Professional welding devices

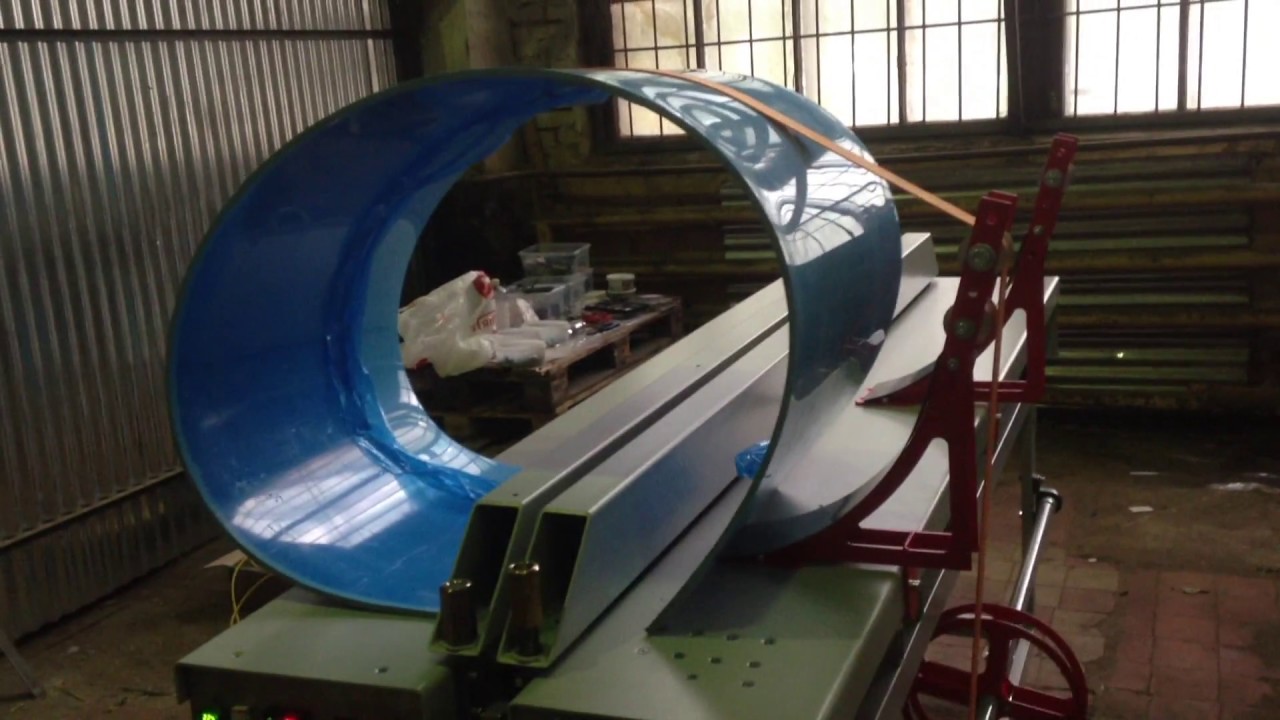

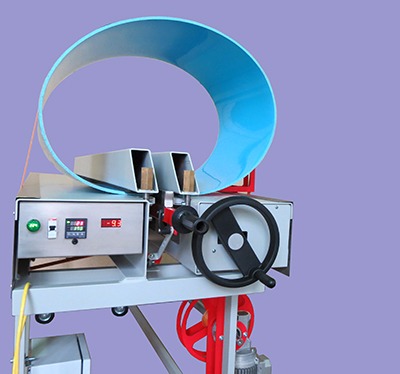

For large-scale works (for example, for creating coverings for large greenhouses or for commercial activities), it is recommended to use professional polyethylene welding devices. The advantages of these devices are that they allow flexible adjustment of the parameters of pressure, temperature, speed of movement along the seam. If you are working with the same batch of polyethylene, then once you set the required values, you can carry out the welding process at high speed.

Sealing devices often have drive and tension rollers that allow the film to be joined to be pulled at the same speed, which has a beneficial effect on the final quality of the seam.

Industrial devices are available in various types. They can be either contact heating or hot air heating.

Operations with large areas of material are cost-effective when choosing a joint by welding, since there is no need for adhesives or scotch tape. The productivity and accuracy of work is significantly increased. The low melting point and pliability of the material makes it possible to carry out the connection by welding at home. The resulting joint strength mainly depends on the temperature and cleanliness of the surfaces to be joined.

Welding parameters for polyethylene and polypropylene products

Material Melt Flow Index (MFR)

Welding of high density polyethylene (PE-HD, HDPE)

Products made of high density polyethylene of the melting group with index 005 (MFR 190/5: 0.4-0.7 g / 10 min.), Group 010 (MFR 190/5: 0.7-1.3 g / 10 min. ) or groups 003 (MFR 190/5: 0.3 g / 10 min.) and 005 (MFR 190/5: 0.4-0.7 g / 10 min.) are suitable for welding together. This is confirmed by the DVS 2207 part 1 (DVS - German Welding Association) and documented by the DVGW (German Gas and Water Association).

Welding of polypropylene: polypropylene homopolymer (PP type 1, PP-H) and polypropylene block copolymer (PP type 2, PP-C, PP-R)

The weldability of polypropylene is indicated within the 006 melting index group (MFR 190/5: 0.4-0.8 g / 10 min.). This is confirmed by the norms DVS 2207 part 11.

Polypropylene and polyethylene welding process temperature

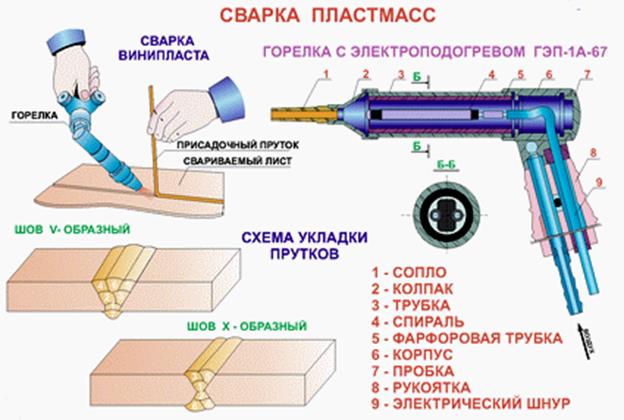

Hot gas welding

| Air, l / min. | Temperature at the nozzle ˚ С | Gas velocity cm / min | ||||

| Nozzle diameter, mm | High-speed nozzle diameter | |||||

| 3 | 4 | 3 | 4 | |||

| Welding polyethylene | 60-7060-7060-70 | 300-340300-340270-300# | 10-1510-15- | approx. 10 approx. 10- | 50-6050-6025-30 | 40-5040-5020-25 |

| Welding polypropylene | 60-7060-7060-70 | 280-320280-320280-320 | approx. 10 approx. 10 approx. 10 | 50-6050-6050-60 | 40-5040-5040-50 |

Welding with a hand extruder

| Extrudate temperature measured at the outlet of the nozzle, º C | Air temperature measured at the warm air nozzle, ºC | Air volume, liters / min. | |

| PE solid PP | 200-230200-240 | 210-240210-250 | 350-400350-400 |

Influence of moisture

Products to be welded (sheets, plates) and welding rod made of polyethylene and polypropylene can absorb moisture under certain conditions. As a result of studies carried out by a number of manufacturers, it was revealed that polyethylene and polypropylene welding rods made of polyethylene and polypropylene absorb moisture depending on the material and the environment. In extrusion welding, moisture can show up in the form of pits in the seam or rough seam surfaces. This phenomenon intensifies with increasing seam thickness.

In order to prevent such undesirable consequences, the following recommendations have been developed:

- Installation of moisture and oil separators in the air supply system,

- Avoiding significant temperature differences between the parts being welded (condensate moisture),

- Storing the welding rod, if possible, in a dry place,

- Drying the welding rod at 80 ° C for at least 12 hours,

- Welding wide seams (> 18mm) in several passes.

Depending on the type of heating of polypropylene and polyethylene, the following types of welding are distinguished:

- Welding thermoplastics with hot air (hairdryer)

- Welding thermoplastics with an extruder

- Welding thermoplastics with a heating element

- High frequency welding of thermoplastics

- Laser welding of thermoplastics

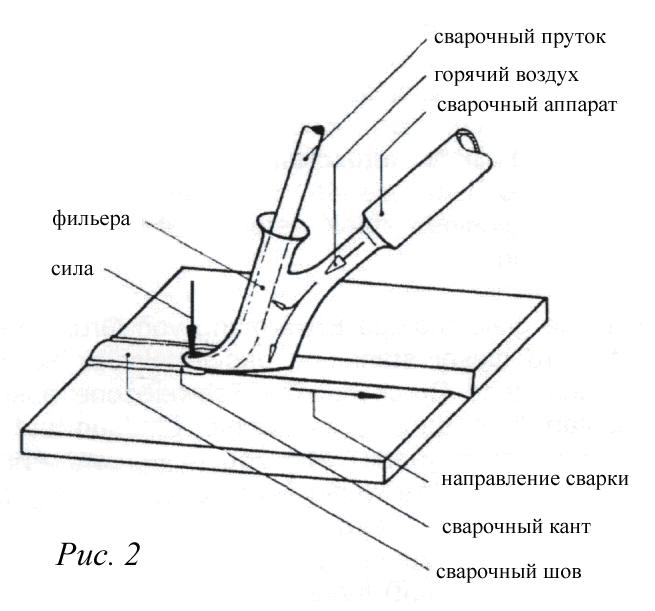

Welding with bar

For example, when laying PVC linoleum, welding using a filler rod is required. Linoleum is pre-prepared. It should fit snugly on the floor.

All joints must be fitted without gaps or gaps. A quality seam without the use of special equipment is very difficult. An ordinary hair dryer is not able to do this due to the significant thickness of the linoleum.

Requires special tools and equipment. Before welding with a bar, the edges must be prepared, the molten bar will ensure their reliable connection. The formed nodules are removed with a special knife.

Welding with a soldering iron

An ordinary electric soldering iron is also suitable for fastening the film in a domestic environment. It is best to put on a student's or poster's nib, made of metal, on its sting. If the polymer is burned through, the tip is slightly shifted from the tip of the device - this reduces the heat transfer area.

Soldering is more reliable if you attach special rollers to the soldering iron. At the tip, the sting is grinded all the way down, a groove is cut in the center of the end, for which a hacksaw is used. You will need a copper disc with a diameter of 1 cm (those who are seriously concerned about the construction of such a device can carve it themselves).

Drill a hole with a diameter of about 5 mm for fastening axles, insert the disc into the slot made and secure. It should rotate freely. To get a smooth weld, follow it along a ruler. The apparatus must be led to the point where the seam ends, without tearing, with pressure. More often this approach is used for sealing bags. To get a beautiful seam, practice a little on the unnecessary pieces.

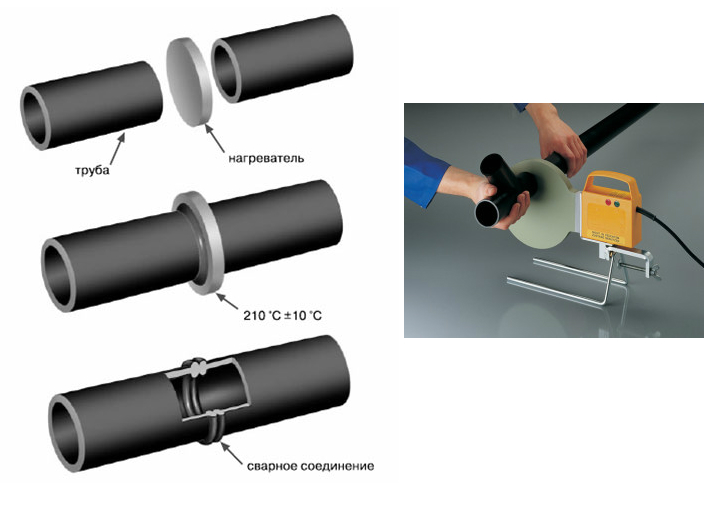

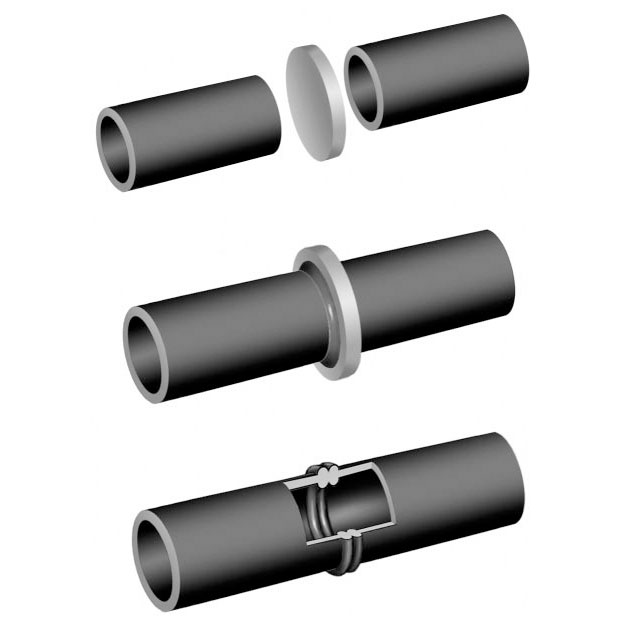

Welding of polyethylene with a heating element (Butt Welding)

Welding of polyethylene with a heating element (also called butt welding) is used to weld plates, blocks and other profiles of semi-finished products. This type of welding is extremely widely used for welding thermoplastic pipelines. Unlike the previous two welding methods, this method does not require the use of filler material.

For welding with a heating element, the so-called. butt welding machines, the principle of operation of which (heating with a heating element of various shapes) is the same, and differing only in the type of drive (manual, mechanical, pneumatic, etc.), which transfers the shear force to the elements to be welded. In addition, butt welding machines can be distinguished by a complete set of special equipment and all kinds of options - for example, for welding sheets at an angle, for folding sheets to be welded.

Some types of butt welding machines, in addition to HDPE, also allow welding of HMPE and UHMWPE.

When welding polyethylene end-to-end, the required heat is supplied directly from the heating element to the welding zone of the surfaces to be joined. In this way, a more favorable heat distribution is achieved, so that none of the zones of the material is more heat loaded than the other. In addition, the mating surfaces of the heating element must be clean and completely adjoining. This type of weld shows little internal stress and can be loaded in much the same way as the original material.

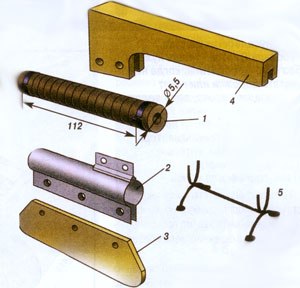

Application of a soldering iron for welding film

Joining polyethylene sheets using a conventional soldering iron (40-60 W) allows you to get a strong seam, while minor tool modifications are required. Using a soldering iron without special tips will not give a high-quality result. The joint will be uneven, the formation of spreading points of the material is possible.

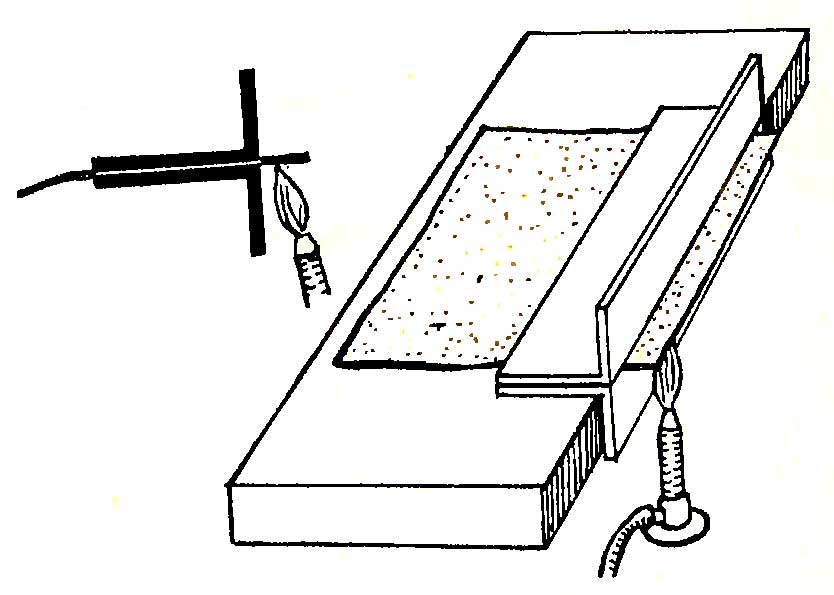

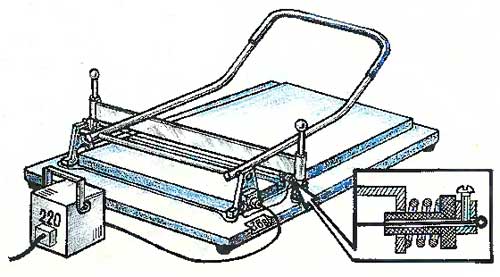

Film welding scheme.

To obtain a good result and weld joints of significant length, the use of additional devices will be required. There are several options for modifying the soldering iron.

An ordinary soldering iron is taken, then the tip of the tip is removed from it. Using a hacksaw, a cut is created. After that, a plate of copper or aluminum is inserted into the cut, which is fixed with a rivet. The surface of the plate is processed, its edges are rounded off with a file. Welding is carried out by slightly pressing the soldering iron at an angle of 45 ° and moving it uniformly.

Temperature and pressure are selected empirically. When creating a joint, it is recommended to put a flat wooden or textolite substrate under the bottom layer of the film, and center the soldering iron on a flat bar. In some cases, thin paper will interfere between the plate and the film. This is important if you are welding a thin film. After creating the seam, the paper is carefully separated.

An approximate sample of the nozzle is shown in Fig. 1 (1 - plate; 2 - soldering iron and its rod).

Ultrasonic welding diagram.

It is possible to install the disc into a separate tip tube, and it, in turn, is put on the tip of the soldering iron. Pieces of film are welded by rolling a heated soldering iron to the required distance. The amount of pressure is regulated depending on the seam welding. This method allows you to carry out a significant amount of work.

Do-it-yourself film soldering

Polyethylene pipelines are installed in two ways: using fittings and flanges or several types of welding.

The connection requires special fittings (couplings and sockets) and without them. For pipes with a wall thickness of less than 4.5 (diameters 50-110 mm), welding using fittings is used, for larger pipes with a thicker wall, butt welding and extruder are acceptable.

Diffusion

The diffusion method consists in heating the ends to a viscous-flow state. The prepared ends of the blanks are joined and slightly compressed. Under the influence of pressure, mobile polymer molecules move into the parts to be joined, mix, when cooled, solidify in a new position, form new chemical bonds and ensure reliable adhesion of the pipes to each other.

Bell method

Not the most typical way. There are two variants of execution: by means of socket pipes and couplings. The method itself resembles the welding of polypropylene pipelines: a socket or couplings and workpieces are heated using a soldering iron with a special nozzle.

Then the workpiece is inserted into the socket of another pipe or coupling, fixed, pressed and held. The welding time is 20 seconds. If couplings are used, then the second pipe is soldered into the coupling in the same way. The cost of couplings is low, products with a socket are rarely found in stores.

The connection is reliable and durable, small diameters can be welded.

Butt welding

Before carrying out work, cut the polyethylene pipe strictly perpendicularly and carefully clean the ends. Then the pipe is fixed in the welding machine and carefully centered.

Cool the joint, then remove the machine. The work has its own subtleties, it requires two people.

Extruder welding

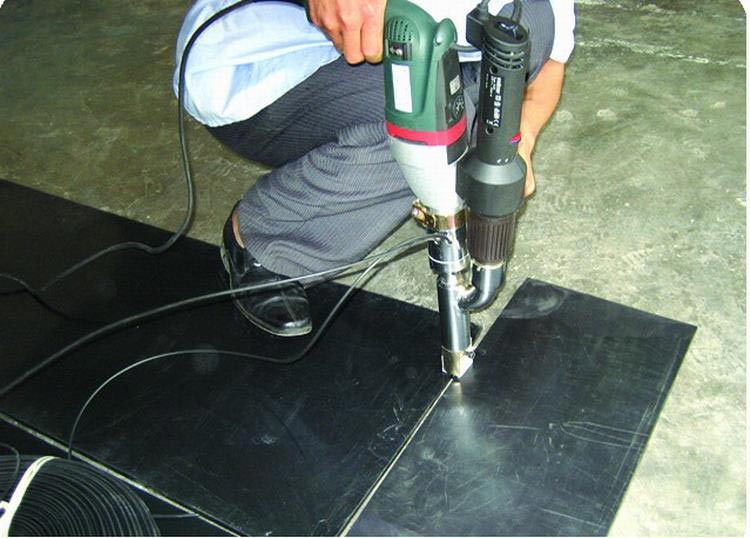

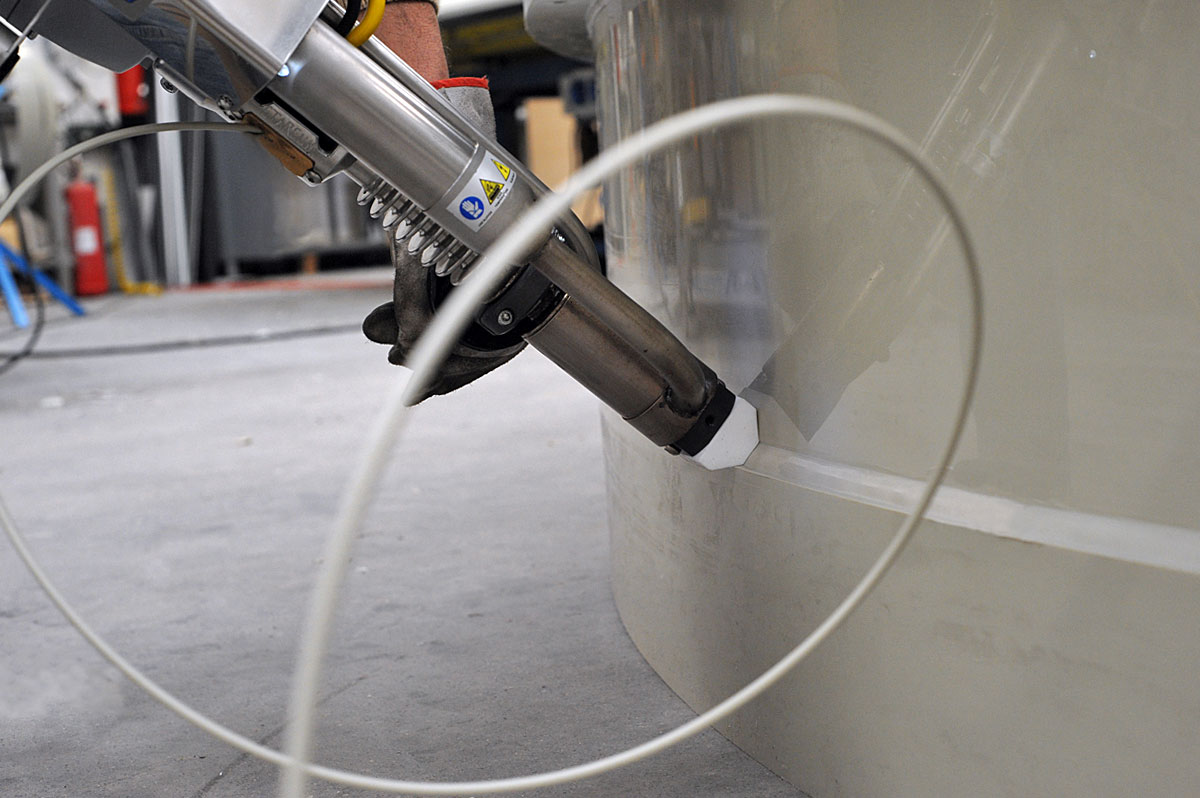

Extrusion - welding using a small apparatus, from which molten polyethylene is squeezed out under pressure. Raw materials in the form of rods or pellets are loaded into the extruder.

Extrusion is used on pressure lines with a wall thickness of more than 6 mm, but it can also be used to patch up non-pressure sewer pipelines with a thinner wall. The junction is heated by a stream of hot air.

It is advisable to chamfer the ends.

Instruments and devices

Iron soldering

This is a fairly simple way to connect parts of the canvases, because there are household irons in almost every home.

To connect polyethylene in this way, you need to place a wooden block on the table. On this kind of stand, the edges of the connected canvases are located.

They should protrude from the edges of the bar by twenty millimeters. From above, the polyethylene is covered with a sheet of refractory material (cellophane, fluoroplastic film).

The formation of the seam can be accelerated by subsequent cooling. To do this, after exposure to high temperatures, the joint is treated with a wet rag.

The iron tilts five degrees when swiping over the junction. You need to move it slowly, along the joint. Once it is not enough to form a strong seam, the procedure must be repeated about four to five times.

Also, to work with the iron, special soldering tips are used, which are fixed on top of the device. They have a flat ribbed base.

Soldering with a soldering iron

A home soldering iron with a power of 40-60W is used to weld two sheets of film. However, this apparatus needs some improvement to do this job.

To work with polyethylene material, the tip of the tip is removed from the soldering iron. After that, a cut is created, into which a plate of aluminum or copper is inserted. The plate is fixed with a rivet, processed and rounded with a file.

The impact on the joint of the canvases is made at an angle of forty-five degrees. The soldering iron is pressed against the surface, and then slowly moves along the joint. The movement should be uniform, without jerking or stopping.

The wheel is a disc with a diameter of eight to ten millimeters. The disc material can be aluminum or copper.

You can make it yourself. The metal wheel is placed in the cut, in which it is fixed with an axle. The method of connecting with a wheel is based on heating it with further rolling along the joint.

Special equipment

When choosing equipment, foresight is necessary

It is important to consider the complexity of the work. To cope with large volumes of films, industrial equipment is used.

Special devices are used to connect polyethylene. Their cost is different. It is worth noting the budget model PP-40.

It allows you to get an even and strong seam on any contour: straight or complex. PP-40 is shaped like a soldering iron, but has a different tip.

They also use special nozzles for electric irons. They are made from sheet metal such as aluminum. The base of the nozzles is made flat and ribbed. Such a surface firmly fixes the film joint during welding.

The edges of the film are fixed with ribs. After that, the rail is moved along the section to be welded. This creates a double seam.

Large jobs require more serious tools. To create a joint of a large area of film, you need special equipment for welding.

Such equipment is equipped with settings for the pressure level, temperature, speed of movement of the heated element over the surface of polyethylene. In household options for the formation of film seams, there are no such functions.

In addition to adjustment knobs, soldering machines are equipped with roller mechanisms. These are the driving and tensioning elements that stabilize the advance speed of the film webs to be welded.

This improves the quality of polyethylene soldering, increases the strength of the joint.

There are devices that use different heating methods: air and contact. Air heating is produced by exposing the material to hot air. With a contact, a heating element in contact with the material is involved.

Using an iron as a welding heater

The next popular method is to melt the film and create a seam using an iron. The advantage of this method is that large portions of the film can be sealed in this way, while creating the desired seam width. Since any iron has a thermal relay and the ability to adjust the temperature, it will not be difficult to choose the required thermal mode for polyethylene of various thicknesses.

The welding process is best done on a smooth wooden surface.Pieces (sheets) of the film are overlapped, the width of which is selected individually, then the top layer is covered with paper or fluoroplastic sheet, after which the iron is pressed and held along the welding line. The clamping force, speed and temperature are selected empirically.

The attachment is made of brass, copper or aluminum.

Conclusion

Welding of polyethylene film is quite feasible at home. Simple household appliances like an iron or a soldering iron are used for it. The soldering iron, however, will require some modifications.

For larger jobs, it is worth using special equipment. It has a list of settings that improve the quality and speed of seam formation.

This will help with protective clothing that does not leave exposed skin, gloves. Glasses and a mask to protect the face and eyes are also desirable.

In the absence of understanding the nuances of technologies and minimal experience in welding polyethylene, you need to contact professionals.