What are they?

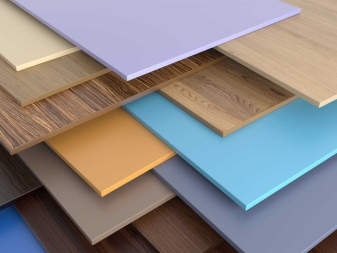

For the manufacture of the material, common and valuable types of wood are used, such as birch, alder, oak, but it can also be an imitation of real wood.

The properties of natural veneer are similar to those of natural raw materials; the material does not require additional processing. In contrast, a surrogate veneer (fine-line) is made on the basis of inexpensive wood by gluing several layers, pressing and imparting a certain texture, color and ornament. This allows you to create panels of exceptional beauty and originality, although their appearance is sometimes far from natural.

Veneered products, as veneer panels are also called, are adapted to different substrates, but, as a rule, these are wood-based panels, the raw material for the manufacture of which is the waste of woodworking enterprises.

The most common base materials for veneer sheets are MDF and chipboard.

- MDF is a wood-fiber material that is especially durable due to its high density. Such panels are resistant to moisture, safe for human health, and durable to use.

- The basis of the panel can be chipboard. This type of material looks beautiful and has a low price, but is less resistant to moisture and requires more careful care - it can crack if it is not properly dried.

Decorative veneered 3D panels made using modern technologies are very popular. Basically, these are MDF wall panels, additionally protected with a special coating. The polymer film on their surface is resistant to temperature extremes and moisture, but also such a skin is virtually insensitive to mechanical stress and deformation.

Volumetric panels are the most demanded product, implying high quality and elegant design. When facing walls, they can be painted, given the desired texture, pasted over with foil, varnished in various ways, or made the veneer structural by gluing.

Thanks to the content of natural organic components, veneered embossed panels allow the walls to breathe, and the method of joining them using decorative strips (rustic materials) helps to make the joints invisible.

However, this product also has its drawbacks: 3D panels require careful maintenance, they accumulate dust, and are subject to aggressive environmental influences. And also it is undesirable to get sunlight on them. In addition, they are more expensive than conventional cladding.

By the way, such a finish can be based not only on wood slabs, but also on the basis of drywall. Fine-line materials have low flammability and moisture resistance.

You can often find veneered products with a PVC base. Their main advantages are lightness, plasticity, any combination of shades, durability, not counting melting with strong overheating.

Installation work

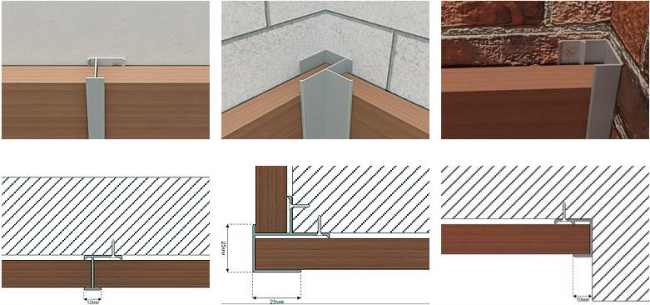

Facade veneered panels are rarely used. Basically, they are used to decorate the walls. There are three main ways of installing a veneered panel: gluing, installation on a connecting profile, on clamps when using decorative rust.

- Bonding. This method is only suitable for flat and smooth walls, which, for example, are lined with plasterboard. If the surface is uneven, it is necessary to install a frame with metal or wooden rails.

- Installation on aluminum profiles.The panels are attached end-to-end or from the visible side of the profile, which serves as a decorative function. It is not necessary to paint the profile itself. The work is simple: the profile is attached to the frame with a step in the length of the panel, the panel itself is inserted into its grooves. If the wall is flat, then there is no need to install the crate, there are enough profiles.

- Use of decorative connecting strips. Rust is used to hide fasteners. Thus, a three-dimensional surface is achieved, which serves as an excellent interior decoration. Rust can be made of metal or veneered MDF. A particularly interesting effect can be achieved by choosing panels that are lighter in color than the decorative strips.

Installation of veneered panels

Facade veneered panels are rarely used, but if desired, they can be included in the exterior. Such designs need to be carefully considered as they do not meet all the properties required for external upholstery.

Veneered wall and ceiling panels are one of the most popular materials for decorating apartments and houses today. The use of wood in the interior is considered a classic, proven over the years. Wood is a versatile and environmentally friendly raw material. But sometimes the use of natural wood is irrational or impossible for some reason. In this case, it is reasonable to opt for specially prepared panels.

Veneered MDF panels

Let's see what veneer and MDF are. Veneer is a thin cut of wood. It is obtained by sawing or peeling timber, most often of elite varieties, for example, oak, elm, maple, walnut and others. In appearance, veneered MDF is very similar to the wood of valuable varieties of trees. However, the cost of such furniture is much lower than that of solid wood furniture. The primer and varnish, which the veneer is covered with, reliably protects the material from mechanical damage, and also makes the furniture more noble in appearance.

Designers are very fond of veneer for the wide opportunities for the implementation of creative ideas, as well as for the natural origin of furniture and interior items in general.

There are several types of coatings for veneer products, such as spray-applied polyurethane varnishes or roller-applied acrylic varnishes. Such paints and varnishes make the product not only more aesthetic, but also form an ideal surface. Also, veneer can be dyed during the varnishing process, which is not applicable for already made synthetic finishing materials. After varnishing, the furniture becomes matte or glossy. Complex geometric patterns can be applied to the veneer surface. If damage has formed on the furniture, then it can be quickly removed. However, the main positive difference between veneer and other finishing materials is its high level of environmental friendliness.

Of the minuses, a rather high cost can be distinguished, but it fully reflects the high quality of the material.

The MDF board itself is made from fine wood chips, which are pressed at elevated temperatures and under high pressure. No additional materials are used to glue the particles. At high temperatures, lignin is released from wood - this compound is completely organic and does not pose a danger to human health.

DIY installation of veneered panels: technology

Installation of veneered panels can be done in two ways - frame and glue.

- The first method involves making a frame. For finishing materials made of wood or its derivatives, it is better to use wooden beams, rather than metal profiles. Depending on the size and method of fastening, the lathing is installed vertically or horizontally. For example, for narrow vertical panels, the beams are mounted horizontally.The panels have grooves at the ends (most often a lock connection or a thorn-groove is used to connect them), and fastening according to the frame method is carried out using cleats or self-tapping screws. This method does not imply the perfect alignment of the walls, and this is its big plus. The lathing is mounted on a clean and dust-free base, while minor surface flaws are allowed, which will hide under the panels.

- The glue method, on the contrary, is used only when the base is aligned very well. It is not worth hoping that the finishing material will hide the errors of the walls. And one more condition - the panels should not be too heavy, otherwise they may fall off. Here everything is as usual - first we clean the surfaces of the old coating, level them, and prime them. Further, if necessary, we cut the panels to size. Apply glue to the panel or base and press it down. After that, we wait for the glue to dry completely and only then can we proceed to further finishing work.

And another tip - before proceeding with the installation, let the material adapt to the temperature and humidity conditions. Let them sit for 1-2 days indoors before installing.

As for durable operation, it not only depends on how you will take care of the veneered panels, but also on the quality of installation. Still, if you are not confident in your abilities, then it is better to hand the installation into the hands of professional craftsmen.

Differences in the way of laying

MDF for construction purposes is produced in the form of sheets, tiles and lining. Each type of product has its own dimensions, installation method and is used for a certain type of work. At the same time, they all retain the same technical characteristics: environmentally friendly composition, high strength and elasticity, good decorative qualities. The difference lies in the size and method of attachment to each other and to the wall or ceiling surface.

Leafy

The most expensive of the above types of products is sheet MDF. It is the basis for creating highly artistic panels or embossed inserts. The sheets are large - up to 2.8 meters in height and 2.05-2.9 meters in length. When ordering from the factory, you can make sheets according to individual sizes and with an exclusive pattern.

Sheet MDF is used for wall decoration in large rooms to create a certain decorative effect of a seamless finish. The sheet is mounted directly on a wall aligned and treated with an antiseptic butt, since it does not have connecting grooves. The best option is to partially include such a finish in the wall cladding due to the bulkiness and cost of the material.

Tile

MDF tiles have similar technical characteristics. It differs from sheets in the form of a square or rectangle of various sizes: from 0.5 x 0.5 meters to 0.95 x 0.95 meters. The tile does not have connecting grooves and is mounted on a prepared wall. Convenience of work with this product - in dimensions convenient for installation and light weight. If the installation of sheet MDF requires the participation of two or more workers, then one person will also cope with laying the tiles. It is enough just to calculate the required number of pieces for finishing, knowing the area of the surface to be finished and the size of the tiles.

The surface texture has standard colors and sizes like tiles. It is convenient to make mosaic panels from MDF tiles of the same type, but with a different color scheme or texture. The versatility of this finishing material lies in the possibility of using it in a room of any size and configuration. On the market of finishing materials, MDF tiles are presented in the widest range, have a lower cost compared to MDF sheets.

Lining

The most popular is the cheap and beautiful lath material - MDF lining. It has excellent technical characteristics and a wealth of decorative finishes. The slats have dimensions from 2.4 x 0.11 meters and beyond.The standard length is 2.6 meters. Lining is used for decoration and walls and ceilings.

The herringbone pattern is of two types. The panels are laid at an angle of 90 degrees relative to each other, the ends are adjacent to each edge of the longitudinal side. Another option involves the location of the rails at any other angles, while the ends are cut to the same angle and installed end-to-end. This installation requires a certain skill in order for the cladding to turn out to be even with the same slope. You can cut several slats in advance, clean the edge of the saw cut and proceed with the installation.

The lining is characterized by ease of installation, lightness of construction and individual elements. Can be easily shortened to the desired size. On the side faces it is equipped with special grooves for connecting the rails to each other without a gap. To ensure strength and to avoid deformation of structural parts, the rail is mounted on a frame made of beams. This frees you from the need to level the wall and allows you to hide communications inside the frame.

The MDF rail, with all the simplicity of installation, requires adherence to the installation technology so that the rail does not lead. The decorative qualities of the coating depend on this. The location of the slats influences the modeling of the space. The horizontal arrangement will lengthen the wall or ceiling. The transverse arrangement on the ceiling will make the room wider.

What are veneer panels

Fitted on various surfaces (MDF panels, plywood, chipboard and others) a very thin sheet of natural wood, which is called veneer, is a veneer panel. Also, such products are also called veneered panels.

Internal structure of veneered MDF

The production of such panels is developed everywhere, and the technological process for each manufacturer is similar - through hot pressing, various adhesives, chemicals to improve some characteristics, a durable adhesion of the veneer and the base material occurs.

Veneering process at one of the woodworking enterprises

Due to their excellent characteristics and advantages over other materials, MDF panels are most often the basis of the wall panel. The veneer, thanks to which the appearance of the wall panels is created, can be used absolutely any of both widespread and cheap wood, as well as from rare and exotic wood. The veneer material will influence the final price of such a facing board.

Externally, the veneer on such slabs can have a smooth and smooth varnished surface or be with open pores and rough to the touch.

Due to their high aesthetic qualities and technical characteristics, as well as for an affordable price, such panels are used everywhere. Veneer panels can be used for the following types of repair and production:

- for cladding walls and ceilings indoors;

- exterior cladding of buildings;

- production of interior doors;

- production of furniture products;

- creation of interior partitions, etc.

Important! It should be noted that there is such a type of wall panels that are faced with cheap fine-line veneer. This material is made from cheap wood species, which goes through various procedures to change the texture for rare types of wood, as well as painting, varnishing and other measures.

Expenses

The cost of such a whim is relatively low considering the bonuses the user receives. At the same time, it depends on a number of factors in addition to the area that is planned to be decorated. These primarily include the price of raw materials - valuable wood, which is used for veneer, and its quantity.

The last factor is important because some creators prefer to veneer both sides of the MDF.This increases not only the amount of natural wood used, but also the accompanying materials, as well as the technological processes used in the production.

Unique decor for the hallway

Creative wall decoration at the head of the bed

In addition, the cost increases when the company that forms the kit on order develops the design of the premises. The same services can be performed by a hired professional who is fully responsible for the implementation of the design project, and not only for the decor.

The material with many advantages competes confidently with other types of interior decoration

Finally, it is worth noting that veneered panels have plenty of analogues. These are both laminated boards and natural wood. However, it is this material that is devoid of all possible drawbacks that complicate the installation and operation of the finished product. Make sure on your own experience, appreciate the high quality and wide variety of assortments that will turn your home and office into a fairy tale!

What are they combined with?

When deciding on the installation of veneered wall slabs, first of all, the owners of the premises are wondering what is the best way to combine them. Among the solutions that favorably emphasize the stylish look of veneer-plates, one can single out:

- painting;

- plaster;

- wallpapering.

It is optimal that the combination is carried out in a single shade range. Depending on the parameters of the room, a combination of decor directions can give a rather striking effect. In addition to improving the aesthetics and presentability of the look, such combinations can bring tangible practical benefits, for example, to hide wires and other engineering communications.

The use of veneer panels in tandem with wood furnishings and stone gives a respectable look to any space. Such a design will be appropriate in the strict office of the head of the company, as well as in the meeting room. This material is often used to create accents and zoning a living space.

Wall decoration with wooden panels in the apartment: masonry options

The finishing material can be fixed to the walls at different angles. It all depends on the chosen design, as well as the priorities of the owner. The finished room looks individual, because there are many options for decorating the interior with wood. The wall will be trimmed with strips diagonally or vertically, yet there will be no repetition, because there are various textured patterns, shades, wood species with their own shades.

One tree can play in different shades, it depends not only on the processing, but also on the age of the tree.

Herringbone

An interesting way to fix the lath material. There are 2 types of herringbone mounting: fixing the slats at an angle to each other (a herringbone pattern is created on the wall, the branches look up from the bottom, and the length of the “branches” depends on the size of the wall and the room), the second method is to lay the battens horizontally on top of each other ...

Reiki is used in various widths and lengths. After installation, the herringbone can be painted in a color that matches the interior, or can be covered with colorless varnish. However, processed and painted slats are sold on the market, so they only need to be fixed on a rough base.

Horizontally

If you mount the slats horizontally, the room visually becomes long. I use 2 methods of fastening: on a frame base or glue. In the first case, there is a benefit:

- insulate the wall;

- hide wires;

- improve sound insulation.

The second method has the following advantages:

- quick installation on a flat surface;

- saving materials;

- saving space.

Each method has its own drawbacks, however, when choosing a fixation method, they practically do not pay attention to them. The horizontally fixed slats have different widths - this is of great importance in the overall picture of the arrangement of the room

The horizontally fixed slats have different widths - this is of great importance in the overall picture of the arrangement of the room.

Basically, cladding is made up to half of the wall from the baseboard, combining with wallpaper, painting and other finishing materials. They create a contrast in the form of "dark-light" or adhere to one tone, emphasizing the overall color scheme of the room.

Vertically

The laths are fixed in the same way as in the horizontal cladding. The vertical position increases the height of the ceiling, so installation is carried out from bottom to top.

Reiki have different widths, colors, patterns. They are used on balconies, in corridors.

If the room is dark, choose light colors. Sometimes one wall is highlighted with decoration, on which there is a niche, shelves with lighting. This makes the room interesting, there is a division into zones: watching TV, the place of necessary significant things.

Abstraction

Abstraction is called 3D panels created from solid wood or under it. These are three-dimensional drawings, paintings with an ambiguous convex relief. The cladding creates one wall in the room that visualizes naturalness.

3D abstraction is created independently from many parts of a tree - a delicate work. Or they purchase ready-made panels to order - installation is carried out on glue.

And also abstraction can be called chaotically scattered panels of small sizes on the wall, combined with other finishing materials or wooden elements, such as shelves, picture frames.

Features of the use of decorative panels in rooms with special climatic conditions: photo examples of interiors

To choose the right material, you need to understand the options for its attachment. The most commonly used glue and frame technique. Not a bad solution and self-adhesive options. To do this, you need to properly attach the material and press it. Conventional panels are fixed with strong adhesive. With the glue method, wires and other communication details cannot be hidden under the coating.

Decorating can be quite functional

For rooms with a high level of humidity, PVC panels are suitable. This option successfully replaces wood, wallpaper, tiles or plaster. Plastic provides tremendous opportunities for creating a room design. Manufacturers apply a special protective coating.

And the beautiful material can have thermal insulation qualities and also protect against noise

Also, special panels with non-combustible properties are used for the kitchen. As an option, acrylic is used, which undergoes additional processing. The use of acoustic options will provide a favorable indoor climate.

How to choose bathroom panels

The bathroom is distinguished by its specificity, in which temperature drops and high humidity can provoke the appearance of a fungus. Therefore, moisture-resistant wall panels are used especially for this room. They are made from a special polymer using additional additives.

You can choose the material with different ornaments

The following waterproof wall slabs can be used to decorate the bathroom walls:

- tile products are square and are used to create a wide variety of ornaments;

- slatted panels are fastened with brackets;

- sheet elements are large.

Combined panel option

For high quality finishes, you can use sheet plates that are made of PVC or fiberboard. The material is covered with special protective compounds.

In order to visually raise the ceiling, it is recommended to install vertically arranged wall panels for interior decoration of the bathroom. You can fix the material with glue, and if the products are fixed to the frame, then screws and staples are used.

Tiled elements are often made of plastic.They are used to simulate a mosaic covering.

It is not necessary to purchase expensive tiles to create a harmonious interior.

What to consider when choosing panels for the kitchen

Instead of regular wallpaper, you can use decorative panels for the kitchen. They are often installed in the apron area. During installation, you do not need to level the walls or purchase additional materials. This finish allows you to mask different communications: cables, pipes or wiring.

Original plates for kitchen apron

When choosing decorative panels for the kitchen wall, it is important to take into account that there is high humidity in this room, temperature fluctuations, as well as frequent cleaning. It is important that the material in the area of the apron ball is moisture-resistant and heat-resistant

In this case, the finish should not absorb moisture.

It is important that the material in the area of the apron is moisture-resistant and heat-resistant. In this case, the finish should not absorb moisture.

A variety of storylines are used as decor.

For any budget, you can choose the best option, taking into account the overall interior. A great solution to use a brick wall panel for the kitchen. A layer of thermal insulation can be placed under the cover. Plastic is a universal solution. In this case, you can pick up slabs of different textures, shapes and colors.

Ideas for decoration with an edible theme

If you plan to glue PVC panels, then you must first prepare the surface. It should be primed and left to dry completely.

Varieties of wall panels

In order to make the right choice of panels for walls, you need to know what types of them are offered by the market of finishing materials. Wall panels are classified by shape and size, the following types are distinguished:

- sheet - panels of large sizes, the shape of which is rectangular. The dimensions of these panels are similar to a sheet of plywood, distinguished by their decorative pattern on the outside of the wall panel. The standard size is 122 * 244 * 0.6 cm, the surface is often smooth, plus such a large panel is that the number of joints is minimal.

- rack - panels in the form of long strips from 240 to 370 cm, width 30 cm, thickness 12mm. Such wall panels are known to all under the name "lining".

- tiled - panels in the form of squares with sides from 30 to 98 cm. Due to their size, these panels allow you to create various design compositions by combining them in color in a different order.

Panel material and texture

In the manufacture of wall panels, different materials are used, which provides them with different operational and external characteristics. So, panels can be made from the following materials:

- MDF;

- wood;

- plastic;

- glass;

- gypsum.

MDF wall panels are wood fibers that have undergone high pressure and heat treatment. At the same time, such panels do not contain resins and toxic phenols, which means that they can be considered environmentally friendly, and they can be used not only when decorating office premises, but also at home in a living room or bedroom.

The surface of the panel is matte, glossy and textured. They do not require special care, because thanks to the laminated surface, dust practically does not stick, therefore it is enough to wipe them with a damp cloth as needed. In addition, such panels do not fade in the sun and are easy to dismantle.

Plastic wall panels are also environmentally friendly, yet they have good sound insulation and retain heat. It is possible to use such panels when decorating the walls of the living room, but we would not recommend covering all the walls with them, but combining them with another material.

It is best to use them in rooms with high humidity. The color scheme of these wall panels is varied, so you can choose them to match the interior. The service life of the panels is very high; they are used to sheathe walls even in country houses, which may not be heated in winter.

Panels made from such trees as alder, maple, cherry, ash, cedar, oak are used not only for finishing ceilings, but also for creating partitions in the living room and architectural structures such as columns and arches. Very often they combine wall panels made of different types of wood. To extend the service life, such panels are coated with a special wax or varnish. But remember that these panels are very sensitive to moisture.

Recently, glass and 3 D panels have appeared. At first, it may not be clear what it is. But in fact, glass panels are a well-known apron in the kitchen. Therefore, we will not talk about this type of panel as a decoration for the living room. As for 3 D panels, they are made of a special material, consisting of three layers: basic, embossed and decorative. The main layer can be made using gypsum or MDF, the decorative one is treated with varnish, enamel, veneer or even leather.

Assembly

The installation of elements can be carried out both from the ceiling and from the floor, depending on what structural form the manufacturer has given to the blanks. They are alternately installed in the grooves of the metal profile, which is fixed to the walls with screws.

Profiles are usually made of lightweight and durable aluminum. They are available in various designs. In appearance, profiles are divided into two types:

- hidden;

- visible.

Mounting with an aluminum connecting profile

Hidden guides are masked by auxiliary strips, which are installed in the corresponding grooves or fixed with an assembly compound.

By appointment, they are:

- universal;

- starting;

- finishing.

Panel mounted on hidden profile

But some manufacturers just make do with the starting profile. All other elements in it are fixed with the corresponding grooves. However, there is a drawback in a functional solution of this kind: it will not be possible to disassemble the structure without destruction, therefore it is almost impossible to reapply its components.

Wooden walls create a fabulous atmosphere

Presentable appearance of the material emphasizes the style of the interior

When installing, special attention should be paid to installation under the ceiling and at the corners of the room. When installed under the ceiling without the use of a plinth, the finishing blanks are cut, removing the remainder and adjusting the height to the required level

Fixing it also occurs in a slightly different way and always depends on the features of the form.

One of the many advantages of this material is the high performance characteristics of heat and sound insulation.

As far as corner joints are concerned, they are organized in different ways. Some developers provide for this special fittings - separate for the inner corners and for the outer ones. Others suggest using such accessories exclusively for outer corners to facilitate assembly.

Where are veneered wall panels used?

Veneered wall panels can be made from both wood and various panels. They make it possible to create extraordinary design solutions that look solid and sophisticated for guests, and for the owner will turn out to be very budgetary.

Among the areas of application are the following objects:

- apartments and living quarters;

- offices;

- administrative buildings;

- entertainment and social establishments.

A wide range of applications for these materials is due to their high performance and aesthetic qualities. In addition, they are distinguished by their wide price range, which will satisfy the needs of most buyers.