Material features

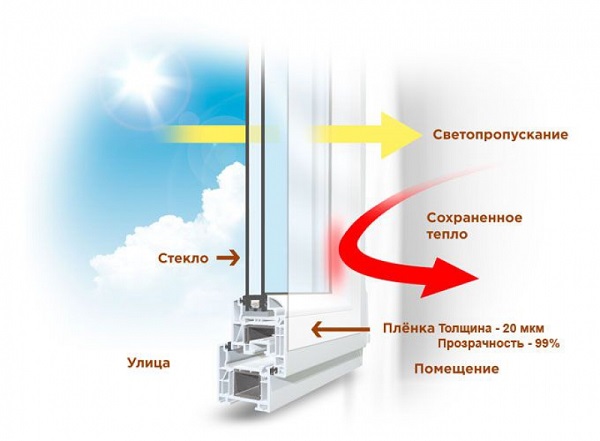

This composite material consists of several elements coated with a protective layer of gold, silver or nickel-chromium alloys. The metal layer is so thin that it does not interfere with the passage of the light flux, so the coating does not impair visibility. But this is enough so that the air does not leave the premises.

The film is an effective heat insulator, its action is based on the refraction effect. Advanced technologies are used to create this unique canvas. Thermal insulation material is useful not only in winter, but also in summer, when you want coolness in the room.

This coating effectively conserves heat

This coating effectively conserves heat

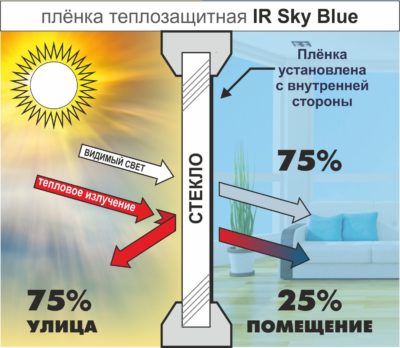

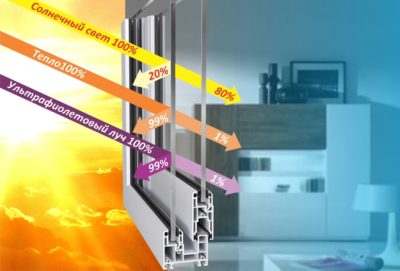

This modern technology is based on the interaction of sunlight with metals that are in the composition of the canvas. The material repels infrared radiation and prevents it from entering the room. Also, the coating saves heat by 70%.

Externally, the coating resembles ordinary polyethylene, but slightly thinner than it. The metallized layer is applied to the film by vacuum method, as a result of which the material acquires heat-saving properties. Recently, some double-glazed windows are immediately supplied with a heat-saving film.

Heat-saving film for windows "third glass" - recommendations for selection

Before ordering the material, you need to pay attention to the main characteristics of the coating. According to the method of application, the film for windows is divided into several types:

According to the method of application, the film for windows is divided into several types:

- Self-adhesive. It is similar to a protective film for screens of mobile technology and electronics. The material comes with a rigid backing, you need to glue it yourself very carefully, otherwise bubbles or wrinkled places will remain on the surface.

- Shrink wrap. For installation, a special consumable material is used - thermal tape. Due to this, an air layer is formed between the glass and the film, which perfectly retains heat. When applied, the surface has a wrinkled appearance; when heated with an ordinary hairdryer, it smoothes and acquires an ideal texture.

- Under a soapy solution. It is similar to a film for tinting car windows, it is durable, practical, and retains heat well. This thermal insulation film is very easy to work with, you need to use a simple soap without aromatic fragrances to stick it.

Self-adhesive varieties are the most effective, blocking most of the infrared radiation.

In addition to the method of application, you need to pay attention to other criteria:

- Manufacturer. The most reliable are goods of German, Polish, British and American production, Chinese and Russian materials cost less.

- Size, form of delivery (in sheets or rolls).

- The presence of an anti-glare surface, darkening, and other additional effects.

The effectiveness of the protective coating

- Increased glass strength. The film covering the glass creates an additional protective layer. This increases the impact resistance by 7-8 kg / m2. But if the glass breaks, it will not turn into sharp fragments, which will exclude possible injuries, and also make it difficult for intruders to enter the house.

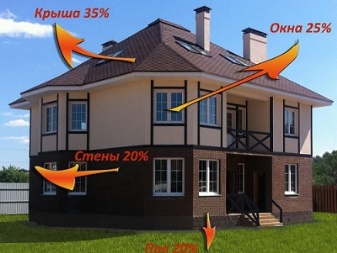

- High efficiency. Since the heat loss will be significantly reduced, the energy consumption for heating a house or air conditioning a room will decrease. Therefore, such films turn the window into a kind and reliable heat shield.Rooms in which light and heat are distributed more evenly get increased comfort. You can make fuller use of areas near window openings that were previously exposed to aggressive sun exposure.

- Ultraviolet filtering. The film is capable of blocking up to 90% of ultraviolet and 30% of infrared rays. This allows the beauty of the interior to be preserved in its natural form. The sun does not spare furniture, wallpaper, wood trim, and art objects. The heat-reflecting film successfully resists this effect.

- Decrease the brightness of the light. Using protective films, you can reduce this parameter from 20 to 80%. This will protect your eyes and make it easier to work with the computer, make it comfortable to watch TV.

- Fast and easy installation. Window coating is done very quickly. To complete the installation, you just need to provide access to the place of work.

- Mirror film. It is an ingenious addition capable of creating one-sided visibility in the home. If the material is selected correctly, viewing from the inside of the room will be normal, but from the outside it will not work to look into the house. For this, the outside lighting level must be higher than the inside.

- Protection of information. Films, which have a very high absorption coefficient for infrared radiation (90-99%), are an obstacle to information leakage. They weaken the intensity of the action of external electromagnetic fields indoors.

What it is?

The structure of the film, which also belongs to the energy-saving class in terms of its characteristics, is not very complicated. This composite material consists of many layers of negligible thickness - on the order of a few microns. Each layer is coated with a metal or ceramic applied by plasma discharge in an argon atmosphere. Precious and rare earth metals, chromium and nickel alloys are used.

To achieve energy-saving properties, all metallized layers are arranged in a certain sequence. They are symmetrical in arrangement to the middle layer: metal 1 - metal 2 - metal 3 - metal 2 - metal 1. This is done to reduce the re-reflection inside the film of thermal radiation.

The thickness of the metal layers is negligible, so the retention of visible light is negligible. This structure makes it possible to regulate the room temperature in some way.

Advantages and disadvantages

Window insulation with a film allows you to maintain a comfortable temperature in the room, preventing heat from escaping from the house. The use of this material saves money on maintaining a comfortable microclimate. There is no need to purchase an air conditioner.

The coating does not spoil the appearance of the room; it is thin and inconspicuous. The material filters ultraviolet light, this contributes to the fact that the interior (wallpaper, curtains, decor) does not fade from sunlight.

Transparency and the absence of a mirror effect are also advantages of the film. In case of violation of the integrity of the glass, it will not break into small fragments and does not injure a person. The material makes the glass stronger. For residents of the first floors, protection from prying eyes is relevant, a coating with one-sided visibility makes it possible not to close the window with thick curtains.

The heat-saving film has some disadvantages. Do not hope that during the period when the central heating is turned off, when it is still cool outside at night, the room will warm up well. In this case, it will not be able to replace the air conditioner or heater.

The use of film can negatively affect home colors, which require UV rays to grow normally.

Species overview

Architectural thermal film is transparent, it is used on glass windows of buildings, structures and cars. An ordinary one does not have transparency, it is placed under a stretch ceiling, wall panels, laminate and parquet, hidden under the trim (upholstery) of the car interior.Both the one and the other delimit the owners and / or workers in the summer from the heat outside, and in the winter - retains most of the heat. In both cases, air conditioning and heating costs are significantly reduced.

Ordinary (ceiling and wall, underfloor) thermal insulation film is made on the basis of the following materials:

- foamed polyethylene;

- fibrous polypropylene;

- lavsan fiber or fabric.

According to the method of applying the heat reflector, the film is divided into the following types:

- foil layer;

- sputtered composite layer.

Foil in damp rooms is subject to accelerated destruction. Because of this, foamed foam or fiber is not used in baths and saunas, bathrooms, toilets and in the kitchen. The spraying is protected by a thin, microscopic layer of plastic, dust particles of metal (aluminum) do not deteriorate. The heated spraying is slightly fused into the polymer base even at the production stage. This is a technology that is higher than foiling, which is closely monitored in factories.

Thermal film for walls and floors - stenofon - is similar to ordinary penofol. It has a porous or bubble structure

It is placed under the decorative coating, which is why it will not be possible to avoid heating the wall panel from the inside of the room, but this is not as important as the real escape of excess heat through the wall to the outside.

Self-adhesive

This subspecies is similar to the film used for the screen of a smartphone or tablet. For clear gluing, without air bubbles under specks and lint, a general cleaning is carried out in the room and all "dusty" things and objects are taken out. To protect the adhesive side from dust and moisture during transportation, a protective layer has been applied to it by the manufacturer. Self-adhesive production is a technology that requires ultra-clean factory conditions; the same cleanliness is ensured at the customer's site.

It is difficult to stick this film on your own - one skew, and it is difficult to remove wrinkles, since removing and re-sticking the same piece of film will dramatically affect the transparency and attractiveness of the window, glass. This film is glued, starting from any of the corners, gradually pulling back the protective layer. Car tinting requires no less care than gluing a film on the windows of a house or building.

Shrink

Shrink option - a film for the window frame. It is fixed with double-sided tape. An air gap forms under it, preventing heat from quickly leaving the room. The initially glued heat-shielding film resembles crumpled polyethylene. To straighten it, direct hot air from a hair dryer at it - now the stretched fabric looks neat.

Under soapy water

This coating is similar to tinted glass and is durable. The second advantage is ease of application. Any soap without aroma additives is suitable as an attracting layer.

Why does the third glass work?

Does the heat reflective film third glass work? Yes and no. After the third glass is insulated with a heat-saving film, the temperature in the room rises. 1-3 degrees, not 6 or 8, as fraudulent sellers claim.

Why it happens? Previously, in villages, oilcloth was nailed onto glass in winter. This helped keep the house warm. The 3rd glass film works the same way. Only you fix it inside, not outside the window. And it lets in more light. Many people still do this:

When insulating with such a film, an additional chamber is formed, similar to that in a double-glazed window. Heat loss due to convection is reduced. The more chambers, the better the heat is retained.

Losses due to convection are reduced. Infrared heat radiation continues to leave the room, and this is the main heat loss. It turns out that the energy-saving film for insulating windows, the third glass, does not save energy so much.

Heat insulating film

Heat insulating film is an affordable and reliable heat insulator for windows, which is manufactured using new technologies. The thinnest layer of this material is coated with a special molecular substance, which provides a thermal insulation effect. Moreover, it is absolutely transparent and does not damage the glass surface.

The main characteristics of this material:

- Can repel dust.

- It can be used both in summer and winter.

- They can insulate not only windows, but also greenhouses, doors and loggias.

Also, the thermal insulation coating can have an opaque structure, which makes it stronger. This material can be applied several times.

Installation of this material is carried out using the following technology:

First you need to prepare the surface of the window - to clean it from dust. You will also need the following tools: Hair dryer. Knife. Scissors. Scotch tape (double-sided). If the window has cracks or cracks, then they should be repaired. After that, you need to glue double-sided tape to the frame. Next, take out the cover and cut off the desired part

Gently stick it onto the tape

In this case, it is very important not to pull the film itself with force, otherwise its integrity can be violated, which will lead to a deterioration in thermal insulation. It is necessary to glue the material tightly so that it adheres well to the entire surface of the glass

Next, you should turn on the hair dryer and warm up the material so that it "lies" even better on the glass and, as it were, completely merged with it.

Operating principle

Compared to sun-protection counterparts, heat-protective films are more effective, they create a barrier to the thermal (infrared) spectrum of solar radiation, excluding overheating of the apartment. To reflect the thermal energy of the sun, heat-shielding materials are used on the windows of private houses, office premises, on panoramic windows, glass roofs.

The solar heat level is reduced by 70%. The load on the air conditioner is reduced, materials and furniture do not fade, do not lose the brightness of shades, the view from the window does not suffer - the protection remains transparent.

The glazing area of modern houses, apartments, offices is at least 20%, with the help of athermal film for the window, you can save electricity, prevent overheating of the room.

How the athermal coating works

Thanks to the multi-layer composite structure, the energy-saving film coating effectively reflects infrared rays, does not interfere with the passage of light.

In the manufacture of the material, a high-tech method is used - spattering: the layers of the film are covered with a microscopic ceramic or metal layer.

Where to glue the film - outside or inside: overview video

Research results

In 2014, a study was carried out at the Ukrainian State Research Institute of Building Structures. A polyethylene film was glued to the frame of the glass unit, its characteristics were checked before and after pasting. Here's the result:

- Tests of the reduced resistance of the window block showed that the additional use of a film installed on the surface of the sash or frame leads to an increase in the heat transfer resistance of the glass unit by 0.2 m2 * K / W. When using the film, the reduced resistance to heat transfer of window blocks that were used for tests increased from 0.45 to 0.56 m2 * K / W, and the heat transfer resistance of a glass unit from 0.32 to 0.46 m2 * K / W.

- The results of calculating the temperature on the surface of the glass unit and the film in the central zone showed that the temperature on the inner surface of the glass unit, not covered by the film, was 5.3 ° C, and the temperature on the surface of the film was 10.4 ° C.

- During the experiment on the surface of the film. no condensation was observed, while the surface of the glass unit, not covered by the film, was covered with condensation.

- Calculation of heat loss through the building envelope during the heating period showed a decrease in heat loss by 64.6 kW / h, which was 13% in percentage for the type of wall structure under consideration.

Based on the results of the study, we can say that insulation with plastic wrap makes sense. Pasting a window block can reduce heat loss by 30.3%. Exactly the same effect can be achieved with the help of the third window energy-saving film, but it will cost more because of the beautiful packaging.

Anti-fog PET film on windows: pros and cons

Thermal saving material has many advantages:

- Effective protection against cold. A comfortable microclimate will reign in an apartment or house both in winter and in summer, you will not need to spend a lot of money on heating or buy a split system or air conditioner.

- Preservation of the integrity of the glass with minor mechanical stress. If, nevertheless, the window breaks, for example, from hitting a stone, the fragments will hang on the film and will not spill out into the room. This reduces the risk of accidental injury.

- The applied coating does not create glare, protects textiles, floor coverings and furniture from fading when exposed to sunlight.

- Relatively low price, due to which you do not have to spend too much money on insulation. Installation of such a film is cheaper than installing reinforced double-glazed windows with several cameras.

- Simple installation. On sale you can find a self-adhesive window film, the application of which takes a minimum of time.

- A rich list of insulation films available on the market, produced by both Russian and foreign brands. In stores you can buy products from Thermolayer, Termok, A-Solar and other companies.

It should be noted that the use of insulating film for insulation is not without its drawbacks. The disadvantages include the following factors:

- It becomes difficult to keep houseplants on the windowsill. The amount of ultraviolet radiation decreases, so they start to waste away. To solve the problem, you can install phytolamps that provide a 12-hour backlight cycle. The disadvantage of this option is the increase in energy costs, which makes the energy-saving properties of the film meaningless.

- Decrease in the effectiveness of heat-shielding coatings in spring and autumn. It prevents the room from heating up by the sun's rays, while if the heating has already been turned off or has not yet been turned on, it will be cold in the room. In some cases, condensation also forms on the windows.

- Some films that create a "thermal" effect can reflect most radio waves, and cellular communication will work poorly in the room.

Installation instructions for heat-saving film

The procedure for installing an auxiliary product is not complicated and does not require the purchase of special tools, you just need to follow a number of rules.

Materials and tools

In the process you will need:

- film;

- roulette;

- marker or pencil for marking;

- cotton gloves,

- transparent double-sided tape;

- scissors or a clerical knife;

- long ruler;

- ordinary household hair dryer.

Before starting work, you should make sure that there are no cracks or cracks in the frame structure. This problem is not typical for a plastic profile, but it is often encountered in a wooden one. In the latter case, the presence of bindings leads to the formation of numerous joint zones through which cold air penetrates. This effect can be avoided by using silicone, any transparent sealant. After application, they should be left intact until completely dry.

First of all, the window is thoroughly washed

Step by step guide

Warming is done in the following order:

- It is necessary to thoroughly wash the windows from the inside, preferably using a soapy solution, cleaning household chemicals.

- The frame must be treated with any degreasing agent, and double-sided tape should be applied to it around the perimeter.

- The roll of film should be unrolled on a clean, horizontal surface, preferably on a large table. A product folded in half must first be stratified by gently blowing into the joints. Next, you need to grasp the edges with both hands, pull them so that they separate without damage.

- It is necessary to measure all the parameters of the glass unit with a tape measure, then the film should be marked based on the obtained geometric parameters. On all sides, you need to leave an allowance of 1.5-2 cm, so that you can fix the product with good quality with adhesive tape. The material is cut according to the markings.

- The protective layer of paper is removed from the tape already attached to the frame. Next, fix the cut piece of film, starting from the top, gently pressing the edges to the sticky strip.

- The canvas needs to be stretched slightly before aligning the edges with the vertical adhesive strips.

Double-sided tape is glued to the frame around the perimeter

The last step is to fix the bottom edge, followed by additional smoothing around the perimeter.

The canvas needs to be stretched a little before aligning the edges with the vertical adhesive strips.

To facilitate the process, it is worth using the following recommendations of the wizards:

- to ensure complete sealing of the opening, the glass must be thoroughly washed;

- cotton gloves will help to avoid the formation of fingerprints, streaks and marks on the film;

- if, during installation, the surface of the material is covered with folds, they can be eliminated with a household hair dryer. The fact is that the product will inevitably shrink if it is blown over with jets of hot air. In this aspect, the most convenient for installation is a heat-shrinkable film;

- you must not over-stretch the product during installation, as it is easily deformed and torn;

- the arrangement of the side window is easier to carry out together.

Film deflections and tight contact with the glass reduce the expected heat savings.

If, during installation, the surface of the material is covered with folds, they can be eliminated with a household hair dryer.

Reflective film

It differs from others in that it may not let the sun's rays through at all, but at the same time it effectively retains the heat that is in the room. It can be used all year round.

The advantages of this material:

- Durability.

- Big choice.

- The effect even at temperatures as low as -35 degrees.

- Suitable for any interior.

- Retains heat from batteries and heaters.

- Minimizes heat loss.

- Thanks to a special aluminum coating, it reflects the heat emanating from the outside.

- Protects furniture, wallpaper and plants from overheating and discoloration from the sun.

- Creates a comfortable microclimate in the room.

- Thanks to light reflection, it protects from prying eyes from the outside, but, nevertheless, does not in the least impair visibility from the inside.

- Helps eliminate the problem of overheating and has the effect of an air conditioner.

- Has absolute transparency, exactly the same as ordinary glass.

- Softens light and makes it more pleasing to the human eye.

The main disadvantage of reflective insulation is its high cost.

You need to glue this material in this way:

Prepare window cleaner, knife, rubber trowel and water spray. Thoroughly wash the entire surface of the window and glass on both sides. Wipe dry so that there are no streaks. Using a spray bottle, apply a solution of soap, which was previously diluted with water, onto the adhesive film and glass. In this case, you do not need to shake it strongly, otherwise a lot of soap bubbles will appear. This is necessary so that the soap makes it possible to calmly move the film over the glass surface to the desired position. Attach tape to stack

As soon as it “sits down”, it should be carefully smoothed with a spatula from the center to the edges, and all bubbles should be removed from there. After the entire surface is flat, you need to let the film dry

At the end, trim the edges with scissors or a knife.

You need to take care of such material with extreme caution so that it does not peel off. It is best to clean it occasionally with a damp cloth or dust cloth

Material advantages

Coating features:

- Energy-saving multilayer material. Reflective, heat-saving qualities it is endowed with metal spraying - gold, silver, nickel, chrome. The high transparency of the coating is preserved.

- Each layer has a minimum thickness of a few microns.

- The coating is universal - it increases the comfort of being indoors both in summer and in winter.

Balcony application

Material advantages:

- Ensuring the privacy of the premises. Visibility remains only from the inside.

- Reduces the level of noise coming through the windows from the street.

- Furniture, finishing materials do not fade due to the reduction of UV radiation.

- The sticky layer retains fragments in case of mechanical damage to the glass.

- Glass becomes stronger, acquires shockproof qualities. Burglary protection is provided if the film is glued from the street side.

- The brightness of the sunlight decreases and becomes more comfortable for the eyes.

- In winter, heating costs are reduced, due to a decrease in heat loss up to 60%, in summer - on air conditioning of the room.

- The service life is over 10 years.

Installation features

Before gluing the film to the window, it is necessary to prepare the glass surface. Remove dirt from it with a scraper, detergent. The seals and the window frame are washed. You can use an all-purpose spray detergent. Abrasive cleaning agents must be discarded - they damage plastic, scratch glass.

A microfiber cloth is suitable for washing windows - it allows you to wash the surface with high quality without streaks and lint, remove excess moisture. Dry the clean window with a paper towel.

You need to wash glass, frame

Self-adhesive backing makes film installation easier

Before gluing, it is necessary to cut the canvas. First, the parameters of the window are measured. The film is laid on a flat surface with a protective substrate upwards, the measurements are transferred. Add 2-3 cm to each side. Cut out a fragment with a clerical knife.

Installation: glass must be moistened with soapy water. For preparation, use liquid soap, mix with water, without shaking, in a spray bottle.

The soap solution is not agitated.

The film is placed on a flat surface, pry off the edge, separate the coating from the protective backing, releasing the adhesive layer. The surface of the film is sprayed with water

It is important that dust and lint do not get on the sticky base. It is recommended to release no more than 5 cm of the cover

The material is applied to the glass in the upper part of the window, leveled, smoothed from the center to the edges. Surplus leads to the frame.

Gluing the canvas

Gradually, as the web adheres, the protective backing is removed. At the same time, the cloth and glass are evenly sprayed with the prepared solution.

The work is done from top to bottom. Air bubbles, excess soap solution are driven out from the center to the edges of the canvas with a rubber spatula.

To remove air, excess soap solution, use a rubber spatula

When the film is glued, leave to dry for the time indicated by the manufacturer on the package. Usually the term is 1-2 weeks.

After application, the coating is ironed with a dry clean cloth, left to dry

The final stage is trimming the excess of the canvas with a sharp clerical knife.

Energy-saving film is a practical, inexpensive, unique solution for quickly warming a room, an easy way to create comfortable conditions on hot days without resorting to installing double-glazed windows with energy-saving glasses.

More details about the installation of the protective coating:

Features of applying energy-saving film on windows

If you have to mount the material yourself, it is advisable to order a version for a soapy solution.Film coatings with a self-adhesive or heat-shrink base must be applied by specialists, lack of experience is likely to affect the quality of the result.

Before gluing the material, you must complete the preparatory steps:

- Wash the glass, wipe it thoroughly with a dry cloth.

- Degrease surfaces with alcohol or alcohol-based products.

- Measure the glass unit, lay the canvas on the table and cut off the excess with a clerical knife or scissors.

- Apply soapy water to the glass surface using a brush or spray.

After that, you can stick the film; work is carried out starting from the top. The material is smoothed with a rubber trowel or roller, working from the center to the edges and from top to bottom

It is important to remove all air bubbles before the adhesive has hardened. After that, the treatment is carried out with a household hairdryer, turning on the flow of hot air: the insulating coating will finally straighten out

To mount the variety on a self-adhesive base, you will need to degrease and clean the surface of the glass unit in the same way, cut it to size and place it on the window as evenly as possible. The substrate layer is removed, starting from the upper side, first the corners are fixed, then smoothly removed further, while gluing the film.

The process is complicated in that it is required to carefully monitor the uniformity of application, immediately straightening the material and preventing the formation of bubbles. As for the shrink film, it is fixed on a special tape located around the perimeter.

Cons of material

Energy-saving film is not a heat source; it does not affect space heating. Retains heat generated by central heating sources. The material maintains the existing air temperature.

Heat from the street does not penetrate through the window, pasted over with athermal protection

Disadvantages of the material:

- Protection does not transmit UV radiation, it is not recommended to use in rooms with indoor plants. Not suitable for tinting glass in greenhouses, greenhouses in the local area. Plants need ultraviolet light to grow. If there are plants in a room with an energy-saving coating, phytolamps can be used. However, you can forget about saving energy - for normal plant growth, compensation for the lack of sunlight, lighting must work at least 12 hours a day.

- The effectiveness of the film coating depends on proper adhesion. Large areas of glazing - for example, panoramic windows or portals, it is better not to paste over yourself.

- The coating prevents the penetration of natural solar heat into the room from the outside, in spring and autumn it will be uncomfortable in the apartment - damp, cold. It is necessary to turn on mobile heating devices.

- The ability to reflect radio signals. Radio waves from the outside, going to the indoor antenna, mobile phone, are reflected by the coating. Cellular communication interruptions are possible.

- If the room has window systems with two - or three-chamber double-glazed windows, it is not necessary to use a film.

Criterias of choice

Only transparent film is suitable for window panes. It protects against excess ultraviolet radiation and retains up to 30% of infrared radiation, but visible light penetrates the room almost completely. There are darkened and even specular options that block out some of the visible light - similar to autotone. During the day, the owners will be protected from prying eyes from the outside. For such secrecy, the landlord pays for the inability to grow anything - the plants need sunlight. Almost any film that does not leave wrinkles after installation is suitable for the frame. Decorative - will change the color of the frame from white to any of those that were available at the time of purchase in the assortment of the building market. Do not skimp on quality: cheap films quickly fade and crack from ultraviolet radiation and excess heat.

Do not use films for glass that have a manufacturing defect - distinct inclusions of metal visible to the naked eye. A film that has been in use for several years can significantly lose its adhesive power. It must hold the shards of accidentally broken glass - this reduces the trauma of people and makes it difficult for thieves to access the locked room. The same applies to car tinting - in case of an accident, the driver will not be covered with broken glass. For batteries, especially those located in the niche of the outer wall of the building, not so much a thin film is used as the usual foil foam. It can withstand heating up to +120 degrees - the battery rarely even gives out +90. The film will last at least several years of constant heat load.

When is it advisable to use a heat-saving film?

It is recommended to use heat-saving film in the following cases:

- if it is necessary to significantly increase the level of heat without using energy-consuming and air-drying heaters;

- if it is necessary to significantly reduce the level of heat without using air conditioners, which tend to accumulate pathogenic bacteria in their filters;

- if an old double-glazed window is installed in the room, which has significant thermal insulation flaws: gaps between the frame and the wall, between the frame and the glass;

- if the room has large window openings that occupy almost the entire wall space;

- if you need to protect the room from sudden changes in temperature, which are typical for most of the territory of our country;

- if you need to protect the decoration of the room from exposure to ultraviolet sunlight, that is, from burnout, which is especially needed by walls, furniture, antiques.

Thus, the scope of use of heat-saving film is quite wide, and this type of product, due to its availability and relative ease of installation, is gaining popularity.

Conclusions and questions that ultimately suggest themselves

Knowing about the shortcomings of the film, we can say that its use is justified in cases where you need to save heat, but there is no way to perform work on capital insulation of a building or structure.

Many consumers value such quality of the film as protection of the room from prying eyes. At the same time, visibility from the room to the street remains one hundred percent. Heavy curtains or blinds are not always appropriate for windows. The film fits well into any interior without disturbing it.

However, all the same, the film does not radically affect energy saving. Therefore, before gluing it, you need to decide what is more important: the effect that it gives by reflecting heat back into the room, or the vital UV rays that the film does not admit the apartment? Maybe it is worth considering other ways of insulation, for example, installing heat-saving windows, or reinforcing the walls with heat-insulating materials? And if you use it during the summer months to protect yourself from the hot sun rays?

For objectivity, it must be said that the properties of the heat-saving film are improving every year. Manufacturers are trying to take into account all the nuances of its use, increasing the energy-saving performance of the product at times.

We bring the third glass to clean water

Manufacturers and sellers of insulating glass insulating film claim that it reflects heat radiation. In fact, this is 100% cheating. Now we will prove it to you.

There are high quality energy saving films that are capable of reflecting part of the IR spectrum. Their cost starts at $ 15 per linear meter (cheap Chinese manufacturers). European heat-reflecting films start at $ 20 per sq. M. depending on the characteristics.

Important

The third glass thermal film can be bought for $ 3. Often there is double-sided tape included

The difference in cost speaks for itself.

Insulation of windows with thermal film, which works, occurs by gluing it to the glass. Its task is to reflect infrared radiation. If you stick the third window on the glass unit, there will be no effect.

In the package, you are sold a piece of shrink wrap. You can buy it at a hardware store. The effect will be the same. The cost of such a film is from $ 0.5 per square meter.