Features and Benefits

Wall panels made of polyvinyl chloride are a finishing material that won the trust of consumers many years ago. The main component of the panels is hard and strong, but at the same time lightweight PVC, due to which the cladding can be carried out in office buildings, shopping malls and residential spaces.

In houses and apartments, this material is usually used for decorative finishing of areas with a high level of humidity - namely for kitchens and showers; the use of plastic is also justified in the corridor, where shoes constantly stain the walls, and any other material quickly deteriorates.

For the manufacture of wall boards, phenol-formaldehyde resins are used, which are absolutely harmless to the body of children and adults, and water-based paints are used to paint plastic lining, which also do not contain any components harmful and toxic to humans.

The high popularity of this type of facing materials is explained by a number of advantages of plastic wall panels, among which are:

- The versatility of the coating. Traditionally, such panels are used to decorate ceilings and walls, however, the structure and physical and technical parameters of the material allow it to find a lot of other purposes: finishing slopes, arranging screens in bathrooms and showers, decorating formwork for steps, many craftsmen even make shelves from such panels. and gardeners often form beds from plastic lining in their gardens.

- Easy to install. Even a novice master can cover the wall with such panels, especially when he has to work with a flat surface - then the slabs are simply "planted" on liquid nails, but to mount the panels on a curved surface, preliminary fixing of the lathing will be required, but these works do not require large expenditures of effort and time.

- Ease of maintenance. Plastic coatings can be easily cleaned with a damp soft cloth dipped in soapy water.

- Environmental friendliness. The panels are made of non-toxic materials, they do not contain volatile substances, do not emit radiation.

- Fortress. For wall cladding, manufacturers produce compacted materials, so that they can withstand impacts during furniture rearrangement or small children playing.

- Sound and heat insulation. PVC panels create additional heat protection in the room and have sound-absorbing properties.

- Resistant to moisture. Plastic has water-repellent properties, the water absorption coefficient approaches zero, and at the same time, due to the smooth surface, water does not linger on the tile. Mold does not form here, fungi and other pathogenic microorganisms do not multiply.

- Resistant to temperature fluctuations. The working range of the panels is large, they can withstand temperatures from -50 to +50 degrees, without changing their consumer properties.

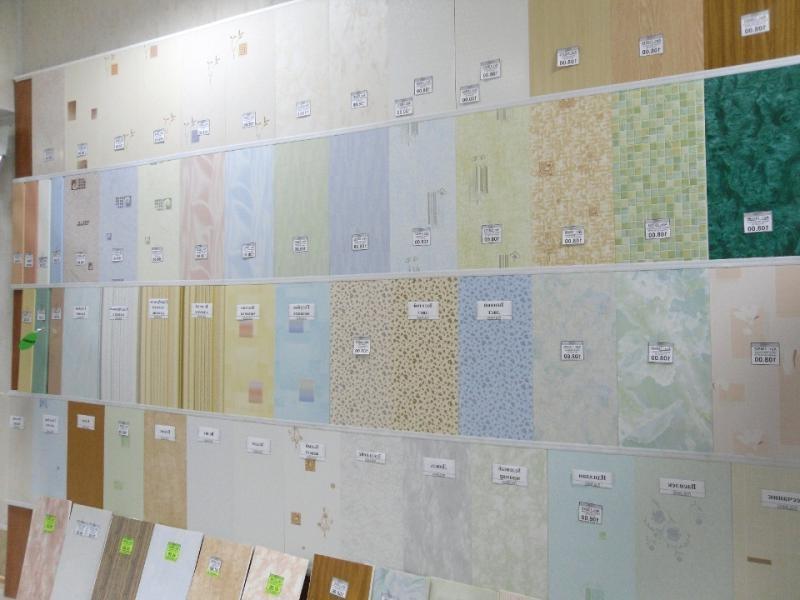

- Wide range of. The panels are available in stores in a wide variety of colors.

However, the panels are not perfect, like any other building material, they have their drawbacks:

- PVC panels are not UV resistant. If they are painted white, then over time they will turn yellow and lose their original gloss.

- Weak impact resistance - naturally, the panels can withstand the loads of weak and medium strength, but there is always a risk of dents that cannot be straightened out.

- Unpleasant smell - some reviews claim that a chemical smell is noticeable at first after installing the plates, however, after a few days it completely disappears.

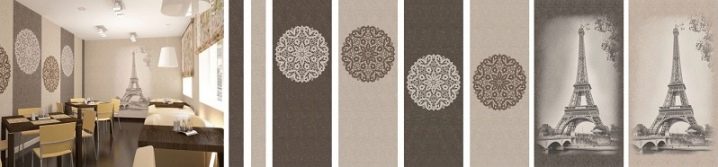

Beautiful examples of finishing

PVC decorative panels are considered the most demanded among buyers today. Indeed, thanks to the cladding of various surfaces with such products, you can independently create a unique look in the interior.

Bedroom

The bedroom requires soothing and relaxing shades, so in this case, choose panels in light shades. Glossy surfaces with a reflective effect are not recommended. Such a design will only tire the owners. An excellent option is considered wall decoration with panels that imitate wood.

You can also sheathe one of the walls in the room, while all the attention will be paid to it.

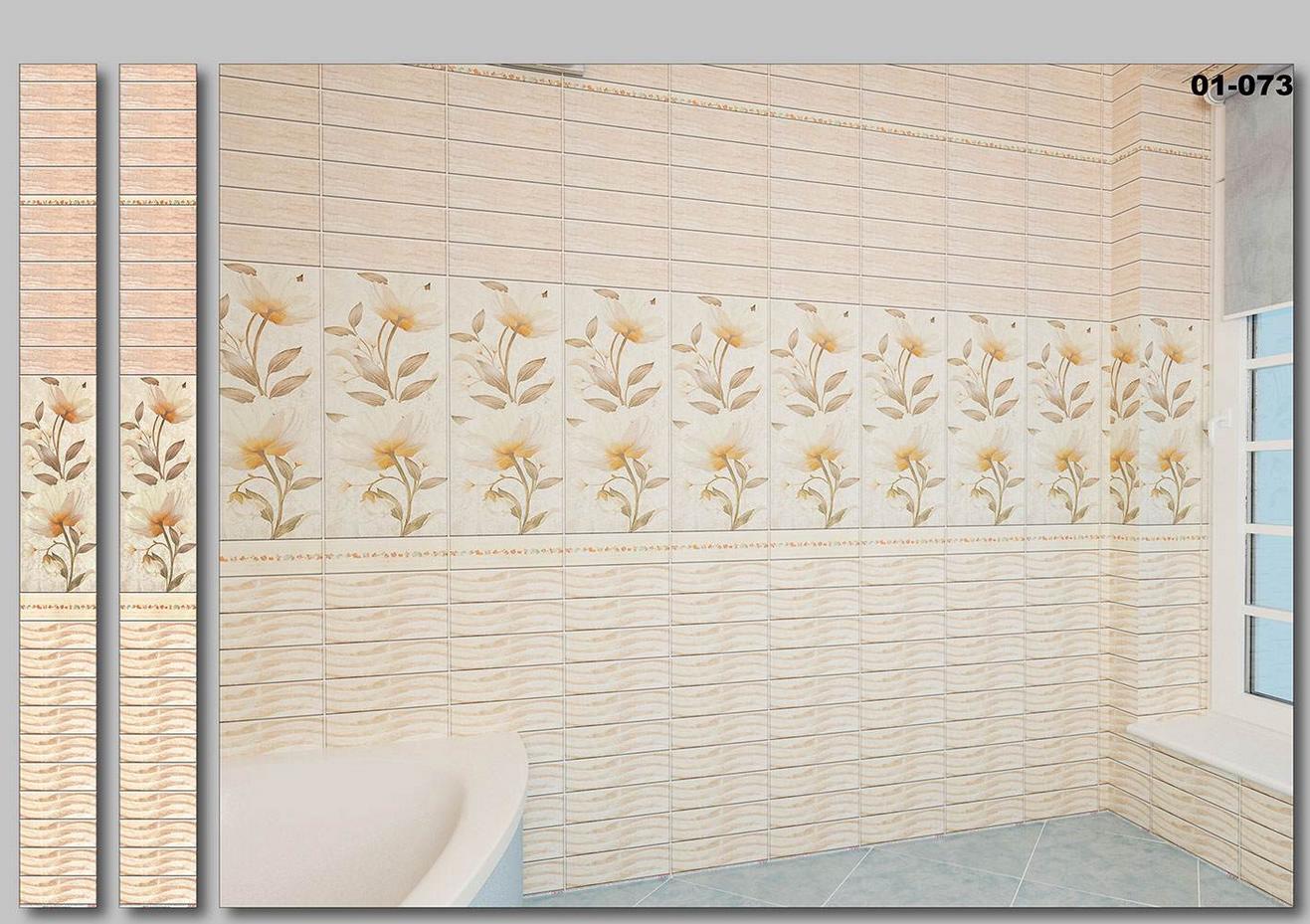

Bathroom

If you decide to decorate the walls and ceiling with plastic products, then be careful with color schemes. It is undesirable to use more than 2 shades in a given room. It is also worth abandoning too defiant color schemes, it is better to opt for neutral tones (gray, beige, white).

In this case, choose seamless types of products so that moisture does not get inside the structure, thereby preventing the appearance of mold and mildew. Tiled plastic panels in combination with natural stone can be used in the bathroom. For a large room, it is possible to use sheet products that imitate mosaics.

Kitchen

Usually, owners use PVC trim in this room in those places that are prone to constant pollution (above the sink and washbasin). It is also appropriate to use zoning here. Thus, you can highlight the dining area in the room. If the kitchen unit is made in light shades, you can use bright shades of the finishing product to dilute the boredom in the interior. When decorating the ceiling with PVC panels, you can install built-in spotlights or lighting.

See below for more details.

Types of PVC ceiling panels

PVC ceiling panels are produced in many types, sizes and shapes. They differ in design solutions, performance characteristics and installation methods.

Design features and physical properties

With the same size PVC panels for the ceiling, 1 m2 weighs less than the wall ones. The lightening of the structure is achieved by reducing the thickness of the constituent components. Due to the fact that the plastic is less likely to be mechanically damaged at the top, I make it more fragile and lightweight.

To avoid unnecessary financial costs, waste of material, you need to make a calculation before purchasing.

For small spaces, such as a bathroom, it is advantageous to take the length of the PVC ceiling panels so that they can be cut in half. If the width of the bathroom is 1.7 m, it is advisable to purchase plastic 3.5 m.

Views

PVC ceiling panels can be divided as follows:

- Material in the form of sheets without locks.

- Plates. Performed without connectors.

- Euro lining. Has a wide type of locking system.

- "Polka". The castle is narrow.

- Lining with reinforcement. Product with a double profile and a width of 125 mm.

- Extended panels. They differ more in width (up to 0.5 m).

Color solutions

Plastic ceiling panels are made matte or glossy. If you need to give additional depth and volume to the room, it is better to use a glossy finish.

For ceiling mounting, white panels of different purities are produced. But you can find colored lining or standard PVC panels of various tones.

Density

The density of the material is a necessary characteristic. Insufficient value of the parameter can lead to the fact that communications laid under the ceiling (telephone, Internet, electrical wiring) will be visible when the light is on.

The denser ceiling elements allow for recessed luminaires and simplify the false ceiling design - fewer cross members are required.

Features of panels in comparison with different finishing materials

From a hygiene point of view, plastic is the best material. It is easy to clean, not susceptible to fungus and microorganisms, moisture does not penetrate into it. In addition, it should be noted that:

The negative feature is that plastic is easier to damage than ceramic tiles, artificial or natural stone.

How to calculate the quantity?

There are several options for calculating the number of panels required for cladding.

Contact the specialists of the store where the purchase of material for outdoor work is made. As a rule, managers of specialized companies are trained to make such calculations, and have the necessary computer programs for this. However, it should be understood that even a professional cannot make an accurate calculation without a building plan indicating the specific numerical values of its parameters.

Regardless of whether you yourself think or entrust this matter to professionals, it is important to understand what makes up such calculations.

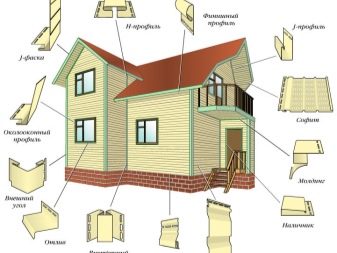

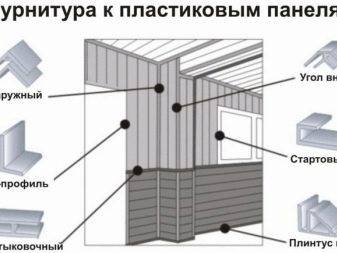

For a beautiful and correct installation, you need to purchase a variety of components.

- The panels themselves for the facade and plinth.

- The starting bar from which the first row begins. It can be replaced with a more durable starting profile.

- A drain bar, which has a decorative function, and also acts as a kind of ebb when placed above a plinth or a protruding element of the structure.

- Connecting strip or H-profile - used to separate elements or join several short profiles.

- Internal and external corners.

- The finishing profile allows you to complete the installation by hiding the top trimmed edge of the panels.

- J-profile with a decorative function or as a window frame.

- The slope profile is used to design openings.

- Soffit - a panel designed for filing a cornice cut.

To calculate the number of panels, it is necessary to divide the area of the facade to be faced by the usable area of the panel itself. In addition, the stock of panels for cutting, scrap and stock should be added - approximately 7% of the number of the resulting number of strips.

There are 2 ways to determine the area to be lined.

- Multiply the length and height of the building. This method is suitable if one of the sides is faced or the building has a simple rectangular structure.

- A more accurate method is to calculate the area of each side and then summarize the results.

From the resulting area, it is worth subtracting the area of those surfaces that are not covered by the profile. These are door and window openings.

Finally, today on the Internet you can find calculators to calculate the required amount of siding. All you need is to set the area of the surface to be decorated and the useful width of the siding. Depending on the functionality of the calculator, you can immediately set the area of the facade or instruct the program to make calculations by specifying the linear dimensions of the length and width of the walls.

To avoid errors and program failures, to get the most accurate results will allow the use of 2-3 independent calculators.

Regardless of the calculation method used, remember that the siding is mounted on a crate, the installation of which will increase the length of the walls, respectively, and the area of the facade will increase. When using insulation and vinyl panels, the length of the walls after the lathing increases significantly - by 4-6 cm.

The most accurate way to calculate the material required for wall decoration is the graphical method. To do this, on a sheet of paper, you need to draw all the parts of the house that are supposed to be finished. The drawing must contain all the elements of the building and correspond to the real object at the selected scale.Next, panels are drawn and cut out on the same scale. They should be a miniature copy of the ones you plan to mount.

After these preparations are over, you start the "mosaic" game, that is, you apply panels to the walls of the building, cutting them if necessary. This method is good in that it allows you to minimize the amount of scraps and rejects, and, therefore, you will not need to buy material with a large margin.

It is not difficult to find out how many starting planks are required - you need to measure the perimeter of the building, subtract the length of the openings from the results obtained, and then divide the resulting number by the length of the panel. On average, the same amount of drain bars will be required.

The number of external and internal corners is calculated based on the number and height of the corners of the building. H-profiles are calculated manually if there is a need to join several profiles. Window panes are calculated by dividing the total perimeter of windows (calculate separately for each window and add the values) by the length of the profile. Slight differences depend on how the window is mounted.

In the next video, you will find a detailed video instruction on how to install Holzsiding vinyl siding from Holzplast.

PVC wall and ceiling panels: properties, advantages and disadvantages

The main advantage of PVC panels is the price - there are no competitors for this parameter. It is worth noting the vapor and moisture resistance, which allows the installation of such material in a bathroom or kitchen. The durability is beyond doubt - in the absence of mechanical action, this parameter is 50 ÷ 70 years. Installing plastic panels is simple - a home craftsman without experience in such work can easily cope with this. Resistant to plastic and liquid detergents or gel-based products.

Plastic made to look like natural wood. Looks original

But one cannot ignore the disadvantages inherent in this finishing material. Let's start with fire hazard. Despite the fact that even cheap panels can withstand temperatures up to 350 ÷ 400 ° C, an open fire can easily ignite them. Such plastic products burn with acrid, poisonous smoke. Mechanical damage is also fatal for such products.

Direct sunlight is contraindicated for materials of low and medium price range - they are "led" from ultraviolet radiation. And, of course, the psychological factor. Many people think that plastic gives living spaces an office look. But this is a misconception based on ignorance of the market.

For a loggia, plastic trim is a good option

Modern finishing materials made of plastic do not differ in appearance from natural wood or stone (depending on the design). Plastic can be distinguished only upon closer inspection.

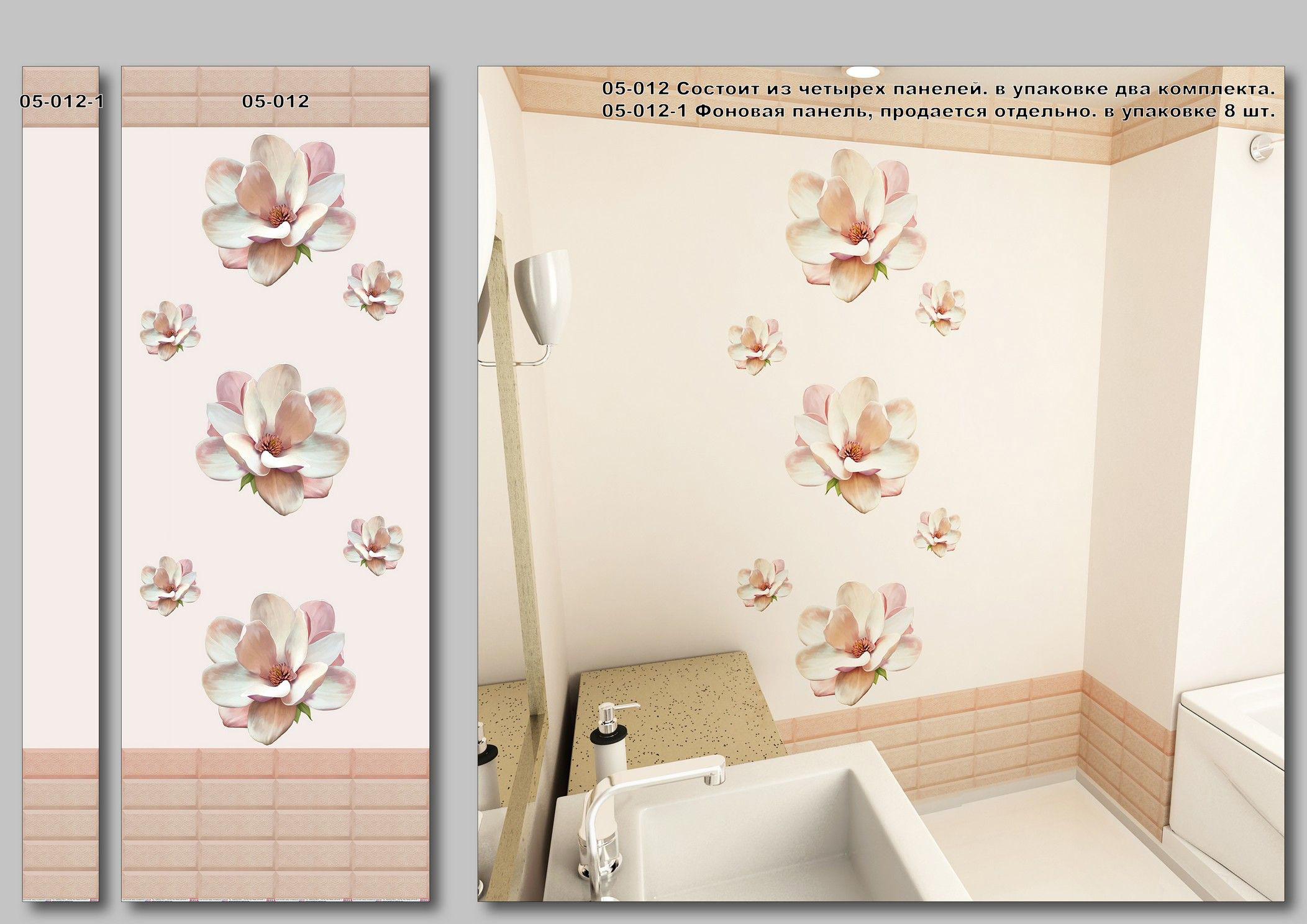

PVC panels

Accessories and tools

Plating a bathroom with plastic panels is a fairly simple work, anyone can do it with their own hands. For a bathroom to acquire a beautiful and stylish look, it does not require special skills and a lot of time. To renovate the premises, it will not be necessary to carry out global preparatory measures during the cleaning of walls and partitions.

Before tiling a bathroom, the following tools and materials should be purchased:

- PVC panels;

- wooden blocks;

- a profile made of plastic, metal or wood along with brackets for fasteners (it is better to use brackets with a metal base);

- construction stapler for fixing products;

- self-tapping screws;

- you can use a hacksaw to cut a metal base; craftsmen advise purchasing a product with fine teeth;

- mounting knife;

- construction hammer;

- an electric grinder, with its help, the products will be cut;

- screwdriver;

- tape measure for construction work;

- building level;

- hammer drill, which has the function of "drill";

- an ordinary pencil or markers, with their help you should make the markup;

- pliers;

- ladder.

In order for the cladding to be made correctly, it is recommended to preliminarily expose the crate along the walls of the bathroom. It is made of plastic or metal profiles. If work is carried out in spacious bathrooms, PVC panels can be mounted on a timber frame. After preparing the items necessary for work, you can do the installation itself. The work should be carried out sequentially in order to exclude the appearance of errors.

What are the moisture-resistant wall panels for bathrooms?

There are quite a few options for finishing the bathroom, to determine the best material, it is important to analyze all the advantages and disadvantages of each of them. Finishing options can be divided into:

- rack and pinion;

- tile materials;

- sheet canvases - it is advisable to choose them for large rooms.

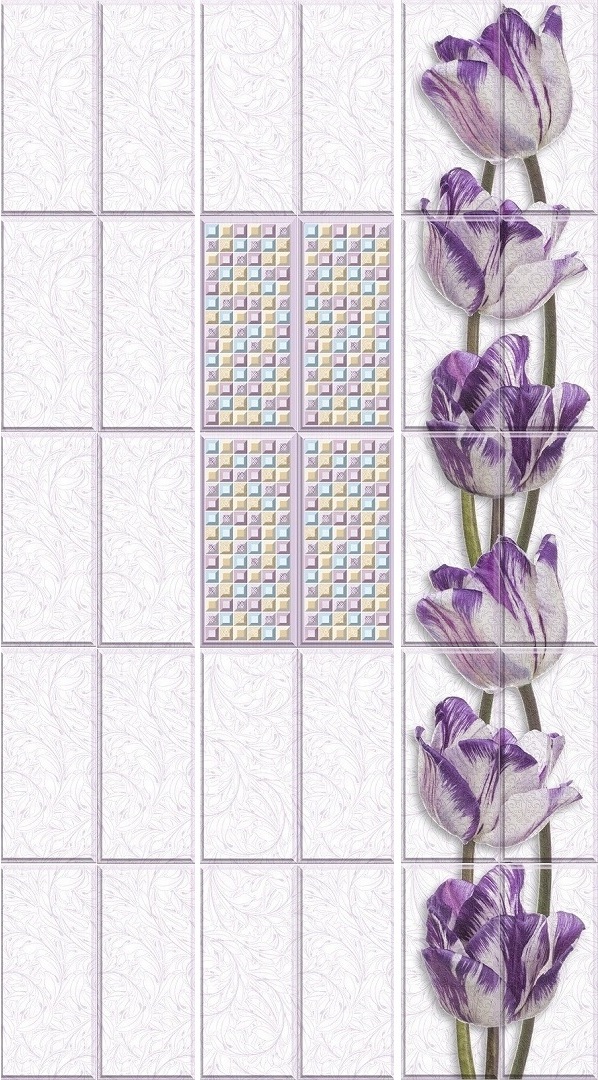

Characteristics of PVC wall panels for bathroom

PVC is the most inexpensive material for bathroom decoration. The technology for the production of polyvinyl chloride allows the production of panels with imitation of wood, natural stone or ceramic tiles in different colors. The main advantage of the material, in addition to moisture resistance, is that it is non-toxic even at high humidity. Interesting interior solutions using PVC panels for the bathroom are presented in the photo gallery.

PVC in the interior is not inferior to tiles

Related article:

Characteristics of MDF panels for the bathroom

MDF bathroom panels are suitable only with a laminated coating, it prevents moisture from entering the chipboard. If we compare the characteristics with PVC, MDF has undoubted advantages:

- high strength;

- a large number of supports are not required, therefore, the structure is more durable;

- the finished product is painted;

- has heat and sound insulation.

The only drawback can completely negate all the advantages: hydrophilicity. Unfortunately, chipboard absorbs moisture, it will take a little time for the board to become unusable. To prevent this effect, it is necessary to apply additional coating and completely isolate unprotected areas.

The finished MDF sheet does not need additional decor

Characteristics of MDF bathroom panels

Fiberboard fibers have a low density, therefore they are afraid of moisture and can swell. To use fiberboard in conditions of high humidity, they must be treated with a composition with the effect of moisture resistance. For use in the bathroom, it is recommended to choose laminated hardboard - fiberboard sheets that are treated with bitumen impregnation, then covered with a film and a special compound with protective properties. As with MDF boards, it is necessary to control the integrity of the film coating, this is an additional protection against high humidity, it must be intact. During installation, all butt joints are treated with a sealant.

It is undesirable to use laminated fiberboard in the bathroom

Related article:

Characteristics of moisture-resistant chipboard-based panels

Chipboards are made of shavings and small chips. Ordinary boards, like fiberboard, are afraid of moisture, they swell and lose their shape, which does not recover even after drying. Manufacturers produce moisture-resistant boards, which include binding components, and the surfaces are additionally laminated. For bathrooms, you should choose a material with a waterproof effect. In terms of cost, it is equivalent to moisture-resistant MDF for a bathroom, however, MDF is much better in terms of characteristics.

Laminated chipboard is also not quite suitable for the bathroom.

Related article:

Characteristics of acrylic bathroom panels

Acrylic lamellas are innovative developments of manufacturers. The concentration of additives affects the color and structure of the material. The gloss on the surface is much higher than that of PVC and MDF. The main advantages of acrylic can be identified:

- high strength;

- resistance to mechanical damage;

- resistance to abrasion and light reflection;

- environmentally friendly product;

- absolutely waterproof.

The only drawback of acrylic does not overshadow the entire list of advantages - it's high price. Only water panels can be considered as its competitor.

Range of acrylic lamellas for the bathroom

Glass wall panels

Tempered glass lamellas are quite in demand for wall decoration in the bathroom. The smooth and shiny surface beautifully reflects the glare from the lighting, this effect will visually expand the space, the room will look radiant. The advantages of finishing include:

- not afraid of temperature changes;

- resistant to high humidity;

- easy care;

- durability.

Glass paneled bathroom interior

Other types of wall panels

When choosing a material for finishing a bathroom, one cannot but highlight the water panels, today this is the most ideal solution. They are a fiberglass mesh filled with weightless expanded clay. Of the positive qualities, it should be noted:

- resistance to high humidity and temperature extremes;

- easy care;

- beautiful appearance;

- the material can be bent.

During installation, the aquapanels are attached to the wall surface using special glue on a pre-assembled frame.

Aquapanel is the best solution for the bathroom

Varieties

The cladding made of polyvinyl chloride may differ in the type of surface. There are three types: glossy, matte and mirror. And also the products have various dimensions. The thickness of the material clearly demonstrates the strength indicator. The higher the number, the more reliable the casing. Another criteria by which this class of finishing material is divided is the method of applying decor to the sheet and the appearance of the product. The standard cladding is white matte panels. Snow-white glossy products are widespread. Manufacturers use a special transparent varnish to shine the surface.

Advantages and disadvantages

The use of decorative 3D panels is due to a number of advantages.

- Ease and simplicity during installation. No special preparation is required for fixing this finishing material.

- Facilitated preparatory work. Before installation, you do not need to level the walls, fill up gaps or joints - an excellent masking of the shortcomings of the base. The panels cover any surface irregularities and even out corners.

- Original design. The room, in the decoration of which this material is present, acquires a touch of luxury and chic and cannot leave anyone indifferent. The room immediately takes on an extraordinary look.

- Correction of imperfections in the geometry of the room. Depending on the pattern used, the visual boundaries of the room can vary greatly: the ceiling can appear higher and the space can appear larger.

- Good thermal insulation. 3D panels perfectly retain heat, which has an excellent effect on the thermoregulation of the room, especially in the cold season. And when using additional heaters laid behind the panels, you can perfectly reduce heat loss by 50–70%.

- Excellent combination with other materials. These wall materials are perfectly combined with wallpaper, tiles, and wood, therefore they are used in a wide variety of interiors.

Despite such a wide range of advantages, 3D panels have some disadvantages.

- High price. This finishing material is considered one of the most expensive in the construction market, so not everyone can afford such a pleasure. The price is due to the complexity of the technological process.

- Some materials used in the manufacture of embossed wall panels are difficult to maintain. For example, gypsum or natural wood is afraid of moisture. In addition, such materials are not recommended to be cleaned with aggressive chemicals.

- The wrong choice of pattern can greatly tire the eyes and worsen the general well-being. Therefore, the choice of drawing must be approached very responsibly and carefully.

Scope of application

MDF panels are widely used for interior decoration. They decorate floors and ceilings, make furniture from them and even transform entrance doors. Such popularity is not accidental, because MDF boards allow not only to hide the unevenness of the walls, but also to refine the interior in the shortest possible time and without unnecessary dirt. They can be mounted in any direction, it is convenient to "hide" wires and communications behind them. In terms of cleaning, it is enough to wipe their surface with a damp cloth, and no chemicals are used.

MDF wall slabs can be slatted (long and narrow), outwardly reminiscent of a wooden lining. Tiled rectangular or square are similar to tiles, and sheet ones are wide, smooth sheets. Thanks to the variety of shapes, you can modify the room by visually narrowing or expanding the room.

Depending on the application, the installation of MDF sheets has its own characteristics.

- Due to the unevenness of the walls, the panels are often mounted by attaching them to aluminum profiles. If the walls are flat, it is permissible to use the glue method. The glue should be thick and retain plastic properties after drying, which will not allow the boards to deform or shrink.

- If you plan to decorate the ceiling, the panels for it should be lightweight and easy to attach. The optimal solution would be the use of slatted panels, the connecting elements of which are liquid nails, a special glue solution or a construction stapler.

- The material is adjusted in length using a jigsaw or circular saw, and you can fix it alone. But for the installation of tiled or sheet MDF, at least one assistant will be required, which is not always convenient.

- Dense moisture-resistant sheet panels are laid on the floor. If the sheets are laid on a subfloor, it is worth using slabs that are more than five millimeters thick. If installation is carried out on logs, you should choose MDF from ten millimeters thick.

- In any case, before work, the base should be leveled and cleaned, and then the slabs should be laid "sprawling". The gap between the panels and the walls is 2–4 millimeters, and the distance between the panels themselves is 2–3 millimeters. Fasteners should be installed along the perimeter of the panels in increments of 10-15 centimeters. Then they begin to sand the surfaces and putty joints, and only then to paint. The base made of MDF can be used both under laminate flooring and under any flexible finishing material.

The design of the front side of MDF panels is also diverse. In addition to the usual flat products obtained in the pressing process, there are slabs with a relief surface. The volumetric pattern obtained as a result of stamps, stickers or milling looks original, but it gets dirty quickly, and such panels will have to be wiped much more often.

On top of the decorative films, transparent glossy or matte polymer coatings are glued onto the laminated boards to protect the panels from mechanical damage. The veneered front sides of the panels reproduce the natural wood pattern, while the matt or glossy shades of the painted surfaces will be a stylish decoration for the interior.

If you want to bring to life any unusual design idea, you should pay attention to the panels with a smooth, raw surface. At home, you can clean it yourself, putty, close the pores, smooth out irregularities, and then prime and paint with the desired color

MDF is "afraid" of water, but a bathroom or kitchen, a loggia or a veranda can be finished with moisture-resistant MDF panels, protected by a laminate on the outside and inside.You just need to take care that they are protected from direct contact with water.

How to choose?

There is no doubt that when buying wall panels, everyone wants to get a practical, high-quality and durable material that will last for many years, allowing you to forget about repairs.

To make dreams come true, you need to pay close attention to a number of performance characteristics: The size of the front panel - it is generally accepted that the thicker it is, the better, since the wear resistance, strength and durability of the plate largely depend on this indicator

Obviously, if the plastic panel can be easily damaged, then moisture will penetrate through the cracks and chips, provoking the appearance of fungal spores and the growth of mold. Of course, there is no panel that will withstand a blow with a hammer or brick, but it should ideally cope with most of the not so significant loads.

The size of the front panel - it is generally accepted that the thicker it is, the better, since the wear resistance, strength and durability of the plate largely depend on this indicator. Obviously, if the plastic panel can be easily damaged, then moisture will penetrate through the cracks and chips, provoking the appearance of fungal spores and the growth of mold. Of course, there is no panel that will withstand a hammer or brick blow, but it should ideally cope with most of the less significant loads.

The number of stiffeners - here the principle and dependence is the same as in the previous case: the more, the more reliable. The number of stiffeners determines the susceptibility of the tile to deformations, so ideally there should be at least 20, and best of all - 29

Separately, focus on their appearance - the edges should be even and have the same width along the entire length, and in addition, their location should be strictly perpendicular to the tiles connecting them.

Appearance - a high-quality panel has a uniform color, dents and ribs are not visible on it, in addition, before the final purchase, it is worth checking how tightly the panels are attached to each other.