Required tools and their selection

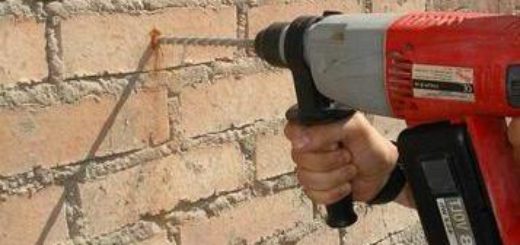

The wrong choice of tool and type of drill will not only not allow you to get the desired result, but can also damage the equipment. Two types of equipment are used to drill bricks - a hammer drill or an impact drill. The correct choice of a drill, first of all, lies in its power. The minimum power of this tool should be at least 600 watts, and the minimum number of revolutions - from 2500 rpm. It is better if the mechanism has a reverse rotation of the drill and the ability to smoothly adjust the power. Drilling holes in brick should be done with a hammer drill, since walls made of this material are very resistant to static loads, and are only subject to impact with a dynamic load. If you drill with a conventional drill, the process will be long and ineffective, since the edge of the drill will not be able to catch on the internal structure of the brick. This can lead to overheating of the tool and breakage of the drill.

In addition to the use of electrical equipment, there is the possibility of using a hand tool, the so-called bolt. It is a pipe with teeth at the end, through which a hole is punched by the application of human physical strength.

In addition, you will need the following tools:

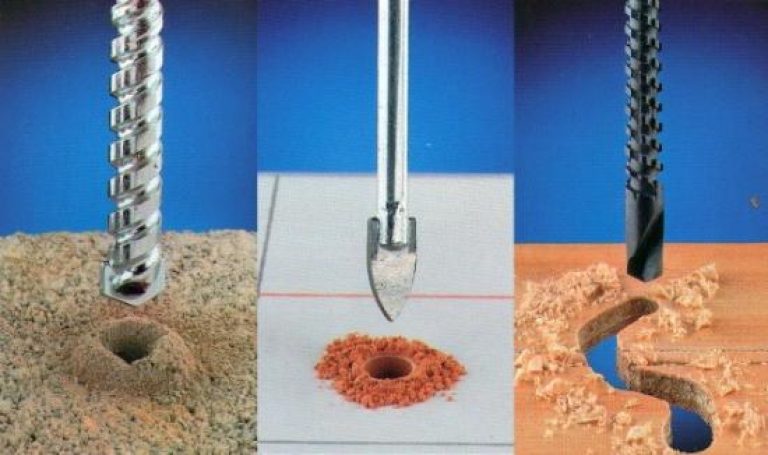

Drills or drills

For drilling holes in a brick wall to be effective, it is necessary to use drills with a specific diameter, made of carbide material. Their difference from the usual ones is the presence of a diamond or victorious cutting edge. With a hole depth up to 15 cm, drills with a diameter of 0.6 or 0.8 cm can be used.The maximum hole diameter that a brick drilled with drills can have is 1.5 cm.

Victory drill for brick walls

If you need to drill a through hole of a much larger diameter, it is better to use a drill that is mounted on a hammer drill and an impact drill. The size of the drill depends on the depth of the hole. If you need to drill a hole in the wall 60 cm wide or more, to speed up the process and make it more efficient, it is recommended to use drills of the same diameter, but different lengths at different stages of drilling, for example, start with a drill 15 cm long, and at the final stage - 50 cm long ...

The maximum drill hole diameter can be up to 2.8cm.

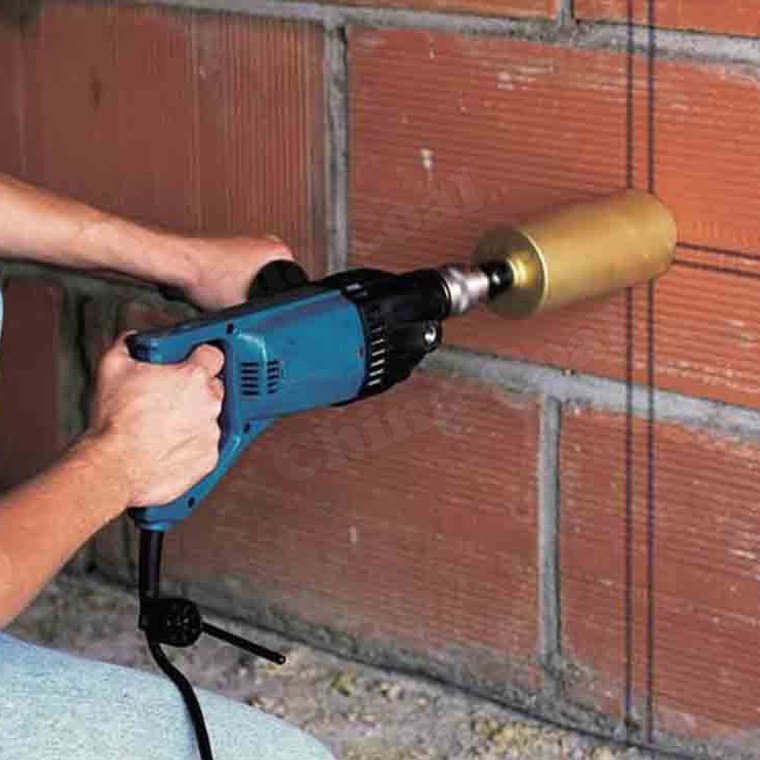

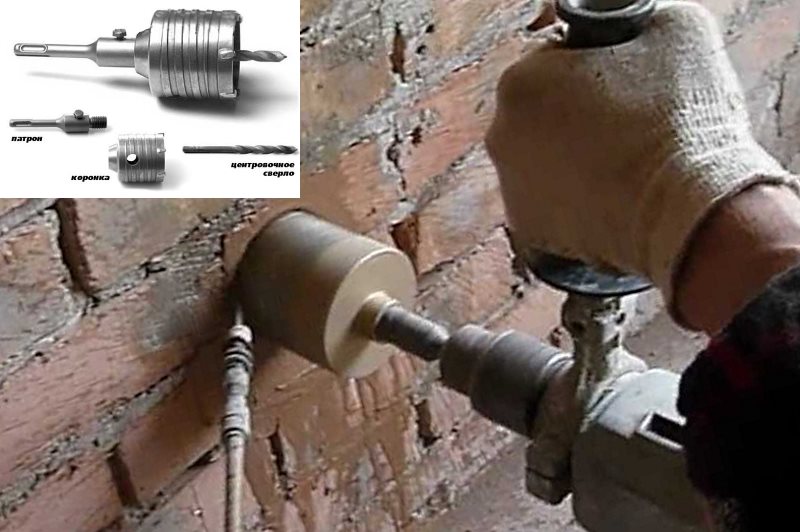

Rotary hammer crowns

For the installation of boxes for sockets, switches, it is necessary to create a niche. In this case, perforator crowns are used, which are made of durable steel and allow you to get holes of large diameter. Drilling with crowns is carried out without the use of the impact function, and their choice depends on the diameter and number of teeth.

Crown on a perforator

- Dowels for fasteners

- Dowel screwdriver

- Protective glasses

- Cooling water tank

- Core tool for marking when drilling with a drill.

- Hammer

- Victory glass

- Metal detector

Nozzles: saving energy and money

If we make a rating of power tools for which manufacturers produce additional attachments and accessories, the electric drill is the leader in it. The drilling tool turns into a multifunctional repairing machine. She saws, cuts, mills, grinds and much more. In terms of productivity, it does not fully replace each tool, but it solves short-term tasks of a home master.

For work, the shank of the nozzle is clamped in the drill chuck, like a simple drill, and the drilling mode is set.

Grinding and polishing

For grinding, use a nozzle for circles with Velcro, where abrasive circles of different grain sizes are attached. Cup or disc polish metal, wood. In hard-to-reach places, use a fan nozzle.

The file attachment is a pin that is attached at one end to the chuck. On the other, it is soldered in the form of a cone, bullet or ball. They are called cones. The holes are bored and ground with a nozzle. For rough grinding, deburring, rasp attachments are used.

The drill becomes an electric grinder with special attachments. The sharpening angle is adjustable, you can sharpen anything: drills, chisels, disc blades.

Polishing attachments: soft felt, special for the car, polishing the ends of the leather and others. To work with rotation in either direction, select a speed of 1000 revolutions.

Scissor attachment for drill "Cricket"

With this attachment, the drill becomes a nibbler for thin sheet metal, corrugated board and plastic. The shank is mounted in the drill chuck. It has two cutting heads, which are set at the desired degree. Produces burr-free cuts at 3000 rpm. You can drastically change the direction of the cut for the manufacture of shaped parts.

Attachments that make it easier

Corner. Works in hard-to-reach places as a drill and as a screwdriver.

Drywall cutters. They are used for the installation of sockets, junction boxes.

Flexible shaft. It is mounted on one side in the drill chuck, the drill chuck has on the other end. Drills where the drill cannot cope without such a nozzle.

Drilling technology

There are three ways to drill a hole in a brick wall: manual, electromechanical and automatic.

However, before starting work, it is necessary to examine the location of the wiring, since accidental hitting the wiring line will not only damage it, but can also shock a person. Most often, electrical wiring is located vertically or diagonally relative to sockets and switches. In case of existing doubts, it is worth using a special device for detecting hidden wiring wires. A portable metal detector will help locate an aluminum or copper wire that is no deeper than 1 cm.

A portable metal detector will help detect hidden communications

Hand Drilling Technology

In the absence of an electric tool, holes can be drilled using a bolt. For this, places are preliminarily marked by drilling with a punch. After that, the bolt, which is applied to the wall at an angle of 90 degrees, is hit with a hammer. Every three strikes, the bolt is turned, and the remnants of the brick are removed from the pipe. Thus, the hole is knocked out until it reaches the required depth.

Electromechanical process

Mechanical drilling is done with a hammer drill or hammer drill, and the process is the same.

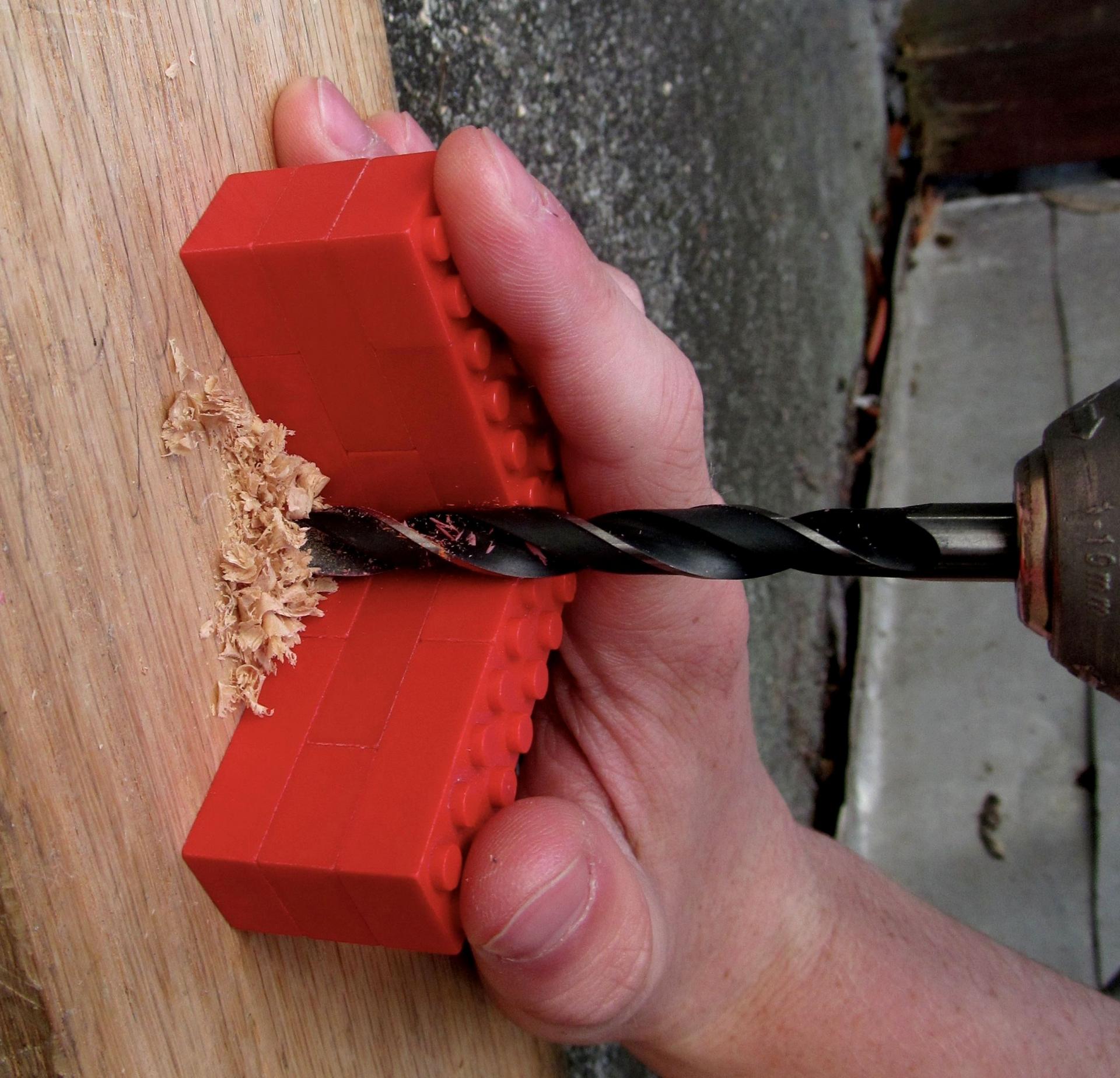

First you need to decide on the type (through, blind), depth and diameter of the hole. This is necessary for the correct drill or drill bit. If you find it difficult to maintain the same distance between the holes, you can use a template. The stencil is made of plywood, chipboard, plastic and other materials at hand. To use it, you need to fix sandpaper on one side with double-sided tape or glue, then lean it against the wall and drill.

After the type and diameter of the future hole has been determined, a core marking should be applied. The drilling process will be easier if it is done in the seam between the bricks. Core notches are made in order to fix the drill and facilitate its entry. When drilling with a drill, the tool must be held perpendicular to the wall, pressing gently on it so as not to break the drill or drill. From time to time, the drill must be taken out for cooling in a container with cold water.

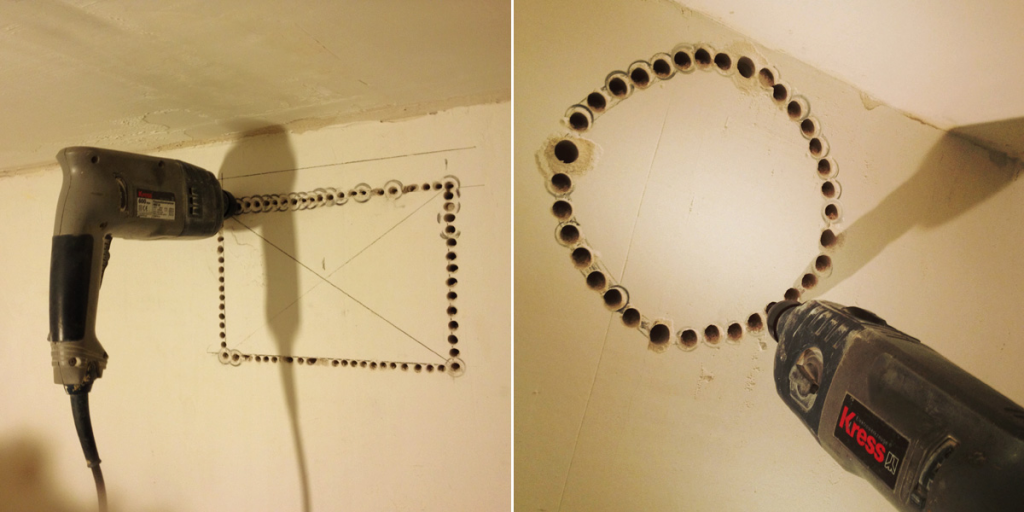

If necessary, drill a hole with a diameter greater than 18 cm, use a perforator with diamond core bits. If these are not available, you can use conventional diameter drills. For this:

- The place of the future hole is outlined, its contour is outlined with a pencil.

- Drilling is performed on the outside of the line, the number of holes depends on the diameter of the contour. The diameter of the drill itself should be 0.8-1.0 cm, the pitch of the holes along the contour should be 1.0 cm.To perform the work more accurately, you can use drills of even smaller diameter, but then the process will take longer.

- With a chisel and hammer, a sample is taken from the drilled contour.

If you need to drill through a thick wall, you can do this in two steps: first, the drilling process, as described above, is carried out on one side of the wall. Then, the center of the resulting hole is drilled through. After that, on the other side of the wall around the intended through center, the marking of the desired diameter is performed, the process is repeated.

Automatic process

With the help of professional, expensive equipment, diamond drilling is carried out. At the same time, it is desirable to have special skills and qualifications. With the help of such a tool, the drilling process is fast, accurate, practically silent, it can be performed at different angles to a depth of 40 cm, while a smooth hole is formed, without chips or cracks. This method does not create a lot of dust and dirt, since the tool is equipped with a nozzle for cooling the drill and removing the dust.

How concrete walls are drilled

It is difficult to drill concrete walls and ceilings - rubble comes across, which complicates the process.

Several tools are used to solve this problem:

- puncher;

- hammer drill;

- ordinary electric drill;

- powerful screwdriver;

- diamond drilling machine.

For large-scale repairs, a hammer drill is more suitable, which is designed for drilling holes in solid building materials: brick, concrete.

It does this job thanks to its capabilities:

- increased engine power;

- different chisels can be used;

- the use of drills of large sizes is available.

But it is not always advisable to use a perforator.

It doesn't fit:

- if you want to make holes of small depth - about 10 mm;

- for foam blocks - the material crumbles;

- if many holes are required, the hammer drill overheats.

An electric drill is suitable for home use. If it is bought for drilling walls, it is taken into account that shock is better, because in a hammerless drill with prolonged use under such conditions, the cartridge quickly deteriorates. You can buy a hammer drill - a powerful tool.

You can make a few holes with an ordinary drill, while using special nozzles and devices that help in the work. Instead of a drill, a high power screwdriver is also used.

For professional designs, diamond drilling is used. Special expensive equipment is used, which makes no sense to buy for home use. If the hole is difficult, it is better to entrust the job to specialists.

How to drill a brick wall

When drilling brick walls, care must be taken to avoid damaging the existing wall. How to choose a team of workers to renovate an apartment

How to choose a team of workers to renovate an apartment

Apartment renovation: how and where to start

Materials for interior wall decoration

If construction equipment and tools are needed only for a while, then it is much more expedient to rent them than to buy them. Today, everything is searched through the Internet. Typing in the search tool rental yekaterinburg

pay attention to the company "Prokat-Ekat", which since 2007 has been operating in the tool rental market in Yekaterinburg.It is enough to call and the necessary equipment will be delivered at the specified time

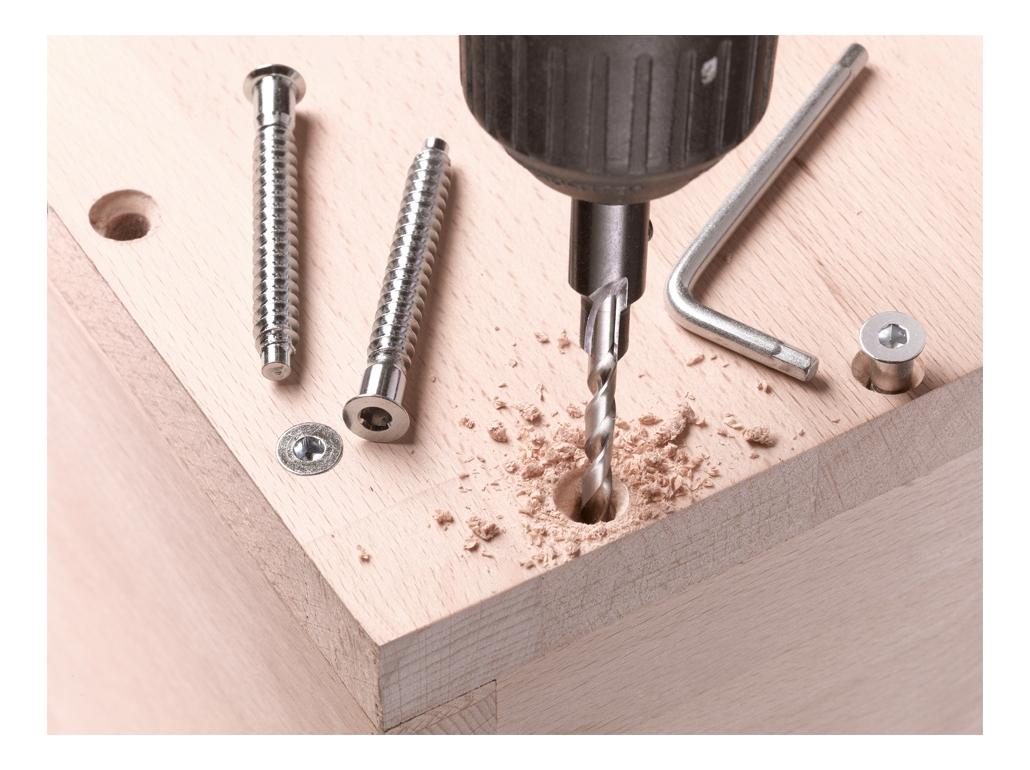

In order not to damage the wall when drilling, it is necessary to have the appropriate materials and follow the sequence of work. You will need an electric drill, bench drill, drills of various diameters, plumbing putty.

Drilling holes is necessary when installing the mount, and also when you need to push something through the wall. First, the width of the hole is determined and the depth of the wall is measured. According to these dimensions, the diameter and length of the drill are selected. To ensure that the hole does not turn out to be larger than necessary, first use a drill of a smaller diameter, and then increase the size of the drill.

Diamond drills and other accessories

Types of diamond drills for drills.

Types of diamond drills for drills.

Concrete rods are brazed along the entire length, which give special strength. Even when working with hard materials, they retain their technical properties.

Outwardly, they are also different, which does not allow them to be confused with others:

- blunt end made of soldered pobedit, which is almost as hard as diamond;

- products are white, in contrast to black for metal and light for wood;

- the tip is wider than the shaft.

Drill bits are relatively small, with cylinder or polyhedron shanks. For hammer drills - large, with the SDS mark, they are often called not drills, but drills.

By design, they are distinguished:

- screw - for drilling deep holes;

- spiral - for large diameter holes;

- shallow - they make small holes.

The drills have a thicker shank, they snap into the chuck.

The section of the nozzles is 35-120 mm. The special demand for the 68 mm crown is the size of the socket. Drill to a maximum depth of 150 mm, if more is required, lengthen. Crowns for hammer drills have soldered teeth, while those intended for drills have carbide spraying instead.

This has some advantages: such a nozzle drills concrete and tiles equally well, and highly specialized rock drill nozzles have to be changed. The crown can be used with an electric drill with a power of more than 1 kW.

Various types of attachments are suitable for drilling:

- Impact crowns with soldered teeth.

- Diamond - for hammerless drilling without a hammer drill. They are abrasive on the edge, they work faster than percussion ones.

- KS crowns - with dusting on the edges.

High-quality products are offered by Bosh, Makita, Metabo, among domestic ones - Interskol, Zubr. Chinese products can also be of high quality if their price is high.

How to smoothly drill concrete with a drill

First you need to know for sure that you have selected the correct nozzle. It is always necessary to drill at low speeds. Usually, the tool is in operation for 10 or 12 minutes. During this time, it is guaranteed that it will not overheat and accidentally break. If the drill bit of the tool accidentally remains in the wall thickness, you must carefully remove it. Force cannot be used. Perhaps the drill will break and its fragments will remain in the thickness of the wall. If necessary, the drill can be easily detached from the nozzle.

The drill must be held strictly perpendicular to the surface. If this is not followed, there is a risk of damaging the drill, and sometimes leaving a dent.

It is also important to take care that drilling dust does not get into the eyes. To do this, purchase protective glasses.

Gloves can also be used to prevent slipping of hands during the process. Only a person with strong enough hands can drill the surface qualitatively. Because the process requires a lot of effort.

Drilling a brick wall directly

The answer to the question of how to drill a brick wall with a drill can be obtained exclusively through independent practical developments. So let's get started!

The drilling process itself, regardless of the finish of the brick wall or its complete absence, begins with the application of a mark.A hole in the wall is marked with a core. Why is the mark needed? After using the core, a slight depression remains, which reliably fixes the cutting part of the drill at the initial stage of work.

The human factor of influence on the drill and the static load on the drill are interrelated quantities. The first, namely the "pressure" on the drill, should be smooth and soft, despite the need for significant loads in order to achieve the final result.

If significant static loads can be handled by regular cooling of the drill (return of the tungsten and cobalt alloy to its original state), then uniform drilling is the result of a uniform and smooth impact on the tool itself.

The drilling process is monotonous and does not require special skills, but it also requires considerable attention. So, for example, the latter will help determine and, of course, overcome a burnt brick, if, of course, one got in the way of drilling. You can determine the burnt brick by the color of the dust. Usually it is black.

The passage of such sections must be carried out at low speeds, which, in turn, must be combined with the activation of the shock function. Observing these two conditions, as well as exerting efforts in relation to the tool itself, it is necessary to carefully control the heating of the victorious drill.

Drilling holes with a size of 12 mm requires a slightly different approach, namely the consistent use of all the above sizes of victor drills. To start drilling a brick wall for a 12 mm hole, you must start with a 4 or 6 mm drill.

One of these drills achieves the planned depth, then the width of the hole is expanded with a 10 mm drill. After the depth in relation to the previous drill size has been reached, the same action should be repeated with a 12 mm drill.

Taking into account this technology to achieve the required hole diameter, namely 12 mm, the end result will be achieved much faster, and, at the same time, bypassing unnecessary efforts. Regarding how to quickly and efficiently drill any brick wall with a drill in order to obtain a diameter, for example, 30 mm, you should pay attention to diamond drilling

First of all, drilling holes in a brick wall is associated with the improvement of an apartment or a country house. This service is in demand in cases when you need to make an internal outlet or securely fasten the TV mount.

The price for drilling holes in a brick wall depends on the diameter and depth of the opening, as well as on factors that complicate the process. These include work in hard-to-reach places and at high altitudes, the need to use antifreeze, etc.

Drilling metal

1. Choice of drill.

To make a neat hole in a metal surface, you should purchase a quality metal drill. In this case, cheap drills should not be used, since they not only will not drill the base, but will also cause a lot of trouble. Therefore, try to buy only proven, high-quality drills from well-known manufacturers. The normal price for a good drill is about 300 rubles.

Varieties of drills and crowns for metal.

2. Surface preparation.

Before drilling metal, it is necessary to punch in the middle of the hole so that the drill does not slide off the surface. This work is done using a punch, which is a sharpened metal rod. A hammer is struck on the center punch, and its point knocks out a notch in the surface. Thanks to this, the drill can be fixed in one position, and the hole will turn out to be correct and neat.

3. Drilling process.

To make a hole in metal that is more than 5 mm thick, it is advisable to use multiple drills. First, the work is performed with a small diameter drill, and then drilled with a large drill to the desired diameter.First, the drill is turned on at low revs, then the speed is slightly increased.

To drill the metal easier, it is advisable to place a board under it. This will make the holes more even and tidy.

When the metal is being machined, the drill heats up. It is advisable to lubricate it with a special paste or coolant before work. If you don't have one, regular machine oil will do. The exception to this rule is gray cast iron, which is always drilled dry.

To pull the drill out of the hole obtained, you need to turn the drill in the opposite direction, if its mechanism has such a function.

Often a drill stand is used for drilling metal, to which the tool is attached. In this case, at the beginning of work, it is necessary to press only lightly on its handle, and when the chips go, the pressing force should be increased.

Drill mounted in a drill stand.

There is a direct relationship between drill thickness and tool revolutions. Remember that the larger the drill diameter, the lower the RPM. Let's say if you are using a 4mm diameter drill, the tool RPM is around 2400-2800 rpm. If the drill diameter is 6-8 mm, the number of revolutions is much less - about 1200-1300 per minute.

How to drill a concrete wall with a conventional drill?

Let's talk a little about drilling with a conventional drill. So, to begin with, the usual is unlikely to work here. Those. theoretically it is, of course, possible. But in practice, it is extremely difficult. Mandatory in in this case use a special winder drill for working in concrete with a tip coated with a hard alloy compound.

The best way is to use a special impact drill. How is it different from the usual one? The fact that in such a drill the movements of the drill are carried out due to special ratchets with teeth interacting with each other. This drill is not difficult to use to get high quality work done. To do this, simply switch the drill from the normal rotary mode to the impact rotation mode.

But it doesn't matter what type of drill you use, how much the use of specialized nozzles is relevant. Bits (crowns) are sold in two configurations: for hammer drilling or non-hammer drilling

The classification of the nozzles is as follows:

Toothed drill bits with impact function.

A concrete wall can be drilled with these bits with a cutting edge made of separately brazed teeth made of tough alloys. For keyless chucks, drills are available for these SDS ponytails. Their strength is so high that it is possible to cut the metal, but only the impact mode contributes to their destruction, creating unacceptable loads. That is why such drills are used to drill a hole between reinforcement of reinforced concrete slabs or brick walls.

Diamond core bit for hammerless drilling.

These are more modern attachments that simplify the task several times better than the usual ones. An abrasive edge with notches on them is created by diamond spraying or corundum sand spraying. As you know, diamond is distinguished by its unprecedented strength. That is why he easily copes with the reinforcement of a concrete wall. With such a nozzle, you can make a hole at least 1.5 meters deep and more than half a meter in diameter. This type of nozzles is already used by professionals, but nozzles with a diameter of up to 100 mm can be used in a domestic environment.

Crowns of the KS standard.

Bits with diamond crystals embedded in the cutting edge. They can be used for slabs, rocky soils, monolithic concrete structures from high-strength grades. It can easily replace carbide teeth.

Based on your conditions, you can safely choose the necessary drill for the drill and drill a hole. But there are also a number of recommendations for working with a conventional drill, which is not equipped with an impact function.

To do this, you start drilling the wall, but intermittently. You need to drive a sharpened drill into the concrete surface with your hands and destroy the concrete with metal punches. We take our drill or chisel, other metal devices of the corresponding and necessary diameter for us and hit them with a hammer / sledgehammer. Rotate the punch periodically. Then take the drill again.

Please note that when drilling a hole in a concrete wall with a conventional drill, you risk breaking the tool. It is imperative that a low-power drill should be given rest. Drills also have heat properties, so you need to cool them with water. In this case, take a break every 10-15 minutes of work, leaving the same amount of time for a break for the tool.

How to drill a hole in concrete without a hammer drill, see the video:

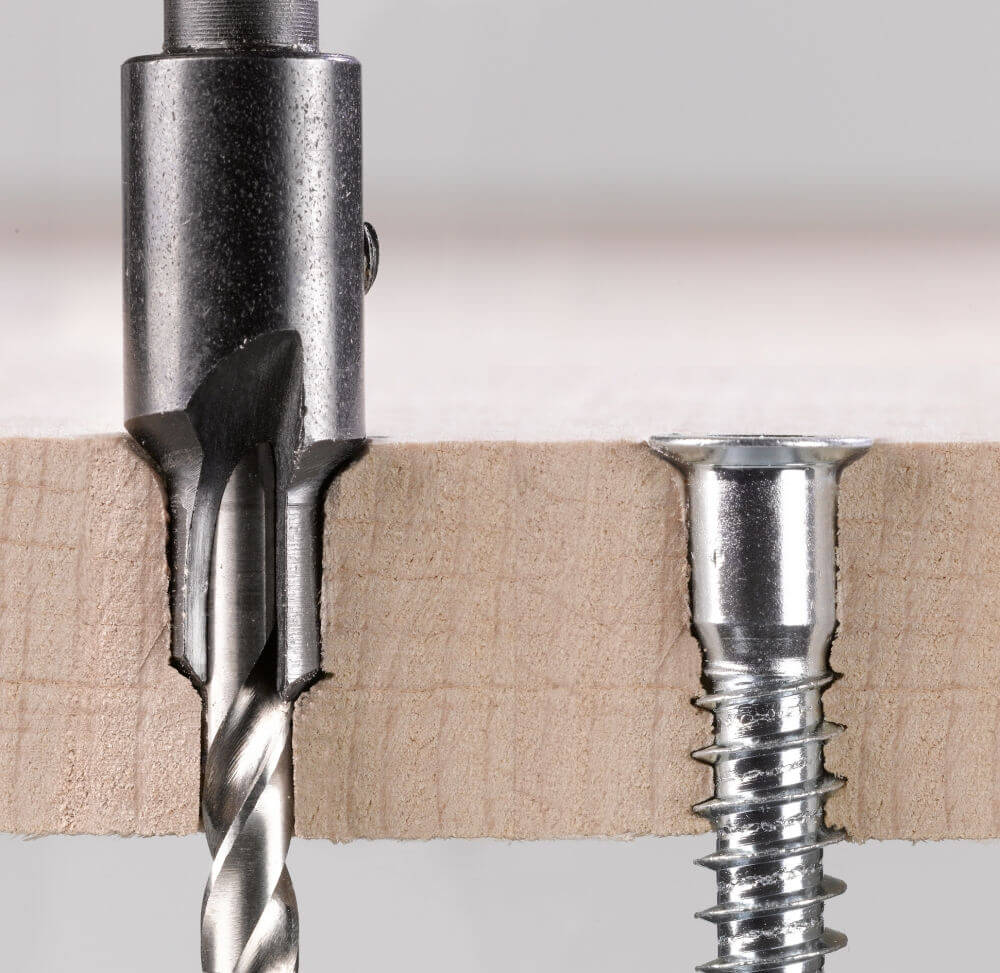

Fastening to an unreliable surface

Modern homes have many surfaces made from materials that are not very durable. These include drywall, old bricks, wood planks, or pressed sawdust slabs. When working with them, it is better to use nylon fasteners with a diameter of more than 10 mm, the installation depth should not be less than 6 cm. It is better to choose a bit smaller in size.

The drilling process must be shock-free, as excessive stress can damage the surface. Using the impact mode may not leave visible damage, but the internal structure of the wall may suffer. If the drill diameter is too large, the fasteners will move freely in the hole, gradually increasing its diameter, especially if the work was carried out with aerated concrete.

For drywall walls, it is not necessary to use a drill of a smaller diameter, the main thing is not to press on the drill and do not use the impact mode. Drywall is a very delicate material, even a small load can lead to the destruction of a section of the wall. The hole should be drilled with light force to match the size of the plastic dowel with a self-tapping screw.

It should be understood that it is not necessary to attach heavy structures to such surfaces, even if the material initially copes with the load, over time, under heavy weight, collapse may occur.

If you take into account the material from which the wall is made, choose the right dowel and drill for it, and also having a quality tool in your hands, you can make a high-quality installation, and not worry about the safety of your furniture or household appliances. Observing the recommendations, even an inexperienced master will cope with such an installation.

Drilling a brick wall directly

The answer to the question of how to drill a brick wall with a drill can be obtained exclusively through independent practical developments. So let's get started!

The drilling process itself, regardless of the finish of the brick wall or its complete absence, begins with the application of a mark. A hole in the wall is marked with a core. Why is the mark needed? After using the core, a slight depression remains, which reliably fixes the cutting part of the drill at the initial stage of work.

The drill must be kept level throughout the entire drilling, otherwise the cutting element (winder drill) will break.

The human factor of influence on the drill and the static load on the drill are interrelated quantities. The first, namely the "pressure" on the drill, should be smooth and soft, despite the need for significant loads in order to achieve the final result.

If significant static loads can be handled by regular cooling of the drill (return of the tungsten and cobalt alloy to its original state), then uniform drilling is the result of a uniform and smooth impact on the tool itself.

Using coolant (water) while drilling can damage the tool.The working cutting victorious drill is lowered into the water only 70% of the working length, that is, the one that remained after fixing the latter in the chuck.

The drilling process is monotonous and does not require special skills, but it also requires considerable attention. So, for example, the latter will help determine and, of course, overcome a burnt brick, if, of course, one got in the way of drilling. You can determine the burnt brick by the color of the dust. Usually, it is black.

The passage of such sections must be carried out at low speeds, which, in turn, must be combined with the activation of the shock function. Observing these two conditions, as well as applying efforts in relation to the tool itself, it is necessary to carefully control the heating of the victorious drill.

Drilling holes with a size of 12 mm requires a slightly different approach, namely the consistent use of all the above sizes of victor drills. To start drilling a brick wall for a 12 mm hole, you must start with a drill of 4 or 6 mm.

One of these drills achieves the planned depth, then the width of the hole is expanded with a 10 mm drill. After the depth in relation to the previous drill size has been reached, the same action should be repeated with a 12 mm drill.

Taking into account this technology to achieve the required hole diameter, namely 12 mm, the end result will be achieved much faster, and, at the same time, bypassing unnecessary efforts. Regarding how to quickly and efficiently drill any brick wall with a drill in order to obtain a diameter, for example, 30 mm, you should pay attention to diamond drilling

The main functions of the tool

The main purpose of an electric drill is to drill holes in materials. It was for this that Wilhelm Fine invented it in 1895.

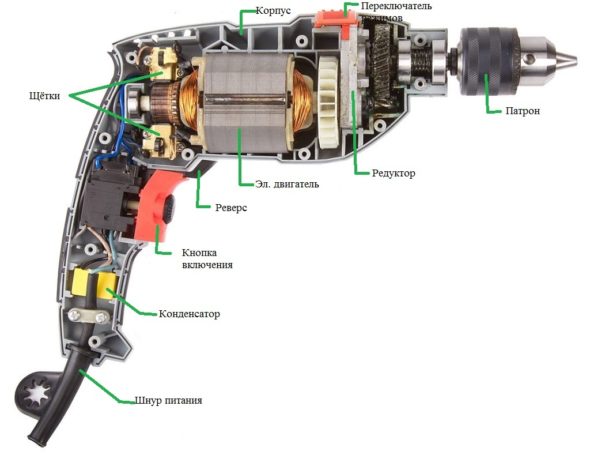

Inside the plastic case are the components:

- electric motor;

- starting switch;

- reducer;

- reverse;

- retainer;

- capacitor;

- impact mechanism.

A chuck for nozzles is attached to the shaft (spindle) of the drill using a thread and a fixing screw.

Photo: electric drill

Drill complete set

The fixed drill rotates both to the right and to the left. For this, a reverse switch is placed on the body. In this mode, it is only allowed to remove the drill from the hole or unscrew the screws and screws. Switch on for a short time at reduced speed.

Drill operating modes

Many had to hammer in the wall with a bolt in order to hang a cornice or a painting. Now this is done with a drill, setting the correct operating mode.

- Unstressed. In this mode, carpentry, locksmith work is carried out.

- Shock. For working on concrete, brick or stone substrates. The rotating drill moves in the longitudinal direction and makes translational (impact) movements.

The drill speed is different for different tasks and can be adjusted in two ways.

- Mechanical. The desired position is set on the scale. As the speed decreases, the torque increases. The power output does not change, even under load. You can set the speed while the drill is running.

- Electronic. The speed is regulated by the built-in rheostat. By lightly pressing the switch button, the drill rotates at a low speed. As the pressure increases, the speed increases until it reaches the set limit. The extreme value can be limited by a special wheel on the button. The output power is reduced with this method.

Tool

Jumper. Used to manually create holes. It is a pipe with teeth at the end. A hole is punched by their own strength of man.

Perforator. This is ideal for mechanized hole making. It is better to choose professional models, because work with them will go faster and easier. It usually has different modes of operation: slotting, drilling and their simultaneous inclusion.It also has other functionality, such as installing and removing fasteners.

Drill. An impact drill can sometimes successfully replace a hammer drill. The presence of an impact mechanism is preferable. In its absence, the speed of creating a hole depends on the force with which the worker presses on the tool. The drill cannot snag on hard material without pressure. And when pressed, the drill rod overheats, which quickly destroys it or slows down the process. Choose a drill with good characteristics: power from 600 W, reverse, rotation speed from 2500 rpm, keyless chuck, smooth speed control.

Drill. The tool requires nozzles to work. The brick will better pass a hard alloy drill with a diameter of 6 to 8 mm. It is worth taking a closer look at models with a tip made of Pobedit (a very durable alloy) or artificial diamond. The drill will make hole with a diameter not exceeding 15 mm.

Boer. If a hole larger than 15 mm is required, then you need to look towards the drill. Drill length can  be up to 1 m, and it is used exclusively with a hammer drill. The diameter can be up to 28 mm. The drill bits are rounded to increase bit life.

be up to 1 m, and it is used exclusively with a hammer drill. The diameter can be up to 28 mm. The drill bits are rounded to increase bit life.

Perforator crown. They are used to create niches for placing junction boxes, sockets, switches. Drilling with crowns is carried out without impact function, and they are made of very strong steel. With this device, large diameter holes can be produced. Crowns are selected by diameter and number of teeth.

Hand tools that are difficult to do without when working: screwdriver, punch, hammer, punch, metal finder, goggles and water to cool the drills.

Brick wall drilling process

For high-quality drilling, a powerful hammer drill is needed, but if there is none, then you can get by with an ordinary drill. Drilling a brick wall does not require special knowledge, however, utmost care and adherence to some recommendations will help avoid trouble when working with the tool. The drill must be kept strictly straight, otherwise there is a chance to break the drill bit by brick and leave an uneven dent in the wall

When the drill is turned on, it is important to wear protective goggles to prevent dust and brick debris from getting into your eyes. Also, when drilling, you need to smoothly and without sudden efforts to press on the drill, providing a uniform load on the surface.

Drilling requires a lot of energy. At high speed speeds, a huge frictional force arises, which heats up the drill strongly, so it must be cooled with cold water as often as possible. Often, when drilling, you can stumble upon a burnt brick, which will not be easy to drill. To understand when such a brick came across, you need to look at the color of its dust, usually it is black.

It so happens that a hole in a brick wall needs to be made with a considerable diameter. This diameter can serve as a ventilation outlet. For such a procedure, it is unlikely that it will be possible to drill a hole with a large diameter with a conventional drill, therefore, a powerful perforator and a crown containing a diamond coating are needed.

First you need to mark the diameter on the wall, and draw a circle on the marked section of the wall. If, for example, a pipe with a diameter of 100 mm, then the hole for the drill must be marked at least 120 mm in order to maintain a margin in case of a twist of the drill in the other direction. After that, in the figure, you need to mark the points for drilling with a distance every couple of centimeters. Then you need to select the appropriate thickness of the drill so that it goes through the brick wall entirely.

At the drilling stage, you need to drill the marked points. The drill must go right through the wall while remaining on the other side of the wall. After this, a lot of dust will turn out, therefore it is recommended to cover foreign objects with a cloth and put on protection, in order to avoid abundant ingress of dust.Upon completion, you should have a large number of drilled points in the circle.

Conclusion

Today it is one of the most popular building materials. It is mainly used for the construction of low-rise buildings and private cottages. This material allows you to build houses of complex geometric shapes without the use of construction equipment, moreover, it has increased strength. The owners of such houses note a high level of heat conservation and an increased sound insulation of the material.

It is much easier and faster to carry out any kind of repair work in a brick building than in a concrete one, since the material lends itself well to all types of processing. The main thing is, in the process of work, follow the safety rules and use personal protective equipment.

Drilling a brick wall includes the practical implementation of certain skills, as well as preparatory processes for the tool used and we process the surfaces of the brick wall itself.