individual protection "

- Inter-sectoral rules for the provision of workers with special clothing, special footwear and other personal protective equipment, approved by order of the Ministry of Health and Social Development

Russia from 01.06.2009 N 290n

- GOST 12.4.128-83 SSBT. Protective helmets. General technical conditions.

How to wear a safety helmet correctly

1. Check the headband attachment system, the attachment straps must be carefully inserted into the special slots.

2. Adjust the helmet to fit using the clamps or ratchet.

3. Turn the helmet with the front end and put the headband down over your head.

4. Make sure the helmet fits your size and does not dangle on your head.

5

It is important that the fixation is reliable, the shock-absorbing equipment of the helmet does not dangle from side to side

6. If you are always working on the ground, especially in windy places, then you should attach the chin straps to the helmet and make sure that it does not fall.

7. Do not wear the helmet around your head or tilt to the side.

First of all, you need to clean the outer surface

1. It is desirable to carry out the processing on a clean and soft surface.

2. Use a simple piece of soft cloth to remove large, non-stubborn dirt from the helmet.

3. Next.

Place the detergent on a damp cloth. For example, dishwashing or a simple soap solution (preferably with warm water), then wipe and lubricate the helmet. Wait a while until the detergent or soapy water dissolves the remaining dirt.

4. Wipe the product again with a damp cloth and warm water. Finally, wipe with a clean, dry cloth.

5. Dry the safety helmet in the shade.

Step 1. Cleaning the plastic parts of the suspension is carried out in the same way as the shells.

Step 2. The cotton or nylon front headband can be quickly cleaned as usual, and can be removed and washed. Meanwhile, this pad can be easily replaced with a new one.

Species overview

By type of use

It is customary to highlight the following options for helmets:

-

winter heat-resistant;

-

universal construction;

-

miners (for underground work);

-

firefighters (with increased fire and electrical resistance);

-

heat-resistant structures;

-

acid and alkali resistant models;

-

intended for other professions.

By color

The color of the safety helmet can vary greatly. And professionals have long come to the conclusion that such color coding allows for increased safety. In addition, it will facilitate the identification of personnel at long distances and in low visibility. The state standard for the coloring of protective headgear, approved in 1987, has long been canceled. The following normative documents say nothing about specific colors.

And yet for convenience, and partly for reasons of tradition, builders and others adhere to established color schemes. White helmets are usually worn by the management of organizations and their structural units, as well as labor protection inspectors. Recently, they have also become an attribute of security services (guards, watchmen, watchmen). And some construction organizations practice white helmets in the outfit of engineering personnel.

The red headdress is worn by foremen, engineering and technical personnel of industrial enterprises. In the industrial sphere, they are also used by chief mechanics and chief power engineers.Yellow and orange helmets can be used by ordinary and auxiliary personnel at various sites. However, there is another approach according to which the color of protective headgear is distributed as follows:

-

orange - surveyors;

-

red - beginners and visitors;

-

yellow - ordinary staff (but not trainees);

-

green - for electricians and electricians;

-

black - locksmiths;

-

blue - plumber service specialists;

-

brown - miners;

-

blue - crane operator;

-

white or red - fire departments.

By type of additional equipment

Some professions strongly require the use of a special headgear with face protection. Helmets with a screen or a shield made of transparent materials provide reliable protection against splashing metal, drops of corrosive liquid, flying chips, fragments and dust. A special part is used to attach such an element. There are also shockproof shields that can be made of transparent materials. Some models can protect against high temperatures.

Some of the helmets are equipped with a visor that maximizes the safety of the face in general and the eyes in particular. Such designs are useful for the logging, construction and installation industries. In many industries, helmets with headphones are actively used. Such an addition allows both to escape from incessant loud sounds and to organize constant communication between employees.

Communication headphones for helmets:

-

equipped with built-in electronics that suppress impulse noise;

-

suitable for work in an explosive environment;

-

can transmit signals via Bluetooth;

-

are calculated to contain sounds of different loudness, different frequencies.

Separate helmets are supplied with (or used in conjunction with) goggles. When the work requiring the use of glasses is finished, they can be returned under the helmet in one motion. Pulling back this protective device is no more difficult.

Any helmet is equipped with a chin strap, without which it cannot be properly held on the head. The width of the strap cannot be less than 1 cm, its attachment can be located on the body of the headgear or on the strap.

Helmets with a comforter, characterized by increased heat resistance, are quite common. It compensates for the danger of increased temperature and heat radiation. Such equipment is used most often by welders and metallurgists. There are also helmets with comforters:

-

for machine builders;

-

builders;

-

miners;

-

oil producers;

-

oil refiners;

-

electricians.

In appearance

Brims and canopies significantly increase light protection. Also holders for flashlights are additionally used. It is worth considering the following options:

-

equipping with a removable cape;

-

adding a warm liner to protect against hypothermia;

-

made from a combination of glass with textolite and plastic.

Popular models

The products of the Czech company JSP are in demand. These helmets have a one-touch system and fit exactly to your head. The range includes models for universal and industrial use. Helmets from this company are painted in bright, rich colors.

It is very difficult to find products from Sweden, but you can pay attention to the goods of Delta Plus (France). This company has been operating for over 40 years.

It is represented all over the world. Today Delta Plus products are shipped to 140 countries. A good example is the BASEBALL DIAMOND V. This helmet comes in 7 different colors. ABS plastic is used for its manufacture; normal operation is guaranteed at temperatures down to -30 degrees

This company has been operating for over 40 years. It is represented all over the world. Today Delta Plus products are shipped to 140 countries. A good example is the BASEBALL DIAMOND V. This helmet comes in 7 different colors.ABS plastic is used for its manufacture; normal operation is guaranteed at temperatures down to -30 degrees.

Granite Wind Model:

-

also made of ABS;

-

has two seating positions - 53 and 63 cm;

-

has 3 fixation points;

-

designed for work at height.

The Airving B-WR model from Uvex is also popular in our country. For its imposing appearance, she was nicknamed the "chief's helmet". The main structural material is HDPE. Operation is guaranteed for at least 60 consecutive months. A long visor and an elongated occipital block are used.

Choosing a light helmet, you should pay attention to the modification of the "Pheos B-WR" of the same manufacturer. This product is made in a classic sports spirit

The release began in 2012. Thanks to the ratchet mechanism, the headband can be adjusted from 52 to 61 cm. Thanks to proprietary adapters, you can use both shields, headphones, and headlights.

Very good results also show:

-

polypropylene helmets RFI-3 BIOT;

-

SOMZ-55 VISION;

-

Peltor G3000;

-

MSA V-Gard.

Checking the condition of the head PPE

Head protection equipment must be visually inspected daily before starting work. Check the surface of the helmet, mountings and adjusters for damage. If, during work, an employee falls from a height, a blow on the helmet, a hot metal hit on it, exposure to chemicals, etc., it must also be carefully examined.

In the presence of chips, cracks, dents, damage to the fasteners, further wearing of the protective equipment is unacceptable.

A helmet that has suffered a strong impact (even if there is no significant damage) should be replaced with a new one.

According to POT R M-012-2000, the expert laboratory periodically tests helmets twice a year to identify existing defects. The expert opinion makes a decision on the possibility of further use of protective helmets or their write-off.

Views

The division of construction helmets is based on two criteria.

- Colour. According to this parameter, hats are allocated for workers, representatives of the management of the facility, and visitors to the enterprise.

- Purpose. Depending on this parameter, the product can have a different shape, size, equipment. Also, helmets can be divided into winter and summer options.

American headwear is made primarily of plastic, polyethylene, and polyester. Also, in the manufacturing process, polycarbonate with additional reinforcement can be used. The listed materials are characterized by shock resistance and improved performance characteristics.

Helmets can counter the following factors.

- Mechanical. Head hats soften impacts, preventing serious injury. They are made of durable materials.

- Temperature. For the manufacture of helmets, materials are used that are resistant to high temperatures. They do not catch fire and reliably protect the head from burns.

- Chemical. For the manufacture of some helmets, special materials are used that are not afraid of the effects of chemically active substances. They also do not deform under hot metals.

- Weather. The products allow you to organize uninterrupted operation at the facility even on a sultry day, even in rain, slush or snow.

History

The ancient helmets include Sumerian protective helmets. They were in the form of low domes, which is reminiscent of modern products. The first means of protection that appeared include a hat - a fur coat that has volume, and also protects against the weather in battle.

During the development of civilization, they began to create protective helmets based on metal and leather.

A protective helmet was used in hostilities, since it was an obstacle for shell fragments to hit. They appeared in the Russian army in the 16th century. Since the 19th century, they began to be used as headdresses for troops - dragoons and cuirassiers.

The product made it possible to protect a person from head injuries. Later, protective helmets were developed.Currently, a protective helmet is actively produced.

Somz is one of the most popular brands among such products. In their manufacture, new technologies are used, which make it possible to obtain hats of high reliability classes. This protects the head from damage from heavy objects.

Color varieties of helmets

There are several color solutions for these hats. Orange construction helmets are especially popular. But color differences were introduced here for a reason. For example, a white construction helmet is recognized to tell about the position of its "wearer".

Let's thoroughly understand this issue. Let's imagine color variations of protective hats in general:

- Yellow or orange construction helmet - for ordinary builders, workers, junior maintenance personnel.

- Red - such a headdress is issued to engineers, foremen, foremen, technical mechanics, as well as chief power engineers and chief mechanics.

- White construction helmet - for heads of industries and organizations, heads of workshops and sections, employees of the safety service at a construction site, public inspection for labor protection.

- Blue - the color is typical for the protective headgear of mine rescuers.

- Brown - this color is used by miners, miners.

RULES OF ACCEPTANCE

3.1. Helmets are accepted in batches. A party is considered to be any number of helmets no more than 3000 pcs. one color, one size, made of one material in one technological mode.

Five helmets are randomly selected from a batch of 51 to 1200 helmets, and eight helmets are selected from a batch of 1201 to 3000 helmets.

3.2. To check the compliance of helmets with the requirements of this standard, acceptance tests are carried out at the manufacturer.

3.3. Helmets for acceptance and periodic tests are selected in accordance with table. 4.

Table 4

|

Number of test helmets |

|||

|

Test type |

acceptance |

||

|

Lot size |

periodic |

||

|

from 51 to 1200 |

from 1201 to 3000 |

||

|

Appearance check Checking for compliance with the reference sample (pi. 2.2, 2.3, 2.8, 2.10, 2.11) |

5 |

All helmets 8 |

|

|

Tightness test of ventilation openings * (and. 2.12) |

— |

— |

3 |

|

Water resistance test (and 2.4) |

— |

— |

3 |

|

The flammability of the helmet shell ** (and. 2.13) |

— |

— |

3 |

|

Checking basic dimensions * (and. 1.2) |

— |

— |

15 |

|

Determination of mass * (and. 1.3) |

— |

— |

15 |

|

Mechanical strength test (and 2.13) |

3 |

5 |

— |

|

Depreciation test (and 2.13) |

— |

— |

6 |

|

Perforation test (and 2.14) |

2 |

3 |

— |

|

Testing the electrical protective properties of the roof of the hull (and. 2.13) |

— |

— |

3 |

|

Test of the strength of the connections of the internal equipment with the body (and. 2.13) |

2 |

3 |

— |

* Helmets can be used in other tests.

** Tests are carried out on helmets that have passed other tests.

Note. All helmets subjected to destructive tests (for perforation, combustibility, the strength of the joints of the internal equipment with the body, as well as the electrical protective properties of the body) are excluded from the number of suitable products and are not subject to further operation.

3.4. Periodic tests are carried out at least once every six months in specialized laboratories or at manufacturing enterprises in the direction of the person responsible for the operation of personal protective equipment.

3.5. Periodic tests are carried out on helmets taken from a batch that has passed acceptance tests and accepted by the manufacturer's quality control department.

3.6. Upon receipt of unsatisfactory results of acceptance or periodic tests for at least one indicator, repeated tests are carried out for this indicator, for which a double number of samples are taken from the same batch of helmets. The retest results are valid for the entire batch.

3.7. If, during acceptance tests, ten consecutive lots were accepted, it is allowed to carry out a light inspection. At the same time, the following volumes are set

rock: for a batch of 51 to 1200 pcs.- two helmets, for a batch of 1201 to 3000 pcs. - three helmets.

All selected helmets are tested for compliance with reference samples and the requirements of paragraphs. 2.2, 2.3, 2.8, 2.10, 2.11, 2.13, 2.14.

If one batch did not pass the tests, then they switch to normal control in accordance with table. 4.

Price

Consideration should be given to whether there is a difference between expensive and cheap products. There are many goods in specialized stores, the price of which varies between 60-2000 rubles. What is the difference? Will an expensive helmet be more reliable?

Many firms buy cheap products. Is it correct? Yes, this decision is correct. You just need to follow the safety of the employee. All batches are tested in the laboratory before the goods get for sale. In stores there are only those helmets that fit the standards of GOST.

Thus, whatever the price of the helmet, it must be safe. And this is confirmed by the quality certificate. The marking should indicate the purpose. Helmets that do not include markings are unsafe. Many are wondering why then produce expensive products? The cost of such products includes a brand fee. The buyer may also need other characteristics: original design, visor, glasses, ventilation regulation.

Which one to choose?

It doesn't make sense to focus on design

This is not a hat! It is much more important to pay attention to good protective qualities. And not "in general", but taking into account the threats that appear in a specific production

Even the simplest helmet must:

-

block the blows of foreign objects, their penetration to the head;

-

absorb the kinetic energy of moving bodies;

-

tolerate moisture.

An additional plus will be, of course, fire resistance. Also important:

-

resistance to electric current;

-

heat resistance;

-

level of protection;

-

the amount of protected space.

In winter, it is important to have a heater. In the heat, the increased work of ventilation is more relevant

For miners and miners, for tunneling, the presence of a mount under the lantern is mandatory. When working in public utilities, it is desirable. But builders can usually do without such an attribute.

The most durable polycarbonate is often chosen, which is especially reliable. Helmets made of it retain their protective properties for a long time. However, the problem is that the load on impact is not absorbed, but distributed, so there is a high risk of injury to the cervical vertebrae. Soft styrofoam will prevent problems when hitting slow objects or falling, but is useless when hit by a falling object.

Exploitation

The safety helmet can be worn together with respirators and goggles. You can use products made of polyethylene at temperatures from -50 to +40 degrees. There is a miner's helmet with a high level of durability. Such products can be used for a long period at a temperature of no more than 150 degrees. They can withstand 1000 degrees for a short time.

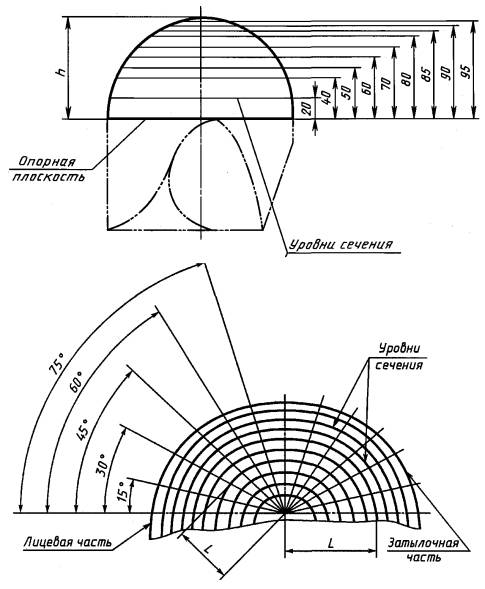

For the safety of work, a protective helmet is used. GOST P 12.4.207-99 approves the size of the margins and visors of the product. According to these rules, the fields should be no more than 1.5 cm wide, and the visors up to 6 cm.The miner's helmet looks a little different: 1 cm and 4.5 cm.If underground work or in a wet environment is performed, then circular fields should be more than 2 cm wide. An obligatory element of the products is a device to fix the lamp or the cable to it.

During operation, it is often necessary to attach headphones or shields. In order to prevent many troubles, you need to purchase after the compatibility of the mounts has been clarified. If you wear such a hat in the summer, then you suffer from strong sweating. It is advisable to wear a comforter under the helmet. This product is considered an accessory, thanks to which sweat will not protrude on the forehead. The body includes product type, size, trademark.

What to look for when choosing

When choosing a helmet and any workwear, it is worth considering the specifics of the work for which they are used. For a certain type of work, the helmet may have its own colors.

For the correct choice, consider all the characteristics of the helmet. The prices for helmets are different, but we do not recommend buying the most expensive or the cheapest one right away. any batch of helmets, before getting to the store, is tested in the laboratory, after which only those helmets that comply with GOST are allowed for sale.

For the correct choice, consider all the characteristics of the helmet. The prices for helmets are different, but we do not recommend buying the most expensive or the cheapest one right away. any batch of helmets, before getting to the store, is tested in the laboratory, after which only those helmets that comply with GOST are allowed for sale.

Any, even the cheapest certified helmet, ensures the safety of the builder. This applies only to those helmets that can be clearly identified by the marking. It is best to buy a helmet in a special store, where they will show you GOST and tell you about the characteristics.

It is worth remembering that in the GOST R certification system, protective helmets are subject to mandatory certification, therefore, a helmet without any designations or with the designation "not subject to mandatory certification" is not considered a safety helmet.

The list of products subject to mandatory certification indicates that "protective helmets (except for construction and fire helmets)" are subject to certification. Construction helmets are those that comply with GOST 12.4.087-84.

As an acceptable solution, you can simply buy inexpensive imported helmets made according to the European standard EN 397. Our new GOST R EH 397 / A1-2010 is identical to the European regional standard EN 397: 1995 + A1: 2000 "Industrial safety helmets", about which there is a direct indication in its text. Therefore, the “EN 397” mark on the helmet will be a sign that it is suitable for construction workers. In addition, the helmet must bear the CE mark - a mark of conformity of the product to the requirements of the European Union directives.

For most domestic helmets, this shelf life is 3 years, for foreign - 5 years.

Manufacturers of construction helmets: TK RIM LLC, ELANPLAST LLC, UVEKS SPR LLC, Spetszashita LLC, MSA (USA), SACLA (France), Peltor (USA).

TECHNICAL REQUIREMENTS

2.1. The helmet must be manufactured in accordance with the requirements of this standard and comply with the reference standards approved in the prescribed manner.

2.2. The helmet should consist of a shell, inner harness and a chin strap.

At the request of the consumer, the helmet can be equipped with devices for attaching shields, ear muffs and other personal protective equipment.

2.3. Helmet shells should be produced in four colors:

white - for the leadership of organizations and enterprises, heads of sections and workshops, public inspectors for labor protection, employees of the safety service;

red - for foremen, foremen, engineers and technicians, chief mechanics and chief power engineers;

yellow and orange - for workers and junior maintenance personnel.

2.4. For the manufacture of helmets, materials permitted by the USSR Ministry of Health must be used. The body and internal equipment of the helmet must be made of non-toxic materials, and the parts in direct contact with the scalp and face must not cause pathological changes in the skin. Materials must be resistant to the action of petroleum products, acid-base electrolyte, hot water (80 ° C), disinfectants.

2.5. The materials used for the manufacture of helmets must correspond to those indicated in table. 3.

Table 3

|

Name of helmet elements |

Material name |

Normative and technical documentation |

|

Helmet body and chinstrap clip |

High density polyethylene |

GOST 16338-85 |

|

Carrying tape, suspension |

Same, low density |

GOST 16338-85 |

|

Drape, carrier tape covering |

Current regulatory and technical documentation |

Note. It is allowed to use other materials with physical and chemical properties not lower than those indicated in table. 3 and ensuring that helmets meet all the requirements of this standard.

2.6.Interior fittings must be made of durable and resilient materials. The carrier tape (except for its back of the head) must be covered with natural or perforated artificial leather or other porous material that protects the skin from chafing.

2.7. The internal equipment of the helmet must provide the ability to adjust its size, if necessary, use a comforter, and must not allow the helmet to move when turning the head and performing work in an inclined position.

The design of the carrying strap and shock absorber should provide for the adjustment of the depth of the helmet on the head.

2.8. The inner harness and chin strap must be removable and have means for attaching to the helmet shell. The chin strap must be adjustable in length, and the attachment method must ensure that it can be quickly detached.

2.9. The outer surface of the helmet shell must be smooth, free of cracks and bubbles. On the surface of the helmet body, inclusions of a different color are allowed in the amount allowed by the standards for materials.

2.10. The inner surface of the helmet shell, as well as the outer and inner surfaces of the rig must be smooth, and the edges and edges are blunt.

2.11. The quality of the seams on the inner fittings must meet GOST 29122-91.

2.12. The side surfaces of the helmet body must have ventilation openings with a total area of at least 200 mm2, hermetically sealed by rotating shields.

2.13. Mechanical strength, shock absorption, the strength of the connection of the internal equipment with the helmet body, flammability, electrical protection properties of the helmet must comply with GOST 12.4.128-83.

2.14. When tested for perforation by impacts with an energy of at least 30 J, the helmet body must exclude the possibility of penetration of the tip of the cone to the surface of the head mock-up.

2.15. Helmets must retain their protective properties during the entire period of operation at an ambient temperature from minus 50 to plus 40 ° C.

Best blog content

Occupational Safety and Health

Coronavirus: Personal Hygiene Practices for Workers

Coronavirus Observatory: Memo

Cargo slinging schemes

How to pass industrial safety certification

Fire safety

Flood preparation plan

Fire safety of wagon houses

Fire advice

Fire safety in a car service

electrical safety

1 group presentation on electrical safety

Electrical equipment checklist

5 steps to assign 1 electrical safety group

An action plan for electrical safety at the enterprise

Ecology

Carcinogenic passport at the enterprise - sample

How to properly dispose of fire extinguishers

MSW management

Industrial environmental control schedule (filling example)

GOSTs

For construction helmets, there is a single GOST 12.4.087-84, adopted in 1984 and which is still adhered to. According to this GOST, construction helmets were divided into three types by color:

For construction helmets, there is a single GOST 12.4.087-84, adopted in 1984 and which is still adhered to. According to this GOST, construction helmets were divided into three types by color:

- white helmets - for heads of organizations, heads of workshops and sections, labor safety inspectors;

- red helmets - for foremen, chief mechanics, power engineers, engineers and technicians;

- yellow and orange helmets - for junior workers and service personnel.

In addition, for the manufacture of helmets, materials permitted by the Ministry of Health should be used. The body and the inner part of the headgear should be made of materials that do not cause allergic reactions and pathological changes on the skin. The material must be resistant to hot water, oil, fuels and lubricants and alkalis.

The inner part of the helmet is made of durable and smooth materials, inside there is a size adjuster and a fastening strap. The seams must be of good quality and the surface of the headgear must be well finished.