Peculiarities

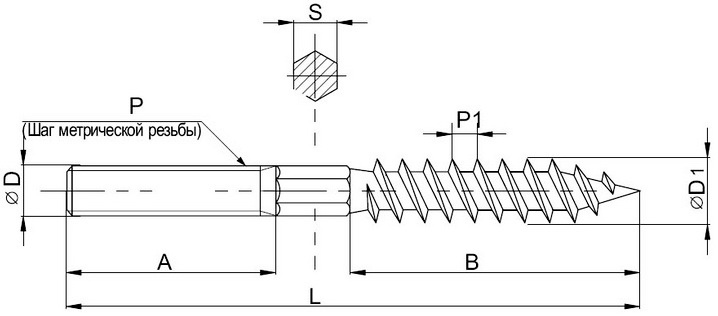

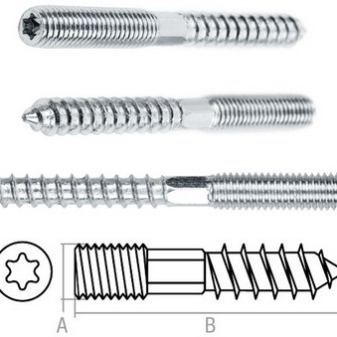

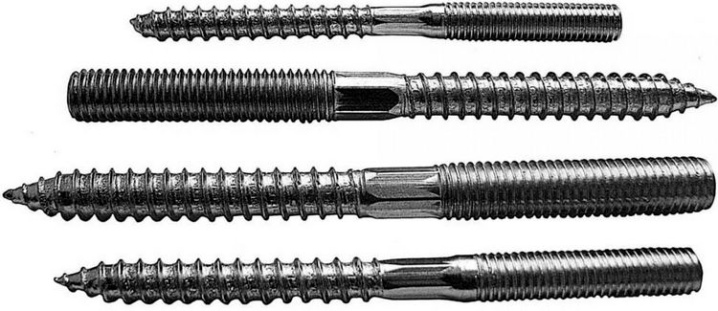

A stud screw is often called a screw or a plumbing bolt. Its design is straightforward. This is a cylindrical rod, which consists of two parts: one is presented in the form of a metric thread, the other - in the form of a self-tapping screw... Between the components there is a hexagon, which is designed to grip the stud with a special suitable wrench.

All stud screws are manufactured in accordance with the requirements of regulatory documents. Each manufacturing enterprise that manufactures this product must be guided by documents such as 22038-76 and GOST 1759.4-87 “Bolts. Screws and studs. Mechanical properties and tests ".

According to these regulatory documents, the stud screw must be:

- durable;

- wear-resistant;

- resistant to various negative influences;

- reliable.

One of the most important criteria for a product is a long service life. To achieve all the above parameters, only high-quality materials are used for the manufacture of fasteners that have excellent physical and technical properties.

The production uses high-quality steel, the strength class of which is not less than 4.8. The finished product is treated with a special zinc coating, which improves its properties. The presence of a zinc coating on the surface helps prevent corrosion.

The plumbing pin is characterized by the following parameters:

- screw diameter;

- screw length;

- coating;

- type of thread;

- metric thread pitch;

- screw thread pitch;

- turnkey size.

Each of these parameters is clearly specified in the regulatory documents.

A prerequisite is laboratory tests, after which the product is marked. Its presence confirms the quality and technical parameters of the product.

Types and sizes

Today, manufacturers make many different stud screws, each of which is characterized by certain parameters and dimensions. You can get acquainted with them in detail by looking at the table.

|

Product type |

Metric thread |

Length, mm |

Metric thread pitch, mm |

Screw thread pitch, mm |

Metric thread diameter, mm |

Screw thread length, mm |

Turnkey size, mm |

|

М4 |

М4 |

100, 200 |

0,7 |

0,7 |

4 |

20 |

4 |

|

M5 |

M5 |

100, 200 |

0,8 |

0,8 |

5 |

20 |

4 |

|

M6 |

M6 |

100, 200 |

1 |

1 |

6 |

25 |

4 |

|

М8 |

М8 |

100, 200 |

1,25 |

1,25 |

8 |

20 |

4 |

|

М8х80 |

М8 |

80 |

1,25 |

3-3,2 |

6,85-7,00 |

20 |

5,75-6,00 |

|

М8х100 |

М8 |

100 |

1,25 |

3-3,2 |

6,85-7,00 |

40 |

5,75-6,00 |

|

М8х120 |

М8 |

120 |

1,25 |

3-3,2 |

6,85-7,00 |

40 |

5,75-6,00 |

|

М8х200 |

М8 |

200 |

1,25 |

3-3,2 |

6,85-7,00 |

40 |

5,75-6,00 |

|

M10 |

M10 |

3-3,2 |

8,85-9,00 |

40 |

7,75-8,00 |

||

|

М10х100 |

M10 |

100 |

1,5 |

3-3,2 |

8,85-9,00 |

40 |

7,75-8,00 |

|

М10х200 |

M10 |

200 |

1,5 |

3-3,2 |

8,85-9,00 |

40 |

7,75-8,00 |

|

M12 |

M12 |

100, 200 |

1,75 |

1,75 |

12 |

60 |

7,75-8,00 |

It is imperative to take into account all the above parameters when choosing and buying a stud screw. You also need to understand that each type of product is designed for fastening certain materials.

In addition to these types of fasteners, there are others. More detailed information on each type of hairpin can be found at specialized points of sale. Today, you can buy a stud screw at absolutely any store that specializes in the sale of various fasteners.