1 Screw with ring - design and function

The ring screw is a fastener made of hardened carbon steel with a zinc coating that protects against corrosion, thereby extending its service life in wet conditions. This hardware owes its name to the design features. The working part, with the help of which the fastening takes place, has a geometry like a conventional screw - a discharged screw thread with a pointed end. But instead of the usual turnkey hat or screwdriver, this product has a ring that is a continuation of the screw and has the correct shape.

The screw, equipped with a ring, is designed for fastening both to soft materials (wood, plastic, etc.) and to hard materials (concrete, brick, others), but using a plastic dowel of appropriate dimensions. When screwing is not done in hard wood, you can do without drilling a hole for a screw. In all other cases, preliminary drilling is carried out. Hole diameter for a product with a ring:

- when fastening it to soft materials (plastic, wood), it should be 50–70% of the screw diameter;

- when fastened to solid (concrete, brick) it is equal to the diameter of a special plastic dowel, which is installed in the drilled hole before screwing in the screw.

2 Scope and method of application of screw-like products with a ring

This screw is used for mounting or hanging light materials, non-lifting devices. This is due to the design of the ring - it is not welded to the metal rod and can bend under significant loads. The main working position of the screw is horizontal, it is mounted in walls and other vertical surfaces.

In this case, the screwed-in part of the product expands in the hole and is reliably held in it, and the thread in the installation material and on the screw itself does not experience pulling or pulling forces. Horizontal mounting allows you to load a product with a ring up to the values for which the screw itself and the material of its installation are designed. When mounted vertically, especially with the ring down (into the ceiling, for example), the load forces of suspended structures, objects affect the threads of the screw and the material into which it is screwed.

In this case, there is a high probability that the fixed massive objects will simply tear the hardware out of the mounting hole. Therefore, a product with a ring is not suitable for hanging chandeliers. A product with a ring is used mainly for fastening, hanging non-removable hinged structures and frames, ropes, fabric, ropes, lanterns, cable laying, and so on. This screw is widely used in household needs.

Hardware is mounted, as a rule, by hand or using tools such as a screwdriver, pliers, metal bar, and others. When installing using a plastic dowel, the prepared hole must be thoroughly cleaned of drilling products - ideally with a vacuum cleaner. Hole dimensions must be as specified by the manufacturer. First, a dowel is inserted, into which the hardware is then screwed.

A screw-ring is selected, the dimensions of which are represented by the values of 3-12 mm in diameter and 10-350 mm in length with ring diameters up to 23 mm, based on the expected load, the type of the object to be fixed, the material and structure of the bearing surface, the structure (the presence of insulating materials, plaster and the like). The plastic dowel is chosen with a length equal to the screw-in depth of the hardware, with a diameter in accordance with the section of the screw and the nature of the fastening material.

Application

Depending on the strength of the material to which the screws are attached, they can be immersed in the following ways:

- hammer into soft structures of wood or slabs based on it;

- twist without preliminary drilling into wood, plastic and other non-rigid materials;

- screw into a pre-drilled hole, which is 0.7 of the outer diameter of the screw thread, while simultaneously cutting the internal thread in the wood structure or on metal sheet;

- screw into a pre-drilled hole of a larger diameter with an insert made of a plastic dowel, for example, into a concrete or brick wall;

- simultaneously drill and thread when screwing special screws into the metal structure of standard steel structures such as a corner, channel, etc.

But regardless of the method of immersion, the screw can always be unscrewed - this is considered one of its main advantages.

How to unscrew a screw with torn edges

In a situation where, when screwing in or unscrewing the screw, the edges scrolled and it is no longer possible to turn it with a standard tool, if the head is not fully immersed and protrudes at least a little above the surface, then you can try to unscrew it with the help of good pliers. To do this, it is necessary to strongly squeeze the protruding part of the screw head with the jaws of a locksmith tool and slowly begin to unscrew the rod.

If the screw is screwed into the surface flush and "tightly", then it is not possible to remove it in a simple way without damage. Then you need to resort to a proven method and use a special device such as an extractor for unscrewing screws.

You can get acquainted with the various ways how you can unscrew a screw with torn off edges in the video:

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

3 Scaffolding screw

The scaffold ring screw is a variation of the product described above. Its main difference from the previous version is that the ring is not just adjacent to the screw shaft, but welded to it. This feature provides a more secure attachment of suspended objects. And since the ring is welded, and therefore cannot bend, such a screw can withstand loads much greater than the non-welded version.

There is also a model (for higher loads) with a round stop plate under the ring for additional retention. Otherwise, the design, material, dimensions of the scaffold screws are the same as those with a simple ring. The diameters of welded products can be up to 16 mm.

These products are mainly used for attaching scaffolding to walls and facades of buildings, supporting frames to natural stone, brickwork, concrete, and so on. When installing hardware, use a plastic dowel. The scaffolds are fastened to the product ring. In addition, the weld screw is well suited for attaching suspended structures and objects to wood. The mounting method is the same as working with a product with a conventional ring. The maximum permissible bearing load is only possible when:

- the dimensions of the prepared hole exactly correspond to those indicated by the manufacturer;

- after drilling, the hole was cleaned or blown out with a vacuum cleaner.

Factors that reduce the bearing capacity include the heterogeneity of the material into which the screw is installed, unaccounted plaster, the presence of voids, close drilling of the hole to the corners of the walls, brick seams.The corresponding safety factors should also be taken into account. After dismantling the scaffolding, other objects and unscrewing the screw, the hole is closed with a special plug. The protective plate adheres optimally to the edges of the hole, insulates it and the dowel (if present) from moisture penetration.

Wood grouse screw

The wood grouse screw is made with a hexagon-shaped head, while the diameter of the rod is from 5 mm to 15 mm and has a length of the order of 30 mm to 350 mm. Wood grouse screws are used exclusively in construction for fastening massive wooden structures, as they are able to withstand significant lateral and longitudinal loads.

The size of the hole should correspond to the diameter of the neck, and the depth of drilling should be equal to the length of the immersed part of the rod, and when fixing hard wood, it is necessary to drill to a greater length than the length of the screw in order to avoid cracking of the wood structure.

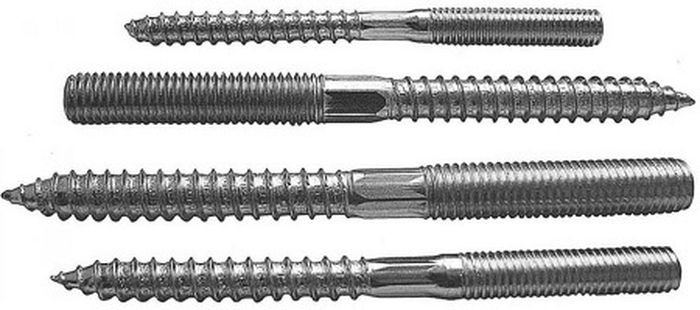

Stud screw

The hairpin screw is made in the form of a steel rod on one part of which the thread is made as in a conventional self-tapping screw, and on the other part a metric thread is cut for the possibility of fastening the bracket with a nut.

This type of screw is intended for fastening various types of brackets, but is mainly used in conjunction with plastic dowels for concrete and brick walls or surfaces lined with ceramic tiles.

A device that transmits a torque to a threaded connection in a stud screw is made of two types:

- with a slot at the end on the side of the metric thread for a Torx screwdriver attachment;

- with a hexagon wrench made on the rod between the screw thread and the metric thread.

Mounting

For the installation of ring screws, first of all, it is worthwhile to calculate their number, which directly depends on the amount of work, the quality characteristics of the materials to be fastened, and the size of the products. The calculation of the exact number of hardware can only be carried out individually.

Fastening a self-tapping hook to a surface can be done by hand or using tools. In this case, you can use a screwdriver or a metal rod. To fasten the screw on a wooden surface, you will need to drill a hole and then start screwing the hardware inside. If you need to insert the product into concrete or brick, you will initially need to insert a spacer plastic dowel into the hole.

The principle of fixing a screw with a ring is practically no different from the procedure with other self-tapping screws. The algorithm traces the need to perform the following actions:

- drilling a hole - brick, concrete or stone walls are often the working surface;

- cleaning the surface from existing debris and dust;

- installation of a plastic dowel;

- screwing in a screw.

To select the correct hole diameter, you can take into account the following recommendations:

- if the hardware will be fixed to a solid surface, then the characteristics of the hole must match the dowel dimensions;

- if the screw ring is attached to a soft plane, then the hole diameter must be approximately 50-70 percent of the product diameter.

Fastening the screw may fail and there are several reasons for this:

- heterogeneity of the structure of the material into which the hardware was mounted:

- the presence of voids in the plaster;

- close proximity of the drilled hole to the corner, wall, brick joint.

After dismantling and unscrewing the hardware from the hole, the latter must be closed with a specially designed plug.

The next video tells about life hacks when attaching ring screws.

Price list

| Name | Unit rev. | Retail price (rub) | Wholesale price (rub) | YOUR SPECIAL.Price, rub) |

| Hook screw ring | ||||

| Screw - hook ring 3.0 * 16 | PCS. | 1,60 | 1,12 | * |

| Screw - hook ring 3.0 * 30 | PCS. | 2,20 | 1,54 | * |

| Screw - hook ring 3.5 * 16 | PCS. | 1,80 | 1,26 | * |

| Screw - hook ring 3.5 * 30 | PCS. | 2,40 | 1,68 | * |

| Screw - hook ring 3.5 * 40 | PCS. | 2,50 | 1,75 | * |

| Screw - hook ring 3.5 * 45 | PCS. | 2,80 | 1,96 | * |

| Screw - hook ring 4.0 * 20 | PCS. | 3,60 | 2,52 | * |

| Screw - hook ring 4.0 * 40 | PCS. | 3,80 | 2,66 | * |

| Screw - hook ring 4.0 * 50 | PCS. | 4,00 | 2,80 | * |

| Screw - hook ring 4.0 * 60 | PCS. | 4,20 | 2,94 | * |

| Screw - hook ring 4.0 * 70 | PCS. | 4,50 | 3,15 | * |

| Screw - hook ring 5.0 * 30 | PCS. | 5,60 | 3,92 | * |

| Screw - hook ring 5.0 * 50 | PCS. | 6,00 | 4,20 | * |

| Screw - hook ring 5.0 * 60 | PCS. | 6,40 | 4,48 | * |

| Screw - hook ring 5.0 * 75 | PCS. | 7,20 | 5,04 | * |

| Screw - hook ring 5.0 * 80 | PCS. | 8,40 | 5,88 | * |

| Screw - hook ring 6.0 * 50 | PCS. | 9,40 | 6,58 | * |

| Screw - hook ring 6.0 * 60 | PCS. | 10,00 | 7,00 | * |

| Screw - hook ring 6.0 * 65 | PCS. | 10,60 | 7,42 | * |

| Screw - hook ring 6.0 * 70 | PCS. | 10,80 | 7,56 | * |

| Screw - hook ring 6.0 * 80 | PCS. | 11,00 | 7,70 | * |

| Screw - hook ring 6.0 * 100 | PCS. | 14,40 | 10,08 | * |

| Screw - hook ring 8.0 * 50 | PCS. | 14,80 | 10,36 | * |

| Screw - hook ring 8.0 * 70 | PCS. | 18,00 | 12,60 | * |

| Screw - hook ring 8.0 * 80 | PCS. | 22,00 | 15,40 | * |

| Screw - hook ring 8.0 * 100 | PCS. | 24,00 | 16,80 | * |

| Hook screw half ring | ||||

| Screw - hook half ring 3.0 * 16 | PCS. | 1,30 | 0,91 | * |

| Screw - hook half ring 3.0 * 30 | PCS. | 1,50 | 1,05 | * |

| Screw - hook half ring 3.5 * 30 | PCS. | 2,50 | 1,75 | * |

| Screw - hook half ring 3.5 * 45 | PCS. | 2,80 | 1,96 | * |

| Screw - hook half ring 4.0 * 20 | PCS. | 3,00 | 2,10 | * |

| Screw - hook half ring 4.0 * 30 | PCS. | 3,50 | 2,45 | * |

| Screw - hook half ring 4.0 * 40 | PCS. | 4,00 | 2,80 | * |

| Screw - hook half ring 4,0 * 50 | PCS. | 4,30 | 3,01 | * |

| Screw - hook half ring 4.0 * 65 | PCS. | 4,50 | 3,15 | * |

| Screw - hook half ring 4,0 * 70 | PCS. | 4,60 | 3,22 | * |

| Screw - hook half ring 5.0 * 30 | PCS. | 5,00 | 3,50 | * |

| Screw - hook half ring 5.0 * 45 | PCS. | 4,30 | 3,01 | * |

| Screw - hook half ring 5.0 * 50 | PCS. | 5,60 | 3,92 | * |

| Screw - hook half ring 5.0 * 60 | PCS. | 6,60 | 4,62 | * |

| Screw - hook half ring 5.0 * 70 | PCS. | 7,00 | 4,90 | * |

| Screw - hook half ring 5.0 * 80 | PCS. | 7,20 | 5,04 | * |

| Screw - hook half ring 6,0 * 30 | PCS. | 7,10 | 4,97 | * |

| Screw - hook half ring 6.0 * 40 | PCS. | 7,40 | 5,18 | * |

| Screw - hook half ring 6,0 * 50 | PCS. | 7,80 | 5,46 | * |

| Screw - hook half ring 6.0 * 60 | PCS. | 8,60 | 6,02 | * |

| Screw - hook half ring 6.0 * 75 | PCS. | 11,60 | 8,12 | * |

| Screw - hook half ring 6.0 * 80 | PCS. | 12,00 | 8,40 | * |

| Screw - hook half ring 6,0 * 100 | PCS. | 14,40 | 10,08 | * |

| Screw - hook half ring 8.0 * 50 | PCS. | 12,00 | 8,40 | * |

| Screw - hook half ring 8.0 * 70 | PCS. | 14,40 | 10,08 | * |

| Screw - hook half ring 8.0 * 80 | PCS. | 20,40 | 14,28 | * |

| Screw - hook half ring 8.0 * 90 | PCS. | 25,60 | 17,92 | * |

| Screw - hook half ring 8.0 * 100 | PCS. | 28,20 | 19,74 | * |

| Hook screw straight | ||||

| Screw - straight hook 10 * 100 | PCS. | 16,80 | 11,76 | * |

| Screw - hook straight 10 * 120 | PCS. | 19,80 | 13,86 | * |

| Screw - straight hook 3.0 * 30 | PCS. | 1,90 | 1,33 | * |

| Screw - straight hook 3.0 * 35 | PCS. | 2,00 | 1,40 | * |

| Screw - straight hook 3.0 * 40 | PCS. | 2,10 | 1,47 | * |

| Screw - straight hook 3.5 * 45 | PCS. | 2,30 | 1,61 | * |

| Screw - straight hook 4,0 * 40 | PCS. | 2,80 | 1,96 | * |

| Screw - straight hook 4,0 * 44 | PCS. | 3,30 | 2,31 | * |

| Screw - straight hook 4,0 * 50 | PCS. | 4,00 | 2,80 | * |

| Screw - straight hook 4,0 * 60 | PCS. | 4,50 | 3,15 | * |

| Screw - straight hook 4,0 * 70 | PCS. | 5,00 | 3,50 | * |

| Screw - straight hook 5.0 * 40 | PCS. | 3,80 | 2,66 | * |

| Screw - straight hook 5.0 * 50 | PCS. | 4,80 | 3,36 | * |

| Screw - hook straight 5.0 * 52 | PCS. | 5,20 | 3,64 | * |

| Screw - straight hook 5.0 * 70 | PCS. | 6,40 | 4,48 | * |

| Screw - straight hook 5.0 * 80 | PCS. | 6,80 | 4,76 | * |

| Screw - straight hook 6,0 * 40 | PCS. | 5,00 | 3,50 | * |

| Screw - straight hook 6,0 * 60 | PCS. | 5,80 | 4,06 | * |

| Screw - straight hook 6,0 * 65 | PCS. | 6,20 | 4,34 | * |

| Screw - straight hook 6,0 * 68 | PCS. | 6,40 | 4,48 | * |

| Screw - hook straight 6,0 * 75 | PCS. | 6,60 | 4,62 | * |

| Screw - straight hook 6,0 * 80 | PCS. | 7,20 | 5,04 | * |

| Screw - straight hook 6,0 * 100 | PCS. | 10,00 | 7,00 | * |

| Screw - straight hook 8.0 * 100 | PCS. | 18,80 | 13,16 | * |

| Screw - hook straight 8,0 * 120 | PCS. | 16,40 | 11,48 | * |

| Screw - hook straight 8,0 * 80 | PCS. | 15,80 | 11,06 | * |

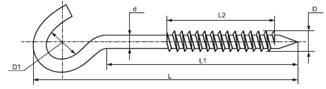

Half-ring screw

Features: Material: 1008 steel Thread: rare pitch Tip: sharp Finish: white zinc

Specifications

| Designation | L length with a half ring, mm | L1 length without ring, mm | L2 thread length, mm | d inner diameter, mm | D outer diameter, mm | D1 hook inner diameter, mm |

| 3*10 | 20,80 | 10,00 | 10,00 | 2,40 | 3,00 | 6,00 |

| 3*20 | 30,80 | 20,00 | 12,00 | 2,40 | 3,00 | 6,00 |

| 3*30 | 40,80 | 30,00 | 20,00 | 2,40 | 3,00 | 6,00 |

| 3*40 | 50,80 | 40,00 | 20,00 | 2,40 | 3,00 | 6,00 |

| 3,5*40 | 53,60 | 40,00 | 20,00 | 2,80 | 3,50 | 8,00 |

| 4*15 | 29,00 | 15,00 | 13,00 | 3,00 | 4,00 | 10,00 |

| 4*20 | 34,00 | 20,00 | 13,00 | 3,00 | 4,00 | 10,00 |

| 4*25 | 39,00 | 25,00 | 11,00 | 3,00 | 4,00 | 10,00 |

| 4*30 | 44,00 | 30,00 | 18,00 | 3,00 | 4,00 | 10,00 |

| 4*40 | 58,00 | 40,00 | 20,00 | 3,00 | 4,00 | 10,00 |

| 4*50 | 70,00 | 50,00 | 25,00 | 3,00 | 4,00 | 10,00 |

| 4*60 | 80,00 | 60,00 | 25,00 | 3,00 | 4,00 | 12,00 |

| 4*70 | 90,00 | 70,00 | 19,00 | 3,00 | 4,00 | 12,00 |

| 4*80 | 100,00 | 80,00 | 18,00 | 3,00 | 4,00 | 12,00 |

| 5*30 | 51,60 | 30,00 | 15,00 | 3,80 | 5,00 | 12,00 |

| 5*40 | 61,60 | 40,00 | 20,00 | 3,80 | 5,00 | 12,00 |

| 5*50 | 71,60 | 50,00 | 25,00 | 3,80 | 5,00 | 12,00 |

| 5*60 | 83,60 | 60,00 | 32,00 | 3,80 | 5,00 | 12,00 |

| 5*65 | 90,00 | 65,00 | 32,00 | 3,80 | 5,00 | 14,00 |

| 5*70 | 93,60 | 70,00 | 32,00 | 3,80 | 5,00 | 14,00 |

| 5*80 | 103,60 | 80,00 | 32,00 | 3,80 | 5,00 | 14,00 |

| 5*85 | 110,00 | 85,00 | 28,00 | 3,80 | 5,00 | 14,00 |

| 5*90 | 113,60 | 90,00 | 32,00 | 3,80 | 5,00 | 14,00 |

| 5*100 | 123,60 | 100,00 | 32,00 | 3,80 | 5,00 | 14,00 |

| 6*40 | 67,60 | 40,00 | 25,00 | 4,80 | 6,00 | 14,00 |

| 6*50 | 77,60 | 50,00 | 32,00 | 4,80 | 6,00 | 14,00 |

| 6*60 | 87,60 | 60,00 | 32,00 | 4,80 | 6,00 | 14,00 |

| 6*70 | 97,60 | 70,00 | 38,00 | 4,80 | 6,00 | 14,00 |

| 6*80 | 107,60 | 80,00 | 38,00 | 4,80 | 6,00 | 14,00 |

| 6*100 | 127,60 | 100,00 | 38,00 | 4,80 | 6,00 | 16,00 |

| 6*120 | 147,60 | 120,00 | 38,00 | 4,80 | 6,00 | 16,00 |

| 6*140 | 167,60 | 140,00 | 38,00 | 4,80 | 6,00 | 16,00 |

| 8*60 | 96,30 | 60,00 | 38,00 | 6,15 | 8,00 | 18,00 |

| 8*70 | 106,30 | 70,00 | 38,00 | 6,15 | 8,00 | 18,00 |

| 8*80 | 116,30 | 80,00 | 38,00 | 6,15 | 8,00 | 18,00 |

| 8*90 | 126,30 | 90,00 | 27,00 | 6,15 | 8,00 | 18,00 |

| 8*100 | 136,30 | 100,00 | 51,00 | 6,15 | 8,00 | 18,00 |

| 8*120 | 156,30 | 120,00 | 51,00 | 6,15 | 8,00 | 18,00 |

| 8*140 | 176,30 | 140,00 | 51,00 | 6,15 | 8,00 | 20,00 |

| 8*150 | 186,30 | 150,00 | 44,00 | 6,15 | 8,00 | 20,00 |

| 8*200 | 236,30 | 200,00 | 46,00 | 6,15 | 8,00 | 20,00 |

| 10*80 | 122,00 | 80,00 | 51,00 | 8,00 | 10,00 | 24,00 |

| 10*100 | 142,00 | 100,00 | 51,00 | 8,00 | 10,00 | 24,00 |

| 10*120 | 162,00 | 120,00 | 51,00 | 8,00 | 10,00 | 24,00 |

| 10*140 | 182,00 | 140,00 | 65,00 | 8,00 | 10,00 | 24,00 |

| 10*150 | 192,00 | 150,00 | 65,00 | 8,00 | 10,00 | 24,00 |

| 10*160 | 202,00 | 160,00 | 65,00 | 8,00 | 10,00 | 24,00 |

| 10*180 | 222,00 | 180,00 | 65,00 | 8,00 | 10,00 | 24,00 |

| 10*200 | 242,00 | 200,00 | 65,00 | 8,00 | 10,00 | 24,00 |

Weight 1000 pieces, kg

| Diameter, mm | Length | |||||||||

| 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 65 | 70 | |

| 3 | 1,80 | 2,05 | 2,47 | 2,78 | ||||||

| 3,5 | 6,20 | |||||||||

| 4 | 3,39 | 3,10 | 3,73 | 3,94 | 4,76 | 5,29 | 5,99 | 6,58 | ||

| 5 | 7,00 | 8,47 | 9,62 | 10,64 | 9,30 | 11,63 | ||||

| 6 | 14,93 | 15,15 | 15,15 | 17,10 | ||||||

| 8 | 37,04 | 42,25 | ||||||||

| 10 |

| Diameter, mm | Length | |||||||||

| 80 | 85 | 90 | 100 | 120 | 140 | 150 | 160 | 180 | 200 | |

| 3 | ||||||||||

| 3,5 | ||||||||||

| 4 | 7,00 | |||||||||

| 5 | 12,66 | 10,80 | 13,70 | 14,49 | ||||||

| 6 | 18,52 | 21,74 | 24,39 | 27,03 | ||||||

| 8 | 41,67 | 48,39 | 50,00 | 55,56 | 63,83 | 66,67 | 83,33 | |||

| 10 | 52,63 | 62,50 | 71,43 | 76,92 | 76,92 | 81,08 | 100,00 | 111,11 |

Application: It is used for household needs of the device of fastening of light type. It is mounted in wood and complete with a dowel in concrete, brick, foam concrete, etc.

Peculiarities

A ring screw is called hardware, which is used for suspended structures or with large volumes. The self-tapping hook makes the installation process of the above items easier and faster. This element is called a screw ring, since it has a special design.

- A head that looks like a ring or half ring. In this case, the hook at the end continues the structure, and is not located as a separate element.

- Screw thread. With the help of this part of the hardware, immersion in the object is carried out.

The self-tapping hook is characterized by horizontal position in the working position. Its installation is usually carried out into walls or other vertical surfaces. This type of installation contributes to a certain loading of the screw to the maximum possible rate. The screw ring holds objects according to a simple principle: the thread expands in the material, and the screwed part in the hole made.In this case, the hardware is leveled and stretched.

The ring screw is made from a hardened type of carbon steel. From above, the surface of the product is coated with zinc, which protects it from corrosion. Bending of the screw occurs from steel wire, while the shape of the half-ring is observed.

The self-tapping hook has found its application with lightweight rigging items. With the help of this self-tapping screw, cables are laid and lights are attached. In construction, with its help, the forest is fixed to the facade of the building. It is not recommended to fix large objects with the ring downwards, as due to the high load on the thread, the product may fall. The manufacture of screws is strictly regulated by GOSTs, in particular GOST 1145-80, 1144-80.

The use of hardware can be directed to various needs. The ring screw is used both inside and outside buildings. Regardless of the operating conditions, external factors such as moisture can affect the device. Due to atmospheric precipitation, hardware often rusts, so the manufacturer often covers them with a special protective layer.

4 Semi-ring screw and its L-shaped analogue

A half-ring screw, also called a hook screw, is similar in design and manufacturing method to products with a ring. The difference from them lies in the absence of a specific element for hanging, instead of which there is a regular-shaped semi-ring. These hardware are produced in the same sizes as with a ring. The installation method for soft and hard materials is also identical.

Hook screw is recommended for fastening light materials, objects. Its main purpose is the hinged installation of various decorative structures. It is widely used for household needs. An analogue of a product with a half-ring is an L-shaped screw-hook (rectangular), which has the same field of application.