Usage Tips

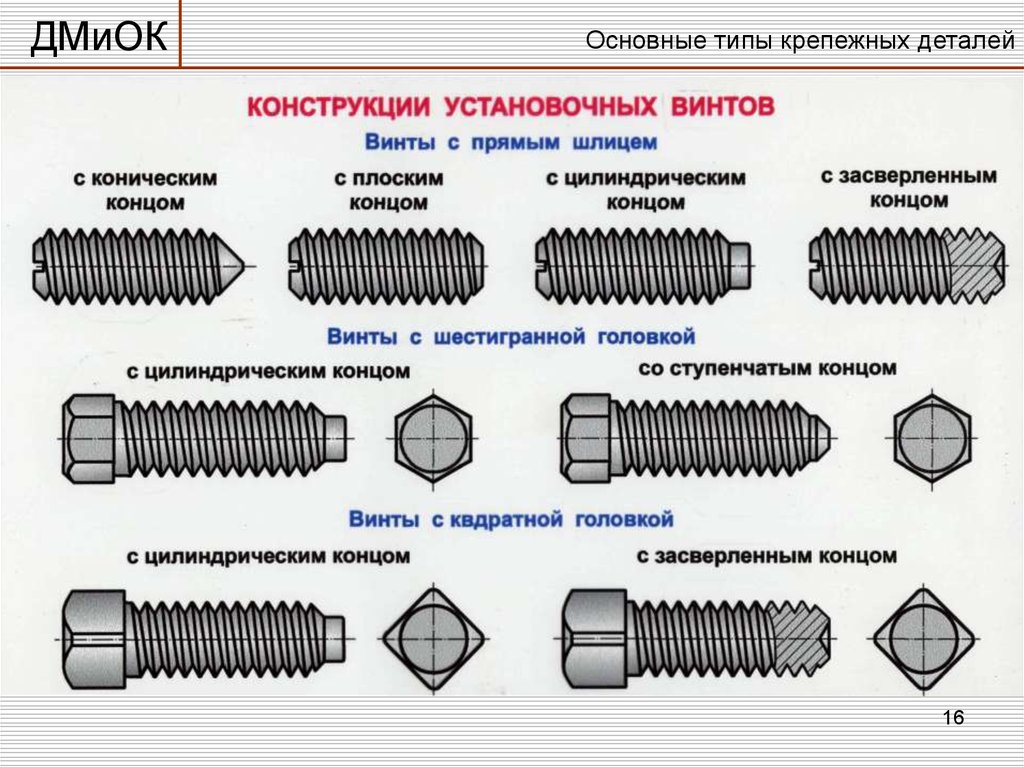

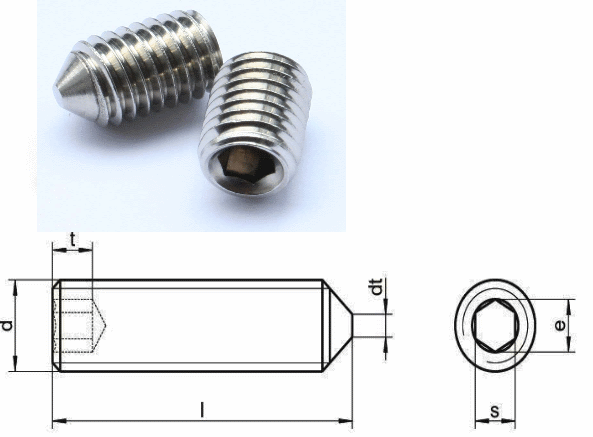

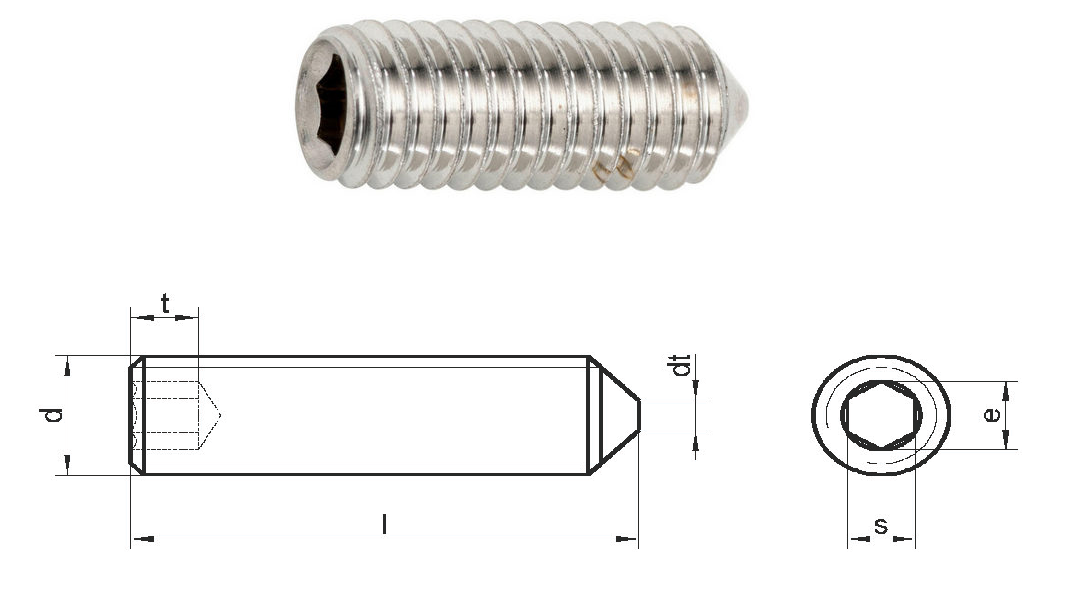

The set screws are devoid of the head typical of conventional mounting counterparts. A cross-shaped or flat slot is applied directly to the end of the product. If you need to achieve maximum strength, you must use modifications with an internal hexagon in the slot. In practice, it has been proven that this performance increases the scrolling power. The risk of premature failure will be close to zero.

It should be borne in mind that the presence of an internal hexagon forces the use of special assembly (so-called imbus) keys. Other tools are not suitable for this job. You can screw the screw completely into the part. The use of grooves and protrusions allows for a tighter hold. First of all, a screw is screwed into the thread, passing the product to the full depth, and then it is tightened on the outside.

Locking screws in mechanical engineering can be used to fasten pulleys or gears to shafts. A screw is tightened inside the hub. This product is inserted end-to-end into the threaded shaft passage. Such a connection perfectly fulfills the frictional force. Along with this, elastic deformation between the fastener and the part plays an important role in tight fixation.

Set screws can be used in a wide variety of applications. They are even used in precision instrumentation. But, of course, it is necessary to carefully study the features of a particular situation and permissible conditions. When using screws with a drilled end and a hexagon inside, it is required to check their compliance with GOST 28964, DIN 916. The normative category of strength is 12.9, before installing such screws, pre-drill and cut a thread.

You can watch a video overview of the set retaining screws in the video below.

Peculiarities

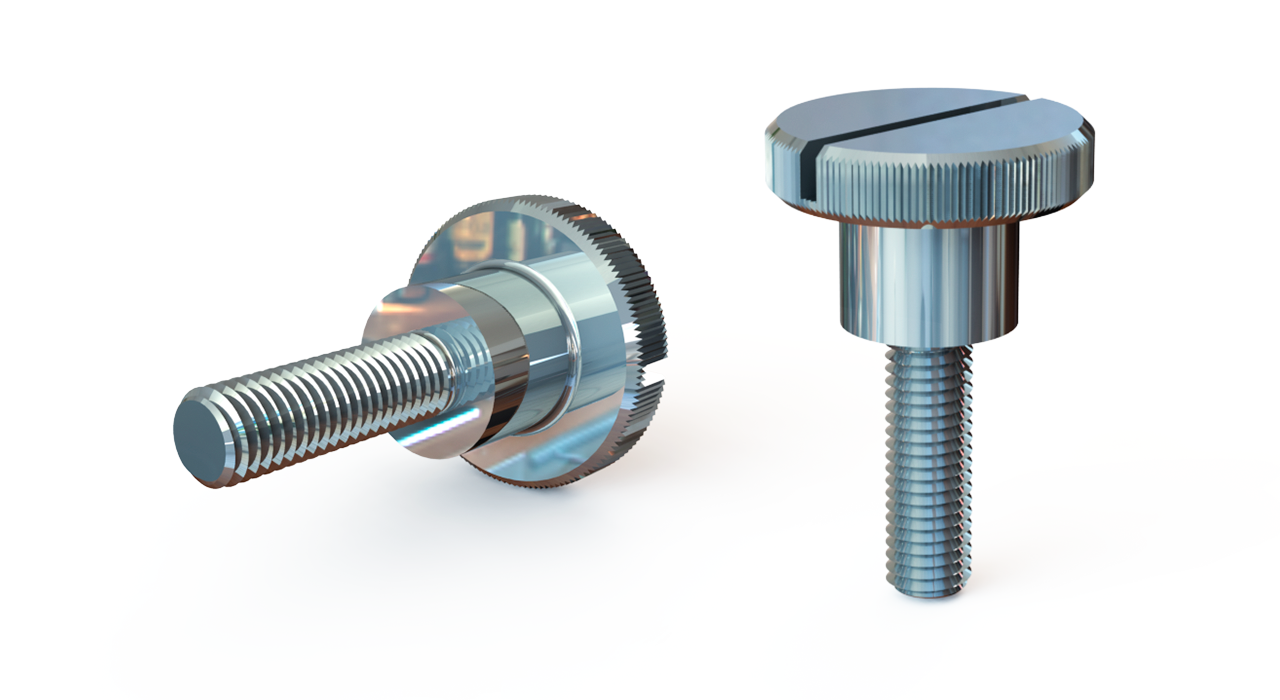

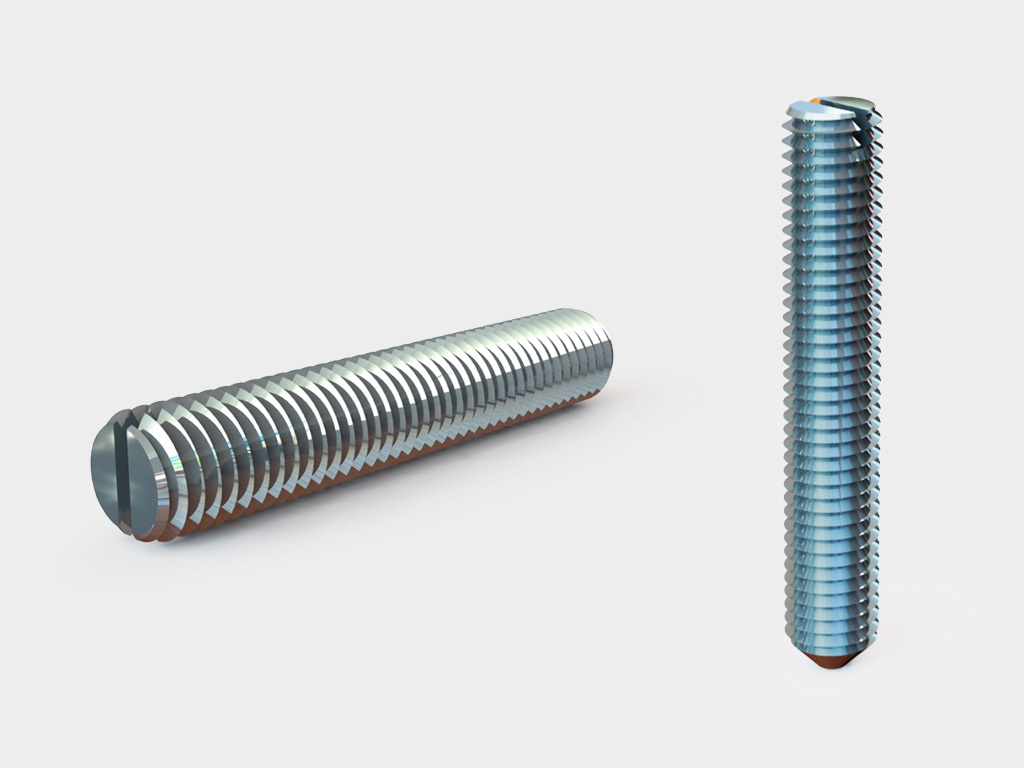

Externally, the set screw (UV), or, as it is also called, the locking screw, can be distinguished by the absence of a head, where the slot (a recess for a flat screwdriver or hexagon) is located directly at the end. The body of the fastener is completely made in the form of a thread and, passing through the socket in the part, abuts against it for its entire length, which increases the reliability of the adhesion. The pressure tip also comes in different shapes, can be made of different materials (for example, nylon) and is designed to increase the stability of the fixation.

Unlike most other threaded fasteners, this is primarily a compression device commonly used to create axial thrust. HC can be made from different grades of iron with different hardness classes, anti-corrosion alloys such as brass and stainless steel, or uncoated and coated carbon metals:

- chrome plated with zinc;

- nickel plated;

- burnished with an oxide film;

- soaked in oil;

- phosphate.

Mild steel mostly comes with a straight or cross recess, and hexes are considered to be the strongest to transmit more torque and withstand maximum loads without risk of deformation.

Peculiarities

Before understanding the features of the locking screw, you need to pay attention to the definition in GOST. For such products, the standard 27017-86 applies.

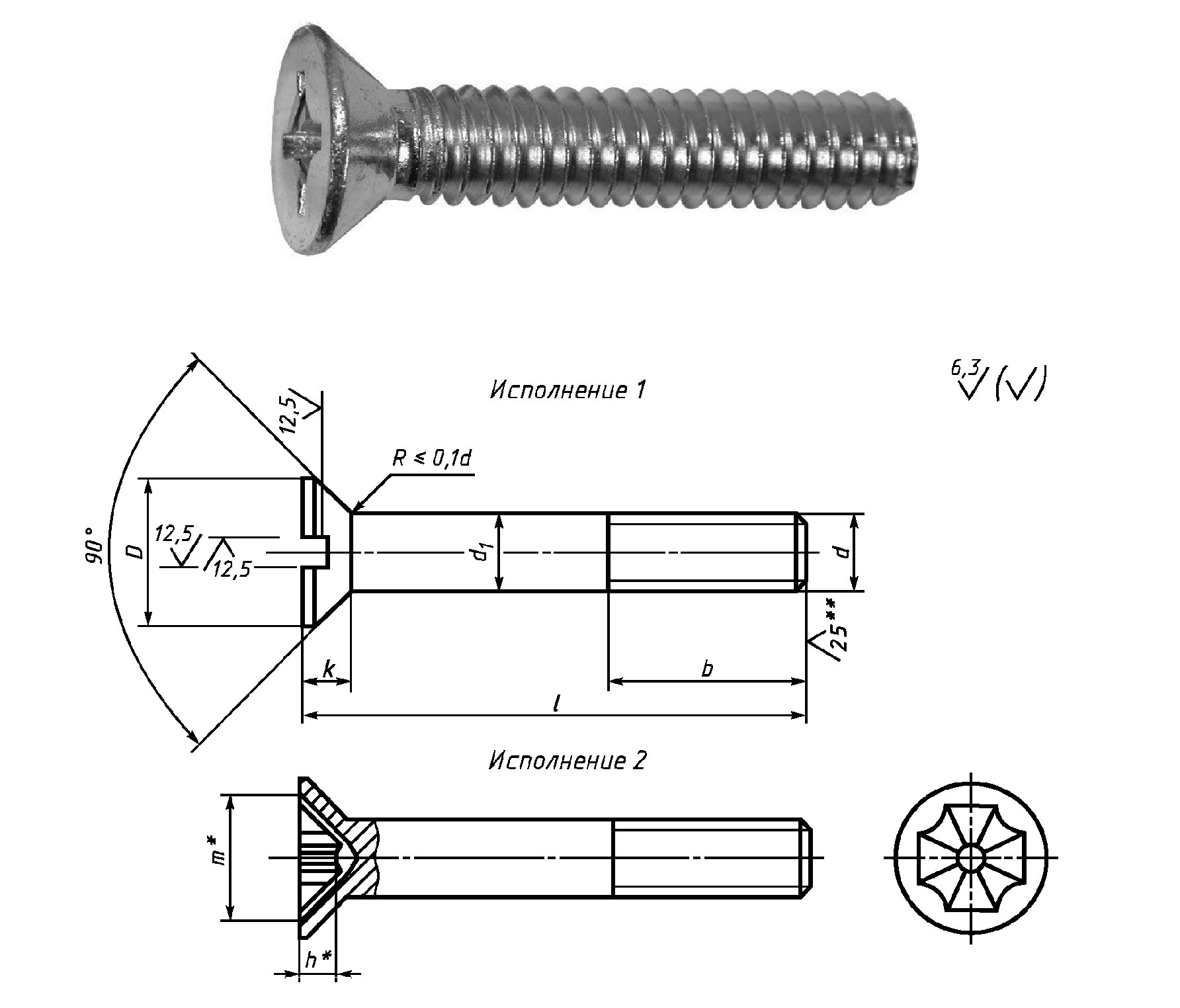

According to him, a screw is called a fastening structure that allows you to connect or fix different objects. The product is a rod with an external thread on one end and with a torque transmitting part on the other end. It is worth noting that the definition of a bolt is very similar, and there is no clear boundary between them.

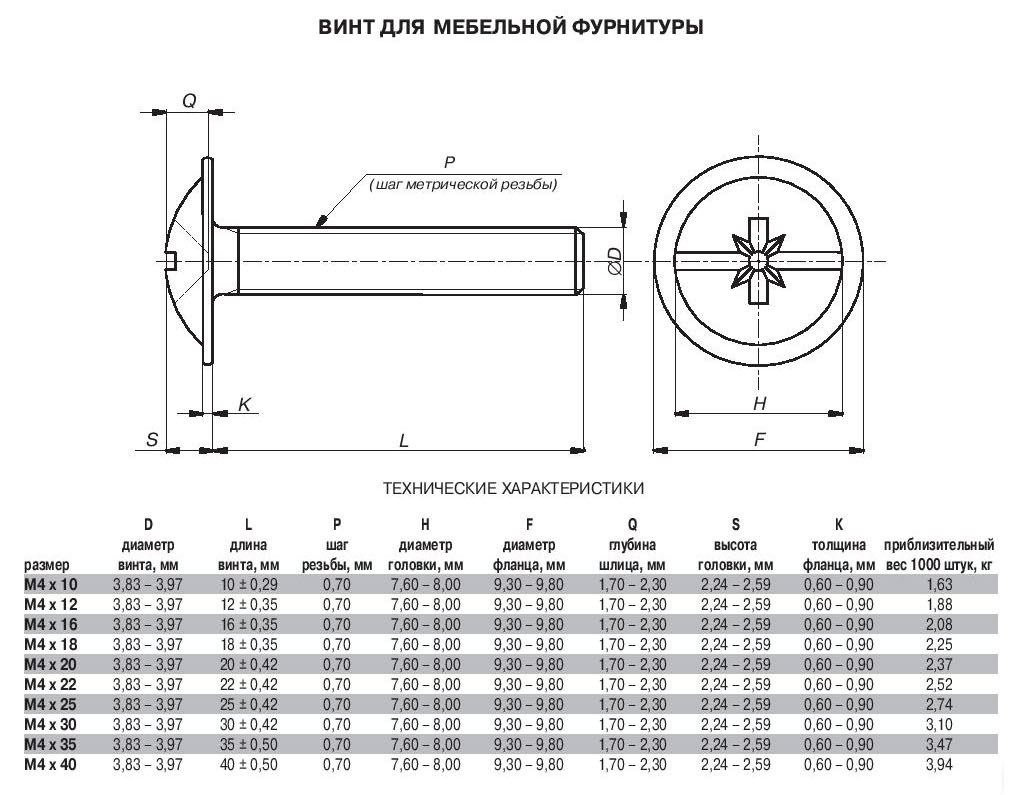

All such constructions are marked with two numbers separated by a multiplication sign. Before it, write the section below the head, and after it - the distance from the tip to the largest transverse section of the head.Both quantities are measured in millimeters. Fasteners for metal have a stable, uniform cross-section of the rod along the entire length. Products are either screwed into threaded holes, or passed into through channels made in the connected packages.

Do not think that locking screws are needed only in some advanced mechanical engineering industries.

It is equally important to use them for a doorknob. Set screw in accordance with DIN 914 standards helps in high vibration environments

Sophisticated geometry increases the strength and stability of the joints created.

Appointment

Set screws are used consistently in many different industries, and one of the fairly widespread is furniture, namely door handles and lever locks. The door hardware is attached to the leaf, and then covered with a special overlay, and with the help of hidden fasteners, the structure is tightly connected from the inside so that it cannot be reached from the outside. They are mainly used where we never see them, for axial and radial fixation on shafts inside mechanisms, machine tools, automobile (and not only) motors, various structures of the furniture and construction industry. In addition to the face spline, they differ in the type of tip.

Here is information about the types and purposes of standard tips.

- Cylindrical trunnion is the most popular type of fastener for temporary, permanent or semi-permanent joining of parts on shafts with a strength class from 14 to 45 H on the Brinell scale and where the edge of the cup is allowed to cut into the shaft. Used for soft materials where strong tightening is impractical. Allows the shaft to rotate freely while keeping the spindle in a locked position.

- The tapered tip is used for permanent positioning of parts. The deep penetration of the sharp tip when tightened provides maximum axial and holding force to develop cross-point shear strength.

- The flat tip is the most affordable, simplest and used in budget types of set screws. It is suitable for situations where full surface blending is required to create compression. This type of fastener is great for items that require frequent assembly and disassembly rather than permanent placement.

- A UV with a drilled flat tip is required for permanent placement and reliable locking of parts. The unevenness of the tip allows it to cut deeper into the metal for a durable grip. They often replace pins. Well suited for hardened steel or hollow pipes.

- The spring-loaded ball screw is designed for use in soft materials such as aluminum and at extreme temperatures, including on parts that require frequent dismantling and locking of assemblies (for door handles). Some have a nylon tip that adds friction to resist loosening.

The holding force can be increased by the depth of the joints. The longer screw length reduces the number of attachment points required, where each can add as much as 15% to the total holding power. Tapered nibs with the deepest penetration will give the most magnification, while small flat nibs such as M3x4 will give the smallest magnification.

In addition, enterprises produce screws according to any parameters of a wholesale customer: with the required dimensions and application of anticorrosive coatings based on organic or inorganic materials (galvanizing, bluing, chrome plating, nickel plating, etc.). Sizing and tightening are important factors in vibration resistance and holding capacity. The screw diameter should be approximately 1/2 of the shaft (check with a specialist). UVs are available with different thread diameters (M1.2 to M 24) and shank lengths from 2 to 302 mm.

See below for set screws.

Types and their characteristics

Depending on the type of connection, the set screws are selected of the required length, cross-section (diameter), with a thread pitch or with a trunnion, with different fixing lugs of a suitable shape.

Each of them has a specific marking in accordance with the regulations. In addition to the GOST quality standard adopted in Russia, there are international analogues of ISO standards, as well as German DINs that have proven themselves all over the world.

Depending on the grade, HCs are used on both soft and hard metals (or universal), can have different compression forces, vibration resistance, be used at different angles, used as adjusting, temporary or permanent holding.

The set screws, depending on the available slot, are divided into two types.

An internal hex can have three types of holding force: torsion (resistance to rotation), axial grip (resistance to lateral movement), and vibration resistance. For work, you will need a special L-shaped key. This type of clamping fastener is more protected from unauthorized access and has a class of increased reliability, which is very popular and much more practical than the usual straight screwdriver, where a flat screwdriver easily slips out when the part is tightened tightly.

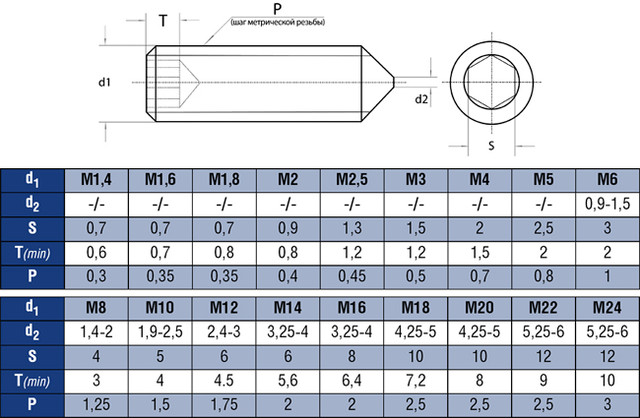

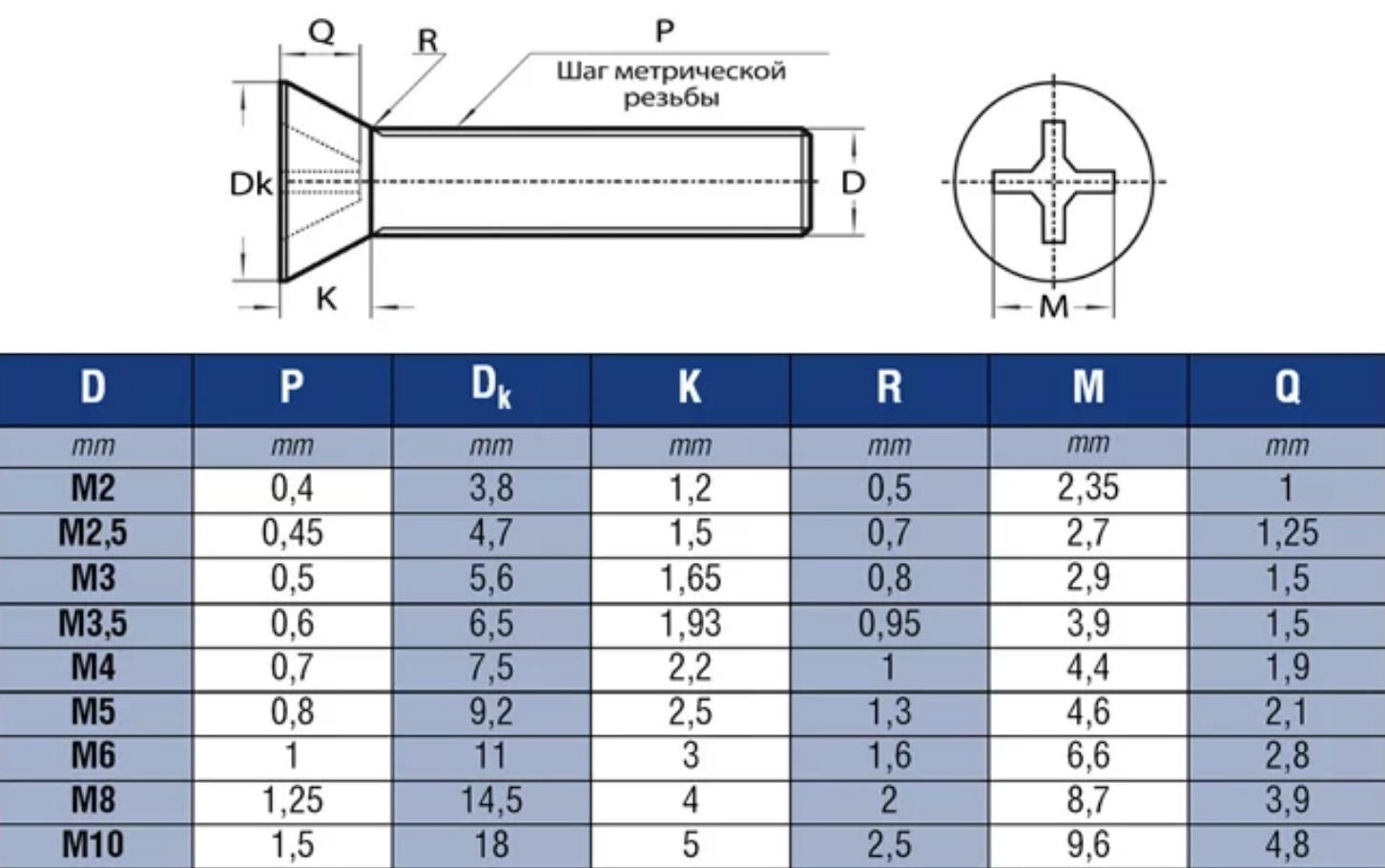

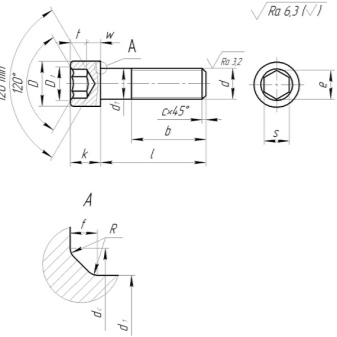

Specification and drawing of standard HC grades of various sizes, depending on their purpose, see below.

The stepped DIN 923 is an unusual shaped pressure screw, consisting of 3 parts: a thin head with a straight slot and a smooth body, and on the other side a threaded trunnion (0.7–11 mm) with a blunt tip. Nominal lengths range from 3 to 25 mm with diameters from M1.4 to M10. They are made of brass, carbon and alloy steel A1 – A5, strength class - 4.8 / 5.8 (for bolts).

Locking UV DIN 551 with straight slot and flat end is analogous to DIN 553 for a standard screwdriver. It is very often used as a hidden fastener in various fields: from industrial instrumentation to furniture production. Pivots until it comes into contact with an internal object, thereby applying pressure and creating a clamping force. They are made of standard materials with a hardness of 14H-22H from A1-A5 steel, as well as brass, aluminum and even plastic. Sizes range from 5mm to 100mm length and cylinder diameter from M2 to M20. Strength class 8.8 according to GOST 1476-93.

The set screw DIN 913 is analogous to DIN 914, 915 and 916. All of them do not have a head, at the end there is a slot for a hexagon. They differ only in the type of tip, which can be blunt, tapered cylindrical or drilled. The benefits of each of them can be found below. The question of choosing this or that material is quite acute when it is planned to use fasteners in conditions of high humidity, for example, in pumping equipment. Alloy steel, titanium and special corrosion resistant coatings are widely used in pipelines. Manufacturing and metallurgical technologies are constantly evolving to allow the use of tough alloys in high wear situations such as hydrogen sulfide concentrations above 35%, temperatures up to 220 ° C, and high pressures. Hardness 45 H complies with Russian standards GOST 11074-93, GOST 8878-93, GOST 11075-93 and GOST 28964-91.

Replacing with an analog is sometimes critical, so sometimes you have to contact a fastener manufacturer. Depending on the size, the chamfer angle of the tip changes, for example, for long screws of size M6x10, the chamfer angle is 90 °, and short and long or thick and long ones, such as 12x12, have a more obtuse chamfer angle of 120 °, which is slightly worse for permanent adhesion.

What are they?

The choice of the appropriate fastener option depends on the following factors:

- intended purpose;

- external parameters;

- the required level of reliability;

- number and dimensions of mounting screws.

The main purposes of the application are:

- assembly of various equipment;

- replacement of items that have become unusable;

- increasing the aesthetics of the appearance of the joints.

External factors can be considered climatic parameters, features of dynamic and static influences. Along with reliability, one has to take into account the availability for installation (dismantling), the quality of protection against deformation of the fasteners. For particularly difficult climatic conditions, galvanized fasteners are used.

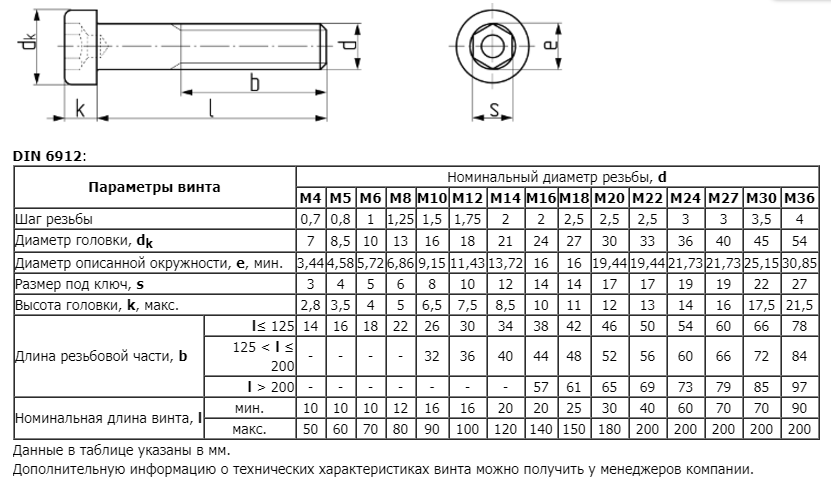

A hexagon (including an internal one) is used when a particularly strong fastening is required. The execution of hexagons can be made according to DIN 912 or GOST 11738, both standards also make it easier to use in hard-to-reach places and protect the structure from dynamic load.

The M6 set screw has a cross-section of 0.6 cm. If we talk about the M6x10 modification, then its length reaches 1 cm. The M8 cone-shaped screw can have a length of 0.8 cm. Usually, 45H HEX 4.0 alloy is used in the manufacture of such fasteners.

Fasteners with a length of 0.6 cm can be made from the same alloy. There are also options without a coating or with a layer of zinc.

M8 screws are also available in lengths:

- 12;

- 14;

- 16;

- 20;

- 25;

- 30;

- 40;

- 50 mm.

As for the M10 screws, their length can be:

- 10;

- 12;

- 20;

- 25;

- 30;

- 35;

- 40 mm.