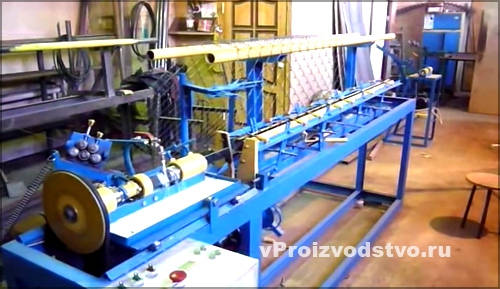

Description of the technological process

The machine performs all the work on the manufacture of products in an automatic mode. The operator is required to: load a spool of wire, program the microprocessor according to certain parameters (wire thickness, mesh diameter, coil dimensions) and press start.

The wire from the coil is pulled up to the area of the spiral formation with the help of an unwinding device and guide bushings, where it is wound onto the auger (an operating mechanism that twists the wire into a spiral for subsequent weaving).

The coiled spirals move to the guillotine mechanism where the wire is cut. One of the ends of the wire is bent in the form of a hook (half the length of the intended cell), the workpiece is pulled through the groove of the continuously rotating shaft and attached to the guillotine device.

The cut off spiral is held by the grippers, stretching under the influence of the suspended load.

Then, the machine winds the next spiral with the interweaving of the one held by the grippers, forming the cells of the chain-link mesh. After cutting the newly formed spiral, the grippers release the held wire and the net is wound into a roll of the programmed length.

The mesh is treated with machine oil, the edges are packed in thick paper and the finished rolls are compactly folded into the storage space.

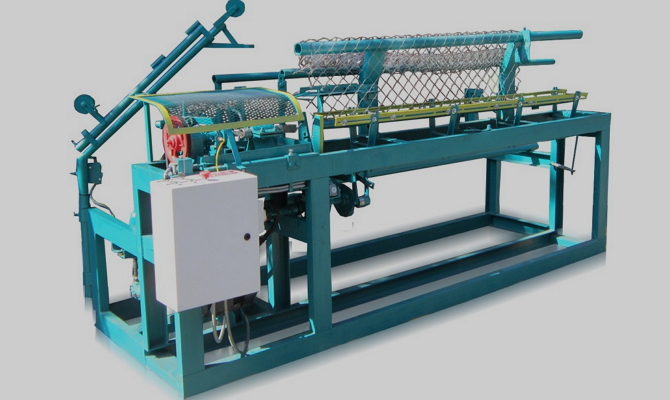

1 Machine model АСР15 / 2

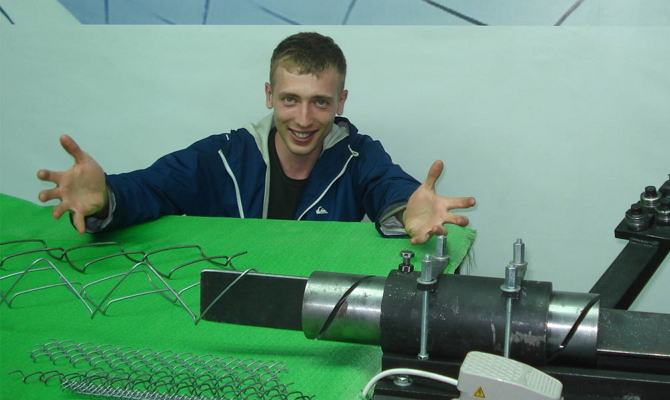

The design device of a semi-automatic machine for a chain-link mesh assumes the presence of an operator who not only monitors the manufacturing process of finished products, but also takes a direct part in the operation of the weaving equipment. This type of equipment for the manufacture of chain-link mesh is distinguished by its simplicity of design and ease of adjustment, relatively small size and low cost.

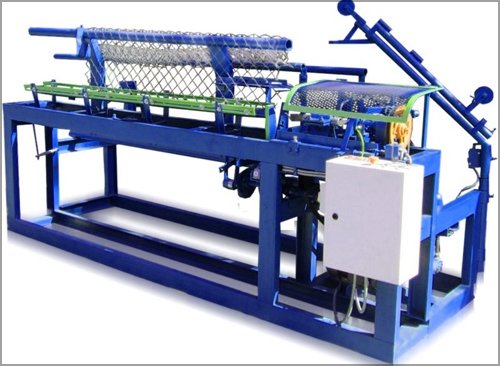

Automatic equipment for the production of mesh netting is a device that allows you to organize the manufacture of products in an automatic mode, when all production processes occur automatically, without significant intervention in the manufacturing process of the operator. This equipment is highly complex both in operation and in setting up.

Manual machines are used only in a subsidiary farm for personal needs, which is due to the low productivity of such equipment. With the help of this equipment, a do-it-yourself netting netting is made at home.

Do-it-yourself mesh netting

Do-it-yourself mesh netting

The machine for knitting a net model АСР15 / 2 perfectly suits as equipment for production lines located in small premises. In the process of operation of this equipment, the bending of the ends, the implementation of winding the web, stopping and cutting the wire are carried out without the direct participation of the operator. This equipment is an improved model with a significantly longer service life, high productivity, and a reduced noise level during machine operation.

The device for the production of chain-link allows the manufacture of products that meet the requirements of GOST 5336-80. Such products have a mesh size of 20 to 60 mm. The knitting process is carried out in one wire. This principle of operation of the device makes it possible to simplify the implementation of the machine setup. The standard height of the finished product roll, produced on this equipment, can be up to two meters. The design of this equipment allows, if necessary, to reconfigure the machine for the production of products with a height of up to three meters.

The design of the machine allows the use of various types of wire in the production of building material with deviations from the accepted standards and having uneven rigidity.

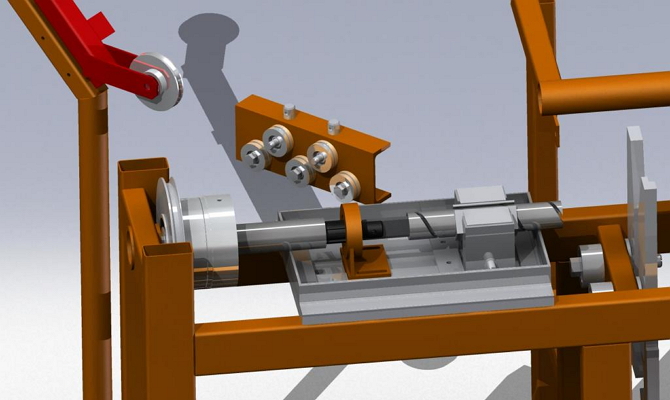

Construction of the ACR15 / 2 machine

Construction of the ACR15 / 2 machine

Manufacturing of building materials takes place in an automatic mode, all processes are controlled by a microprocessor. Setting up production parameters on this machine is quite easy and does not require much effort and special knowledge.

This model has a system of continuous circulation of lubricants and coolants. The presence of such systems in the device of the model makes it possible to increase the service life of the consumable tool up to 1000 rolls.

The operation of the model is designed in such a way that in the event of a wire jam, the machine automatically stops, and the previously established technical settings are not lost.

Equipment types

The equipment used for the production of chain-link differs in the level of mechanization of manual labor. There are the following types of equipment for the production of mesh:

- manual machines;

- semi-automatic machines;

- automatic installations.

Machine tools, depending on the degree of automation, differ in price and performance.

Hand tools

The manual machine makes it possible to independently produce the mesh of the required size. A compact, low-noise, inexpensive machine does not require electricity costs, since it is powered by human muscle strength.

The installation allows you to produce up to 50 meters of mesh netting per shift, subject to the work of an experienced craftsman. The machine is not intended for the production of a chain-link on a commercial scale, since it has low productivity and a limited service life. However, manual installation is quite capable of ensuring the production of products to meet their own needs.

Among the machines offered on the market, it should be noted:

- The machine for the mesh of the BMP brand, the cost of 18,700 rubles;

- Manual machine for the chain-link "MODEL SB - 1406", cost from 12,000 rubles.

Semi-automatic device

Working on a semi-automatic machine implies the constant participation of the operator in the production process. However, no special training is required. Responsibilities include threading the wire, and at the end of the production cycle - winding the net into rolls. Aggregates of this type have advantages over other models, consisting in compact dimensions and low weight of devices with their high productivity (one machine produces 120-150 l / m chain-link per shift), efficiency, ease of adjustment and control, as well as a relatively low price.

Among those on the market, the following models are distinguished:

- Semi-automatic reinforced Machines 74, cost from 95,000 rubles;

- Semi-automatic SB - 1407, cost from 62,000 rubles;

- Machine Machine 74, cost from 40,000 rubles.

Automated constructions

Automatic machines themselves provide the entire production cycle without the participation of an operator: you just need to program the necessary parameters and load the wire into the machine. Such a machine guarantees powerful performance, weaving precision and high working speed. The productivity of the installations reaches 120 l / m mesh per hour. Before starting work, the operator must undergo an introductory briefing on operating the unit. When purchasing an automatic machine, you should also take into account the potential costs of commissioning, technical inspection and maintenance of the equipment. Plants of this type are oriented towards commercial production.

The high quality and productivity of the following automatic installations is noted:

- ASP-6, cost from 359,000 rubles;

- ASU-174M, cost from 155,000 rubles;

- SB - 1408, cost from 215,000 rubles;

- MODUL B-747, cost from 335,000 rubles.

Equipment for the production of mesh-netting and a room for a mini-workshop

The main expenditure part of the organization of the production of the netting is the acquisition of machines that make the netting.There are many types and manufacturers (you can even find instructions on how to assemble a machine yourself from "improvised" parts on the network). We will not delve into the delights of folk craftsmen, therefore, we will consider two main industrial options: semi-automatic machines and fully automated machines.

Semi-automatic - require the participation of an operator who controls the process of making the mesh. Advantages: small size, ease of setup and operation, low cost (35,000 - 40,000 rubles). The main disadvantage: despite the partial automation of the process, a lot has to be done with manual labor, incl. and the fold of the mesh, which allows for a certain asymmetry in the sizes of the cells and other minor flaws.

Automatic - provide a fully debugged production process that does not require external intervention.

Advantages: high productivity, precision weaving, fast bending and minimal operator intervention (load the spool, remove the finished roll).

Disadvantages: higher price compared to a semiautomatic device (from 200,000 rubles), the cost of repair and maintenance, the need for special training of personnel.

To calculate the business plan, it is planned to purchase an АСР15 / 2 automatic machine at a cost of 250,000 rubles. in the following configuration: machine, unwinding device, 2 sets of accessories (screw sleeve, winding plate, receiving pipe), passport, operating instructions. The machine produces a mesh in accordance with GOST 5336-80 in a wide range of mesh sizes (20-60 mm). The cost of the equipment includes delivery, personnel training and warranty maintenance throughout the year.

Additional costs - the purchase of shelves for storing finished products, a receiving table, an operator's workstation worth 50,000 rubles.

Total capital investment for opening a mini-shop: 300,000 rubles.

Before purchasing equipment, you need to select premises for production.

For the operation of one machine, 15 m2 + 10-15 m2 for storage of finished products will be enough. The main requirement for the room is the presence of a 3-phase power supply.

Types of machines

Equipment for knitting mesh-netting is represented by a large number of machines. They differ in type, and sometimes it is not easy to choose the right one. When choosing, an important condition is the quality of the machines, which will make it possible to make a good chain-link. The weaving process should be easy to operate and highly manufacturable. The chain-link mesh is made on various types of machines.

Manual option

Suitable for weaving mesh at home. In order for this equipment to work, the constant participation of the worker is required. This makes the process unprofitable and time-consuming. As a rule, such a machine has a manual drive. Among the differences, it is worth noting the small size. For a manual unit, 3 square meters are enough. You have to wind and braid the spirals of the mesh with your hands. Such a machine consists of a strong supporting frame for fastening the working units (bed), a working element responsible for winding the mesh (auger), a drive lever, a gearbox, and guide rollers. These machines are not used commercially as they require constant presence and intervention from the worker. As a result, the process turns out to be unprofitable from an economic point of view and time-consuming.

Using a manual setting, you can make spirals from wire with a diameter of 1.5-6 mm. The cell size can vary from 0.3 to 0.6 in. This parameter depends on the different augers. Subject to experience in one shift, you can make 50-60 meters of chain-link fabric. It is difficult to produce commercial mesh on such a machine, and the machine has a short service life. On a manual unit, you can make a sufficient amount of chain-link to create some kind of fence (for a site around the house). A large number of units of this type are offered for sale, but among them the BMP brand stands out.Its features are simple design and fault tolerance.

Semiautomatic device

The semiautomatic device combines wide functionality and compact dimensions at the same time. Such a device is suitable for weaving mesh even in the garage. Unit cost starts from 45 000-50 000 rubles... A person must necessarily work on semi-automatic equipment, since some processes are manual. For example, this includes the folding of the mesh. The disadvantages of the device include inaccuracies associated with the human factor present. Most often, such machines are stationary and are distinguished by their significant weight and good performance. It is best to place them on 10 square meters. m, in a place where there is constant power supply.

Wire feeding and cutting as well as web weaving are carried out mechanically. The level of performance of such devices is sufficient for the average commercial production. Moreover, the quality of the mesh on the semi-automatic equipment is better than on the manual device. For a shift using such a unit, it is possible to produce from 120 to 160 running meters of mesh. A distinction is made between devices that do not have a control module (PS) and those with a control unit (PS-A). Among the most popular options, PSR-2 is known, which works with a wire with a diameter of 0.1-0.3 cm. It produces a mesh with cells of 0.2-0.6 dm. In this case, the width of the canvas will be about two meters.

Machine

The machine is perfect for mass production of high quality chain-link. When working with such a device, the operator only loads the tray with raw materials, and then removes the finished roll. The automatic unit is highly efficient. In an hour, he is able to create 100-120 sq. m of mesh-netting. You can place such a device on an area of 15 square meters. m

When using the equipment, it is important to observe that the operating modes are performed correctly and the machine is in good working order. The machine automatically curls spirals, weaves mesh cells, bends the ends and even rolls into rolls

Wire with a diameter of 0.8-6 mm can be used as raw material. In this case, the cell size can be obtained up to 8 cm, and the width of the web - 20-250 cm. Due to a good control system, one employee is enough to operate several automatic machines at once. In such installations, all parts are of high quality and reliability. The working resource of the units reaches 15-20 km of track.

2 The main advantages of the АСР15 / 2 model

This model is very easy to operate and has a high level of operational reliability. When using several machines of this model, they can be operated by one operator.

The main advantages of this model are:

- high reliability of the mechanical part of the model due to the use in the design of a reliable single block of a gear motor instead of separate gearboxes and electric drives;

- the use of a unique emulsion pump in the liquid supply mechanism for cooling allows to extend the service life of the equipment set;

- carbide inserts are installed in the guide bushings designed for feeding the initial material, which makes it possible not to replace them throughout the entire service life of the equipment;

- the model has an improved performance of the weaving process, which is achieved by reducing the downtime between technical stages in the operation of the equipment;

- the machine does not require anchoring to the floor during installation;

- the equipment has a high maintainability.

Highly maintainable equipment

Highly maintainable equipment

The payback of the model is approximately two to three months, which is achieved due to the high performance of ACP15 / 2. The delivery set includes an automatic machine of the АСР15 / 2 model, a special device for unwinding, passport and technical documentation and two sets of equipment. One set of accessories includes a front pipe, screw sleeve, winding plate.

Analysis of demand and assessment of the sales market for mesh-netting

According to consumption estimates, about 90% of all manufactured mesh is spent on arranging fences and other fences at construction sites, backyards and summer cottages, making aviaries for birds and animals. The remaining 10% is occupied by various needs of construction, agriculture, mechanical engineering, energy (reinforcement during plastering, sieving crushed rocks and building materials, strengthening slopes from embankments, making protective screens for ventilation shafts, protecting heating mains and pipelines, etc.).

The price of a net and its application depends on the following factors:

- cell sizes;

- material for manufacturing (black, galvanized metal, polymer coatings, stainless steel);

- wire thickness;

- roll sizes.

Before starting production, you should evaluate the demand for a netting in your region: take into account the quantity, approximate sales volumes, assortment (and the most popular positions) from competitors, analyze existing offers and prices at wholesale construction depots and retail stores.

The main channels for the sale of mesh-netting (finished products):

1) Self-realization. The final consumer is individuals.

Pros: the ability to set the maximum markup.

Cons: Advertising costs, store or showroom space, shipping costs (shipping).

2) Retail stores (construction, household). Oriented to summer residents, owners of country houses, private construction. The final consumer is individuals.

Pros: when concluding a sales contract with a network of retail stores, you can achieve relatively constant sales of products.

Cons: high store markup (about 30%), high competition, small volumes, sales that depend on many unpredictable factors (seller recommendations, product location on the shelf, attractive appearance);

3) Wholesale depots (firms selling various metal products). Focused on large orders, construction firms, industrial enterprises, retail chains. The final consumer is legal entities of all forms of ownership, private entrepreneurs.

Pros: large volumes, time saving (no need to run around the shops, negotiate, sign agreements, etc.).

Cons: high competition, large, but irregular, mostly seasonal sales, which can be described in one phrase: "rare, but aptly."

4) Direct sales to industrial enterprises (participation in tenders)

Pros: the ability to work "on order", a guaranteed level of sales. The products are not stored in the warehouse, they are paid according to the contract, without vague terms of sale.

Cons: It is almost impossible for a "novice" in business to win a tender on favorable terms.

Of course, in theory, the best option would be to work out all the channels, but in practice, such a volume of work in a short time is not feasible. Therefore, the general recommendation is to start with retail sales, while simultaneously looking for alternative options, building up your own customer base.

Calculation of a business plan for the production of wire mesh

To calculate the profitability of the business, we will take as the finished product the most popular mesh for fences with a mesh size of 55 * 55 mm, made of galvanized wire with a thickness of 1.6 mm.

Income part

Machine productivity (for cell size - 55 mm) - 48 m2 / hour. With one-shift work and 22 workdays / days per month, the production volumes will be: 48 m2 * 8 hours * 22 days = 8448 m2 / month.

Standard mesh roll sizes are 15 m2 (10 m long, 1.5 m wide). That is, the volume of production from one machine will amount to 563 rolls per month.

Selling price:

- retail - 650 rubles / roll (30% of sales),

- wholesale - 450 rubles / roll (70% of sales).

Total income: (169 roll * 650 rubles) + (394 * 450) = 287 150 rubles / month.

Cost calculation

Raw materials for the production of mesh-netting - low-carbon wire (according to GOST 3282-74) uncoated, galvanized or with colored decorative polymer coating.

The price per ton of galvanized low-carbon wire with a tensile strength of 560-900 N / mm2 and a diameter of 1.6 mm is 37,000 rubles.

Wire consumption per 1 m2 of netting is calculated by the formula: Mass (kg) = (13.40 * D2 / A, where 13.40 kg / mm is a constant coefficient; D is the wire diameter in mm; A is the cell diameter in mm ...

According to this formula, the wire consumption for a chain-link mesh with a cell of 55 mm will be: (13.40 * 1.6²) / 55 = 0.62 kg.

Roll cost (based on wire spent) = (wire weight * number of m2 per roll * net cost) = 0.62 kg * 15 m2 * 37 rubles = 344.10 rubles.

The cost price of 563 rolls (productivity per month) = 193,728.30 rubles.

Expenditure part

For an accurate calculation of costs, from the difference between the profit from the sale and the cost of production, you need to subtract the wage fund for employees, utilities, electricity, rent and other costs, which are calculated on an individual basis, based on tariffs, prices and agreements in each specific situation and for a specific area.

Approximate calculation algorithm:

Labor remuneration (1 operator, 1 sales manager) - 32,000 rubles / month,

Payroll taxes - 14,400 rubles / month,

Rent of a mini-workshop 30 m2 - 10,000 rubles / month,

Electricity (when the machine consumes 1.5 kW / h) - (1.5 kW / h * 176 h) * 4 rubles / hour = 1056 rubles / month,

Other utility bills (heating, garbage disposal, water) - 2000 rubles / month.

Income tax (STS) - (287 150.00 - 193 728.30 - 59 456.00) * 15% = 5094.86 rubles / month.

Total expenses: 64,550.86 rubles / month.

Top Models

The rating of machine tools showed that among the whole variety, three models stand out especially.

ACR15 / 2

In the first place is the ACP15 / 2 machine, which is distinguished by simple settings and controls. He makes small quantities of netting. Due to the low noise, any place is suitable for installation, even near residential buildings. Without an operator, the unit is able to independently bend the ends of the mesh, wind the web, cut and stop. As for all other processes, they are performed by a person. At the exit from the machine, a mesh with a mesh of 18-50 mm and a height of 2-3 meters is obtained. For knitting, wire is used in one thread. Moreover, it can have a polymer coating or be unevenly rigid.

Among the advantages of the device, it is necessary to single out a gear motor as a whole, as well as an improved cooling system due to an emulsion pump. Guide bushings serve for a very long time and without failures, as they are coated with special hard alloys. When the unit is forced to stop, the program settings specified earlier are not lost.

SPA 01-04

The second place went to a knitting machine called SPA 01-04. This machine creates a mesh with a mesh of 2-6 cm. Conveniently, one millimeter thick wire with a galvanized coating is suitable as a starting material. The unit works completely independently. The operator only prepares the work template in advance, as well as supplies the initial and removes the finished materials from the unit.

The device automatically unwinds the wire, weaves a chain-link, bending the ends on each of the cells. At the end of weaving, the finished fabric is rolled into a roll. If material becomes entangled at one of the stages of the device's operation, it will stop automatically. Conveniently, the unit is equipped with high-quality cooling to avoid overheating. The device is capable of producing 65-180 sq. meters of chain-link. If desired, the machine can be supplemented with special devices that allow the net to be wound on a separate coil. It is convenient that the unit can bend the ends of the chain-link on both sides.

BCA-97

The BCA-97 model also entered the top of the best chain-link weaving machines. With this device, you can get a canvas with a mesh of 10-60 mm and a width of 50-200 cm.Among the advantages of the unit, users note the universal design of the passage elements, which allows the use of any wire. Machine repairs can be carried out using simple car parts. You can find the latter in any specialized store, which can be found even in small towns.

To install the machine, you will need approximately 20 square meters of floor space. One operator will be able to work simultaneously with three such devices. The quality of the wire directly affects productivity. For example, with a stable feedstock, the machine can produce 50 square meters per hour. m of canvas with a cell of 50 mm. Also, many people like that the device is easy to configure and at the same time performs all the functions automatically.

Semi-automatic machines

Such machines for the manufacture of mesh netting are stationary, they have a large weight, dimensions and productivity.

To place them, you will need from 10 square meters and a constant power supply. The main working bodies of this device are the same as those of the manual one. It mechanized the following operations:

- wire feed;

- wire cutting;

- weaving of a mesh fabric.

The operator feeds the wire and engages the spirals while weaving. The operator also has to roll the web into rolls.

Semi-automatic machine

Such equipment provides sufficient capacity for commercial mesh production on a small to medium scale to make sense. Due to the constant bending force and the rolling speed, the quality of the final product is significantly higher than with manual production. One machine is capable of producing 120-150 running meters of chain-link per shift.

Among the models on sale, the PSR-2 machine stands out. It is capable of working with wire from 1 to 3 millimeters, forms cells from 2 to 6 centimeters. The width of the produced web is up to 2 meters. The sturdy welded frame made of metal profile provides good support and does not need additional anchoring to the floor.

Choice of organizational form and other legal issues

To open a mini-workshop, the optimal organizational form is an individual entrepreneur (IE). OKVED 28.73 - "Manufacture of wire products". But the choice of taxation system depends on your target audience of buyers. If the end consumer is private individuals, it will be most beneficial to choose a simplified taxation system. Enterprises prefer to cooperate with legal entities or individual entrepreneurs - VAT payers.

For a business plan, we will take into account taxation according to the simplified taxation system - 15%. The tax base is income minus expenses (of course, all financial transactions for calculating taxes must be documented and correctly executed).

The production of a chain-link mesh is regulated by GOST 5336-80. According to the current legislation, manufacturers are not required to confirm the quality of products with an appropriate certificate. But in practice, the passage of voluntary certification and compliance with the requirements of GOST in production significantly increases the chances of a successful business.

Chain-link weaving technology on manual and semi-automatic machines

When producing mesh, it is recommended to follow the following guidelines:

- The wire is lightly greased with mineral oil. This is done with a brush in a coil or with a lubricator attached in front of the rollers.

- The end of the wire is bent into a hook.

- The shaft is scrolled until a spiral of a given length is obtained.

- Raw materials are calculated based on the ratio: 1.45 meters of wire per meter of spiral.

- For joining the mesh canvases, several additional spirals are made.

Tension mechanism in the production of chain-link

The finished mesh is attached to wood or steel posts with wire ties. It is recommended to paint the netting made of non-galvanized steel.