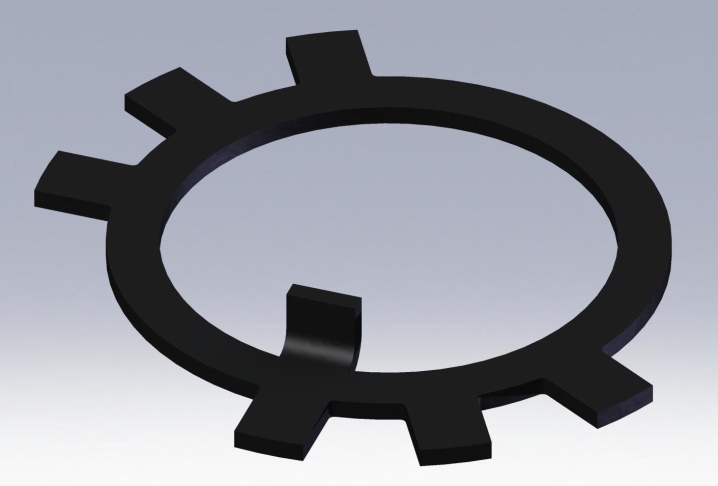

Description and purpose

With long-term operation of many technical devices, the main criterion for durability is the strength and reliability of the connection of different parts of the structures. Correctly selected locking multi-foot washer avoids spontaneous loosening of fasteners, and so-called feet help it in this.

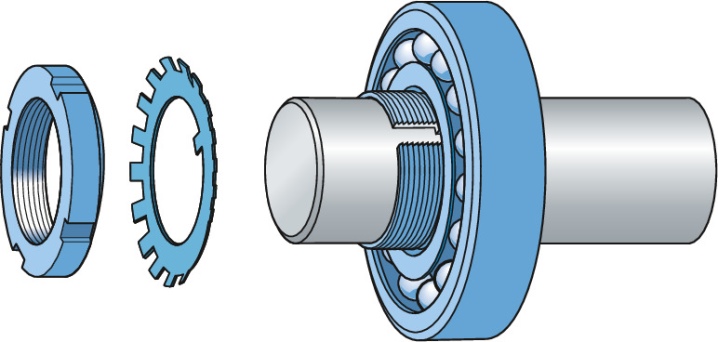

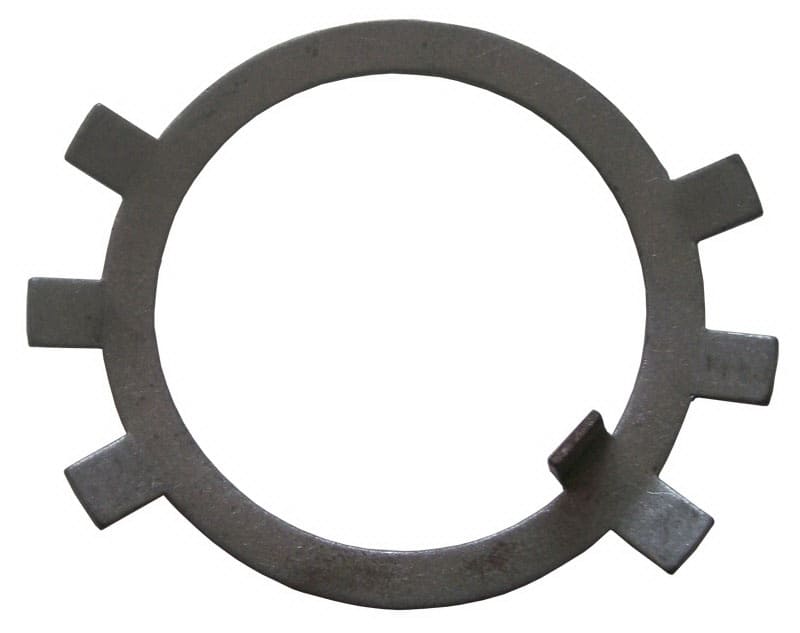

When using slotted nuts on the shafts, these devices completely save the structural unit from destruction. In the grooved groove, the lock washer is fastened with a lug on the inner side, in turn, this makes axial rotation impossible, while maintaining the normal, unobstructed movement of the fastener in the direction of length. 6 special lugs, tilted at 25 degrees, exclude unscrewing, but the part is effective only in relation to slotted types of nuts.

Therefore, the latching device with an inner tab has the following characteristics:

- the presence of external and internal protrusions;

- mainly the fastener is used for nuts of a certain size - with a diameter of 10-130 mm;

- the arrangement of the legs along the outer diameter can be different, sometimes they are made to order according to the presented drawings, which is due to the specifics of the design for which the fasteners are used;

- since the legs of the element can be bent many times during operation, the main material for their production is high quality plastic stainless steel;

- depending on the diameter of the thread of the spline parts, lock washers are made of thin metal sheets 0.8-2 mm thick, in addition, the surface of the washers is covered with a protective anti-corrosion layer.

The main area of application of the part is all kinds of structures and structures of industrial importance (any mechanisms that are subjected to loads on the rotation axis during operation, on the shafts of centrifugal, vane pumps, gearboxes that change the power of cars and production equipment). But in everyday life, the device also found its use - they are often replaced by ordinary flat washers with a hole inside. True, then it is required to select the desired type of nut for engaging the legs.

Washer types

The din lock washer is often used as a fastening element, which excludes the possibility of unscrewing under normal operating conditions. It should be borne in mind that there are a fairly large number of different types of such products, the classification is carried out according to the form and type of material used. An example is the fact that spring steel is often used, which is characterized by high elasticity. All lock washers are divided into several main groups:

- Grover.

- Serrated.

- Poppet.

- With special notches and grooves.

- With paws.

- Wedge.

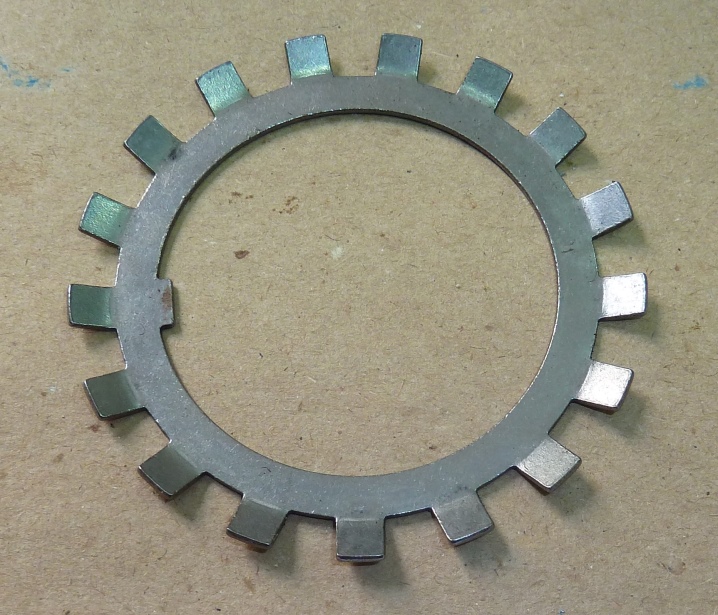

All varieties of lock washer types have their own specific features that must be taken into account. An example is the common version with internal tines or grooving. Their features are as follows:

- The main part is represented by a ring made of metal.

- Cuts are created along the surface, located in different planes.

In most cases, the washer is manufactured using spring loaded steel. During the production process, it undergoes elastic deformation, due to which the likelihood of spontaneous unscrewing of fasteners is excluded

Almost all Grover type retainers have a square cross section. At the same time, for a significant expansion of the field of application, an anti-corrosion coating can be applied to the surface.The problem with most metal parts is that prolonged exposure to high humidity causes rust to appear, and over time it reduces performance.

There is also a split washer on the market that is flat or tapered. In this case, depending on the field of application, the teeth can be located inside and outside. This group is divided into several subgroups:

- Poppet.

- With different paws.

- With protrusions.

A lock washer with lugs is used when it is necessary to ensure high reliability of the connection. The multi-footed surface engages with special grooves, thereby eliminating the possibility of the fastener turning. The feet can be of different lengths.

Locking persistent quick-release washer

In some cases, it is necessary to ensure a quick dismantling of the mechanism. For this, a quick release thrust washer is preferred. It is suitable for cylindrical products with diameters ranging from 1 to 38 mm and more. A variety of alloys can be used in the manufacture:

- Spring steel, which is characterized by increased elasticity.

- Stainless steel with a high chromium concentration.

- Bronze. This non-ferrous metal is also highly resistant to moisture and certain chemicals.

When choosing, attention is paid to a fairly large number of different parameters, most of which are indicated in the technical documentation. The main ones are:

- Diameter of a suitable shaft groove. The installation of the fixing element is often carried out in special grooves that are machined into the shaft.

- The outer diameter of the product. It is also indicated in the applicable technical documentation.

- Outside diameter of the shaft. This parameter is considered the most important. In this case, the diameter of the threaded surface can differ significantly.

- Washer thickness. The strength and reliability of the resulting joint depends on this parameter, since axial displacement can cause deformation.

- Groove width.

- Minimum overhang.

The manufacture of a persistent quick-release washer is carried out taking into account the standards that are specified in GOST or DIN. All the required parameters can be found in the tables, according to which the selection of a suitable version is carried out.

Application area

Retaining rings are very widespread. This is due to the fact that screw fasteners are found in industry, everyday life, are part of vehicles and other complex mechanisms. Among the features of the application, we note the following:

Most often used for fixing on a shaft.

When choosing, attention is paid to the outer and inner diameters.

The product can only serve for a long period if it is correctly selected.

At the time of installation, the nuts are tightened under force. This is due to the fact that a certain load is required to overcome elastic deformation. A fairly large number of different companies are engaged in the production of fixing elements.

When choosing, you need to pay attention to the fact that all the standards set in GOST or DIN were taken into account

A fairly large number of different companies are engaged in the production of fixing elements.

When choosing, you need to pay attention to the fact that all the standards set in GOST or DIN were taken into account

This is due to its intermediate location. There are also quick-detachable versions that cannot be reused, but for removal it is not necessary to disassemble the entire structure.

Contact grooved washer

In a specialized store, a product with a grooved surface is also found. Their field of application is to ensure the reliability of the connection. The corrugation of the contact surface can significantly increase the degree of adhesion of the two products. The key points are the following:

- In most cases, spring steel is used in the manufacture of the main part, which is characterized by increased elasticity and wear resistance.

- The diameter of the washer is selected depending on the size of the part.

- Often, to significantly increase the degree of surface protection against environmental influences, the surface is coated with zinc or plastic.

That is why it is used only when creating critical products that endure serious variable or constant loads.

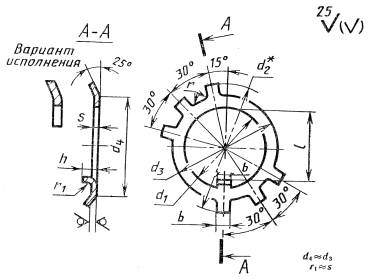

1. DIMENSIONS

1.1. The dimensions of the washers must correspond to those indicated in the drawing and in the table.

___________

* The size d2 in the sweep.

mm

|

Nut thread diameter d |

d1 |

d2 |

d3 |

b |

l |

h |

r, no more |

s |

|

|

not less |

no more |

||||||||

|

4 |

4,2 |

14 |

6,5 |

2,7 |

1,5 |

2,5 |

0,2 |

0,8 |

|

|

5 |

5,2 |

16 |

8,0 |

3,2 |

|||||

|

6 |

6,2 |

18 |

9,5 |

1,8 |

4,2 |

2,0 |

3,0 |

||

|

8 |

8,5 |

24 |

14,0 |

3,0 |

5,5 |

1,0 |

|||

|

10 |

10,5 |

26 |

16,0 |

3,5 |

7,0 |

2,5 |

4,0 |

||

|

12 |

12,5 |

28 |

18,0 |

3,8 |

9,0 |

||||

|

14 |

14,5 |

30 |

20,0 |

11,0 |

|||||

|

16 |

16,5 |

32 |

22,0 |

4,8 |

13,0 |

0,5 |

|||

|

18 |

18,5 |

34 |

24,0 |

15,0 |

3,5 |

6,0 |

|||

|

20 |

20,5 |

37 |

27,0 |

17,0 |

|||||

|

22 |

22,5 |

40 |

30,0 |

19,0 |

|||||

|

24 |

24,5 |

44 |

33,0 |

21,0 |

|||||

|

27 |

27,5 |

47 |

36,0 |

24,0 |

4,5 |

8,0 |

|||

|

30 |

30,5 |

50 |

39,0 |

27,0 |

|||||

|

33 |

33,5 |

54 |

42,0 |

5,8 |

30,0 |

1,6 |

|||

|

36 |

36,5 |

58 |

45,0 |

33,0 |

|||||

|

39 |

39,5 |

62 |

48,0 |

36,0 |

|||||

|

42 |

42,5 |

67 |

52,0 |

39,0 |

|||||

|

45 |

45,5 |

72 |

56,0 |

42,0 |

|||||

|

48 |

48,5 |

77 |

60,0 |

7,8 |

45,0 |

0,8 |

|||

|

52 |

52,5 |

82 |

65,0 |

49,0 |

5,5 |

10,0 |

|||

|

56 |

57,0 |

87 |

70,0 |

53,0 |

|||||

|

60 |

61,0 |

92 |

75,0 |

57,0 |

|||||

|

64 |

65,0 |

97 |

80,0 |

61,0 |

|||||

|

68 |

69,0 |

102 |

85,0 |

9,5 |

65,0 |

||||

|

72 |

73,0 |

107 |

90,0 |

69,0 |

6,5 |

13 |

|||

|

76 |

77,0 |

112 |

95,0 |

73,0 |

|||||

|

80 |

81 |

117 |

100 |

76 |

|||||

|

85 |

86 |

122 |

105 |

81 |

|||||

|

90 |

91 |

127 |

110 |

11,5 |

86 |

1,0 |

2,0 |

||

|

95 |

96 |

132 |

115 |

91 |

|||||

|

100 |

101 |

137 |

120 |

96 |

|||||

|

105 |

106 |

142 |

125 |

101 |

|||||

|

110 |

111 |

152 |

130 |

13,5 |

106 |

||||

|

115 |

116 |

157 |

135 |

111 |

|||||

|

120 |

121 |

162 |

140 |

116 |

|||||

|

125 |

126 |

167 |

145 |

121 |

|||||

|

130 |

131 |

172 |

150 |

126 |

|||||

|

135 |

136 |

177 |

155 |

131 |

|||||

|

140 |

141 |

182 |

160 |

136 |

|||||

|

145 |

146 |

192 |

165 |

141 |

|||||

|

150 |

151,0 |

202 |

175,0 |

15,5 |

146,0 |

7,5 |

14,0 |

1,6 |

2,5 |

|

160 |

161,0 |

212 |

185,0 |

155,0 |

|||||

|

170 |

171,0 |

222 |

195,0 |

165,0 |

|||||

|

180 |

181,0 |

232 |

205,0 |

175,0 |

|||||

|

190 |

191,0 |

242 |

215,0 |

185,0 |

|||||

|

200 |

201,0 |

252 |

225,0 |

195,0 |

An example of a conventional designation of a multi-blade lock washer for a round slotted nut with a thread diameter of 64 mm, with a thickness specified in the standard, made of steel grade 0.8 kp, coated with chemical oxide impregnated oil:

Washer 64.01.08.кп 05 GOST 11872-80

The same, made of steel grade 15 with a zinc coating with a thickness of 9 microns chromated

Washer 64.03.019 GOST 11872-80

(Modified edition, Amendment No. 1).

1.2. The theoretical mass of the washers is indicated in the datasheet.