What are they?

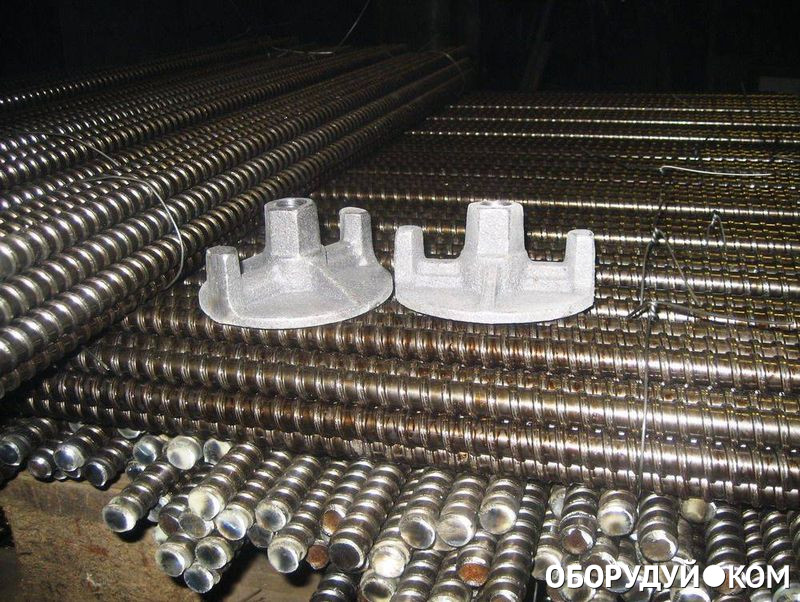

The size range of formwork fasteners is now quite wide. Their strength according to DIN 18216 can range from 85 to 240 kN. For the manufacture of such bolts, steel from St20 to St35 is used. The M16 size is relatively rare. Products with a diameter of 15, 20 or 25 mm are much more common.

Structures with a cross section of 15 mm have an actual cross section of 177 mm2. In this case, the specific gravity of 1 m of rolled products will be 1.38 kg. The maximum deviation for all indicators is taken equal to 4%. With a cross section of 20 mm, these parameters:

-

314 mm2;

-

2.44 kg;

-

4%.

With a section of 25 mm, they will be:

-

490 mm2;

-

3.8 kg;

-

4%.

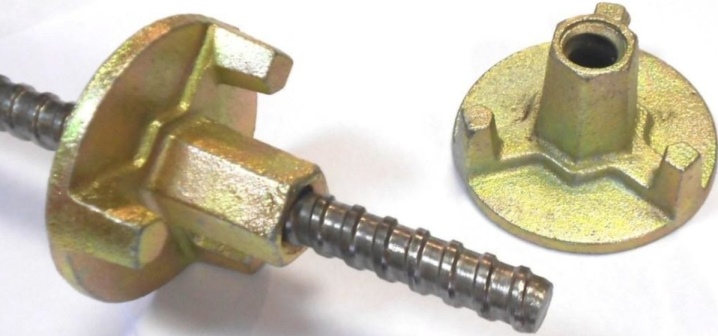

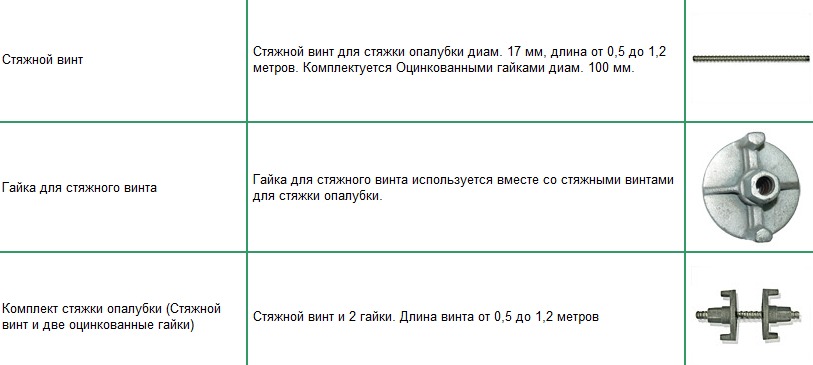

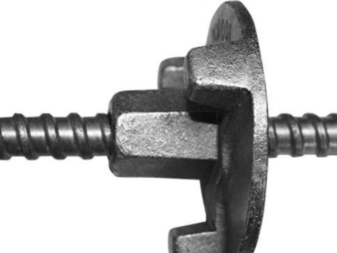

Compression screw (bolt) and nut

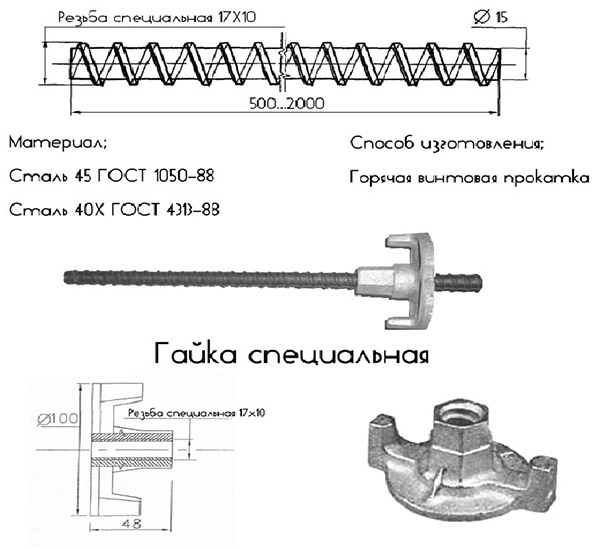

The set for fixing the formwork sheets consists of clamping screws, which are metal rods with a threaded regular thread along the entire length and special screw-on nuts, in which the head is of a universal type. The outer diametral dimension of the thread is 17 mm, and its inner size is 15 mm.

The thrust elements for the shuttering panels are two nuts, which are screwed on both sides along the screw thread. In order to improve the stop in front of the nut, as a rule, massive washers with a square shape are installed.

- The standard dimension for this thrust piece is 18 mm.

- Formwork equipment manufacturers produce formwork screws in various sizes, ranging from 0.5 m to 3 m.

This production factor of need is due to the fact that in terms of technical parameters, formwork panels for arranging monolithic foundations, walls, columns and ceilings have significant differences.

In order to make the right choice of fixing elements for the formwork, the following technical points must be strictly taken into account:

- the thickness of monolithic walls;

- the thickness of the shields, to which it is necessary to add a spare length of 300 mm for screwing the nuts and installing the thrust elements, in the form of washers.

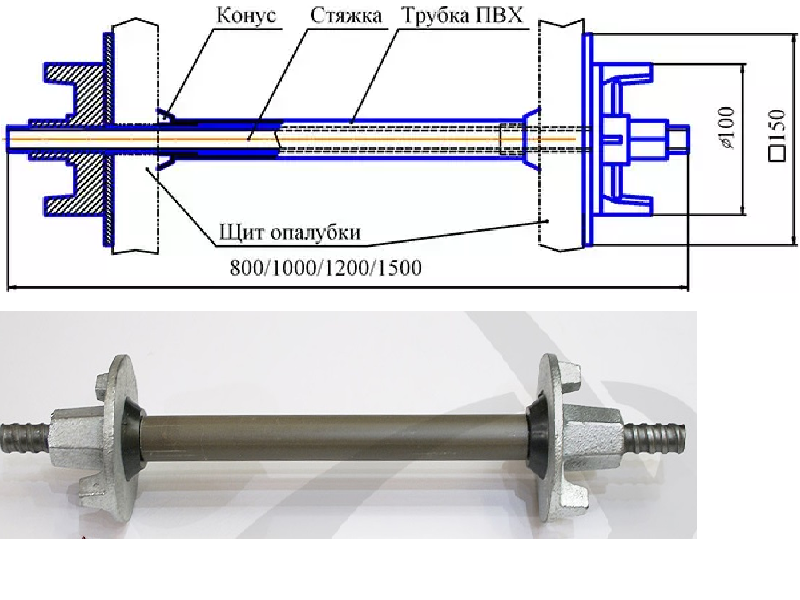

To avoid the appearance of corrosion on the fixing bar elements, special metal sleeves must be used, into which they are inserted during the assembly of the formwork structure. Such sleeves make it much easier to dismantle the screw connectors when disassembling the panels.

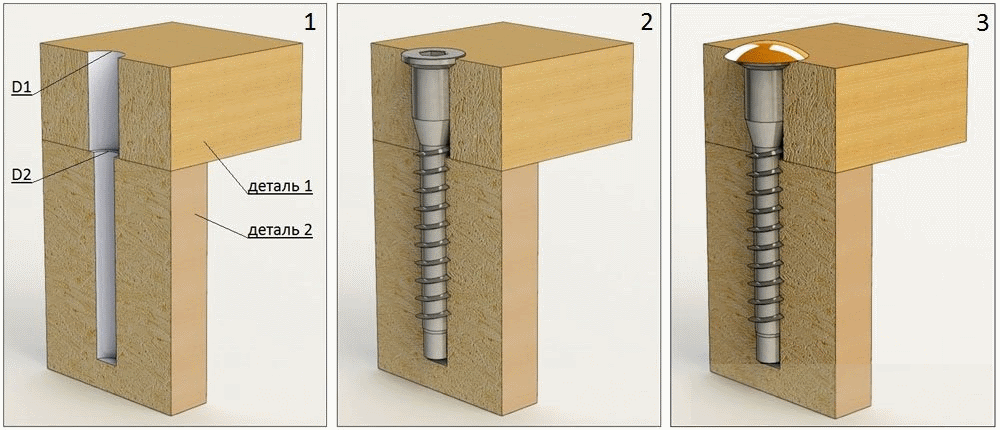

Mounting

A pair of special nuts helps to secure the formwork clamping screw. They must be accurately cast from an extra strong or malleable grade of cast iron. To avoid difficulties with screwing the nut onto the bolt, chamfer is removed for its entry. In this case, the contact area with the formwork shield increases. Usually it is 90 - 100 mm.

But in especially difficult situations, due to the additional completion of washers with a cross section of up to 180 mm, the size of the contact area increases even more. A polymer pipe will help prevent the destruction of the screws by the concrete mixture. Thanks to it, further dismantling of the formwork is greatly simplified. The outer cross-section of the threaded tie should be 1.7 cm, and inside it is 1.5 cm. Thread smelting is usually done immediately, but it can be cut later.

Such fasteners are universal and compatible with formwork of any shape and size. Therefore, it can be used when working with a wide variety of types of monolithic wall blocks. Additionally, a plastic tube is used (which should be larger than the bolt in cross section). Cone clips are inserted from both sides of the pipe. When installing a clamping block without plastic protection, reuse is impossible; if such protection is used, the bolt can be easily removed.

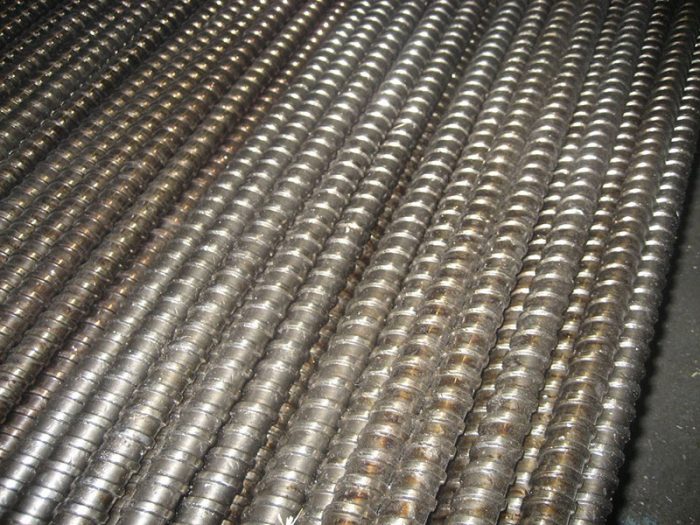

Low alloy steel formwork bolts give the best results. They are made using hot rolled products.For your information: in professional sources, the same product can be referred to simply as a "tie", an anchor rod or even a "hairpin". Together with the tie bolt the following can be used:

-

lamb;

-

hex;

-

hinged type of nut.

Before installing the shields, it is necessary to drill channels of a suitable section inside them. If a typical tie bolt is used, screeds with a diameter of 2.2 cm are used. It is necessary to punch channels not at the very edge, but at least 10 cm from the edge. A fixing cone, a plastic pipe and the next fixing cone are attached to the inserted bolt. The opposite edge of the hairpin comes out through a special hole in another shield; the edges of the bolt extend beyond the shields to the extent that the nuts are loosely fastened, and washers could be placed in front of them.

The following video talks about the tie bolt.

What are furniture hardware?

When assembling soft corners or sofas, furniture bolts and screws are used that comply with GOST 7801. The head of such bolts is semicircular. or with a mustache (the mustache saves the screw from turning). To make the fastening more reliable, special flat washers are installed. Their sizes may vary. Most often, M6 threaded bolts are used with a length of 30-40 mm.

The clamping parts are convenient for working with different materials. They are installed on furniture made of wood, plywood or chipboard.

The fastening reliability is ensured by accurate marking. Tightening hardware can be made with a countersunk head installed in a specially prepared hole. In mass production, parts 5 × 50 and 7 × 50 are used. Their appearance is made with a galvanized imitation or yellow passivation is used.

Tightening occurs by screwing one part of the bolt into another

If there are hidden places in the headset, furniture bolts are installed without a protective layer. True, such parts are used only for products that are operated at low humidity levels.

In high humidity, fittings with a zinc coating are installed, which reliably protects it. Sometimes parts are chrome plated to give a beautiful appearance.

Furniture bolt "Din 603" became a striking representative of such products. It is made in the form of a cylindrical rod ending with a head. The thread is cut entirely or only to a specific length. A special nut is used to create a powerful connection.

Such a fastening is characterized by increased strength, therefore it is used not only for fastening wooden products, but also for assembling metal structures. If we talk about furniture, then a similar furniture bolt is used in garden furniture made of thin sheet metal.

Furniture bolt "DIN 603" 10x45

Characteristics of tie bolts and nuts

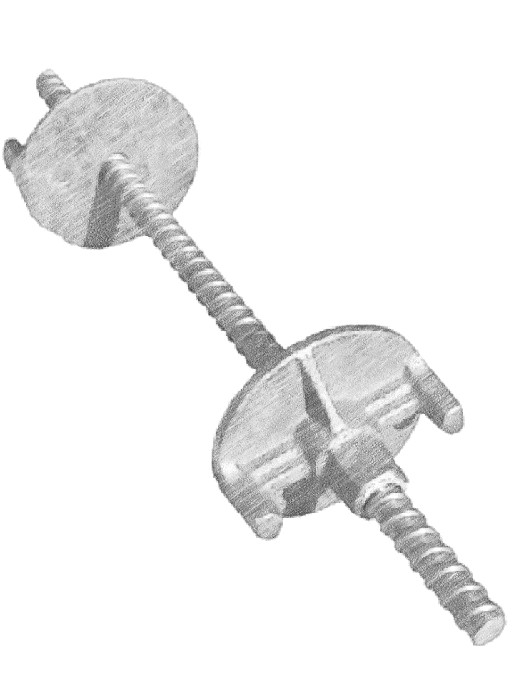

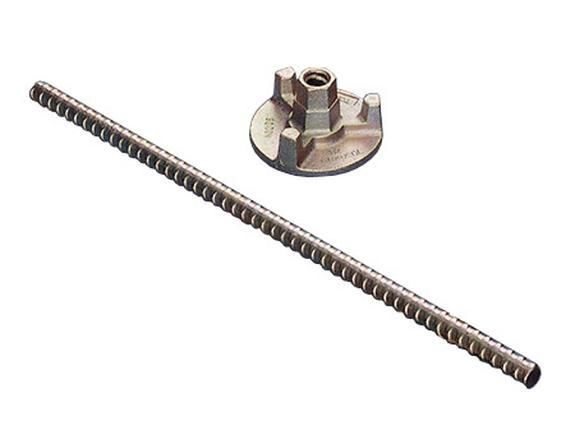

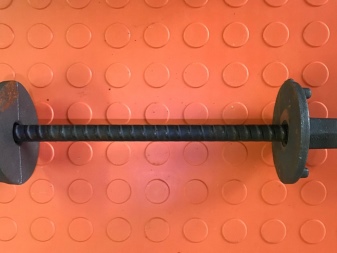

The use of tie screws for formwork allows you to assemble strong forms to give concrete structures the configurations specified by the project. This part is a full-length threaded metal rod.

Its main purpose is to hold the boards in a given position and ensure the design thickness of the concrete structure. The screw is used to assemble various types of construction formwork (small-panel, girder-girder, etc.).

Equipment

When assembling the formwork, a screed kit is used. The kit includes:

- the actual coupling bolt;

- two nuts;

- two washers larger than the nuts.

In addition, the installation uses:

- plastic tube, the diameter of which is greater than the diameter of the bolt;

- cone clamps to be inserted on both sides of the pipe.

If the clamping element is installed without the use of a plastic protective tube, it will not be possible to remove it after the concrete has set. And since the hairpin is not cheap, it is more rational to use it repeatedly.

Therefore, a PVC tube is first inserted into the mounting holes, and a clamping screw is inserted into this tube. After the mixture hardens, the bolt is easily removed, and the tube remains in the concrete structure forever.

Characteristics of the straining screw

Low alloy steel is used for the production of formwork tie bolts. Work is underway to manufacture them by hot rolling.

Standard screw sizes are:

- diameter 17 mm;

- length from 0.5 to 3 meters.

If necessary, you can order the production of tie screws for the formwork of a greater length, but in this case, you will have to pay more than when buying standard products.

Characteristic of nuts

Two nuts are supplied with the tie rod. This element can be:

- hex;

- lamb;

- articulated.

This element is made of high-strength cast iron by high-precision casting, and a zinc coating is used to protect against corrosion. The inner part of the nut, which adjoins the shields, is flat.

To ensure a more tight fit, the nut is equipped with a washer. The purpose of the washer is to increase the area of support on the shield. Main characteristics of the nut:

- base diameter - 900-100 mm;

- design load - 14 tons;

- thread diameter (outer) - 17 mm;

- thread diameter (internal) - 15 mm;

- thread pitch - 10 mm.

Peculiarities

The construction of various buildings and structures is unthinkable without many connections. And in many cases it is possible to perform these very connections with the help of tie bolts. This type of fittings is becoming more popular from year to year. Unlike the same concrete screed, it can be easily dismantled, restored if necessary, or moved to a new location. In addition, the installation time is significantly longer than when using other options, and there is no particular difference in reliability.

This type of fastener is covered by GOST 7798-70. According to this standard, a grade B hex head must be used. The thread cross-section is 6 to 48 mm. Additionally, it is worth considering the use of GOST R 57899-2017. This standard sets out the general technical conditions for anchors and ties used in formwork.

A high-quality tie bolt connects the formwork quite effectively. Mechanical deformation of concrete mixes is excluded. This property is typical even when installing heavy, powerful structures.

Technical specifications

Tightening hardware is made of carbon steel. In order for the part to resist corrosion, it is coated with a layer of zinc, sometimes even chrome plated. There are copper or brass products. If the installed furniture is handled carefully, and it is not subjected to heavy loads, such parts are used for many years.

The clamping fixing screws for the handles are equipped with a thread. The length of the part is in the range of 2-20 cm. It all depends on the thickness of the material to which the handle is attached. Together with the screws, the furniture is completed with nuts and special washers corresponding to the dimensions of the part.

Clamping screw M6 with cylindrical head

How are the door handles attached?

The handles are attached to the canvas in two ways:

- using a square rod;

- clamping screws.

Fittings with a pin are fixed with special fastening parts

It is important that the square of the door handle pin matches the section of the hole on the door body

The pin should have a length corresponding to the thickness of the blade on which the handle is mounted. If the fastening is carried out with clamping elements, the handle is attached to the door much stronger and more securely.

Consequences of a weak attachment of the handle without a tie

You can use different methods for attaching furniture handles, but practice shows that a reliable and strong fixation is possible only when installing clamping screws. Installation of such a handle and its installation can be done independently, without using the services of professionals.

A detailed overview of the Din 603 bolt model is shown in the video below.