Features and properties

In its most general form, a wire is a metal flexible metal rod, usually of a cylindrical shape. It is used to withstand increased mechanical stress, as well as transmit TV and audio signals and electricity. Steel wire can be solid, stranded, or braided. In most cases, it is performed with a rounded cross section, a little less often it is made in square, hexagonal, rectangular and some other shapes.

Steel wire belongs to the category of structural products; it is widely used in the production of steel cord products, steel ropes, metallized nets, springs, as well as various heating elements of electric furnaces. Hardware (nuts, bolts and rivets) are made of wire - in this case, the production is based on the cold heading technique.

The main consumers of steel wire and goods made from it are such areas as metalworking and mechanical engineering, the goods are purchased for the needs of the construction, chemical, petrochemical industries, ferrous and non-ferrous metallurgy. The most widespread wire is made of low-carbon steel alloy, it is a metallized long product with a low carbon content. Thanks to these technical properties, the product is obtained with increased strength in combination with good ductility.

If a zinc layer is additionally applied to a general-purpose steel wire, then it acquires resistance to corrosion. That is why galvanized wire is used in conditions of high humidity, while it retains its initial physical and operational characteristics for a long time. In accordance with the current GOST 3282–74, the steel wire that has been fired becomes softer.

This feature makes it possible to use it for carrying out reinforcing work, as well as include the product in the technological process for knitting reinforcement, packaging possible goods and producing various parts. The wire of the most general purpose is more in demand among all other types of wire.

2 Types and technical characteristics of PP in accordance with GOST 9389-75

According to this Gosstandart, spring wire can be of increased and normal degree of accuracy. In terms of mechanical performance, it is divided into four classes (3, 2A, 2 and 1) and three grades (A, B, C). Class 2A products are always produced with increased accuracy.

Main characteristics of PP:

- diameter - 0.14–8 mm (permitted deviations - from ± 0.01 to ± 0.05);

- ovality - no more than half of the indicated deviations;

- tensile strength - from 1030–1230 (spring wire of class 3 with a cross section of 8 mm) to 2740–3090 (products of the 1st class with a cross section of 0.14 mm) N / mm2;

- the number of twists that the PP can withstand is from 4 to 35 (the specific indicator depends on the raw material from which the wire is made, as well as on the class and type of the finished product);

- weight (set by theoretical calculations) 1000 meters of wire products - 0.1208–394.6 kg.

High precision spring wire

High precision spring wire

GOST 9389-75 requires that carbon spring wire, which is used for winding springs according to the cold method without hardening, be made from carbon steel grades specified in standards 14959, 1050 and 1435. At the request of the consumer, PP can be produced from other steel alloys, in which the content of phosphorus and sulfur does not exceed 0.035 and 0.030%, respectively.

Gosstandart 9389–75 does not allow waviness, rust, hairline, captivity, shells, sunsets, cracks on the surface of finished products, rust, the phenomenon of decarburization (complete) PP. Partial decarburization is possible, but its depth should not exceed 1.5–3% of the section of the wire product.

Spring wire GOST 9389-75

Spring wire GOST 9389-75

The wire is supplied on spools as well as in coils. They wind it in such a way that when unwinding the material does not curl up into eights. On coils and coils weighing less than 250 kg, PP is wound in one piece, more than 250 kg - with a maximum of three pieces. Moreover, GOST 9389–75 specifies the need to lay special plugs in places where the segments are divided. One piece of wire cannot be less than 0.3 kg for products with a diameter of up to 0.25 mm and less than 30 kg for products with a diameter of more than 3 mm kg.

Acceptance rules

Requirements have been established for the accepted products that allow you to monitor their quality. The list of these requirements includes the following provisions:

- the wire is accepted in batches;

- each batch must include a product of the same technical parameters (class, diameter, processing method, type of coating);

- each batch is documented;

- the document includes the following information: product name, manufacturer's details, marking in accordance with GOST, test results;

- weight and size characteristics.

According to the established procedure, the quality of the surface coating is checked on each reel or skein. Diameters and tolerances are checked selectively for 5% of the finished product. Only three percent of the entire batch is tested for mechanical properties.

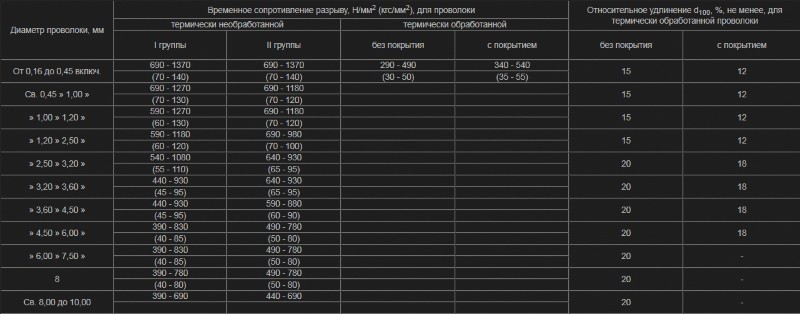

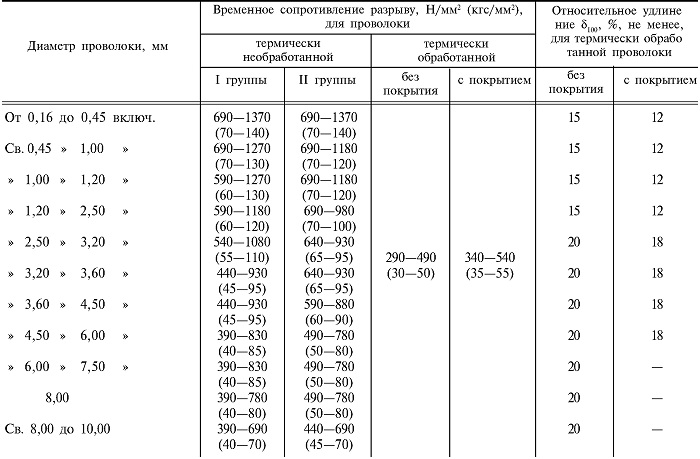

Mechanical characteristics of the wire

If the results are unsatisfactory, re-sample is made, the tests are repeated again.

The end results are considered acceptable for the entire lot.

1 Areas of application of steel wire

For many years, low-carbon steel wire (GOST 3282-74), which is used in various industrial and economic areas, has remained the leader among consumers. So, very often it is used in electrical engineering, when it is necessary to build a ground loop or supports for telephony or power transmission lines. Ropes for berths or ships are also made of this material.

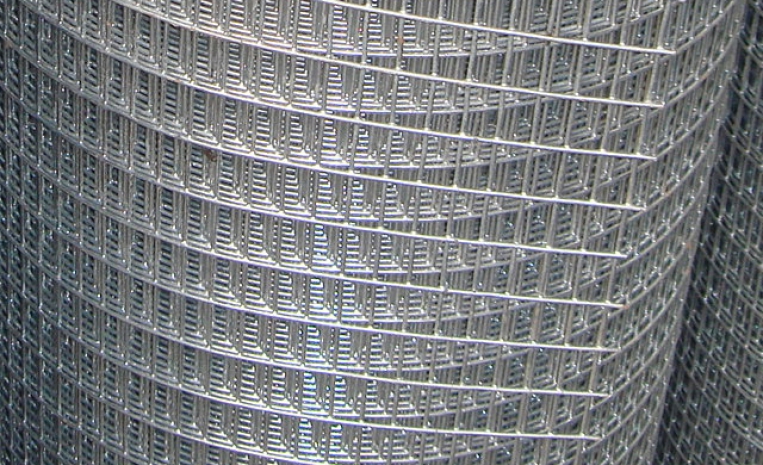

For fastening any parts in any production or household, this product is also used from galvanized steel (GOST 3282-74). Most often, material finds its purpose during the construction of a chain-link mesh, as well as for the manufacture of nails, barbed wire, welded mesh.

Welded wire mesh made of galvanized steel wire

For tying fittings, logging and other items, wire has found its purpose in the construction industry. Also, galvanized wire is widely used in agriculture, medicine and other industries.

It should be said about the use of galvanized steel product in hardware production. It can be noted that the material is general purpose and use.

1.1 Varieties and assortment of steel wire

There are many varieties of galvanized steel wire.

The main ones are:

- stainless - made of a specialized heat-resistant alloy that does not undergo corrosive processes, it is most often used in hardware production;

- welding - there are various diameters of 0.5-8 mm, it is often used during electric arc welding;

- reinforcing - used for additional strengthening of all kinds of reinforced concrete structures that are under high pressure or without tension. Due to the sections that are in the steel material, good adhesion to the concrete surface occurs during reinforcement;

- spring (cold-drawn) - this analogue is intended for the manufacture of springs, which are made by the cold winding technique, without further heat treatment;

- cable car - for the manufacture of marine and other ropes, it is best to weave;

- cable - for the design of armored protective sheaths for cables and wires;

- knitting - made of low-carbon (GOST 3282-74) steel, has high strength and ductility, is most often used in construction and agriculture, for example, for tying weaving plants, and is also considered a general-purpose wire.

The limitation of the validity period was lifted according to the protocol No. 4-93 of the Interstate Council for Standardization, Metrology and Certification (NUS 4-94)

6. EDITION (December 2006) with Amendments No. 1, 2, 3, 4, 5, approved in May 1977, November 1978, December 1983, June 1984, September 1988 (NUS 7-77, 1-79, 4-84, 9-84, 1-89), with Amendment (NUS 2-99)

Editor M.I. Maksimova Technical editor V.N. Prusakova Proofreader E.D. Dulneva Computer layout I.А. Naleykina

Signed for printing on January 15, 2007. Format 60 x 84 * / 8- Offset paper. Times headset. Offset printing. Uel. print sheet 1.40. Academic and Publishing House 1.10. Circulation 95 copies. Zach. 30.S 3573.

FSUE "Standartinform", 123995 Moscow, Granatny per., 4.

Typed in the Federal State Unitary Enterprise "Standartinform" on a PC.

Printed at the branch of the Federal State Unitary Enterprise "Standartinform" - type. "Moscow printer", 105062 Moscow, Lyalin per., 6.

REFERENCE REGULATORY AND TECHNICAL DOCUMENTS

|

Designation of NTD referenced |

Item number |

Designation of NTD referenced |

Item number |

|

GOST 1050-88 |

2.1 |

GOST 15150-69 |

5.10 |

|

GOST 1579-93 |

4.3 |

GOST 15171-78 |

5.3 |

|

GOST 3118-77 |

4.6.1 |

GOST 15846-2002 |

5.4 |

|

GOST 4165-78 |

4.6.3 |

GOST 16272-79 |

5.4 |

|

GOST 4204-77 |

4.6.1 |

GOST 16536-90 |

5.4 |

|

GOST 5530-2004 |

5.4 |

GOST 18617-83 |

5.4 |

|

GOST 6507-90 |

4.2 |

GOST 20435-75 |

5.8 |

|

GOST 8828-89 |

5.4 |

GOST 20799-88 |

5.3 |

|

GOST 9569-79 |

5.4 |

GOST 21650-76 |

5.5 |

|

GOST 10354-82 |

5.4 |

GOST 22225-76 |

5.8 |

|

GOST 10396-84 |

5.4 |

GOST 23639-79 |

5.3 |

|

GOST 10446-80 |

4.3 |

GOST 24597-81 |

5.5 |

|

GOST 10447-93 |

4.3 |

OST 14-43-80 |

5.4 |

|

GOST 10877-76 |

5.3 |

OST 14-15-193-86 |

2.1 |

|

GOST 14192-96 |

5.9 |

OST 38.01436-88 |

5.3 |

|

GOST 15102-75 |

5.8 |

Packaging, labeling, transportation and storage

After the production of steel wire, checking its quality, it is necessary to solve important problems - logistic. They can be successfully solved only with strict adherence to the established standards for packaging, labeling, storage, and transportation.

The following requirements are imposed on the packaging of such a specific steel product:

- finished products are packed in spools, coils, coils;

- to give strength, each skein is tied with the same steel wire (the attachment points should be distributed along the length);

- all packaging units are neatly wound, the ends are brought out in such a way that they are available for unwinding;

- coils of thin steel wire (for example, 0.8 mm and thinner) are tied with steel wire of the same diameter;

- on the spool, the end of the wire must be brought up and have a fastening loop;

- if a whole batch of skeins of the same name is being prepared for shipment, they are combined and tied into bays;

- preservation of shipped steel products is carried out only at the request of the customer.

Wire packing

At the request of the standard, finished products can be packed and preserved as follows:

- spools ready for transportation with wound 0.5mm wire must be wrapped in special paper and placed in boxes;

- coils with wire of a larger diameter, in addition to the paper layer, are wrapped with a polymer film;

- in addition to polymer film, the standard allows the use of nonwoven materials;

- coils of thick wire with a total weight of 500 kg to 1.5 t are not packed.

Based on the established standards, it is allowed to use as packaging material for wire:

- thick paper impregnated with paraffin (in one or two layers);

- various types of films;

- certain types of nonwoven materials (for example, the so-called container stitched fabric, in several layers, impregnated with a special composition);

- special types of fabrics: made of chemical fibers, synthetic fabrics, packaging fabrics;

- for strapping and fastening, it is allowed to use various types of technical tapes.

Preparing the wire for transportation

Finished and packaged steel wire can be sent to the consumer by any type of transport: rail, road, water

When sending a finished order, special attention is paid to the length of the transport arm and the geographic location of the customer.If the transportation involves the movement of the finished order for several thousand kilometers, to areas with a cold and humid climate, then as agreed by the customer, the sender can additionally take measures to protect against corrosion on the road.

The main limitation in the transportation of such cargo is the weight limitation of a single batch. It should not exceed 1.5 tons. The consumer can reduce this rate to a value convenient for him, for example, 100 kg.

When moving the ordered steel wire by covered transport, the weight limit for the package is 1250 kg. Transportation by rail can be carried out: in wagons, open wagons, on open platforms, special and universal containers. In all cases, there is a procedure and rules for securing such cargo on railway transport. These rules are established by order of the Ministry of Railways.

The finished elements are marked before shipment. As required by the standard, it should include the following information:

- information labels;

- transport markings;

- special manipulation signs;

- additional inscriptions can be applied if necessary.

Finished product marking

This information is printed on a label and attached to each reel, regardless of size or weight. Usually this label is made in a typographic way and has columns for the following information: trademark or company logo, product designation, main characteristics. There is a stamp of the technical control service on the label. It confirms the compliance of the shipped products with standards. This label is marked with manipulation signs. They indicate what actions are allowed to be performed with this cargo.

The storage of such products made of low carbon steel does not require special conditions. These conditions are determined by the manufacturer and the consumer himself.

2 GOSTs for steel wire

According to GOST, the groups of steel materials are the same as described above. What kind of GOST of this or that galvanized steel assistant we will describe below.

Table of conformity characteristics of products GOST 3282-74

So:

- Low-carbon steel for general purpose GOST 3282-74.

- Steel welding wire GOST 2246-70.

- Low-carbon steel wire, cold-drawn GOST 6727-80.

- Rope wire GOST 7372-79.

- Spring steel carbon GOST 9389-75.

- Galvanized barbed wire GOST 285-69.

It should be noted that of all these groups, the most common and demanded is steel wire, which corresponds to GOST 3282-74. Nails, welded mesh and other attributes are made from it.

Due to the fact that the material GOST 3282-74 undergoes heat treatment, it becomes flexible, has no deformation properties and is durable.

All kinds of fences are made of steel wire

2.1 Major steel wire manufacturers

Any manufacturer of steel attributes claims that the factor that affects the price of a product is: the type and composition of steel, length, diameter, sectional shape, as well as features of physical and chemical properties.

This is due to the fact that the production process is more laborious and requires more meticulous and filigree work, as well as a greater number of processes.

Also, various hardware is manufactured from steel wire.

A popular manufacturer of wire GOST 3282-74 and other varieties in Russia and the CIS countries is:

- "BALTIJA-MKZ", Latvian-Russian JV, LLC, (Riga);

- TECRUBE SINAQ ZAVODU, (Baku);

- "Belarusian Metallurgical Plant", JSC, (Zhlobin);

- Volgograd Steel Wire Rope Plant, JSC, (Volgograd);

- Dneprometiz, JSC (Dnepropetrovsk);

- West Siberian Metallurgical Plant, JSC, (Novokuznetsk);

- "Zaporozhye Steel Rolling Plant", JSC, (Zaporozhye);

- Izhstal JSC (Izhevsk);

- "Industry", JSC, (Chernivtsi);

- "Kiev hardware plant named after Written ", JSC, (Fastov);

- "Artictrade Company", LLC, (Moscow);

- "Krasny Profinter", Dnipropetrovsk plant, JSC (Dnepropetrovsk);

- "Lepsinsky hardware plant", state joint stock company "Zerger", (Lepsy).

Each manufacturer offers a similar assortment, however some of them have their own characteristics and special offers for consumers.

One or another manufacturer can specialize in the production of a certain type, for example, GOST 3282-74.

Since this particular type, as already mentioned above, is the most demanded, and therefore will bring more benefits.

To get the right kind of wire, you need to clearly know for what purposes it will be used.

In some cases, the steel assistant GOST 3282-74 may not be suitable

That is why it is very important to take into account the type of activity and industry in which the metal material will be used.

Cold Drawn Steel Wire Workshop

If you are unsure which type you will need, it is best to turn to production consultants.

It is the manufacturer who will be able not only to provide you with a quality product, but also advise which type to purchase.

Pay attention to GOST, each manufacturer is obliged to manufacture their products in accordance with the norms and requirements, often on automatic or semi-automatic equipment. Each type of wire can have its own dimensions, which can vary within a certain range.

It is imperative that before purchasing the required wire, you should find out about the required diameter and the amount of material that will be spent.

2.2 How does a steel wire drawing mill work? (video)

Rebar portal »Mesh» Wire »Varieties and assortment of low-carbon steel wire

Production

The release of steel wire is carried out by drawing wire rod on specialized equipment with further firing in a special furnace or without it.

The broaching and drawing process is not particularly difficult from a technical point of view. Compressed wire rod is used as a working raw material, all manipulations are performed on drawing machines. Compared to metal rolling, this operation has many advantages:

- automated operation of machine tools provides increased productivity;

- Drawing allows to obtain products of ideally regular shape with a clean and leveled surface - due to this, the degree of subsequent processing is greatly reduced, and the wire itself acquires improved mechanical properties.

In general, the production of twisted steel wire involves several steps.

- At this stage, etching is performed, the main task is to remove the surface layer of metal and scale, which can interfere with drawing. Surface preparation is performed by degreasing, grinding, polishing and mechanical cutting of rejected areas. Since complex chemical compounds can be present in the scale, the wire rod is treated with acid solutions heated to 50 degrees. After that, the workpiece is washed and dried when heated to 75-100 degrees in special drying chambers.

- At this stage, heat treatment takes place, the purpose of which is to make the metal workpiece softer, relieved of internal stresses. For this, the material is heated, kept for some time and cooled. As a result, the properties of steels change significantly and the wire drawing and firing process is facilitated.

- Further, with the help of a hammer, the steel billets are flattened and leveled. In this way, you can fix the metal on the drum of the drawing machine in order to pass it through the die.

- At this stage, drawing is performed directly.For this, the processed and flat raw materials are drawn on the machine at the highest possible speed through a tapering channel. Depending on the amount of wire drawn, this process can be single or multi-strand.

- At the final stage, firing is performed - the main task of these manipulations is to minimize the stress after drawing the metal. The steel becomes elastic, tensile-resistant and stiff, at the same time pliable to elongation and twisting, such parameters as resistivity and weight of 1 meter are improved.

There are two types of heat treatment.

- Light firing - performed in a furnace filled with inert gas. Due to this, the metal does not undergo oxidation, and scale does not form on it. Finished products acquire a light shade and a very impressive cost.

- Black firing - in this case, the simplest atmosphere is used, scale forms on the surface of the finished products, therefore it acquires a dark color. The cost of such wire is much lower than that of light wire.

Given that the steel alloy belongs to the category of metals that corrodes quickly, galvanizing is often included in the production cycle. The best and highest quality wire is produced using the hot-dip galvanizing technique, since in this case the maximum adhesion of the zinc directly to the wire is ensured.

The finished products at the exit are not afraid of rust and at the same time have an increased level of protection against such unfavorable external factors as the action of ultraviolet rays, wind and temperature fluctuations. In addition, galvanized steel wire is much more ductile than non-galvanized, and thus more durable. After that, the products are cut into pieces and marked.

In accordance with GOST 3282–74, steel wire is produced from steel in accordance with the current standard No1050. The finished wire with a cross-sectional area of 0.5 to 6 mm, which has not undergone heat treatment, at the exit must withstand at least 4 bends without violating the overall integrity and destruction of the metal structure. On the surface of a product not coated with zinc, technological standards allow the presence of small dents and scratches - while their depth should not be more than 1/4 of the size of the deviation of finished products in diameter. But the presence of all kinds of cracks, scales and films of any size is strictly not allowed.

Galvanized wire may have a slight whitish coating on the surface, as well as glitter - but only if they do not impair the overall quality of the coating. It is strictly forbidden to sell and use in the production process steel wire with unmetallic areas and black spots.

Types and main dimensions

Steel wire is divided into two types: zinc-coated and non-zinc coated. This coating is zinc. Also, steel wire is heat treated and not. Products after heat treatment are light and black. The thickness of such a steel wire ranges from 0.16 mm to 10 mm.

The size range of zinc coated products ranges from 0.2 mm to 6 mm. The coverage itself is divided into two classes: first class and second class. The difference between one class and another lies only in the thickness of the coating. All products of the second class have a denser zinc coating, and therefore thicker. Products of the second class are more durable.

Test methods

The following methods have been developed for checking the conformity of the quality of manufactured products:

- weight;

- volumetric gasometric;

- immersion.

Their reliability is based on the sampling method of the general theory of statistics. Therefore, as experience shows, it is sufficient to sample one sample from each given batch.

The first method involves visual inspection and weighing.Visual inspection allows you to determine the state of the selected sample, determine the diameter and depth of the detected defects. These parameters are usually measured using suitable measuring instruments. The diameter and ovality of the steel wire are measured in two planes using a micrometer. Then the data obtained is verified with GOST 6507-78. A prerequisite for such measurements for galvanized wire is the absence of excessive sagging.

Wire quality control

Based on this method, the mass of zinc located on the surface of the sample is determined by calculating the difference between the mass of the sample with zinc and the mass of the sample with the coating removed. Further, according to the well-known formula, the arithmetic mean is calculated. The error of such estimates, with careful testing, does not exceed 0.001 g.

Then proceed to the assessment of the sample according to the following indicators: bending, stretching, rupture. If the diameter of the selected sample does not exceed 0.5 mm, it is possible to replace the usual test by the value of the rupture with the formed knot.

After that, a check is carried out for the so-called winding. The steel wire is wound onto a rod of the same diameter as the wire itself. If the diameter exceeds 6 mm, then the diameter of the rod should be double the diameter of the sample. Then the weight characteristics are measured.

It is used in resolving controversial situations, for conducting arbitration analyzes.

Volumetric gasometric method.

In preparation for the study, remove the entire zinc coating of the sample to the steel surface. For this purpose, it is immersed in a special solution.

The final result is calculated as the arithmetic mean of several test results.

Heat-treated steel wire

The order in which this method is implemented is determined by the following sequence of operations:

- several pieces of wire of the same length are selected from the presented sample (the difference in length should not exceed 0.5 mm);

- each segment is thoroughly degreased (degreasing solutions can be: alcohol, gasoline or other suitable chemical solutions);

- then, using the chemical properties of zinc, they dissolve it (they try to catch all the released hydrogen);

- in laboratory conditions, the volume of hydrogen obtained is measured;

- the known formula calculate the surface density of zinc;

- in sulfuric or hydrochloric acid, the so-called zinc etching is performed.

Immersion method

In this method, a selected sample is immersed in a solution of copper sulfate. The density of the solution should be 1.116 g / cm3. At a temperature of 18 ° C.

In this case, the following order is followed to obtain the results:

- Prepare several test steel bars of equal length (usually 150 mm);

- produce degreasing with rinsing with distilled water;

- each steel sample is thoroughly wiped from traces of liquid and dried;

- then dipped into the prepared solution (it contains copper sulfate);

- the distance from the position of the bars to the surface of the solution should be 100 mm, the immersion time - 60 sec;

- six steel samples are tested simultaneously;

After this test, check the remains of the copper coating on the surface of the bars. If on the surface of at least one steel bar there are areas with residues of copper coating, the sample did not pass the test. The assessment is done visually.