Compaction and moisture content

The weight of a cube of building sand also depends on the degree of compaction of this material. Experts, focusing on this indicator, divide the mixture into the following types:

- the state of natural occurrence of sand;

- artificially compacted or compacted material;

- bulk sand mixture.

The more compacted the material, the greater the weight of the sand cube will be. Since builders use in most cases bulk mixes, the purchase should also be made in this form.

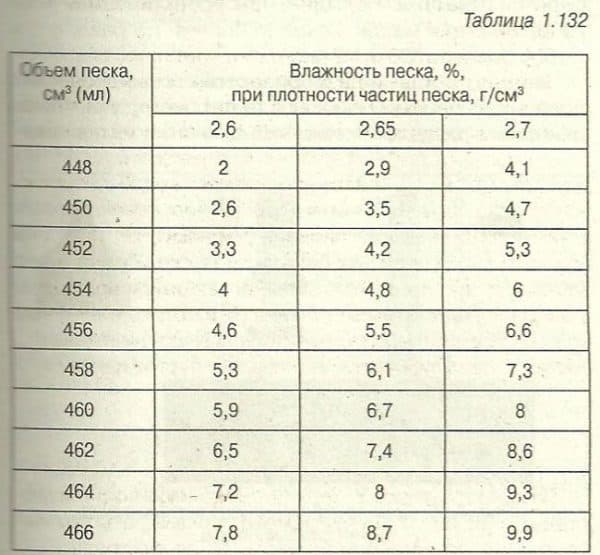

It is worth paying attention to such a physical quantity as humidity. It affects the volume of the material, but not very significantly

Most often, a decision should be made taking it into account in the winter season.

Humidity

This is primarily due to the fact that in frost and in the presence of snow, the amount of water in the sand mass can be about 15 percent of its total weight.

How to determine how much a cube of sand weighs: material characteristics

Many country house owners are trying to calculate how much sand is in one cube. This indicator is especially relevant for suburban construction, affecting such serious arrays of work as the construction of a building or the arrangement of the courtyard and the local area. How much does 1 cube of sand cost with delivery is one of the burning questions of any person who undertakes independent construction or is concerned about the purchase of material for hired workers.

Depending on how many kilograms of sand are in a cube, the basic proportions of the concrete mixture will be calculated. This point is very important, since an incorrect calculation will lead to a violation of technology and serious consequences.

Sand is used for a wide range of construction works

Why is it so important to determine how many cubes of sand are in 1 ton

An indicator reflecting how many kilograms in 1 cube of sand, with erroneous calculations, can cause many difficulties:

- violation of the formulation of a mixture of concrete;

- incorrect consistency of the finished solution;

- loss of adhesive properties;

- poor concrete quality;

- disturbances in the solidification process;

- decrease in the strength of concrete;

- premature destruction of a structure made of cement mortar.

For this reason, it is very important to determine not only how much sand is in 1 cube, but also how much material is contained in this volume.

When calculating the required number of cubes of sand, take into account its specific gravity

The indicator reflecting 1 cube how many kg of sand is contained in a specified volume is called specific gravity or specific gravity. This measure, applicable to bulk materials, is in the range of 1500-2800 kg / m2. Accordingly, you can now estimate how many kg are in a cube of sand.

The specific gravity of a material can be influenced by various factors, including:

- composition of minerals;

- grain composition;

- size of fractions;

- humidity level;

- the percentage of compaction;

- impurities.

Tamping paving slabs using wet sand

Sand density

Today, many are concerned about the cost of a cube of sand, but few know that the final price is influenced by the characteristics of the material, one of which is density. Sand, like crushed stone, belongs to the category of bulk materials. Its density depends on the air spaces that form between the solid particles.

The density of sand is:

- technological;

- real;

- bulk - represents the ratio of the specific gravity of sand to the volume occupied by this material. In this case, the volume includes not only solid particles of sand, but also all the pores, as well as voids in the composition of the embankment (taken as a basis for determining how many cubes of sand are in a bag or bucket);

- true or conditional - the value is considered as the limit of the ratio of the specific gravity of the material to the volume it occupies, minus all pores and voids present in the embankment.

The density of sand varies in the range of 1.3-1.8 t / m ?, and is equal to 1.3 t / m? for river sand, and 1.4 t / m? - for a career.

Density of construction sand is from 1.3 to 1.8 tons per 1 cubic meter

Sand fraction size

How many cubes of material are in a bag of sand can be determined taking into account its grain composition. To do this, it is enough to sift the grains of sand using special sieves. As a result, you will be able to determine the level of content in the material of gravel particles with certain dimensional data. Usually, the size module of the material is used in calculations.

Table 1. Sand size modulus:

| Material type | Size of material fractions, mm |

| Small | 1,5-2 |

| Average | 2-2,5 |

| Large | more than 2.5 |

If you have fractions in front of you that exceed 2.5 mm, most likely you are dealing with quarry or river sand, how much a cube of material weighs in this case will depend on water demand.

According to the particle size, the material is divided into 2 classes:

- I - more than 1.5 mm;

- II - with any dimensional data.

The class of material and the size of its fractions determines how much 1 cube of sand costs for construction work.

There are three sizes of sand grains - fine, medium and coarse

Specifications

The document strictly regulates the partial proportion of dusty lumps in the sand. The percentage of clay is also determined.

| Classification | Amount of acceptable components in natural sand | In the sand from the screenings | Content in natural sand clots | Clay in the screening sand |

| Class I | ||||

| Very big | – | 3 | – | 0,35 |

| Large - Medium | 2 | 3 | 0,25 | 0,35 |

| Small | 3 | 5 | 0,35 | 0,50 |

| Class II | ||||

| Very big | – | 10 | – | 2 |

| Large - Medium | 3 | 10 | 0,5 | 2 |

| Small and very small | 5 | 10 | 0,5 | 2 |

| Slim - very thin | 10 | There are no regulations | 1,0 | 0,1 |

Strength grade

Deviation in fine-grained material of the second class is allowed, but by prior agreement with the manufacturer and within 7%. The grade of sand depends, especially in the screening type, on the resistance of the material.

Standard characteristics are presented in the table:

| Strength grade | Resistance limit of the rock when it is saturated with water, MPa | Crushed gravel grade |

| M1400 | 140 | |

| M1200 | 120 | |

| M1000 | 100 | Dr8 |

| M800 | 80 | Dr12 |

| M600 | 60 | Dr16 |

| M400 | 40 | Dr24 |

With preliminary agreement of both parties to the contract, it is possible that GOST 8736 sand will have differences (screening out when breaking) strength. Instead of a minimum threshold of 40 MPa, a decrease in this indicator is allowed, but still not lower than 20 MPa.

Sand, which is intended for filling concrete, among other characteristics, must be resistant to the effects of a chemical reaction on alkali. This is influenced by the composition of the sifting sand.

Filtration coefficient

The necessary indicator is the coefficient of filtration and compaction of sand, which allows you to assess the penetrating ability of the material.

Filtration coefficient

The higher the value, the more qualitative characteristics it has. The lowest throughput brings the value closer to 0. A low indicator indicates a clay component, which may narrow the scope of use of sand.

In position A, sand GOST 8736 contains instructions on the types and possible components, impurities that are considered harmful. Bulk and true density, filtration coefficient, grain components - sand made according to GOST 8736 93 must be kept individually by the manufacturer and indicated in the documents.

True and bulk density

Natural quarry or mining

Quarry and screened sand, which has a grain density of more than 2.8 g / cm3 or contains rocks, impurities with a negative impact may have a limited number of applications.

Career

When there are any deviations from the standards, then such sand has a narrow focus on undemanding areas of production. This is preliminarily regulated with specialized research centers.

Coarse for construction work

Building sand that has passed GOST 8736 93 is allowed to mix between natural type and screening sand. Mass fraction of the second type is not more than 20%.

Building

The manufacturer is obliged to provide the buyer with full information on geological exploration, which indicates: petrographic and mineral structure of the rock, the amount and type of organic matter, the density of grains, and voidness.

Medium-grained river

Natural river sand should have a reference color even when the material is treated with sodium. Radiation-hygienic assessment is carried out in special laboratories, where the level of natural radionuclides is determined.

River

Based on the estimated data, a conclusion is drawn about the scope of use of sand:

- content less than 370 Bq / kg - the material is applicable for the construction of new buildings;

- the amount from 370 to 740 Bq / kg allows the use of sand as filling for highways that are located within populated areas. Also allowed for use in the construction of enterprises;

- if the assessment showed 740-1500 Bq / kg - this is the least valuable type, it is used only for laying highways outside cities.

Road laying

Sand GOST 8736 93 is cleaned of garbage, if possible, otherwise it is excluded from production.

For more information on the use of sand, see the video:

Types of sand

Sand is a type of inert material, which is a loose mixture of yellow or brown color. The size of sand can vary from 0.16 - 5 mm, and all types of sand, without exception, are classified primarily by location.

River sand, as the name implies, is mined in rivers. The size of river sand can be from 0.3 to 0.5 mm. Sand of this type is widely used for construction purposes, as well as at treatment facilities when arranging purification filters.

For plaster, river sand is poorly suited due to its rapid settling. Therefore, for plastering it is best to use sand extracted from quarries, but only without admixture of clay.

Quarry sand - is extracted from artificial quarries. Its fraction is not so large, from 0.6 - 3.2 mm. Sand extracted from quarries often contains impurities of dust particles and stones.

Most often, this type of sand is used as a sand cushion under the foundation, in the manufacture of monolithic products, etc. For finishing work in the form of plaster, quarry sand can also be used, especially since many sand manufacturers today wash and sift their products before selling.

Well, you can read about how to wash the sand at home in another article in this construction magazine.

Separate types of sand include sea sand and artificial sand. The first is mined from the bottom of the seas and practically does not contain any impurities in its composition. This material is very much in demand in the construction industry, but due to its rather difficult method of extraction, there is a certain shortage in it.

Artificial sand is produced by crushing various types of stone, such as marble or granite. Quartz sand, which also belongs to artificial types of sand, is the most in demand today.

It is widely used in sandblasting, as well as for the manufacture of various decorative materials, in the production of concrete mixtures and much more. You can read about sandblasting sand by clicking on the highlighted link.

Sand classification by size

All types of sand are classified according to the so-called coarseness modulus (GOST), depending on the grain size

And since it is important to use only suitable sand to perform certain types of construction work, it is advisable to understand this issue

Dusty sand has a very fine dust-like structure. The size of grains of dusty sand is not more than 0.14 mm. A slightly larger grain size is observed in sand of fine modulus, up to two millimeters. Sand of medium size, has a grain size of 2.5 - 3 mm. Well, everything above 3 mm is sand of increased coarseness.

It should always be remembered that the smaller the sand is, the more liquid will have to be used to prepare a construction mixture from it. As a rule, the finest types of sand are used in the manufacture of various solutions, and medium-sized sand is most in demand for concrete solutions.

Choice

When purchasing the material, it is important to correctly calculate the required amount of sand. For this:

- the given number is required * by 1.1-1.3. This is due to the fact that volumes change during transportation and storage;

- contact the manager to clarify the bulk density;

- carry out specific gravity calculations.

If possible, it is better to postpone the purchase. It is beneficial to do it when it is spring or summer outside.

Volumetric and specific gravity may be different

Therefore, at the stage of real estate construction, it is important to pay attention to all errors

The average volumetric weight in 1 cubic meter is 1.5-1.8 tons. These indicators are taken into account in accordance with a special GOST.

The specific gravity of alluvial quartz sand (the one that is mined from the bottom of the river) can be in the border from 2.74 to 2.80, these indicators are average, if there are no organic impurities there.

Sand has the ability to retain heat and accumulate energy. This number is considered to be a witness to the thermal performance of the sand. The ability to heat up depends on the chemical elements. They are also based on the structure and quantity of the material used, as well as its structure and physical characteristics.

Indicators of heat capacity are also necessary at the stage of concreting the walls.

Depending on the type, sand can have the following specific gravity:

- wet quartz-based - 2.9 kJ / kg.

- extracted from the bottom of the river - 0.8 kJ / kg.

- extracted by mining - 0.84 kJ / kg.

- extracted from a part of the world's oceans - 0.88 kJ / kg.

How to calculate the amount of sand in kg using the density of GOST 8736 sand

To calculate the mass of sand GOST 8736, you can use the formula: m = V * p (m is the mass index, V is the volume, p is the density). For example, you need to find out the amount of material in question in 15 m3, then the numbers are substituted in this way:

m = 15 x 1.3 = 19.5 t.

In the example described above, the average density number p was used, which equals 1.3 t / m3. This is how the density of building sand is measured, t m3.

Why is it completely unprofitable for the construction of houses? Due to the increase in the volume of the binding material, the costs and the price of the concrete mix become much higher. As a result, the construction of real estate becomes unprofitable in terms of recoupment. For a construction company, this is imperative.

For private housing construction, such a difference in price will not greatly affect the costs, because here completely different scales are taken into account and taken into account. If the material has accumulated a lot of moisture, this will cause a decrease in density.

This can be explained by the fact that adhesion of fractions occurs.

If the material has accumulated a lot of moisture, this will cause a decrease in density. This can be explained by the adhesion of the fractions.

The density decreases until the moisture content is ten percent.Further changes increase the volumes of liquid, it actively fills the free space, which has a positive effect on the density, it begins to increase.

The fact that the cement slurry is constantly changing its parameters affects its quality. The main thing here is that certain standards are observed during delivery.

Concrete mix

You can also take measurements using improvised methods. Material of the same height is poured into a ten-liter container. The container should be completely filled, a slide may appear, which should be cut strictly horizontally. The result is a horizontally flat surface.

The remaining amount of material must be weighed, then the density is calculated. To do this, the mass is divided by the volume: the obtained indicators must be converted into tons, and the total number is divided by 0.01 m3

For a more accurate calculation, it is important to carry out all measurements several times, at least 2

How is it checked?

As mentioned above, the building material must meet a number of stringent requirements. The conformity of the material to certain properties and characteristics is checked during specially designed tests. All of them are regulated by official documents and GOSTs.

- Determination of the composition of grains. In order to correctly assess the composition of sand (to determine the properties of its fractions), the material is sieved through a sieve specially designed for this purpose. After all the sand has been sieved, but especially large particles remain in the sieve, they are measured and weighed. In this way, the average grain size is determined.

- Determination of the presence or absence of impurities. In order to assess the level of purity of the sand, experts select the viscous particles of the material from its total volume.

- Calculation of the amount of clay and dust. To make such calculations, the method of varying the weight after soaking the fractions is traditionally used. In some cases, so-called pipette and photoelectric methods can also be used.

- Determination of the presence of organic matter. The composition of building sand quite often includes various substances of a humic nature. In order to understand how many of these components are present in the composition of the material, experts began to carry out a comparative analysis. To do this, the sand itself is painted with ethanol, and then the resulting mixture is compared with the coloring of the alkaline solution.

- In relation to the sand that is mined by processing various rocks, the method of analyzing the amount of minerals in the composition is used. For these purposes, devices such as a binocular loupe or a microscope are used.

- For a clear determination of the density index, a pycnometric method is used.

- An important step in assessing the quality of sand is determining the presence or absence of voids between grains, as well as calculating an indicator such as bulk density. For these purposes, use specific measuring glassware.

- In order to analyze the moisture content of the sand, compare the material in its natural state, as well as the sand in the state of the material dried in a special cabinet.

What affects the weight characteristics?

There is a whole list of factors to consider when calculating the weight of sand. Among them are grain size, size of fractions, amount of moisture and even density. The weight will also differ when there are impurities in the composition of the building material. They strongly affect the indicator in question.

It is also worth taking into account that there is always free space between the grains. It, in turn, is filled with air

The more air, the lighter the material and vice versa. The heaviest is compacted sand. Speaking specifically about the mass of natural material, then it can be real, bulk and technical. Indicators are determined taking into account the ratio of mass to volume.

To derive the final index, not all account for porosity. You need to understand that the real mass is lower than the same true value. And all because in real terms, the indicator is only conditional. Now let's talk about the bulk density. If this is dry material, not mined from a quarry, but from a river, then its indicator is 1.4-1.65 tons per m3. If we take the same type of sand only in a wet state, the indicator will already be 1.7-1.8 tons. In a compacted state, the same sand shows a figure of 1.6 tons per m3.

But there are other types as well. For example, material that is mined in a quarry way. Sand with small grains, which is also called fine-grained, has a bulk density of 1.7-1.8 tons. If it is a material made of crystalline silica, then its bulk density is 1.5 tons per m3. If it is crushed sand, then the indicator will be 1.4. and if compacted, then 1.6-1.7 tons per m3. There is also material that is mined in a different way, in this case we are talking about the development of rock, which goes under the 500-1000 brand. Here the bulk density is 0.05-1.

Of great importance on the weight under consideration is the amount of foreign constituents, which are also called impurities, and the saturation with minerals. Sand can be made from an initially heavy mineral or from a light one. In the first case, the indicators will be more than 2.9, in the second less than this level.

Speaking specifically about volume, there are three types of sand. It is supplied for coarse, medium and even fine construction mixes. Why is faction size so important? Because this parameter affects the ability of the sand to absorb moisture. How much you have to spend to create a mixture will also differ. You can find on sale sand 1, 2 classes. If the grains are from 1.5 mm, then we are talking about the first class, in the second this indicator is not taken into account.

The specific gravity largely depends on the method of laying the building material. This can be either a classic bedding, or a compaction by workers, or just a loose surface. The more water is contained in the sand, the greater the mass of such building material. Also, if it was kept wet at a temperature with a minus sign, then its specific gravity increases.

Species overview

There are several types of quarry sand. According to the method of processing, each type has its own characteristics and differences. Each type has its own purpose. All types of material are mined by licensed enterprises, which, even before the start of work, submit estimates and plans for the development of quarries to government agencies. According to the type of processing, sand is washed, seeded and unpaved.

Alluvial

This type of sand is mined by means of hydromechanical devices. By using the water rinsing technique, it is possible to rid the sand of foreign suspensions. This species is distinguished by its purity, it is washed several times. It does not contain harmful components and various suspensions, they are removed immediately during extraction.

This type of sand is used in the production of concrete and bricks, reinforced concrete products. With its help, they build highways, they buy it for the construction of buildings for various purposes. This is a high quality type of material. It is mined from flooded deposits, washing out impurities and even dust.

Seeded

The method of extracting seeded sand is different. It is considered extremely simple. In this case, the technique of technical and mechanical sieving is used. In the course of cleaning, equipment with a mass of sieves and cells is used. As a result, large fractions and stones are removed from the total mass. A fine-grained product of this type is used in the manufacture of plaster mixes and mortars.

Sandy

Open pit sand is classified as a less pure variety. The content of foreign inclusions in it can reach 40%.Because of this, it is not suitable for finishing work, it is more often used as a trench filler and for leveling land plots. This is a low quality draft.

However, it is actively used in utilities and agriculture. It is he who is used in winter for sprinkling on ice. It is also used as a way to preserve vegetable crops. But it is not suitable for either concrete or cement mortars. Its impurities impair performance.

In the next video you will find interesting information about the extraction, delivery and application of quarry sand.

Species overview

Depending on the method of sand extraction, there are several types of natural material (ordinary, black, gray, etc.). Let's consider the main ones.

River

As you might guess from the name of this material, it is mined from the bottom of the rivers. It should be borne in mind that the composition of river sand includes stones, but clay is completely absent. Due to this composition, river sand is an important component of almost all concrete mixtures. As for the fractional division, river sand belongs to the middle category.

Career

A distinctive feature of the material that is mined from quarries is the presence of a large number of various impurities (for example, clay, plants, organic residues, etc.). Due to the fact that the composition of the quarry material includes fractions of different sizes, the sand is very dusty. In order to clean the quarry sand, use water or a sieve.

Artificial

Despite the fact that most of the sand belongs to the category of natural materials, artificial varieties can also be found on the construction market. To obtain them, a wide variety of complex techniques are used, for example, the separation of rocks into small fractions. Artificial sand comes in several varieties.

Expanded clay artificial sand is a material that is obtained through the processing of raw materials (techniques such as crushing, foaming, thermal methods, etc. are used). Due to the fact that no additional chemical components are used for processing raw materials, it is an environmentally friendly material that does not harm the user. The fractions that make up the sand are porous in structure. The distinctive characteristics of the material also include properties such as durability and resistance to water.

The value of measuring the density of river sand in an unconsolidated state

Why is it so important to determine this indicator before the future construction of real estate? It is he who is able to display the real amount of materials in a single volume - a cubic meter. Thanks to him, you can use the material in terms of the ratio of spent resources and functionality.

After making the necessary calculations, you can calculate an approximate budget for future construction.

The building material considered in the article is subject to the norms of a separate GOST 8735-88, and this indicates:

- material with such indicators has fully passed the compliance with construction technologies;

- the properties of the material during work and after the construction of the house are quite predictable;

- a method to determine the mass of a material in a unit of its volume, tested and approved as a reference, allowing you to get the long-awaited and truthful result;

- During the material verification phase, only approved methods and technical recommendations were used.

You should remember that when purchasing river sand, its bulk density will be equal to 1600 kg / m3, which fully meets the construction standards. In addition, this material can be stored for a long time, it does not accumulate moisture, and lumps and voids do not form in it over time.

This indicator is critically important for many non-ore elements. To clarify this indicator in a specific batch of material, the manufacturer uses correction values.These numbers make it possible to determine the values from the technological and economic point of view.

During the acquisition of a large batch, the coefficient allows you to level out deviations that are caused by the spread of indicators. For example, at the stage of purchasing ten tons of material, the amendment will allow determining the amount of material up to 2 tons per batch.

Composition and characteristics

First of all, you need to keep in mind the fact that if you plan to use sand in construction, you must make sure that the material meets all the requirements (they are detailed in the current GOST). Before purchasing the material, be sure to ask the seller to demonstrate all the documents he has (for example, a certificate of conformity). The most important indicator is the specific gravity. He plays a significant role in the process of creating a variety of building compounds and mixtures. To calculate the specific gravity, it is necessary to determine the ratio of the weight and volume of dry sand.

Specific gravity largely depends on characteristics such as place of origin, density, graininess, moisture percentage, and others. If we talk about a specific indicator, then the specific gravity of a building material usually corresponds to a coefficient of 2.55-2.65 units. In addition to the specific gravity, the bulk density is also important. This takes into account the weight of both the sand itself and all the available impurities. The average bulk density is 1500-1800 kg.

Another important characteristic is density. The compaction coefficient depends on what percentage is the clay of the total composition. Humidity is also important. If the material is clean and does not include additional unwanted impurities, then the level of its density will be 1,300 kg per m3

With regard to composition, it is important to consider the chemical, mineral and particle size properties. It is important to read the relevant tables

- For example, the chemical properties of sand affect its color. If the material contains a variety of oxidized metal compounds, then the natural material can acquire orange and red hues. On the other hand, if aluminum particles are found in the composition, then the sand will be blue or even blue. Generally speaking, if the color of the material is very different from its natural color, then it is unsuitable for use in construction.

- Depending on the mineral components, the sand can be limestone, feldspar, quartz or dolomite. Quartz material is considered to be the highest quality and durable.

- In order to determine the particle size (or grain size) composition, it is necessary to sift the material through a specially designed sieve, the holes of which are about 0.5 cm.