Species overview

Products with a semicircular head are widespread. This item meets the requirements of GOST 10299-80. The cross-section of the rod is from 0.1 to 3.6 cm. A steel rivet for a countersunk hammer must comply with GOST 10300-80. For products with a flat head, standard 10303-80 applies. Finally, for semi-hollow samples, GOST 12641-80 is used.

For the manufacture of such devices, steel of the following types is used:

- 10kp;

- 15kp;

- St2;

- St3.

All metal shank rivets have excellent load carrying capacity. However, it is rather difficult to establish them. The semi-hollow type is formed in such a way that the section of the rod near the insert head is partially empty. Finally, the hollow product is easy to rivet. The flip side of this advantage is insufficient connection reliability. Semicircular heads can have different heights. Their use is considered the optimal solution from the point of view of the reliability and stability of the seam being formed.

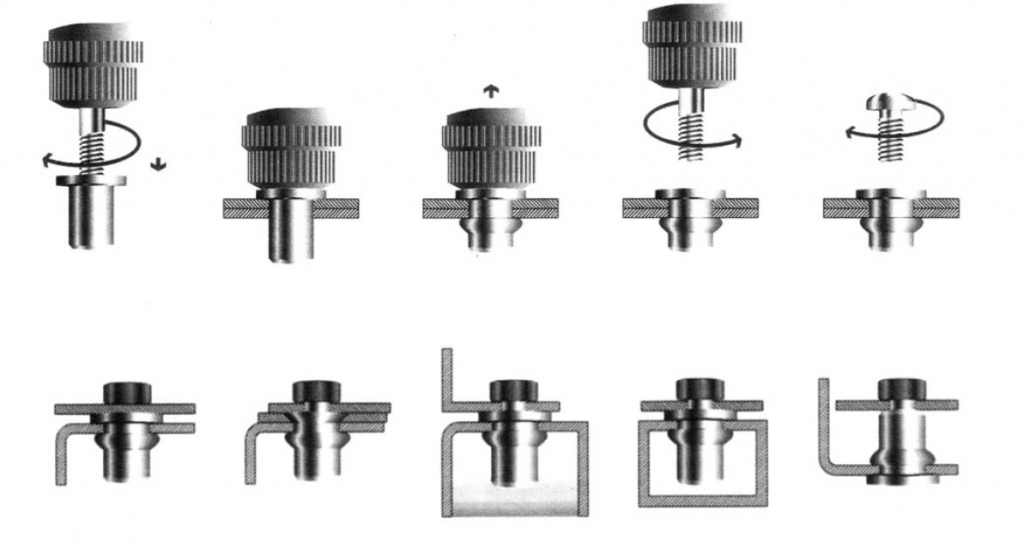

In aggressive environments, rivets with a cylindrical or cone-shaped head are used. Countersunk and semi-secret types are needed if you want to exclude the formation of a protrusion above the surface. Such constructions are used only in cases where there is no worthy alternative to them. A universal type of fastener for a riveter in shape resembles the contours of a mushroom. A separate category is embedded, exhaust, traction and detachable products. Such hardware consists of two main parts. There is no need to hold them on the other side of the seam. This circumstance is very attractive when creating fences and forming roofing.

Sometimes there are so-called threaded rivets. They are used when it is necessary to connect parts with especially thin walls (no more than 0.03 cm). Inside there is a special thread, and outside there is a vertical notch that blocks rotation around its axis. Driven rivets are usually made from:

- brass;

- aluminum;

- copper (and all such products are calculated for hammering and do not require a riveter).

Sometimes a zinc coating is used to improve corrosion resistance. Both "cold" and "hot" galvanizing shows itself well. After such processing, not only performance is improved, but also the visual perception of products.

Important: it is necessary to take into account the formation of galvanic pairs and electrochemical reactions between them. The copper-steel bond results in accelerated destruction of the product

What is riveting

The mechanical connection of parts using a series of rivets is called a riveting, and the connection itself is a riveted seam. It is used where it is inconvenient to weld parts or where non-weldable materials are connected. Not only metals are riveted, thus they connect parts in clothes, accessories, etc. But there it is more of a finish than a loaded connection. So further we will talk about riveting in construction or home improvement. In principle, instead of riveting, you can use a screw connection, but bolts and nuts are more expensive, and their installation takes more time.

This is what a riveted joint looks like

If we talk about installing fences made of profiled sheet, rivets are more reliable, since they can only be removed by reaming the fasteners. When installing screws or self-tapping screws, they can be unscrewed and carried away both metal and hardware. In some cases, riveting is more convenient when installing a roof from corrugated board or metal. On the roof, the installation of screw connections is problematic and time-consuming. And with rivets, and with a good tool, you can do it in an hour or even less.

The most common use in the personal household

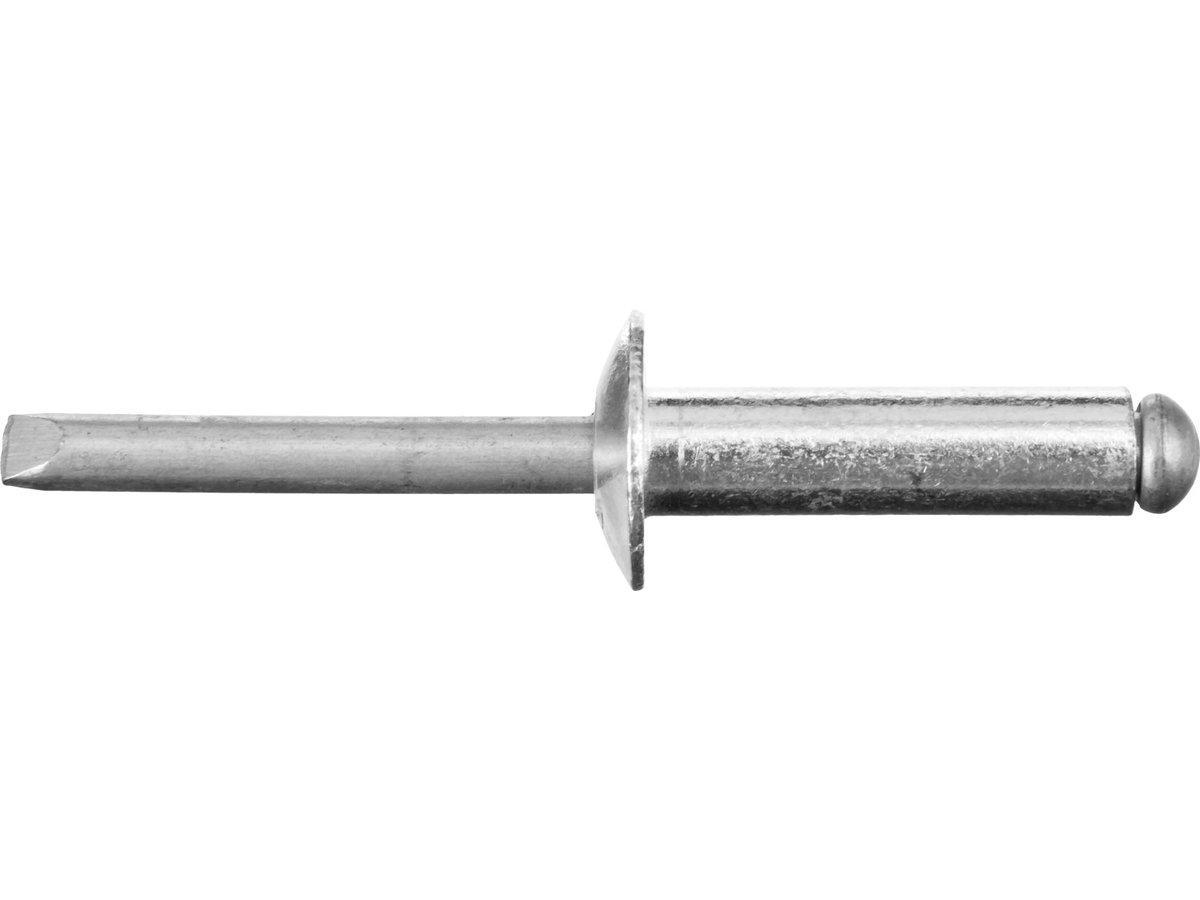

How are parts connected with rivets? The rivet is inserted into the prepared through hole. It has a head that rests against the material and the rod. During the riveting process, the end of the rod is flattened, changing its shape under the influence of force. Therefore, plastic metals are used for these hardware.

Description

These hardware are used to inseparably connect different materials. Before starting work, you need to make sure that this type of product is suitable for specific details. In general, a rivet is a smooth, cylindrical shank with a crown at one end. It is capable of connecting 2 or more elements. For this, the product is installed in a specially prepared hole with a slightly larger diameter than itself.

After the hardware is installed, its back is flattened with a special tool or an ordinary hammer. As a result, the rod becomes approximately 1.5 times thicker, in addition, a second head appears. Aluminum rivets are predominantly painted at the production stage. Most often they are available in black.

They are readily used in the construction of ships and aircraft, in the cosmetic and food industries, and are also successfully used in the chemical industry. This is due to the huge number of positive properties that the material of manufacture possesses.

What material should the rivet be of

Rivets are usually taken from the same material as the parts to be joined - this avoids electrochemical corrosion

Pay attention to the strength characteristics. But, as a rule, when connecting aluminum parts, the strength of aluminum hardware is sufficient

In general, rivets are made from the following metals:

- steel:

- ordinary - grades St2, St3, St10;

- corrosion-resistant Х18Н9Т;

-

galvanized;

- alloyed (stainless) - 9G2, 304, 316.

- copper MT and M3;

- aluminum alloys (more often AD1, D18);

- aluminum-magnesium (AlMg2.5; AlMg5; AlMg3),

- brass (L63).

When connecting copper parts, the installation of brass and copper is permissible. Aluminum is bonded with aluminum alloys. Steel sheets - corresponding grades of steel rivets. There are also mixed hardware - from two different metals (chemically non-conflicting). Most often, there are aluminum-steel.

For the installation of facade elements, slopes, ebbs, metal tiles and profiled sheets, blind rivets made of galvanized painted steel are usually used. Coloring - in tone with the details.

general information

Hammer rivets are used to create a secure connection. To do this, the builder must have access to all sides of the elements to be connected.

It is important to note that the holes in the materials to be joined must be similar to the diameter of the rivet (possible errors are determined by GOST)

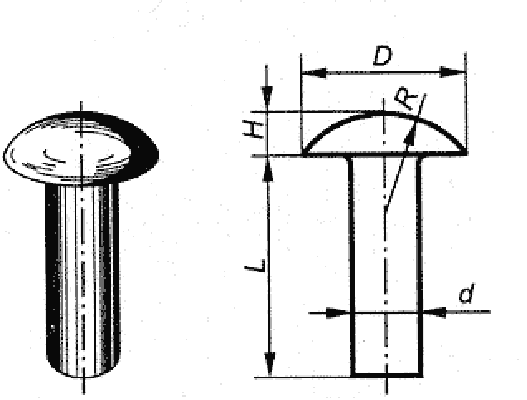

The sizes of the rivets can vary considerably. So, the diameter is in the range from 1 to 36 millimeters, and the length is in the range from 2 to 180 millimeters. This spread makes it possible to use parts in various fields for joining materials of different thicknesses. However, at the same time, it is worth remembering that the size must correspond to the loads that the rivets will experience during operation. That is why experienced builders often advise and recommend using rivets with a "dimensional margin" - it is better to take a part more than less.

Sizing rivets

The rivets are selected based on the thickness of the metals to be joined. In this case, the following are important: the parameters of the insert head, the diameter of the rod. The diameter of the bar determines the diameter of the drill, which is used to prepare a hole in the parts to be joined. You can roughly determine the diameter of the rivet by doubling the thickness of the parts to be joined. The length of the rod is at least 2 diameters of the rivet, and the protruding part must be at least 1.25-1.5 of the diameter.

| Rivet diameter | 2.0 mm | 2.3 mm | 2.6 mm | 3.0 mm | 3.5mm | 4.0 mm | 5.0 mm | 6.0 mm | 7,0 mm | 8.0 mm |

|---|---|---|---|---|---|---|---|---|---|---|

| Hole diameter for precision assembly | 2.1 mm | 2.4 mm | 2.7 mm | 3.1 mm | 3.6 mm | 4.1 mm | 5.2 mm | 6.2 mm | 7.2 mm | 8.2 mm |

| Hole diameter for rough assembly | 2.3 mm | 2.6 mm | 3.1 mm | 3.5mm | 4.0 mm | 4.5 mm | 5.7 mm | 6,7 mm | 7.7 mm | 8,7 mm |

In general, the diameter of the rivet shank can be from 1mm to 36mm, and its length can be from 2mm to 180mm. Moreover, a larger diameter is not equivalent to a greater bond strength. Here both the material from which it is made and its type (hollow or solid) play a role. How do you choose? According to the characteristics of rivets. After all, you choose them for the connection of certain materials of a certain thickness. You know about the load that will be applied to the connection.

Therefore, when selecting, pay attention to what the manufacturer recommends

How to choose a rivet according to the thickness of the material to be fastened? According to the manufacturer's instructions, but in general, the diameter of the rod should be at least twice the thickness of the materials

It must be indicated:

Recommended connection diameter. You just have to pick up the drill and make a smooth hole without burrs.

Minimum and maximum thickness of the bundle to be joined

It is important that your connection is in the specified range.

Shear force. This is the load applied perpendicularly to the joint that the rivet can withstand without breaking.

Breaking force

At what load along the rivet will it collapse?

It is the tensile and shear forces that determine the strength of the future seam. The higher these values are, the more loads it will withstand.

How to use?

It is not too difficult to use rivets - for cylindrical products, you can even do without a special tool, an ordinary hammer is enough. You can work very successfully even in the "field" conditions, not to mention a full-fledged workshop. The largest steel rivets are used in the assembly of bridges and overpasses. Smaller products are in demand in mechanical engineering, instrument making

Important: riveted joints are not tight enough by default, and it is possible to seal them properly only when using sealants and special brands of rubber

A hole is usually drilled beforehand. If a countersunk rivet is used, countersink is recommended. The process in the case of a blind rivet is something like this:

- insert a rivet;

- pull together the necessary details;

- form a closing head (using a tool);

- check the readiness of the connection, if necessary, clean it.

For information on how to make a steel rivet with your own hands, see the next video.

Types of riveted seams

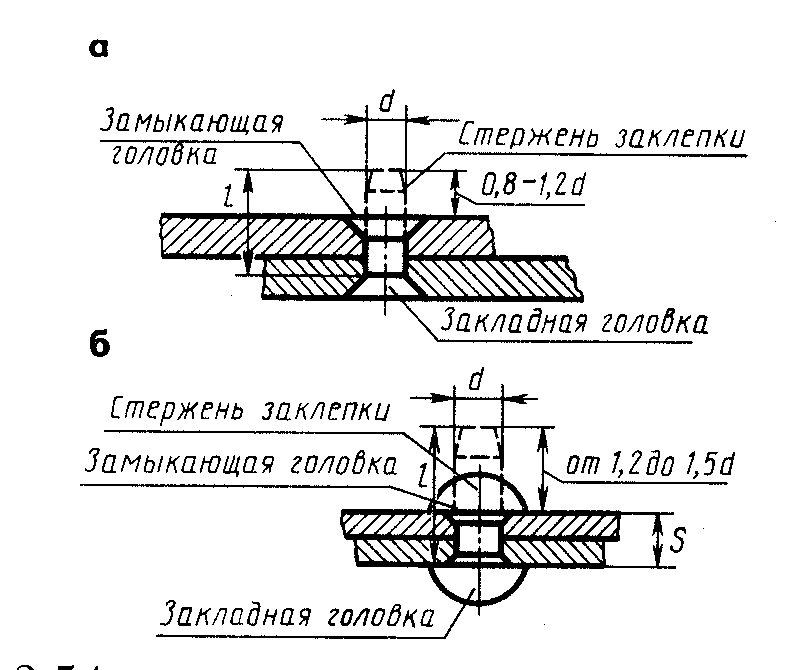

If we talk about the method of joining sheets, then riveted seams are overlapped (one sheet is superimposed on another) and end-to-end. Docking seams can be with one or two overlays. More reliable with linings, used in critical and loaded places.

Types of riveted seams: overlap and butt with overlays

By location of rivets:

- single row;

- double row;

- multi-row.

They can be located opposite each other or in a checkerboard pattern. Seams can be strong, tight (sealed) or strong-tight. Dense ones are performed using elastic gaskets laid between the parts to be joined. Strong-tight are mainly used in boilers. Now they are more often replaced by welding.

Advantages and disadvantages

Like any product, aluminum rivets have a number of advantages, but also some disadvantages. Let's consider all positions in more detail. First, let's talk about the merits. One of the main advantages is the ductility of aluminum. This is very convenient, since it turns out to be fastened quite quickly.

This characteristic allows you to add here low energy consumption, as well as efficiency. In addition, if you carry out the installation correctly, the strength of the connections will not be in doubt, and work can be carried out even at home, without using special equipment.

Installation is quite easy and most often does not require the use of special tools. Aluminum is considered a fairly resistant material, therefore it tolerates aggressive substances well and does not corrode. It is environmentally friendly, which can also be attributed to the indisputable advantages. Moreover, products made from it are very light.

As for the disadvantages, the following points should be noted. Undoubtedly, compared to copper or steel, aluminum is a less durable material. It should not be used if the structure is expected to be exposed to strong and prolonged mechanical stress. Also, its use should be abandoned if the use of aggressive materials is planned. In this case, for example, an aluminum pulling rivet can be used in conditions of negative environmental impact.

If the materials are held together with aluminum hardware, care should be taken to insulate the surfaces as carefully as possible. This will help the metals avoid contact with each other. In this case, it is best to use rubber or copper.

Manufacturing material

Hammer rivets can be made from a variety of materials. For consideration - the most popular varieties.

Aluminum

This type of building parts is also often called exhaust. Their manufacture is regulated by several domestic standards:

- with countersunk head - GOST 10300-80;

- with a semicircular one - GOST 10299-80;

- with flat - GOST 10303-80;

- semi-hollow - GOST 12641-80.

The size grid is quite diverse: diameter - from 1 to 10 millimeters, length - from 5 to 45 millimeters. Moreover, these indicators may vary depending on the type of rivets (hammer, pull, threaded).

Steel

A special place among all hammer rivets is occupied by stainless steel parts. The production of these elements is carried out not only in Russia, but also abroad.

Most often, steel rivets are produced without any additional coating, and their sizes may vary. So, for example, the diameter of the head can be from 1.8 to 55 mm, the height of the head - from 0.6 to 24 mm, the height of the entire element - from 2 to 180 mm.

Due to such a variety of indicators, these parts can be used to connect sheets made of metal, to fix facade plates to substructures, as well as to connect metal structures with parts made of other materials.

Copper

Building parts made from this material are characterized by several distinctive features:

- due to their anti-magnetic properties, they are widely used in the radio industry;

- due to the fact that copper does not rust, rivets made from it are in demand in almost all areas (especially in cases where the materials fastened with them often come into contact with water and air);

- copper elements are used to assemble apparatus and tools for the chemical industry, as they are quite resistant to the action of various artificial substances.

Brass

Brass parts are quite ductile, but durable at the same time. And due to their appearance, they can perform not only their direct functions, but also serve as a decorative or design element. Most often, such elements are used in industrial and instrument-making spheres.

Brass rivets are 4–70 mm long and 2–8 mm in diameter.

In order to choose the right crimp (mandrel) for brass parts with a semicircular head, you should choose crimps that have:

- long service life;

- uniform hardening;

- working ends are polished;

- impact heads are inductively annealed.