Density of clinker bricks

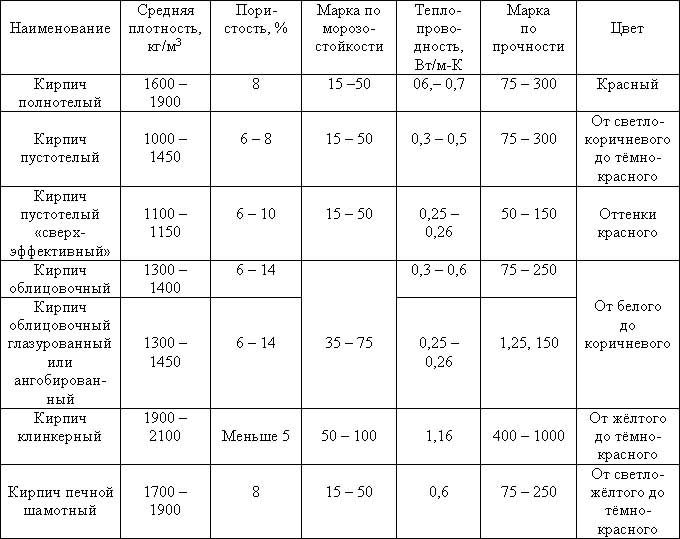

Clinker blocks are made from dry red clay. After hardening at high temperature conditions, the composition acquires a stable density - from 1900 to 2100 kg / cm3. Wear resistance is also due to low porosity - only 5%, which is achieved by sintering the mineral composition, which reduces the volume of cracks in bricks, and reduces the likelihood of moisture entering the raw material.

Block brands differ in shades and textures, which are produced by selecting special compositions of clays, changing temperature conditions and time during firing. But the indicators of the compaction of the composition remain at the average level for the subspecies.

Disadvantages - high price and thermal conductivity. Therefore, when laying, the costs of thermal insulation work will be required.

Density of fireclay bricks

The density of fireclay bricks is average and varies from 1700 to 1900 kg / cm3. High wear resistance is achieved due to low porosity, which is no more than 8%. The material is durable and does not deform under the influence of high temperatures, the maximum indicator is + 1600 ° C.

70% of the material consists of refractory clay, which is very heavy. When designing, it is necessary to take into account the mass of the building material in order to avoid increasing the load on the load-bearing parts of the building.

Varieties of fireclay bricks (arched, classic, trapezoidal or wedge-shaped) have similar density indicators. Blocks are used for laying stoves and fireplaces, industrial structures, industrial steel-making plants, etc. Manufacturing technology, composition and wear resistance indicators determined the high price of the building material.

Used species

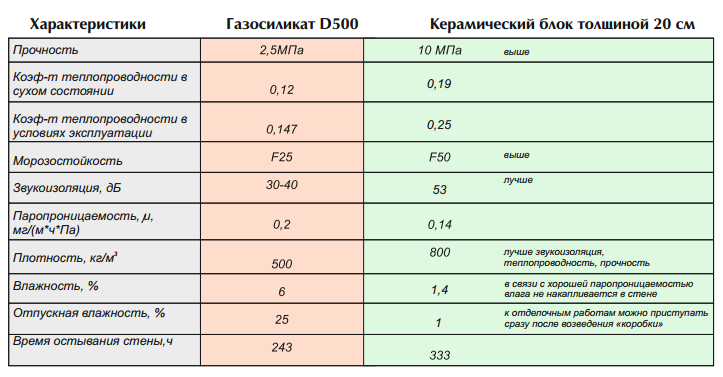

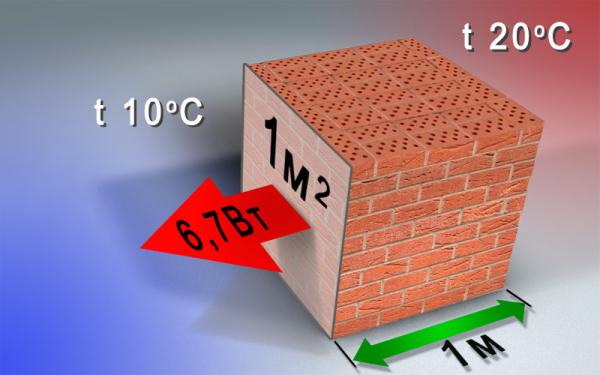

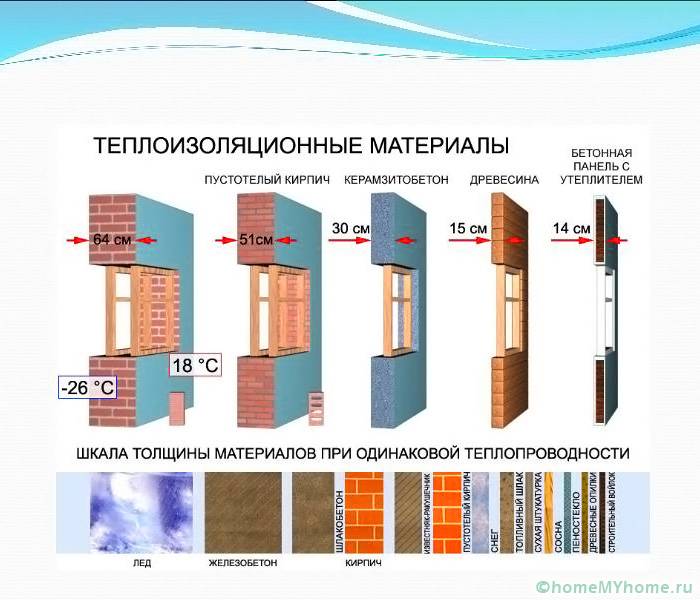

thermal conductivity of a brick wall

The relevance of just such a choice is confirmed by its undeniable advantages. Among them are environmental friendliness, frost resistance, fire resistance - and all this, not to mention the strength and long service, which is implied a priori

Along with this, when erecting objects, it is important to take into account the thermal conductivity of a brick wall.

Currently, several species are actively distributed. Among them, the following are distinguished:

Such blocks can be of very different shapes and textures. They are similar only in their geometric parameters. In fact, the differences are much deeper:

- The ceramic contains clay and various additives.

- Silicate is obtained from quartz sand, lime and water.

The thermal conductivity of red brick (ceramic type) has real popular recognition. And this is not without reason: it is found in a variety of interpretations (empty and full-bodied, facing and having an interesting texture), but each of them will be unique and suitable for the construction of any type of building.

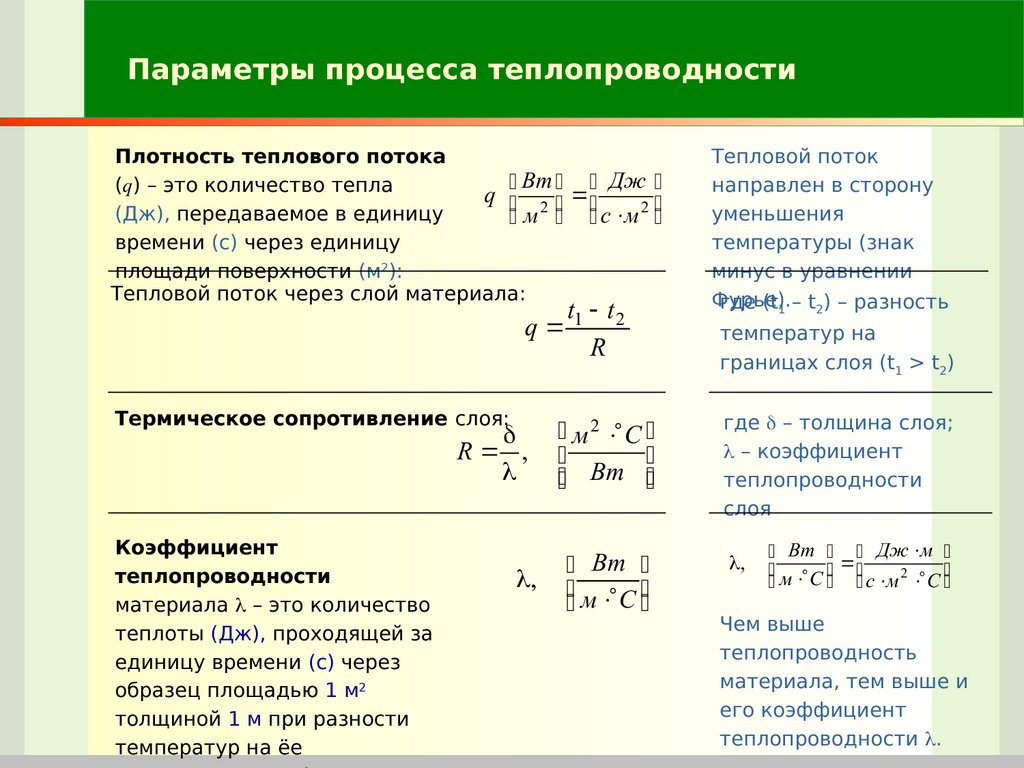

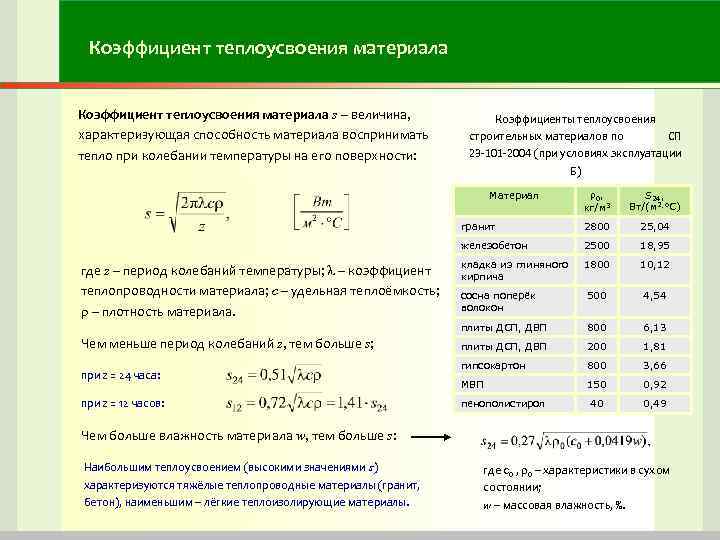

What is thermal conductivity?

At the design stage of any house, solid cottage or suburban building, along with architectural and constructive solutions, technical and operational characteristics of the structure are laid down. The thermal engineering values of the building directly depend on the materials from which it was built.

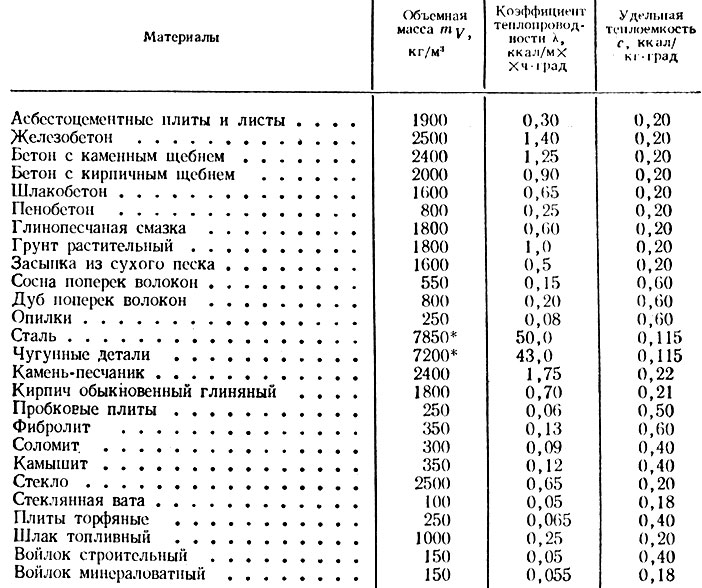

In accordance with SNip 23-01-99, SNiP 23-02-2003, SNip 23-02-2004 developed

technologies for providing climatology, thermal protection of housing, as well as the rules for their design. Thermal conductivity tables have been created, which are useful in determining the criteria for materials to create a favorable microclimate, depending on their thermal conductivity indicators.

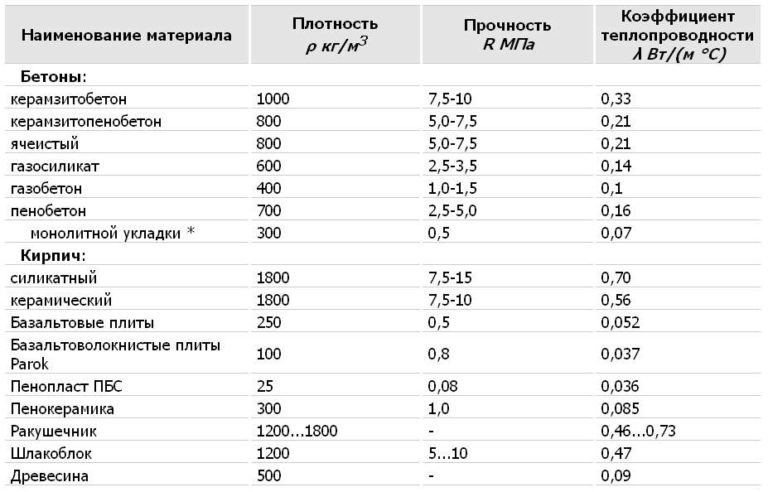

Indicators of thermal conductivity of building materials

Thermal conductivity is understood as the physical process of energy transfer from heated particles to cold ones before thermal equilibrium occurs, before temperatures equalize. For a residential building, the heat transfer process is determined by the time for equalizing the temperature inside and outside it. Accordingly, the longer the process of temperature equalization (in winter - cooling, in summer - heating), the higher the thermal conductivity index (coefficient).

The coefficient is an indicator of the amount of heat that is lost per unit of time, passing through the surface of the walls. The higher, the more heat is lost, the lower, the better for a residential building.

Important! The design task is to select materials with the lowest thermal conductivity coefficient for the construction of all building structures

Coefficient of thermal conductivity of materials.

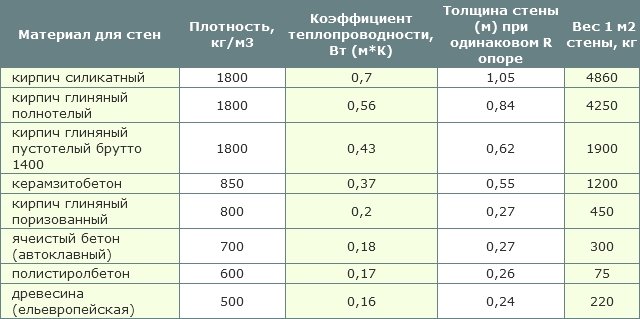

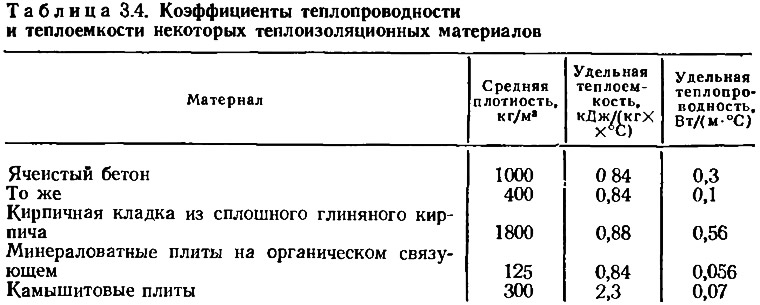

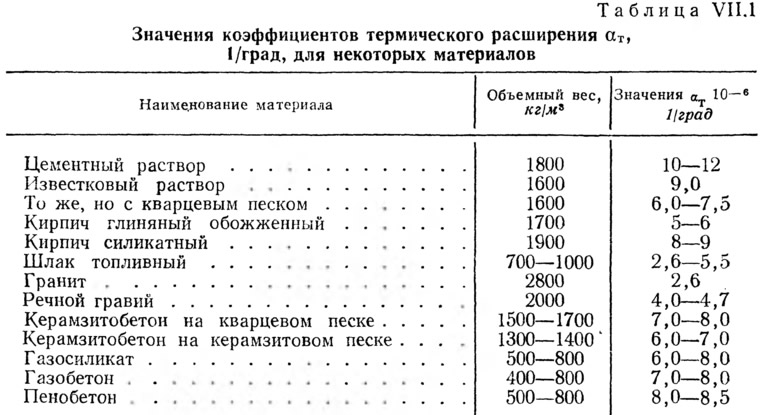

The table below shows the values of the thermal conductivity coefficient for some materials used in construction.

| Material | Coeff. warm W / (m2 * K) |

| Alabaster slabs | 0,470 |

| Aluminum | 230,0 |

| Asbestos (slate) | 0,350 |

| Fibrous asbestos | 0,150 |

| Asbestos cement | 1,760 |

| Asbestos-cement slabs | 0,350 |

| Asphalt | 0,720 |

| Asphalt in the floors | 0,800 |

| Bakelite | 0,230 |

| Concrete on crushed stone | 1,300 |

| Concrete on the sand | 0,700 |

| Porous concrete | 1,400 |

| Solid concrete | 1,750 |

| Insulating concrete | 0,180 |

| Bitumen | 0,470 |

| Paper | 0,140 |

| Light mineral wool | 0,045 |

| Heavy mineral wool | 0,055 |

| Cotton wool | 0,055 |

| Vermiculite sheets | 0,100 |

| Woolen felt | 0,045 |

| Building gypsum | 0,350 |

| Alumina | 2,330 |

| Gravel (filler) | 0,930 |

| Granite, basalt | 3,500 |

| Soil 10% water | 1,750 |

| Soil 20% water | 2,100 |

| Sandy soil | 1,160 |

| The soil is dry | 0,400 |

| Compacted soil | 1,050 |

| Tar | 0,300 |

| Wood - planks | 0,150 |

| Wood - plywood | 0,150 |

| Hardwood | 0,200 |

| Chipboard chipboard | 0,200 |

| Duralumin | 160,0 |

| Reinforced concrete | 1,700 |

| Wood ash | 0,150 |

| Limestone | 1,700 |

| Lime-sand solution | 0,870 |

| Yporka (foamed resin) | 0,038 |

| Stone | 1,400 |

| Construction multi-layer cardboard | 0,130 |

| Foamed rubber | 0,030 |

| Natural rubber | 0,042 |

| Fluorinated rubber | 0,055 |

| Expanded clay concrete | 0,200 |

| Silica bricks | 0,150 |

| Hollow brick | 0,440 |

| Silicate brick | 0,810 |

| Solid brick | 0,670 |

| Slag brick | 0,580 |

| Siliceous slabs | 0,070 |

| Brass | 110,0 |

| Ice 0 ° C | 2,210 |

| Ice -20 ° С | 2,440 |

| Linden, birch, maple, oak (15% moisture) | 0,150 |

| Copper | 380,0 |

| Mipora | 0,085 |

| Sawdust - backfill | 0,095 |

| Dry wood sawdust | 0,065 |

| Pvc | 0,190 |

| Foam concrete | 0,300 |

| Polyfoam PS-1 | 0,037 |

| Polyfoam PS-4 | 0,040 |

| Polyfoam PVC-1 | 0,050 |

| Polyfoam resopen FRP | 0,045 |

| Expanded polystyrene PS-B | 0,040 |

| Expanded polystyrene PS-BS | 0,040 |

| Polyurethane foam sheets | 0,035 |

| Polyurethane foam panels | 0,025 |

| Light foam glass | 0,060 |

| Heavy foam glass | 0,080 |

| Glassine | 0,170 |

| Perlite | 0,050 |

| Perlite-cement slabs | 0,080 |

| Sand 0% moisture | 0,330 |

| Sand 10% moisture | 0,970 |

| Sand 20% moisture | 1,330 |

| Burnt sandstone | 1,500 |

| Facing tile | 1,050 |

| Thermal insulating tile PMTB-2 | 0,036 |

| Polystyrene | 0,082 |

| Foam rubber | 0,040 |

| Portland cement mortar | 0,470 |

| Cork plate | 0,043 |

| Lightweight cork sheets | 0,035 |

| Heavy cork sheets | 0,050 |

| Rubber | 0,150 |

| Roofing material | 0,170 |

| Slate | 2,100 |

| Snow | 1,500 |

| Scotch pine, spruce, fir (450 ... 550 kg / cubic meter, 15% moisture) | 0,150 |

| Resinous pine (600 ... 750 kg / cubic meter, 15% moisture) | 0,230 |

| Steel | 52,0 |

| Glass | 1,150 |

| Glass wool | 0,050 |

| Fiberglass | 0,036 |

| Glass fiber laminate | 0,300 |

| Shavings - packing | 0,120 |

| Teflon | 0,250 |

| Roofing paper | 0,230 |

| Cement slabs | 1,920 |

| Cement-sand mortar | 1,200 |

| Cast iron | 56,0 |

| Granulated slag | 0,150 |

| Boiler slag | 0,290 |

| Slag concrete | 0,600 |

| Dry plaster | 0,210 |

| Cement plaster | 0,900 |

| Ebonite | 0,160 |

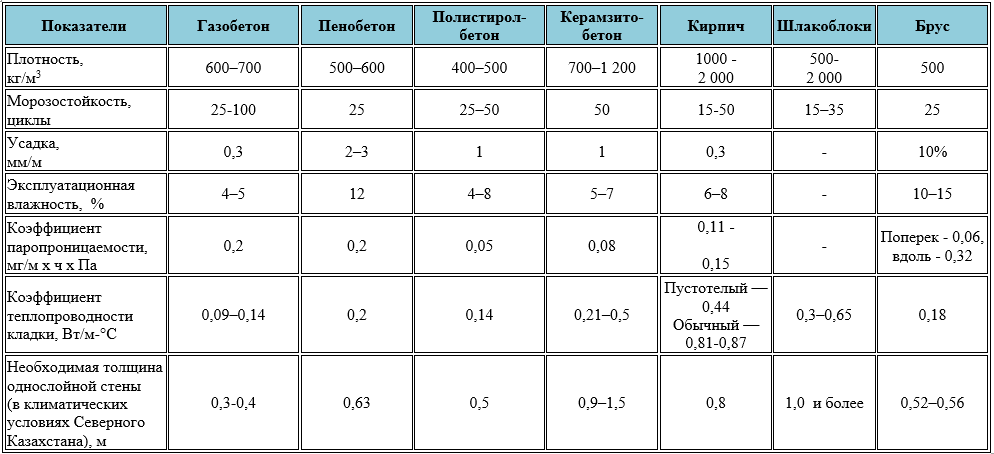

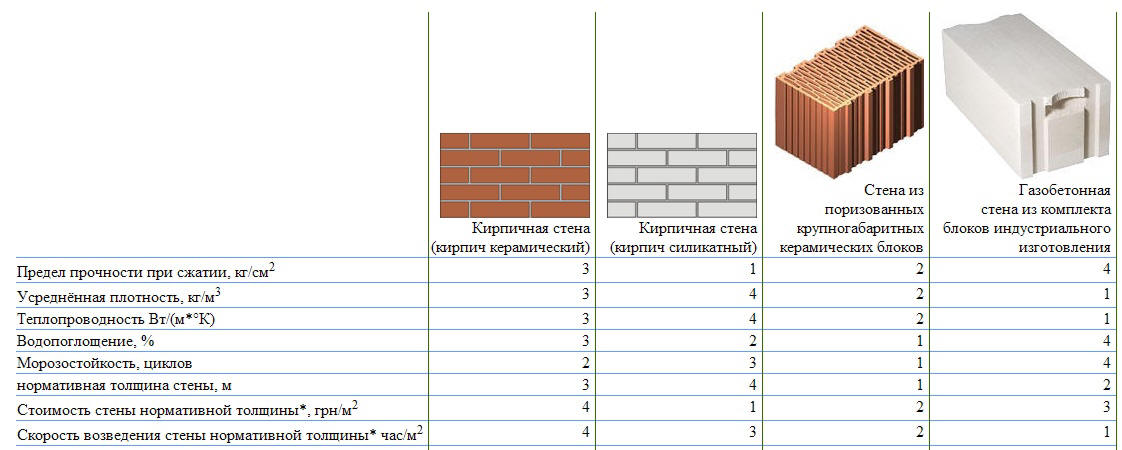

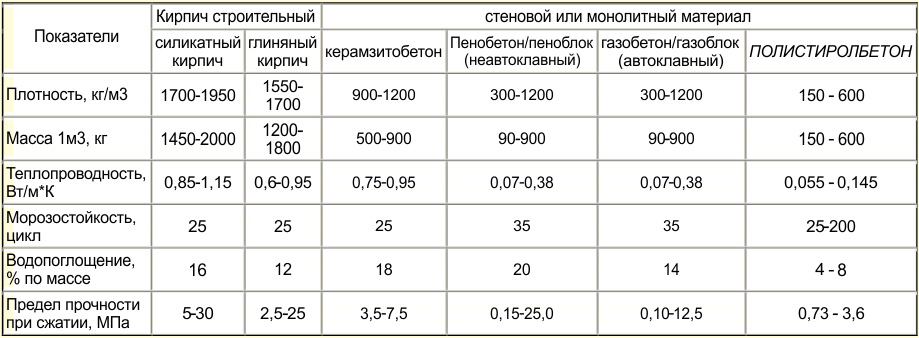

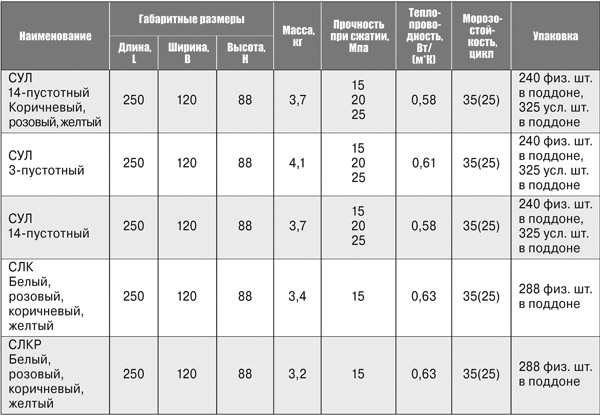

Construction of houses from porous bricks and their advantages

The construction of houses from porous bricks allows you to build a solid and reliable structure. This material can withstand a load of 150 kg per sq. cm. Therefore, buildings of nine floors can be erected from it. Due to this strength, porous bricks can be used in any type of construction.

This brick has convenient dimensions that differ from the standard brick. Porous bricks of various sizes are produced. In this case, the thickness of the wall made of this material will be 250 mm. The speed of building buildings is also high, it can be compared with the speed of building a house from aerated blocks. Any team of builders, even without much experience, has the opportunity to deliver a box of a structure made of porous bricks in just one week.

Porous bricks are lightweight. The volumetric weight of the material is less than 800 kg per cubic meter. meter. This indicator can be compared only with aerated concrete, which is used in the construction of low-rise buildings. Low density reduces the pressure on the foundation, and this makes it possible to build a house of porous bricks on almost any kind of soil.

Due to the low thermal conductivity of bricks, it is called one of the best building materials. Aerated concrete has a similar thermal conductivity. Walls made of porous bricks do not need to be additionally insulated. To comply with energy saving standards, it is necessary to build walls that are at least 40 cm thick.

Buildings made of porous bricks are not afraid of adverse weather conditions and precipitation. The material can withstand exactly the same number of freezes and defrosts as a simple brick. In addition, porous brick is an inert material in terms of its biological characteristics, so it is not susceptible to the formation of fungus or mold. The only exception is the decay process.

Inside the buildings, built of porous bricks, there is always a favorable microclimate. This is facilitated by the pores that are present in the building blocks. It is with their help that the natural humidity inside the room is regulated. The house, for the construction of which porous bricks were used, can be compared with buildings built of wood and aerated concrete. Such a building has the highest sanitary and hygienic properties.

Wall construction made of porous bricks

Houses made of porous bricks are distinguished by fire resistance, since this building material, like silicate and clay, does not burn and is able to withstand the effects of open fire for several hours.

The double porous brick used for the interior and exterior decoration of the building has no restrictions. Finishing work can be carried out using a wide variety of materials. At the same time, a house made of porous bricks does not need to be painted from the outside, since this material is produced in a large assortment of different color shades.

Types, properties and application

By designation, brick is divided into construction, special and facing. Construction is used for masonry walls, facing - for the design of facades and interiors, and a special one is used for foundations, road surfaces, masonry of stoves and fireplaces.

A narrower specialization is due to the different structure of products.

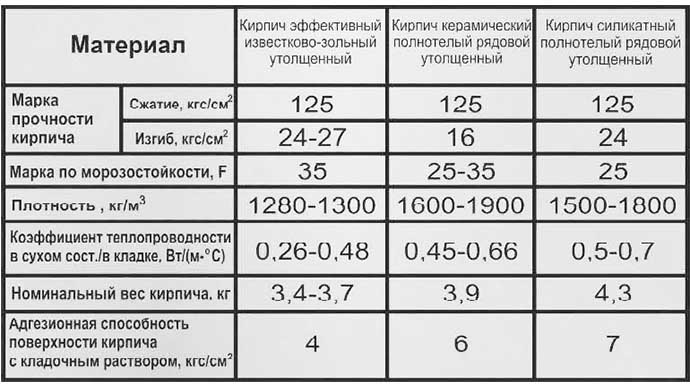

Solid brick

It is a solid bar with random voids less than 13%.

Bricks are full-bodied:

Silicate, ceramic - used for the construction of self-supporting walls, partitions, columns, pillars, and so on. Solid brick structures are reliable, frost-resistant, capable of carrying additional loads. Partitions provide good sound insulation with a small thickness, retain a large amount of heat.

In addition, the material is quite decorative and popular with many modern designers. But the high coefficient of thermal conductivity and water absorption forces to construct external walls of great thickness or to make them three-layer, combining with insulating materials and other types of bricks.

Fireclay - is made from special refractory crushed clay and fireclay powder by firing with an increased temperature regime. It is used for laying out fireplaces, stoves and other structures where fire resistance is required. The specificity of the application has determined a wide variety of product shapes:

- wedge-shaped and straight;

- large, medium and small sizes;

- shaped with profiles of varying complexity;

- special, laboratory and industrial crucibles, tubes and other equipment.

Clinker - made from refractory clays with various additives.Fired at very high temperatures until completely baked. Various components and variability of the firing mode give the bricks increased strength, water resistance and a wide palette of shades from greenish, when fired with peat, to burgundy with charcoal tan. It used to be widely used for paving sidewalks, now it is used in masonry and cladding of foundations. The thermal conductivity of ceramic bricks is quite high.

Hollow brick

The material allows 45% of voids from the total volume, and also differs in shape, structure and location of voids in the bar. The thermal conductivity of a hollow brick directly depends on the amount of air in its body - the more air, the better the thermal insulation.

A brick with voids is a block with two or three large through holes, which serve rather to facilitate and reduce the cost, rather than improve thermal insulation. It is used on a par with a full-bodied analogue, with the exception of foundations and other structures that require increased strength.

Slotted brick - the entire body of the block is pierced with holes of various shapes and sizes.

- rectangular;

- triangular;

- diamond-shaped;

- through and closed on one side;

- vertical and horizontal.

Quite good strength and low thermal conductivity determine its demand for the construction of external walls of residential buildings.

Porous bricks - available in several sizes. In addition to a large number of holes, it has a porous material structure, which is formed when special small fractions added to clay are burned out. Possesses the best set of qualities for the construction of external walls. Strength, low thermal conductivity and large dimensions reduce the construction time by several times, while observing the latest SNiP requirements. Warm ceramics are characterized by the lowest thermal conductivity, but due to their fragility, they have limited application so far.

Facing brick is also hollow, successfully combining artistic and insulation properties.

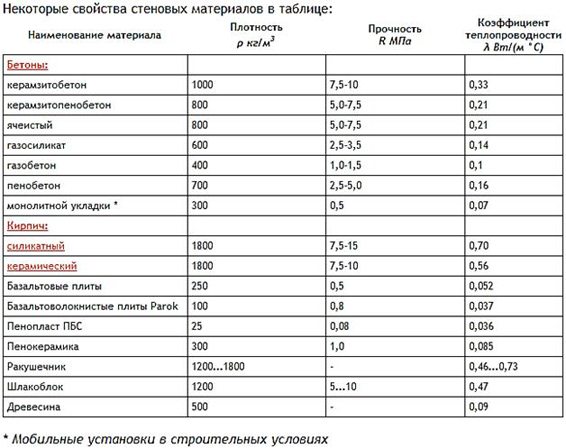

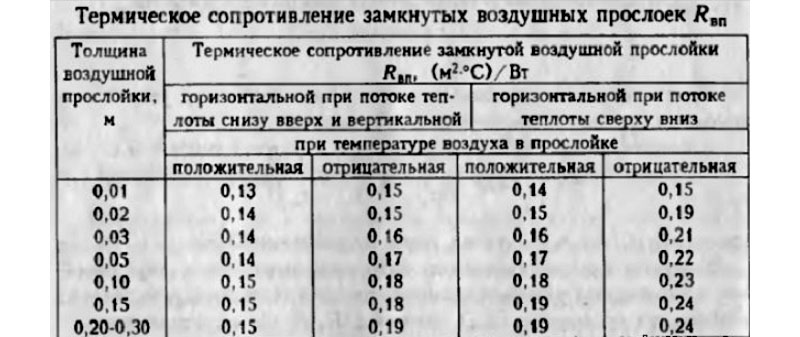

Table of indicators of thermal conductivity of building materials

| Material name | Thermal conductivity coefficient, W / (m * K) |

| Ceramic block | 0,17- 0,21 |

| Porous brick | 0,22 |

| Ceramic slotted brick | 0,34–0,43 |

| Slotted silicate brick | 0,4 |

| Ceramic brick with voids | 0,57 |

| Ceramic solid brick | 0,5-0,8 |

| Silicate brick with voids | 0,66 |

| Solid silicate brick | 0,7–0,8 |

| Clinker brick | 0,8–0,9 |

Almost always, in the construction of a house, several types of bricks with corresponding characteristics are used for different structural elements.

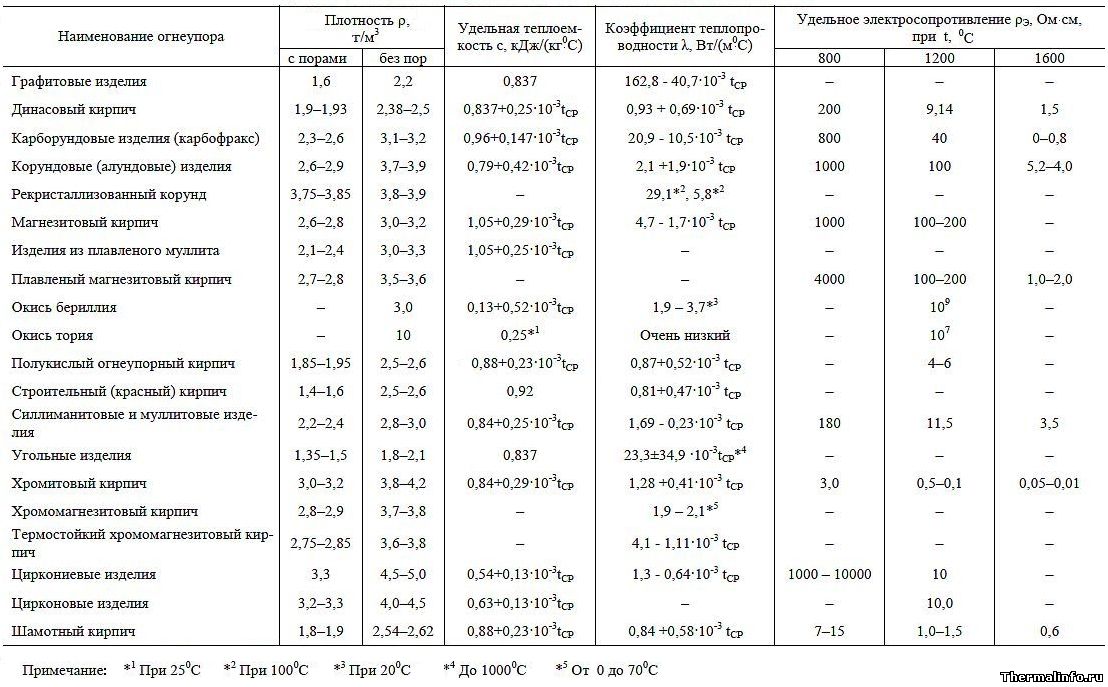

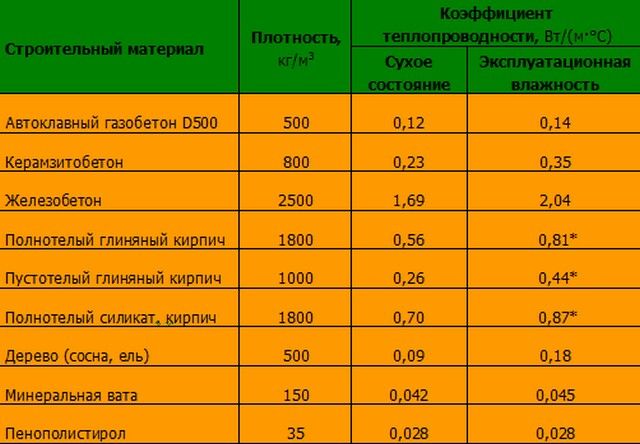

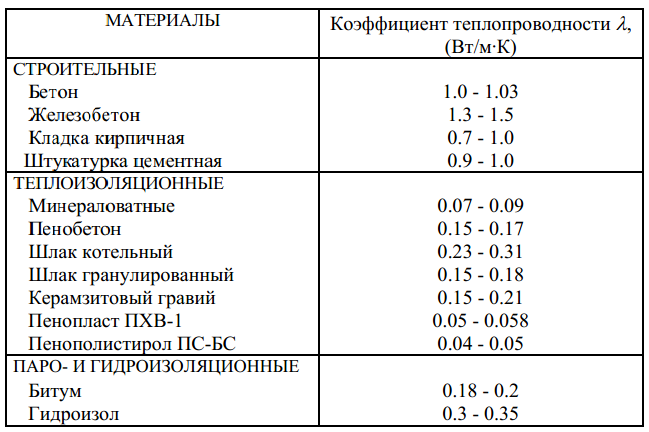

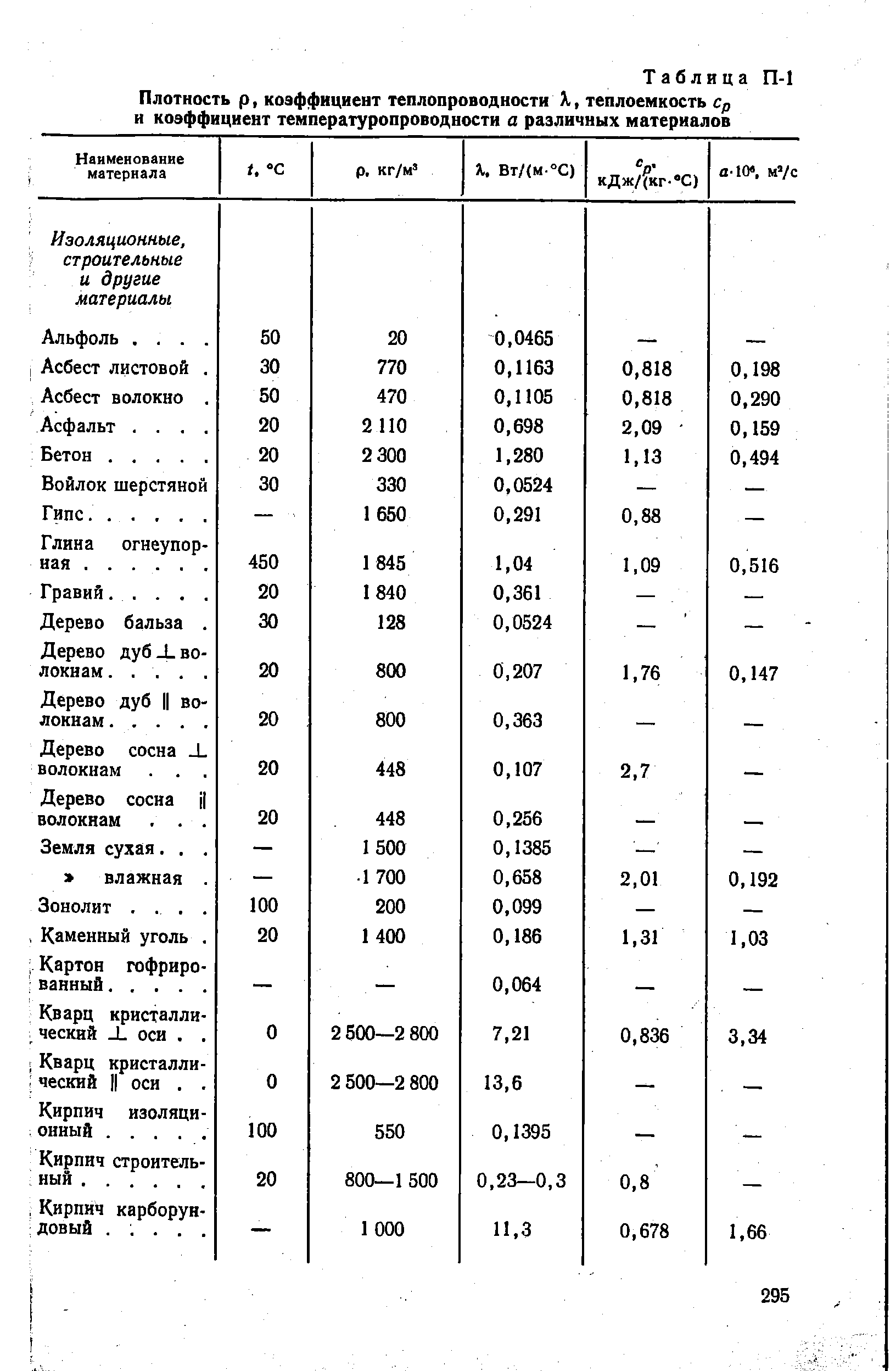

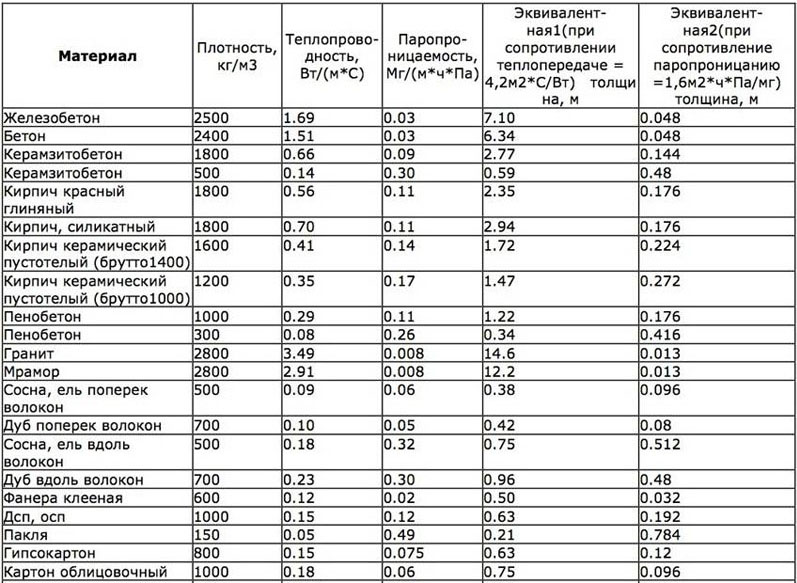

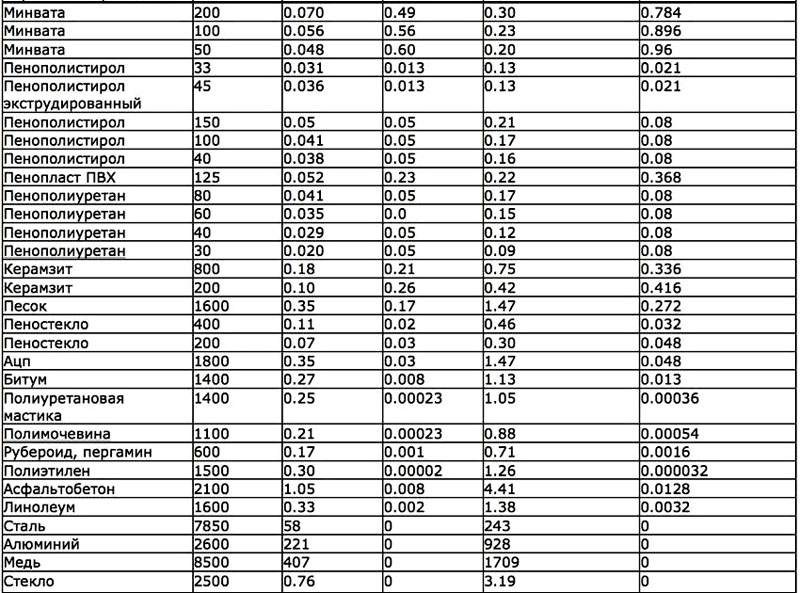

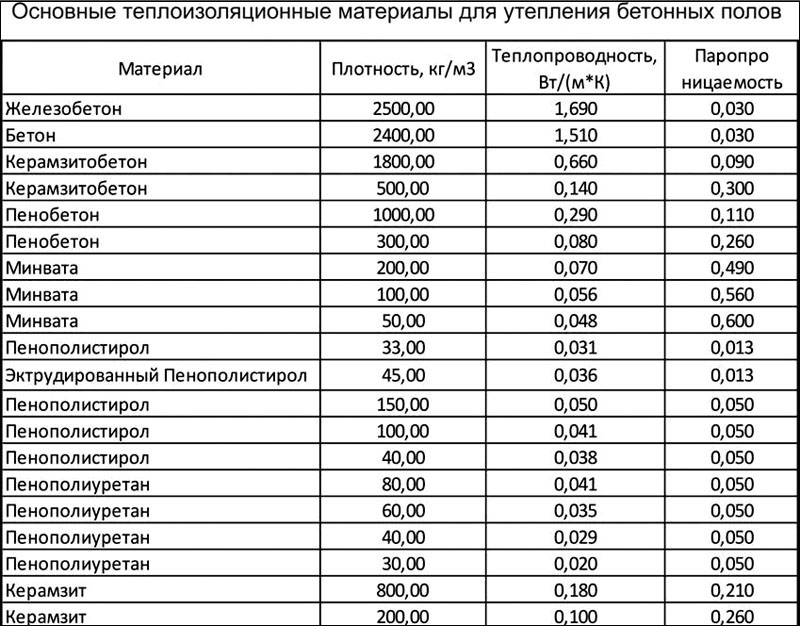

Thermal conductivity coefficient of building materials - tables

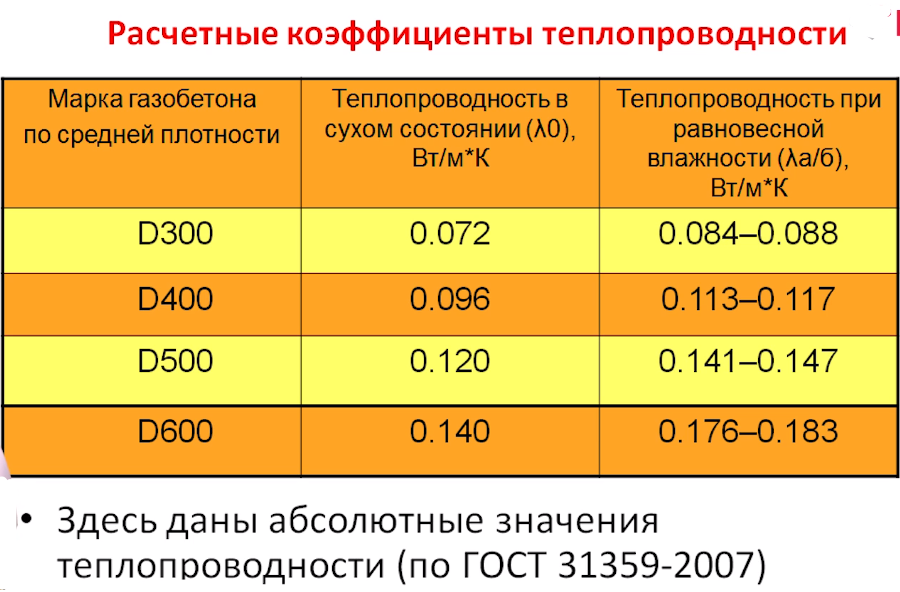

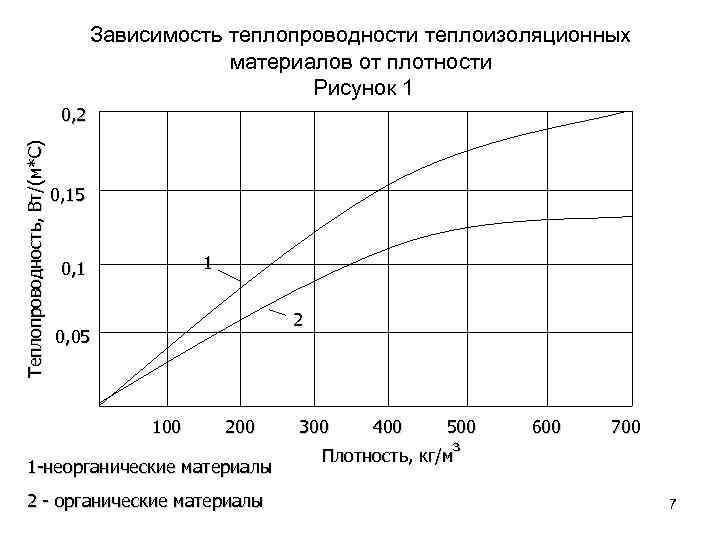

The thermal insulation properties of materials are perfectly demonstrated by the summary tables in which the standard indicators are presented.

Table of heat transfer coefficients of materials. Part 1

Table of heat transfer coefficients of materials. Part 1

Heat conductivity of materials. Part 2

Heat conductivity of materials. Part 2 Thermal conductivity table of insulation materials for concrete floors

Thermal conductivity table of insulation materials for concrete floors

But these tables of thermal conductivity of materials and heaters did not take into account all the values. Let us consider in more detail the heat transfer of the main building materials.

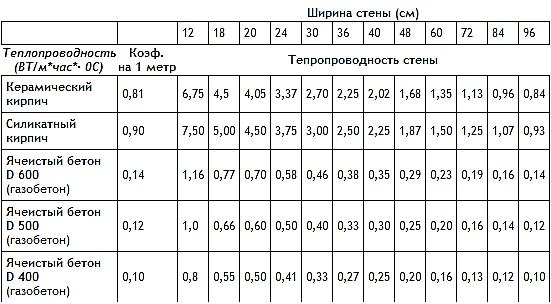

Brick thermal conductivity table

As we have already seen, brick is not the "warmest" wall material. In terms of thermal efficiency, it lags behind wood, foam concrete and expanded clay. But with proper insulation, cozy and warm houses are obtained from it.

Comparison of thermal conductivity of building materials by thickness (brick and foam concrete)

Comparison of thermal conductivity of building materials by thickness (brick and foam concrete)

But not all types of bricks have the same thermal conductivity coefficient (λ). For example, for clinker, it is the largest - 0.4-0.9 W / (m · K). Therefore, it is impractical to build something out of it. Most often it is used for road works and flooring in technical buildings. The smallest coefficient of such a characteristic is in the so-called thermal ceramics - only 0.11 W / (m · K).But such a product is also distinguished by its great fragility, which minimizes the scope of its application as much as possible.

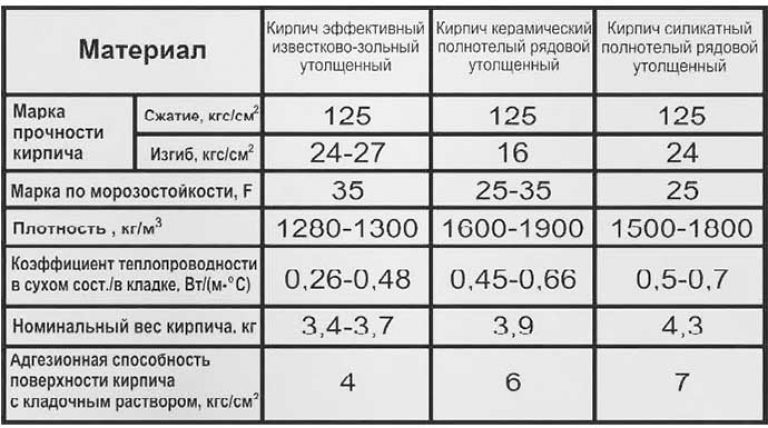

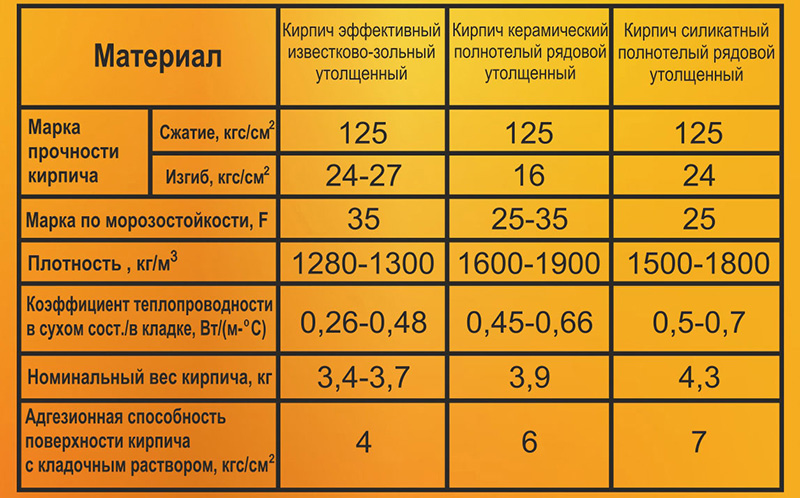

Quite good match of strength and thermal efficiency of silicate bricks. But the masonry of them also needs additional insulation, and, depending on the region of construction, possibly also thickening the wall. Below is a comparative table of heat conductivity values for different types of bricks.

Thermal conductivity of different types of bricks

Thermal conductivity of different types of bricks

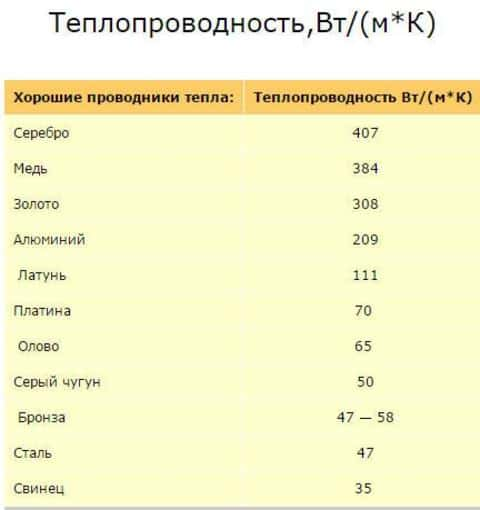

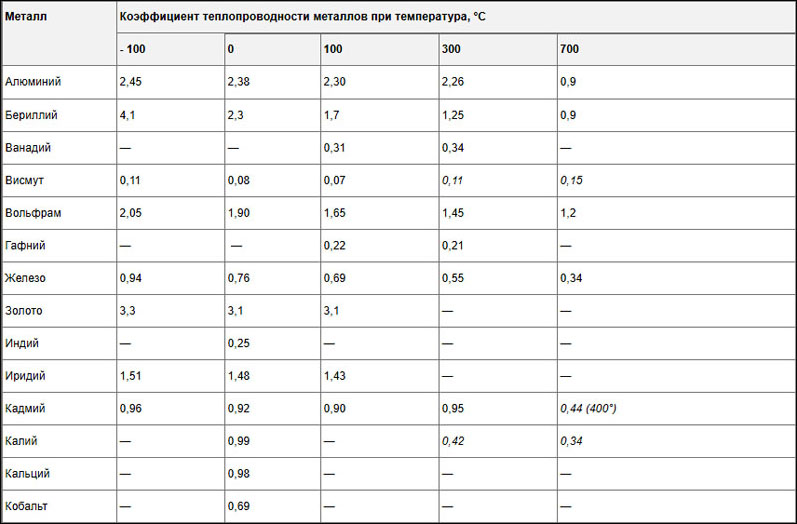

Thermal conductivity table of metals

The thermal conductivity of metals is equally important in construction, for example, when choosing heating radiators. Also, one cannot do without such values when welding critical structures, producing semiconductors and various insulators. Below are comparative tables of heat conductivity of various metals.

Thermal efficiency of different types of metals. Part 1

Thermal efficiency of different types of metals. Part 1 Thermal efficiency of different types of metals. Part 2

Thermal efficiency of different types of metals. Part 2 Thermal efficiency of different types of metals. Part 3

Thermal efficiency of different types of metals. Part 3

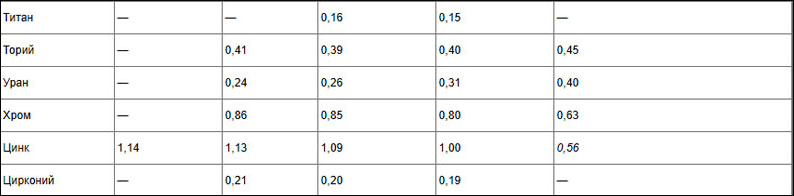

Thermal conductivity table of wood

Wood in construction tacitly refers to the elite materials for the construction of houses. And this is not only due to environmental friendliness and high cost. Wood has the lowest thermal conductivity coefficients. Moreover, such values directly depend on the breed. The lowest coefficient among building species has cedar (only 0.095 W / (m ∙ C)) and cork. Building houses from the latter is very expensive and problematic. But on the other hand, cork for flooring is valued because of its low heat conductivity and good sound insulation qualities. Below are tables of thermal conductivity and strength of various rocks.

Wood heat conductivity

Wood heat conductivityThe strength of different types of wood

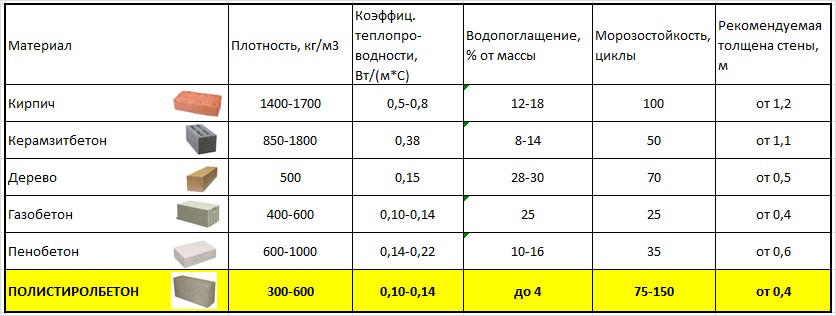

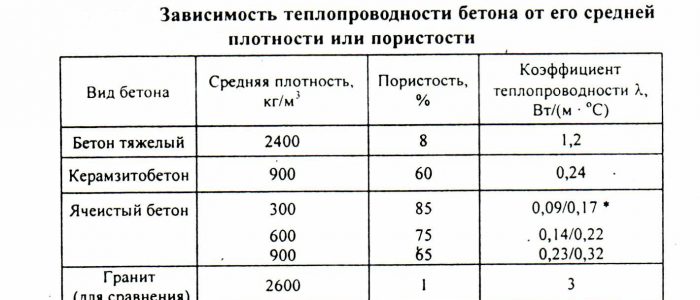

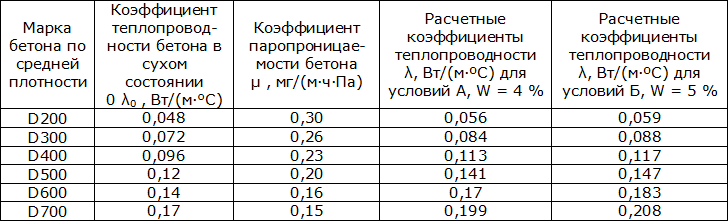

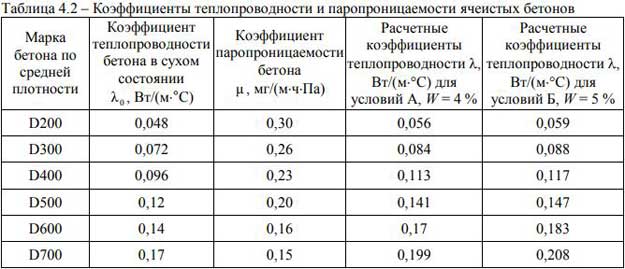

Concrete heat conductivity table

Concrete in its various variations is the most common building material today, although it is not the "warmest" one. In construction, structural and heat-insulating concretes are distinguished. From the first, foundations and critical units of buildings are erected with subsequent insulation, from the latter, walls are built. Depending on the region, either additional insulation is applied to those, or not.

Comparative table of thermal insulation concrete and thermal conductivity of various wall materials

Comparative table of thermal insulation concrete and thermal conductivity of various wall materials

The most "warm" and durable is aerated concrete. Although this is not entirely true. If you compare the structure of foam blocks and aerated concrete, you can see significant differences. In the former, the pores are closed, while in gas silicates most of them are open, as if "torn". That is why, in windy weather, an uninsulated aerated block house is very cold. The same reason makes such lightweight concrete more susceptible to moisture.

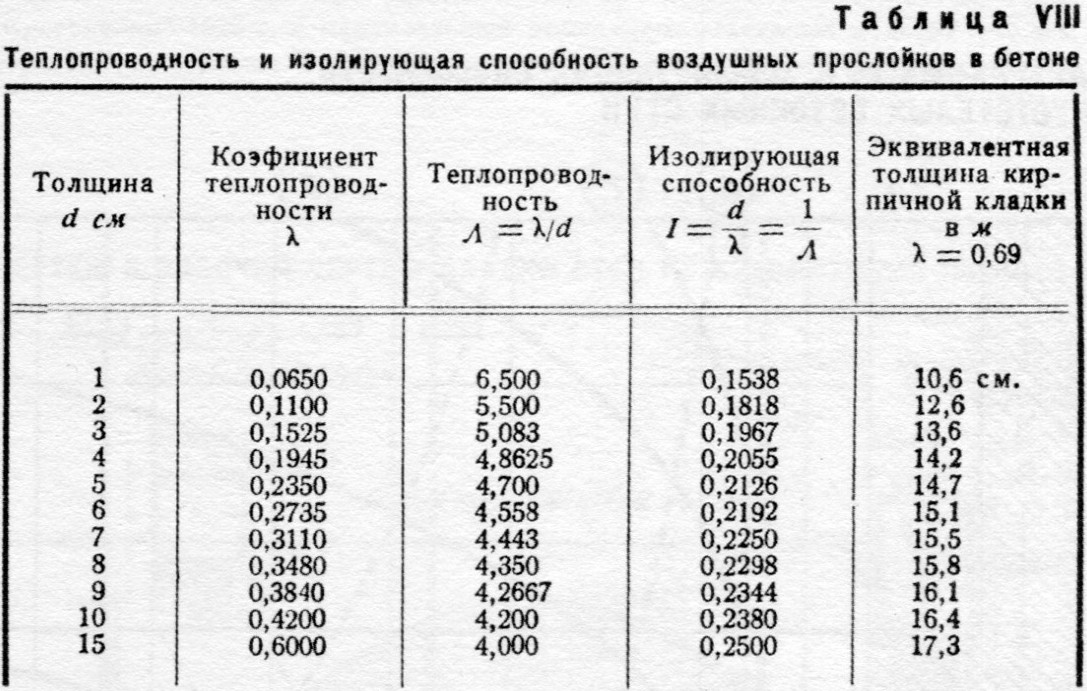

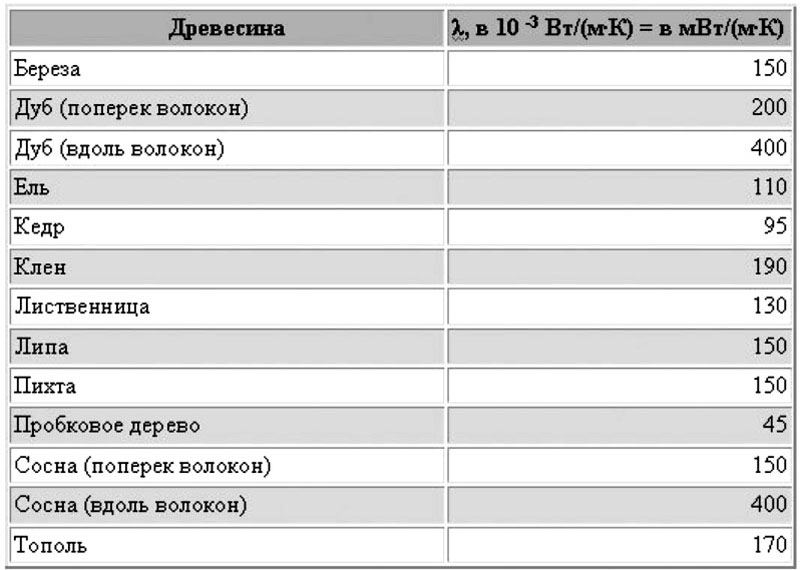

What is the coefficient of thermal conductivity of the air gap

In construction, wind-blown air layers are often used, which only increase the heat conductivity of the entire building. Also, such vents are necessary to remove moisture to the outside.

Particular attention is paid to the design of such interlayers in foam concrete buildings for various purposes. Such interlayers also have their own coefficient of thermal conductivity, depending on their thickness.

Air space heat conductivity table

Air space heat conductivity table

How to determine the coefficients of thermal conductivity of building materials: table

Helps to determine the coefficient of thermal conductivity of building materials - table. It contains all the meanings of the most common materials. Using such data, you can calculate the thickness of the walls and the insulation used. Thermal conductivity value table:

Required ratios for a wide variety of materials

To determine the value of thermal conductivity, special GOSTs are used. The value of this indicator differs depending on the type of concrete. If the material has an index of 1.75, then the porous composition has a value of 1.4.If the solution is made using crushed stone, then its value is 1.3.

Technical characteristics of heaters for concrete floors

The value of thermal conductivity can be judged by comparative characteristics

Helpful hints

Ceiling losses are significant for those living on the top floors. Weak areas include the space between the floors and the wall. Such areas are considered cold bridges. If there is a technical floor above the apartment, then the loss of heat energy is less.

When insulating the ceiling on a veranda or terrace, you can use lighter building materials

The insulation of the ceiling on the upper floor is done from the outside. Also, the ceiling can be insulated inside the apartment. For this, expanded polystyrene or thermal insulation boards are used.

When insulating the ceiling, it is worth choosing a material for vapor barrier and waterproofing

Before insulating any surfaces, it is worth finding out the thermal conductivity of building materials, the SNiP table will help with this. Insulating flooring is not as difficult as other surfaces. Materials such as expanded clay, glass wool or expanded polystyrene are used as insulating materials.

Creating a warm floor requires special knowledge

It is important to consider the height and thickness of the materials. To insulate an apartment on the top floors with high quality, you can fully use the capabilities of central heating

In this case, it is important to increase the transfer of heat from the radiators. To do this, you should use the following tips:

To insulate an apartment on the top floors with high quality, you can fully use the capabilities of central heating

In this case, it is important to increase the transfer of heat from the radiators. To do this, you should use the following tips:

- if some part of the batteries is cold, then it is required to deflate. This opens a special valve;

- so that the heat penetrates inside the house, does not heat the walls, it is recommended to install a protective screen with a foil coating;

- for free circulation of heated air, it is not worth cluttering the radiators with furniture or curtains;

- if you remove the decorative screen, the heat transfer will increase by 25%.

The choice of quality radiators allows you to better save heat in the room

Heat losses through entrance doors can be up to 10%. In this case, a significant amount of heat is spent on air masses that come from outside. To eliminate drafts, it is necessary to reinstall worn-out seals and gaps that may appear between the wall and the box. In this case, the door leaf can be upholstered, and the gaps can be filled with polyurethane foam.

The choice of insulation depends on the material of the door itself

Windows are one of the main sources of heat loss. If the frames are old, then drafts appear. About 35% of thermal energy is lost through window openings. For high-quality insulation, double-glazed windows are used. Other methods include insulating cracks with polyurethane foam, pasting the joints with the frame with a special seal and applying silicone sealant. Correct and comprehensive insulation is a guarantee of a comfortable and warm home, in which mold, drafts and cold floors will not appear.

Save time: select articles by mail every week

Coefficient of thermal conductivity

Materials have the ability to conduct heat from a heated surface to a colder area. The process occurs as a result of the electromagnetic interaction of atoms, electrons and quasiparticles (phonons). The main indicator of the value is the coefficient of thermal conductivity (λ, W /), defined as the amount of heat passing through a unit of cross-sectional area in a unit time interval. A small value has a positive effect on maintaining the thermal regime.

According to GOST 530-2012, the efficiency of dry masonry is characterized by the coefficient of thermal conductivity:

- ≤ 0.20 - high;

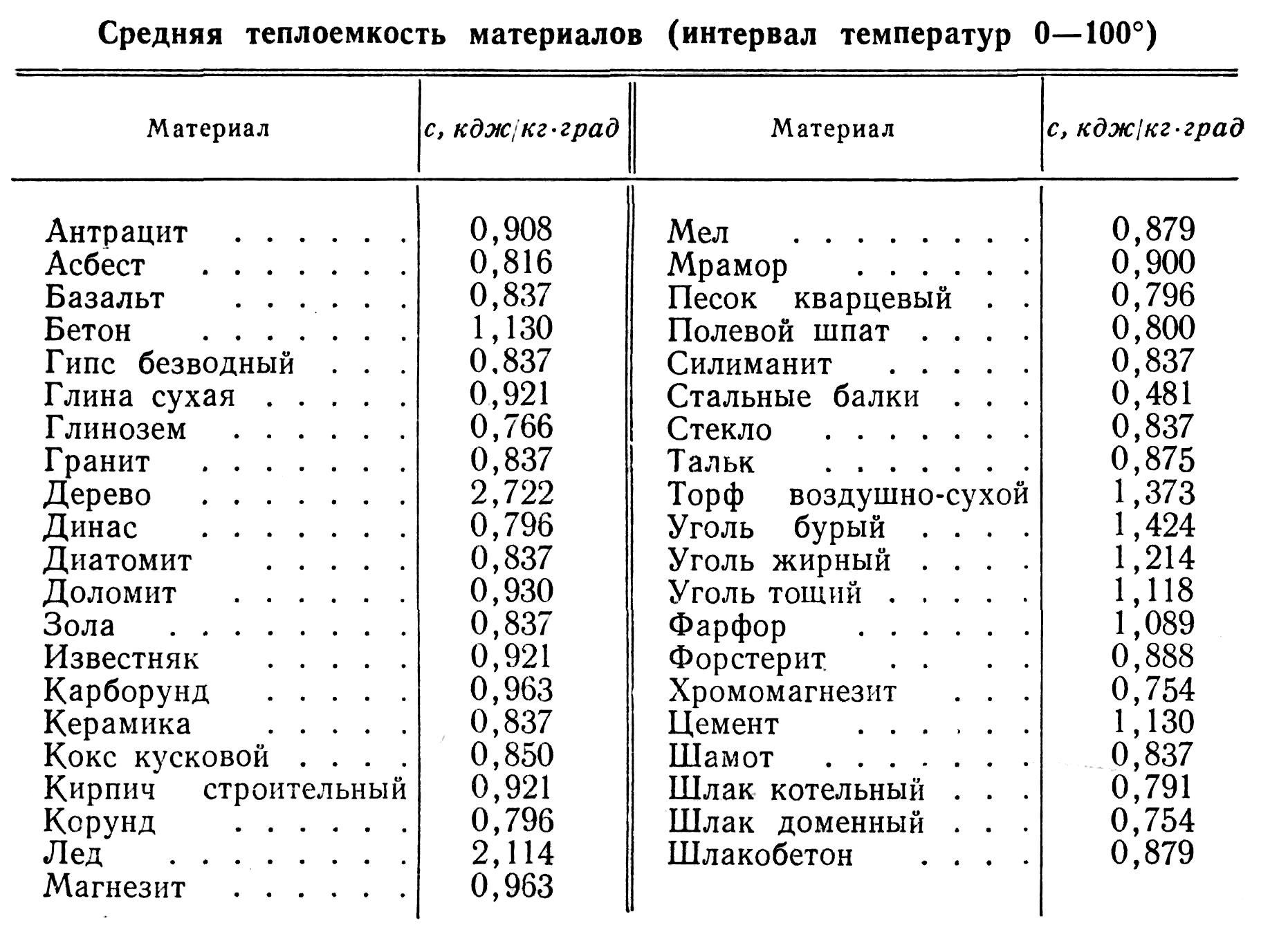

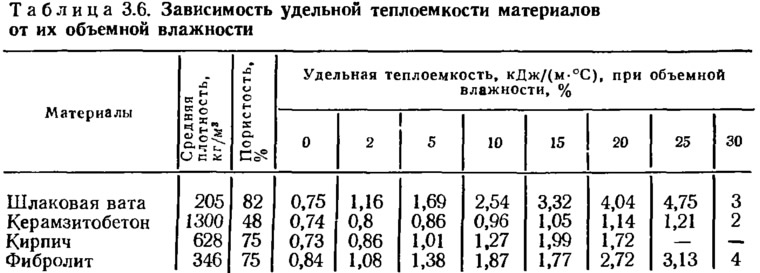

- 0.2 Specific heat

The required amount of heat supplied to the body to increase the temperature by 1 Kelvin is the definition of "total heat capacity". Measurement unit: J / K or J / ° C. The greater the volume and mass of the body (thickness of walls and floors), the higher the heat capacity of the material, the better the favorable temperature regime is maintained. This property is most accurately confirmed by the characteristics:

- The specific heat capacity of a brick is the amount of heat required to heat a unit mass of a substance in a unit time interval. Unit of measurement: J / kg * K or J / kg * ° C. Used for engineering calculations.

- Volumetric heat capacity - the amount of heat consumed by a body of a unit volume for heating per unit of time. Measured in J / m³ * K or J / kg * ° C.

| Product type | Specific heat, J / kg * ° С |

| Red corpulent | 880 |

| hollow | 840 |

| Silicate corpulent | 840 |

| hollow | 750 |

Heat convection is continuous: radiators heat the air, which transfers heat to the walls. When the room temperature drops, the opposite process takes place. An increase in specific heat capacity, a decrease in the coefficient of thermal conductivity of walls provide a reduction in the cost of heating a house. The thickness of the masonry can be optimized by a number of actions:

- The use of thermal insulation.

- Plastering.

- Use of hollow brick or stone (excluded for building foundations).

- Masonry mortar with optimal heat engineering parameters.

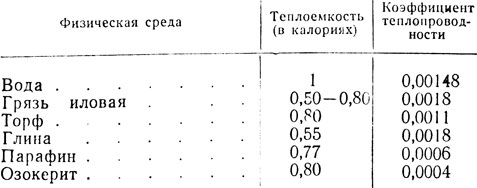

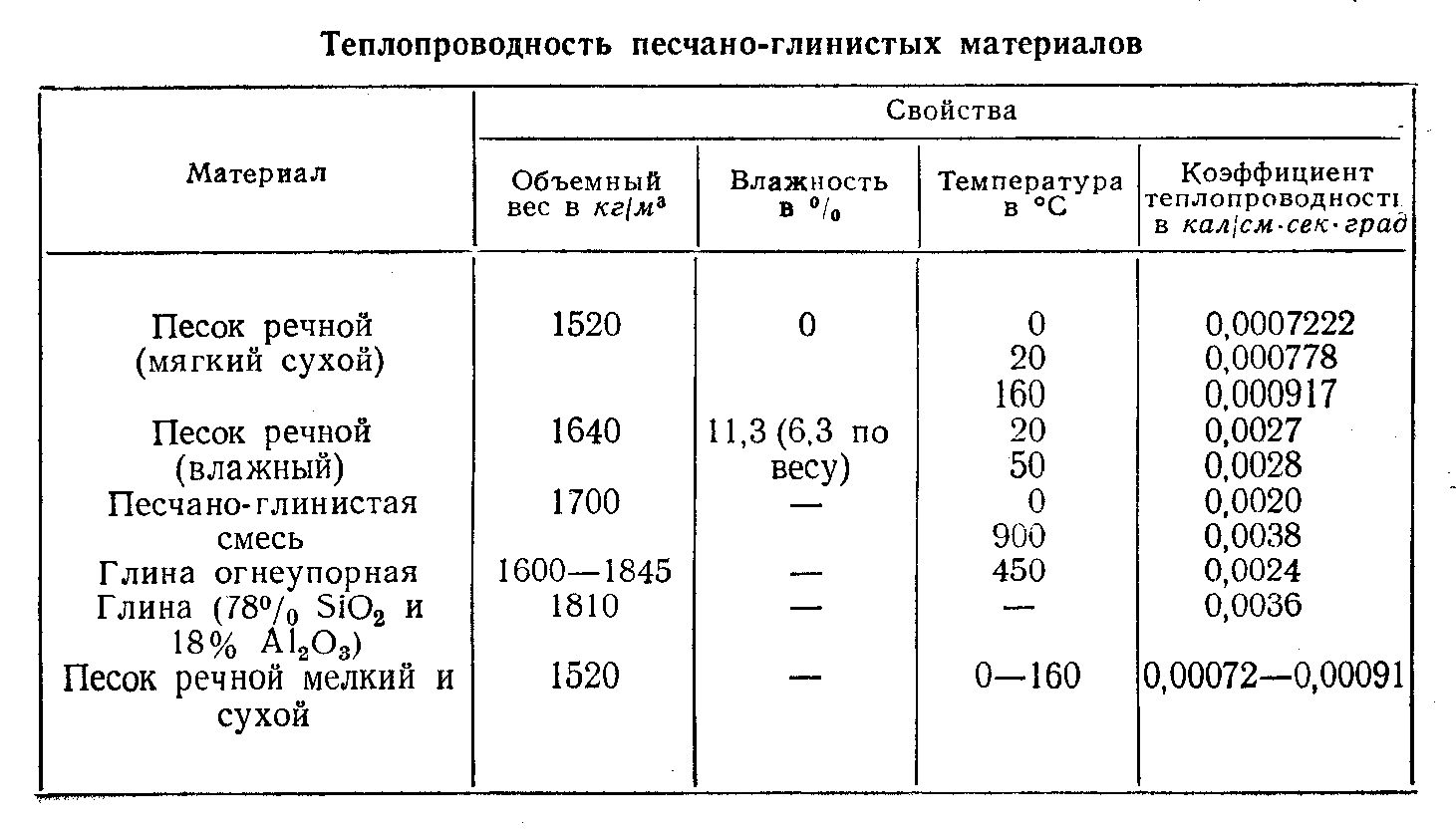

A table with the characteristics of various types of masonry. The data of SP 50.13330.2012 were used:

| Density, kg / m³ | Specific heat, kJ / kg * ° С | Thermal conductivity coefficient, W / m * ° C |

Ordinary molten brick on various masonry mortars

Cement-sand

1800

0.88

0.56

Cement-perlite

1600

0.88

0.47

Cement-sand

1800

0.88

0.7

Hollow red of various density (kg / m³) at the central heating station

1400

1600

0.88

0.47

1300

1400

0.88

0.41

1000

1200

0.88

0.35

Frost resistance of brickwork

Resistance to negative temperatures is an indicator that affects the strength and durability of a structure. During operation, the masonry is saturated with moisture. In winter, water, penetrating into the pores, turns into ice, increases in volume and breaks the cavity in which it is located - destruction occurs. Frost resistance is usually low, water absorption should not exceed 20%.

Determining the number of freezing and thawing cycles without losing the strength of each type of product allows you to identify frost resistance (F). The value is obtained empirically. The laboratory carries out repeated freezing in refrigerating chambers and natural thawing of samples.

The frost resistance coefficient is the ratio of the compressive strength of the experimental and the original element. A change in the indicator of more than 5%, the presence of cracks, spalls signal the end of the tests. Product brands contain frost resistance characteristics: F15 (20, 25, 35, 50, 75, 100, 150). The digital parameter indicates the number of cycles: the higher the number, the more reliable the system being built.

The purchase of high grade bricks of frost resistance will devastate the construction budget. Measures to improve the properties of structures, extend the service life in cold climate zones without increasing costs:

- The use of steam and waterproofing.

- Treatment of masonry with hydrophobic compounds.

- Control, timely correction of defects.

- Reliable waterproofing of the foundation.

Thermal conductivity of concrete and insulation of buildings

The decision on the thermal insulation of the walls of the buildings being erected is made depending on what types of concrete are used to construct the walls. Concrete products are divided into the following types:

- structural, used for solid walls. They are distinguished by increased load capacity, increased density, as well as the ability to conduct heat at an accelerated rate;

- thermal insulation used in unloaded structures. They are characterized by a reduced specific gravity, a cellular structure, due to which the thermal conductivity of the walls is reduced.

Thermal conductivity table of building materials: coefficients

Thermal conductivity table of building materials: coefficients

To maintain a comfortable temperature in the room, walls can be erected from various types of concrete. In this case, the thickness of the walls will change significantly. The same level of thermal conductivity of the main walls is ensured with the following thickness:

- foam concrete - 25 cm;

- expanded clay concrete - 50 cm;

- brickwork - 65 cm.

To maintain a favorable microclimate, as part of energy saving measures, thermal insulation of building structures is carried out. At the stage of project development, specialists determine possible ways of heat loss and choose the best insulation option.

Comparative graph of thermal conductivity coefficients of some building materials and heaters

Comparative graph of thermal conductivity coefficients of some building materials and heaters

The main volume of heat losses occurs due to insufficiently effective thermal insulation of the following parts of the building:

- floor surface;

- capital walls;

- roofing structure;

- window and doorways.