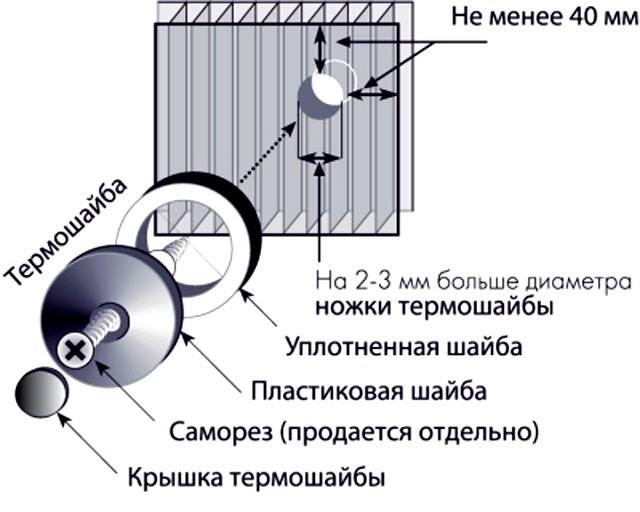

After preparing the polycarbonate sheets, to install the thermal washers, it is often necessary to make holes into which the washers will be inserted. A drill can be used for this purpose. The diameter of the drill should be such that it would be possible to drill holes larger than the diameter of the legs of the thermowells by 2 or 3 mm. After all, as we already know, polycarbonate tends to expand in heat, which means that if this feature is not taken into account when the material is swollen and compressed, it will begin to collapse. And neither the thermal washer nor the structure will stand for a long time in such conditions.

The installation of washers with self-tapping screws is carried out at a distance of 20-30 cm. Remember that the attachment points are between the stiffeners. The step increases if the panel thickness is small. The distance reaches 70 mm when working with a very thin sheet and is equal to 50 mm when the thickness is 4 mm. It is worth retreating 40 mm from the edge of the polycarbonate sheet.

The use of thermal washers for polycarbonate is focused on preventing damage to such material. They successfully provide tightness and protection from the inside.

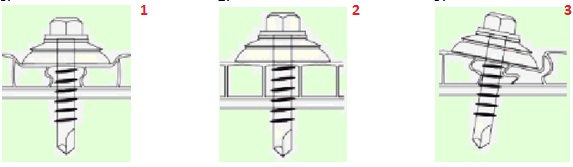

When you install the thermal washer, make sure the leg of the washer rests against the frame and that the mount is at right angles. The gasket should fit well to the sheet, the head should be level, not at an angle and not pressed into the panel. It is possible to use thermal washers when installing polycarbonate for fastening it with self-tapping screws, the head of which is the same as that of the bolt. Remember to close the washer with a cap to keep moisture out of the hole.

Based on these features of the installation of polycarbonate with press washers, you can start construction point by point.

- Drill holes at the attachment points. The pitch is measured and marked before drilling is performed.

- Insert a thermal washer with a self-tapping screw into the holes.

- Washers are installed with tools such as a screwdriver or screwdriver.

- We close the screw with a plug.

Thermal washers are a reliable fastening of polycarbonate in any construction.

How to drill polycarbonate and fix it with a thermal washer, see the video.

What is a thermal washer

Definition

Thermal washers are special fasteners that are designed for point fixing of polycarbonate sheets on a frame made of wood, metal, durable plastic, and the like. They are designed taking into account all the features of polymer webs, namely: the presence of cavities, the so-called cells (cellular thermoplastic), the ability to change their dimensions (to an insignificant extent) under the influence of changes in temperature conditions, and much more.

The size

For both cast and honeycomb polymer, the washers should be selected in certain dimensions corresponding to the thickness of the web, so that the "leg" of the washer exactly coincides with the thickness of the end face of the thermoplastic plate. It is worth noting that if the length of the leg can be either short (from 4 mm) or long (16 or more millimeters), then its width, like the width of the cap, remains the same (rare exceptions).

Structure

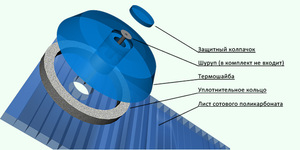

So, thermal insulating washers consist of three key parts: the first is the plastic washer itself with a leg, and the leg height can be 4, 6, 8, 10, 16 mm, but sometimes there are more authentic options. The second part is a kind of sealant, which ensures the most tight and reliable fastening of the polymer to the structure and prevents moisture from entering not only into the structure (room), but also directly into the cells of the sheet. The third and uppermost part, which some builders unknowingly neglect, is the upper "hat", that is.stub. It not only gives the structure a more aesthetic and attractive look, but also serves as an additional protection - a kind of cover, preventing the penetration of dirt and moisture inside.

Correct fastening

It is worth noting that any thermal insulation washers will be ineffective if not properly fixed.

It is important to arrange these elements in such a way that they are clearly perpendicular to the coating, and as they do not overtighten the polycarbonate sheet, and do not "dangle" on the surface, that is

option "2" is the only correct one.

Self-tapping screws

Fastening of carbonate sheets takes place with bolts and washers, which serve as a seal. The roofing screw is used when attaching carbonate panels. The product is coated with zinc, which serves as a corrosion protection, as seen in the photo. Can withstand heavy loads. Fasteners are used with thermal washer or rubber washer. Roof bolt sizes: 25,29,32,38,51

First, you need to drill a hole, the diameter of which should be equal to the diameter of the screw plus 2 millimeters. In this case, the ability to control the thermal change of carbonate is ensured. The hole should be at a distance of 20 mm from the edge of the panel. You can drill polycarbonate sheets with drills designed for wood products. Moreover, you need to drill at a low speed, observing the rules of heating in the places of drilling. Correct assembly provides for tightly clamping the panels to the frame, but not overtightening. Nothing should interfere with the displacement of the product when the temperature changes.

At the time of fastening the screws, you do not need to make any special efforts when tightening. Otherwise, deformation of the polycarbonate panel may occur. In addition, the bolts must be tightened strictly perpendicular to the sheets, as seen in the photo.

During assembly, do not leave the sheets at the place of work unattended if you have not yet fully strengthened them and not all screws are screwed in. Also, make sure that the sheets are not damaged by an unexpected hurricane.

Thermal washers are used in addition to the bolts. You can insert a bolt into it, with which the thermal washer is attracted to the frame. The leg of the washer will rest against the frame and the self-tapping screw will not be able to damage the carbonate panel.

To fasten polycarbonate sheets to a supporting metal frame, it is better to use bolts with a diameter of 5 millimeters. In this case, you can use a cordless screwdriver. With it, you can make it much easier to screw the bolts into the metal base.

If you have a wooden frame, then you can connect carbonate sheets to it without using thermal washers. The fact is that the wood almost does not conduct heat. In this case, you can use galvanized self-tapping screws or stainless steel, and washers with a diameter of 25 millimeters. The holes in the panels need to be drilled larger than the bolt diameter in order to provide a margin for thermal change in the material and avoid damage.

Fastening polycarbonate with self-tapping screws and thermal washers is considered the most accurate. Installation of monolithic carbonate (vertically or on the roof) can be done using bolts and rubber washers with a seal. According to GOST, the fastening step should go along the frame of about 500 mm.

The dimensions of the diameter of the leg of the plastic washer and the thickness of the carbonate panel must be the same. A hole in the honeycomb sheet must be drilled along the stiffeners two millimeters larger than the leg. The fixing step is 400 mm, and approximately 40 mm must be retreated from the edge of the panel.

Conclusion

Correctly selected fasteners will provide a high-quality and reliable assembly of the structure, which will serve you for a long time and delight you with a beautiful view.

How many thermal washers do you need per polycarbonate sheet

If it becomes necessary to determine exactly how many thermal washers will go to one sheet, then it is worthwhile to first calculate the perimeter of the material used.The resulting value is divided by the selected step distance, as a result of which you can get the number of fasteners that will go to each polycarbonate sheet.

If you plan to use a monolithic building material in your work, then it is important to understand that thermal washers in this case can only be used when the thickness of the material does not exceed 5 mm. Often, when erecting structures, a material with a thickness of 16 mm or more is used.

In this case, it is recommended to abandon the drilling of polycarbonate sheets and use the clamping strips. During the installation process, it will be necessary to mount on both sides, while on one of the sides there must be a fulcrum. In such situations, it is best to use thermal washers with self-tapping screws, making a step from 10 to 20 cm

Often, when erecting structures, material with a thickness of 16 mm or more is used. In this case, it is recommended to abandon the drilling of polycarbonate sheets and use the clamping strips. During the installation process, it will be necessary to mount on both sides, while on one of the sides there must be a fulcrum. In such situations, it is best to use thermal washers with self-tapping screws, making a step from 10 to 20 cm.

Types of thermal washers

As a rule, all fasteners are made from different materials. This affects the strength and durability of the mounts. Types of thermal washers are used from such material as:

- stainless steel;

- polypropylene;

- polycarbonate.

Steel, unlike other materials, practically does not deform and can serve for more than 100 years. Polycarbonate is in second place in terms of quality, as its service life is about 20 years. Washers made of polypropylene can be used for no more than 4 years, and then they begin to lose their quality and deform under the influence of external factors.

Steel washers

steel washers are used infrequently in the form of fasteners

The dimensions of the thermal washer are large and from the side it may seem that this is just a small plate. The washer is about 3.3 cm in size and 0.8 mm thick. There is a hole inside the mounts, which is necessary for installing bolts or screws. Before installation, a polyurethane gasket is also inserted into a small recess for sealing. The service life of such a gasket reaches 50 years, so it actually does not require replacement. In addition, the polyurethane gives the gasket strength and elasticity.

The strength of the material from which the thermal washers are made allows you to withstand even strong gusts of wind, so you don't have to worry about the quality of installation of roofing or facade sheets made of polycarbonate. To increase strength, it is recommended to install such washers at a distance of 25–30 cm.

Washers made of polypropylene

Thermal washers made of polypropylene are available in transparent and any other color version. This makes it possible to select fasteners that match in shade with the polycarbonate roofing. The cost of such an attachment is quite low, but we must not forget that polypropylene has a number of negative qualities.

Basically, there is little demand for polypropylene fasteners due to the fact that the material cannot withstand ultraviolet rays. With constant exposure to sunlight, the material simply collapses, therefore, its service life does not exceed 3-4 years. As a rule, when the fasteners are deformed, polycarbonate sheets begin to vibrate and subsequently can fall off the surface of the building. Because of this, polypropylene thermowells are mainly used only in shady places or indoors.

Thermal washers made of polycarbonate

Polycarbonate washers have many positive characteristics.

- Due to the unique design of thermal washers, honeycomb sheets are not deformed during installation.

- The aesthetic properties of the washers make them look great on transparent resin sheets.

- The quality, thanks to the protection against ultraviolet radiation and temperature changes, allows the fasteners to stay in working order for up to 20 years.

- Polycarbonate thermal washers can be used even in harsh environments with extreme heat or cold.

- The choice of fasteners on the market is huge, so you can easily choose the right size and color to match the shade of the building facade.

Polycarbonate thermal washer design includes:

- sealing rings;

- a leg corresponding to the thickness of the washer;

- self-tapping screw made of stainless steel;

- cover.

The cover is necessary in order to firmly close the hole in the thermal washer and thereby prevent the ingress of moisture and dust.

Types of hats

For self-tapping screws for metal, an 8 mm hex head is ideal. The tightening of such screws can be easily performed with a screwdriver equipped with a nozzle for an eight-millimeter nut - a bat. Self-tapping screws for wood can also be with a round head that has a groove for a Phillips screwdriver.

Self-tapping screws with a four-sided head are not recommended for use, as they are not intended for multiple twists and turns.

Experts do not recommend using self-tapping screws with a head for a four-sided and curly screwdriver to install polycarbonate. The grooves in these hats are very thin and are not suitable for numerous twisting and twisting. During the operation of such self-tapping screws, the caps become unusable very quickly and problems may arise with dismantling the panels.

The square screwdriver tends to pop out of the slot if too much force is applied. In this case, you could accidentally damage the polycarbonate sheet. In addition, this type of self-tapping screws is not easy to use, therefore, it is not recommended to use them either.

The thermal washer, which is installed between the self-tapping screw and the panel, is a special spacer, the main function of which is to completely seal the connection. Thermal washers protect plastic from punching and deformation. There are several types of spacers: flat and equipped with a special leg, which acts as a pressure limiter on the material.

Thermal washer performs a sealing function when installing polycarbonate with self-tapping screws

Thermal washers with foot are great for installing thick panels. Also, the leg allows the sheet to deform under the influence of temperature without damage. The design of the thermal spacer includes a gasket and a cover, which directly ensure the tightness of the connection.

The presence of these components helps to protect the polycarbonate material, which is hollow inside, from clogging from the inside and falling into the channels of snow, rain or dust. In addition, thermal spacers prevent cold bridges from forming, which appear when polycarbonate panels are installed on a metal frame.

Types of washers for polycarbonate

Manufacturers produce thermal washers from materials of different strength, durability and transparency.

Today you can purchase these products made from the following raw materials:

- of stainless steel;

- polycarbonate;

- polypropylene.

Based on the material used, the service life of the fastening material is calculated. For steel products, it is practically unlimited. Polycarbonate fasteners can last up to 20 years, and polypropylene ones - up to 3-4 years.

Steel thermal washers

As a rule, steel fasteners are used for work with a large coverage area, as well as for installing polycarbonate in areas with strong winds. In addition, this fastening material is installed on a metal profile, where it looks beautiful and organic. The size of the thermal washer for polycarbonate is 3.3 cm in diameter with a thickness of 0.8 mm.The inner hole for a self-tapping screw or bolt is 6 mm.

The washer is shaped like a shallow dish. A polyurethane foam gasket is inserted into the recess of the plate. This material is elastic, strong and durable. The service life of the gasket can be up to 50 years.

The size of the washer and the strength of the metal from which it is made guarantees the reliability of the fastening of the plastic sheets. Such fasteners, in combination with aluminum profiles, will be able to hold polycarbonate roofing and façade covering even in very strong winds. For reliability, it is recommended to screw it every 25-30 cm.

These products are made in a transparent and colored design, which allows them to be harmoniously placed on a roof or facade covering. The range of colors allows you to choose products that are close in color to polycarbonate. The size of the polypropylene fasteners is 35 mm in diameter and 12 mm in height. The inner hole allows the use of screws with a thickness of 6 mm.

Among the undoubted advantages of polypropylene washers are their beauty and affordable price. However, before purchasing these products, it is worth considering that they have certain disadvantages. Polypropylene has no UV protection. As a result, the material becomes brittle and collapses after 3-4 years. Looseness of the fastening can lead to vibration and destruction of the sheeting.

It is recommended to use polypropylene washers in shady places or indoors.

Thermal washers made of polycarbonate

Thermal washers for cellular polycarbonate are the most popular material for point attachment when erecting structures made of transparent sheet material. Practically not inferior to steel products in strength, polycarbonate washers have a number of significant advantages.

These include:

- The beauty. Installed on a transparent surface, these products look very good without standing out or striking the eye.

- Sophisticated design. The thermal washer device allows you to create a strong sealed connection without damaging the structure of the honeycomb sheet.

- Durability. Having protection from ultraviolet radiation, the material retains working qualities for 15-20 years.

- Thermal stability. The product does not lose its qualities, neither in extreme heat, nor in extreme cold.

- Wide range of sizes and colors. The choice of fasteners on sale allows you to choose thermal washers that are color-compatible with any plastic, up to 10 mm thick.

The photo of the thermal washer for polycarbonate gives a clear idea of this product.

The polycarbonate thermal washer consists of the following parts:

- a plastic washer with a leg, the length of which is equal to the thickness of the sheet to be fixed;

- an o-ring made of elastic polymer material;

- thermal washer covers;

- self-tapping screw made of stainless steel with a galvanized tip.

The cover for the washer not only gives the product a finished look, but also protects it from dust and moisture. The leg on the body of the product, resting against the supporting frame, prevents excessive tightening of the self-tapping screw and wrinkling of the sheet.

Assembly process

Installation instructions for thermal washers:

- Measure the diameter of the leg of the product.

- Choose a drill with a diameter of 1–2 mm larger.

- Drill holes in the sheet at the attachment points at a distance of 20-30 cm.

- Insert the leg of the thermal washer into the hole in the sheet until it stops with the material of the structure profile.

- Insert the screw and tighten. The applied force must be sufficient to tighten. When tightening, the self-tapping screw must be released.

- Close the self-tapping screw head recessed in the washer head with a lid.

When installing and securing polycarbonate sheets, observe the following requirements:

- use only properly sharpened drills;

- the axis of the hole in the polycarbonate sheet should be perpendicular to its plane, which will prevent skewing of the thermal insulating washers with self-tapping screws, will not cause mechanical damage to the sheet material, and will ensure tightness;

- the holes should not penetrate the stiffeners of the sheet material;

- when tightening the self-tapping screw, do not overtighten;

- the distance between the mounting holes should not exceed 50–70 cm.

After reading the information provided, you will make sure that there is no better product for fastening sheet material than a thermal washer.

Panel fixing materials

To solve the problem of how to attach polycarbonate to metal, you need to use the following:

- Various types of profile, including end, corner, connecting, wall and ridge.

- Fasteners in the form of thermal washers and mini-washers.

- Different types of plugs.

- Adhesive tape for ends, including perforated tape for bottom edges.

- Profile seals.

Types of profiles and their purpose

End profiles are used to protect the edges of the polycarbonate, and the short shelf is always located outside.

Connecting profiles can be detachable universal or solid H-shaped. They are designed to join the edges of the panels.

It is important to remember that only split profiles can be attached to the frame.

The corner profile allows the elements to be joined at right angles.

The wall profile makes it possible to tightly adhere the panel to the wall. Can be used as an end profile.

A ridge profile is required to connect the panels on the ridge of the roof, provided that the elements are connected at an angle greater than 90.

Varieties of thermal washers

Fastening polycarbonate to metal is carried out with different types of thermal washers. These fasteners can differ in the following ways:

- Design features make it possible to highlight individual and universal thermo washers. In the first case, the element has a length in accordance with the thickness of the sheet, which prevents the polycarbonate from being pinched or deformed. The second option does not have a leg, therefore, it can be used for material of any thickness.

- Depending on the material of manufacture, the fasteners can be made of stainless steel (for covering large areas), polycarbonate (ensure tightness of the connection without damaging the panel), polypropylene (for working indoors or in the shade).

- Mini washers are used for lightweight panels.

Plugs

To make the structure attractive, and to protect the ends of the profiles from the ingress of water, dust and insects, it is necessary to use plugs.