Veneered wall panel or natural wood board

It is impossible to say unequivocally which wall panels are better, natural or veneered. After all, each product has its own clear advantages and disadvantages. And if someone is more impressed by natural products, then someone prefers veneer coverage. It is the comparison of the advantages and disadvantages that will help you better familiarize yourself with the materials and choose the best option for yourself.

Veneered panels - advantages and disadvantages

The products are used for interior wall and ceiling decoration. It has the following advantages:

- Price. It is much lower than that of solid wood products. This is a significant argument in favor of veneer. If the budget is limited, then everyone can afford imitation of natural wood in the form of veneered panels.

- Large assortment of goods. Wood veneer can be natural and fine line. Manufacturing companies can have more than 300 types of veneer of different types of wood, which differ in their texture, color and characteristics.

- Clear geometry. Each panel has standard dimensions without deviations and bevels. The panel will not crack from shrinkage. Over time, the finish will not curl or deform, the panels will remain the same smooth and even.

- Great appearance. It is difficult to distinguish them from natural wood. The decoration looks noble, beautiful, modern, cozy and comfortable inside. For protection, the material is covered with a colorless varnish. No color, water or alcohol stains are used.

- Thanks to the varnish layer, the board is protected from moisture.

- Long service life. If you properly care for the surface, then it will last for more than a dozen years.

- Good sound and heat insulation characteristics. Wood is a warm material that also acts as a sound insulator. This additional protection will not be superfluous.

- Ease of installation. There are several options for fixing, for example, wireframe, glue or rustic. Depending on the skill level, you can choose one of them.

Disadvantages of veneer panels:

- Veneer is a thin cut of wood. Under strong mechanical stress, it can crack or scratch.

- The paint and varnish material is a flammable substance. Therefore, the fire safety of the products is not too high.

- If the protective lacquer layer is damaged, moisture can penetrate under it. The panel may swell and rot.

Advantages and Disadvantages of Solid Wood Panels

Wood has long been used for construction. It has not lost its popularity and there are people who want to see the finish exclusively from natural wood. And there are several reasons for this, associated with the advantages of the material:

- Although the tree has a high price, especially such species as bog oak, larch, mahogany. However, there is the option of using inexpensive wood species.

- The products have excellent sound and heat insulation qualities.

- The tree breathes, there will be no condensation inside, the climate in the rooms is comfortable.

- Strength, durability and practicality.

- Great appearance. There is a possibility of carving on the massif, forming patterns and beautiful relief patterns.

Disadvantages of wood panels:

- Products are not protected from deformation. If not dried properly, the panel can curl, crack and change shape. This can happen after six months or 2 years.

- High price.

- Without a layer of varnish, the tree is not protected from moisture, which negatively affects it.

Comparing all these advantages and disadvantages, you can decide on the choice for finishing: buy wall panels made of veneer or natural wood.

Varieties

Consider in more detail the existing options for such a finishing material.

Made of MDF

These fiber boards are medium density, hot pressed under severe pressure and temperature conditions. In the process, lignin is released - a component that has a binding effect.

The standard density of the material varies in the range of 600 - 850 kg per cubic meter, but sometimes this figure is less important, which reduces the final cost of the material.

Such panels are used when decorating offices and living rooms. For a kitchen, a panel protected by a film or plastic layer is considered the best option.

The main advantages include:

- attractive appearance, variety of patterns and colors;

- ease of installation and dismantling works;

- no need for preliminary preparation of walls;

- the strength indicator is higher than that of chipboard;

- affordable cost;

- resistance to high temperatures and humidity;

- isolation from extraneous sounds;

- the ability to retain heat energy in the room;

- environmental Safety.

Wall material made of MDF does not need special care, its surface can be easily cleaned from dirt with a damp cloth.

Unfortunately, there are certain downsides. The material is prone to fire, the coating is damaged from strong impacts, and does not withstand prolonged exposure to water.

PVC

Such wall panels for kitchen bricks are made from polyvinyl chloride raw materials, which are based on vinyl chloride polymer and a special softener. During their manufacture, they are painted with special compounds that increase their resistance to mechanical damage and ultraviolet radiation.

The undeniable advantages are:

- the duration of the service life;

- ease of installation work;

- absence of harmful components dangerous to the human body;

- soundproofing qualities;

- ability to repel dirt, unpretentious care.

As disadvantages, builders note a lower strength indicator compared to MDF material, the ability to ignite.

Plastic

This version of a wall panel for a brick kitchen has the following advantages:

- quickly and easily attached to the surface, so that all work can be done on their own;

- the material can be easily cut with a hacksaw for metal;

- the service life of the panels reaches ten years or more;

- there is no need to carry out preliminary preparation of the wall;

- small weight;

- it is easy to care for such a surface - it is enough to periodically wipe it with a damp sponge;

- the material is universal, suitable for external and internal walls and even the ceiling;

- if the installation work is carried out correctly, the rate of sound insulation and the safety of thermal energy increases, additional protection against water penetration is created.

For completeness of the "picture" a few words should be said about the disadvantages of plastic. It deforms easily from exposure to high temperatures. The brick masonry imitated by plastic panels does not differ in high mechanical strength, dents and small scratches remain on the surface from shock effects.

Tempered glass

A surface finished with such a material serves for a long time. Glass does not break from impact, it is resistant to mechanical stress, because its thickness is four or more millimeters. The material is hygienic, dirt does not linger on its smooth surface.The glass is resistant to humid environments, retains its original appearance for a long time, and is easy to clean.

There is one drawback associated with the high cost of the material.

Non-tempered glass

The panel also has a hygienic surface, is easy to clean, retains its original appearance for a long period, is not scratched and does not allow moisture to pass through.

Unfortunately, such material reacts negatively to high temperature conditions. This means that the panel is not mounted on the slab, so that cracks do not form on its surface.

With a glass panel, you will create an extraordinary design in your kitchen due to the fact that there are options decorated with individual patterns and patterns. One of them is masonry under brick material.

Views

In terms of their dimensions and shape, all wall panels made of veneered material are presented in several versions.

- Rack - they are sold in the form of elongated strips, this is one of the most popular types of material. Installation is carried out by the tongue-and-groove method, for this, a recess is provided on one side of the slab, and a ledge on the other.

- Sheet - these products are produced in the form of sheets of different sizes, can be presented in large dimensions. Fastened to the frame or by glue method.

- Tiled - outwardly similar products are similar to tiles, only in large sizes. The installation process is carried out using the tongue-and-groove technique.

The base of the material can be chipboard, MDF board, less often plywood sheet is used. According to the manufacturing technology and structure, two variants of veneer panels are distinguished.

- Natural veneer - a thin cut of the surface of an array of valuable wood. Initially, it has an attractive texture and a unique shade, be it classic Russian pine, Karelian birch or exotic wenge.

- Fine-line is a cheaper veneer made from low-quality woods. In the course of production, natural material goes through a variety of manipulations to change the texture so that it resembles precious woods.

Highlighting the zones in the bedroom

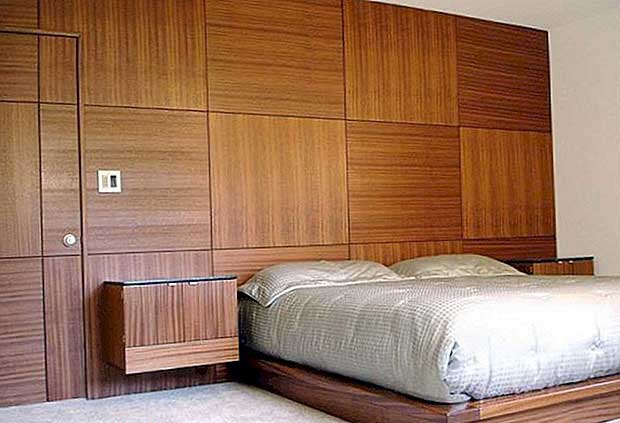

The bedroom is a place primarily intended for relaxation after a hard day's work. But this does not mean that this room can be monotonous or uninteresting in terms of style. To diversify the interior of the bedroom and make it bright and expressive, the designers, after consulting with the client, decided to highlight the area in which the bed is located. The selection was made by placing wall panels covered with dark veneer in the form of vertical stripes. This solution made it possible to emphasize the bed and added a certain color shade to the room, which made it more comfortable. The veneered wall panels for interior decoration, arranged in the form of vertical stripes, made it possible to visually increase the height of the ceilings. To prevent the dark veneer from causing an atmosphere build-up, lamps were placed directly on the strips.

Accents in the interior of the house

In a relatively miniature living room, it was decided to focus on one of the walls. A popular technique is that one and the same room is decorated in several ways. This is what we did in this case. Half of the wall is covered with photowall-paper, which depicts shelves with books. It was decided to decorate its second part with veneered panels. The horizontal texture of the veneer made it possible to visually increase the height of the wall. Dark veneer wall panels were used to decorate the living room. I must say that this did not become a problem, since there are quite a lot of light sources in the room, including windows.

In addition to the living room and bedroom, another room was decorated by specialists. Wall panels were placed not only on the walls, but also on the front of the cabinet, making it completely invisible.

Veneered wall panels for interior decoration are quite practical material. This is primarily due to the fact that their surface is resistant to mechanical stress. Thus, the panels are not afraid of scratches and chips. In parallel with this, the panels provide good thermal insulation and sound insulation. If for some reason the panel has been damaged, it is easy to replace it.

Interior doors in enamel

The described project was notable for its full scale. Along with the veneered wall panels, we have also produced a number of door models. More specifically, we installed swing and sliding doors, the finishing material for which is enamel.

The color for the doors was not chosen by chance. They are an effective counterbalance to the prevalence of dark shades in the interior of the room. You can see the result of the work done in the presented photos.

If you liked this project, and you want to see something similar in the interior of a house or apartment, we recommend that you contact the managers. They will be happy to advise you and answer all your questions related to possible cooperation. We guarantee high quality of all products and the shortest possible time for project implementation.

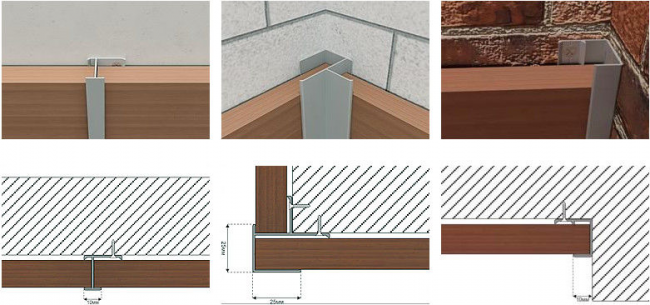

Assembly

Installation of elements can be carried out both from the ceiling and from the floor - depending on what structural form the manufacturer has given to the blanks. They are alternately installed in the grooves of the metal profile, which is fixed to the walls with screws.

Profiles are usually made of lightweight and durable aluminum. They are available in various designs. In appearance, profiles are divided into two types:

- hidden;

- visible.

Mounting with an aluminum connecting profile

Hidden guides are masked by auxiliary strips, which are installed in the corresponding grooves or fixed with an assembly compound.

By appointment, they are:

- universal;

- starting;

- finishing.

Panel mounted on hidden profile

But some manufacturers just make do with the starting profile. All other elements in it are fixed with the corresponding grooves. However, there is a drawback in a functional solution of this kind: it will not be possible to disassemble the structure without destruction, therefore it is almost impossible to reapply its components.

Wooden walls create a fabulous atmosphere

Presentable appearance of the material emphasizes the style of the interior

When installing, special attention should be paid to installation under the ceiling and at the corners of the room. When installed under the ceiling without the use of a plinth, the finishing blanks are cut, removing the remainder and adjusting the height to the required level

Fixing it also occurs in a slightly different way and always depends on the features of the form.

One of the many advantages of this material is the high performance characteristics of heat and sound insulation.

As far as corner joints are concerned, they are organized in different ways. Some developers provide for this special fittings - separate for the inner corners and for the outer ones. Others suggest using such accessories exclusively for outer corners to facilitate assembly.

Views

There are many types of panels, from textile to gypsum, therefore it is important to choose the appropriate material and wall design for the interior

Plastic

Due to moisture resistance, plastic panels on the wall are used in the shower, they are fireproof and have a long service life.

3-d panels

They create a unique interior due to the volume and 3-d effect on the walls. The texture is painted in different shades (glossy or matte) with acrylic paints, or covered with veneer.

Gypsum

Gypsum wall panels are very durable and provide sound insulation. They are lightweight, but they look monumental in the interior. There are imitations of stone, wood, volume and high relief.

Wooden

Wooden ones are the best option for a house or apartment because of the environmental friendliness of the material. For protection, they are impregnated with wax.

Pictured is a large living room with wood paneling and classic English-style interiors.

Bamboo retains heat and is less susceptible to change when exposed to moisture.

Veneered

Veneered look like solid wood, it is a thin cut of wood glued to an MDF or chipboard board. It is often used in the interior and is an affordable option for wall decoration.

Cork

Cork has a characteristic texture and a unique pattern that is suitable for the interior of the house. The cork retains heat, allows air to pass through, and creates sound insulation.

In the photo there is a tiled cork cladding, which creates additional soundproofing of the living room.

Fiberboard, MDF, chipboard

Fiberboard, MDF, chipboard are sheet and tile. This saves assembly time, it is convenient to lay out the drawing and combine colors. Fastened with glue or clamps.

MDF panels are pressed and glued with natural resins, retaining heat and creating sound insulation.

Fiberboard is not suitable for the bathroom, but it is resistant to changes in humidity in the room.

Particleboard chipboard is less durable and subject to deformation under the influence of changes in humidity or temperature in the room.

Rack panels are connected by grooves and attached to the crate, they are made of chipboard, MDF and other material.

In the photo there is a slatted wall cladding in the interior of a modern kitchen, which coincides with the design of the apron above the work table.

Soft

Soft ones are made of fabric, leather, felt, felt and are filled with a soft filler (synthetic winterizer, foam rubber). Suitable for a living room with a karaoke system, children's room. You can decorate one wall or part of it.

Mirrored

Mirrors are suitable for ceilings and walls, they will increase the space and reflect the light. There are glass and mirror-coated panels. The panels are more flexible and weigh less than glass.

Leather

Leather panels do not accumulate dust, like other soft panels, the wall is protected, the room is insulated. They are easy to keep clean.

Vinyl

Vinyl ones retain the pattern and will fit the interior of a loggia or balcony. They transfer moisture, are made in different colors and patterns of wood, stone, are attached to the crate.

Polyurethane

Polyurethane ones are smooth, embossed, combine 2-3 colors or a composition. Elastic, good shape, porous and lightweight.

In the photo, the wall is finished at the head of the bed with soft polyurethane in the interior of the blue-white bedroom, where the color balance is observed.

Aesthetics and beauty

The use of veneer panels for interior decoration of various premises in an apartment, house or public buildings is widely practiced in the interior. The pattern, unique structure and wide range of colors of veneers in the panels allow you to create truly beautiful rooms that take on their own character and soul.

Wall cladding in the apartment with veneered MDF brings comfort, aesthetics and warmth to the atmosphere of the rooms. The very process of installing these plates on the wall is very simple and does not require special knowledge in repair and construction.

Veneered slabs on the walls and ceiling in the lounge

The use of veneer panels in combination with pieces of furniture that are finished with natural wood creates a prestigious look for the premises. For example, this design is perfect and will add solidity to the office of the boss or in the meeting room.

It is also worth noting that such material can be used to form accents or zoning a room. It will look nice to highlight the work area in the bedroom or the bar area in the kitchen or living room with a wall veneer panel.

Highlighting an area on a wall using veneer panels

Creating accents in the guest room with veneer panels

Ceiling cladding can also be carried out with just such panels, but for the play of lines, colors and shapes, it is recommended to use them in combination with other materials, for example, MDF boards with a 3D effect.

Veneered panels can also act as a frame or facade of all kinds of furniture elements, as well as interior or exterior doors. Often, apartment owners create sliding wardrobes from such material in the hallway or bedroom.

Due to the simplicity and ease of installation, excellent sound insulation and other characteristics, cheapness, such veneer plates can be used to create partitions in rooms. For example, in spacious bedrooms, you can safely fence off a certain piece of space to highlight a dressing room. For such a partition, there is no need for coordination with housing and communal services and other authorities.

Partition sliding from veneer panels in the office

Important! This building material, without appropriate impregnation with a special compound, is characterized by fire safety. Because of this, all electrical communications should be placed in special boxes.

Some types of wall panels can also be used in bathrooms, but remember that they must be impregnated with a special compound to protect them from moisture.

Aesthetics, naturalness, practicality, ease of installation make it possible to use such veneered panels wherever the need arises.

Features and scope

From a technical point of view, veneer is a thin cut of valuable natural wood, most often oak, alder or ash. The base layer is made of MDF or chipboard, the layers are bonded using the hot pressing method. This technology makes it possible to achieve a significant reduction in the cost of the product - for relatively little money, the buyer receives an aesthetic and elegant finishing material, which, in terms of its performance characteristics, is practically not inferior to natural wood. Of course, the "filling" of such panels is not very attractive, but the democratic price fully compensates for this disadvantage.

Veneer panels have a presentable decorative look, such products will easily decorate any interior, be it an entrance hall, a living room or a strict study.

The undoubted advantages of the material also include the following.

Environmental friendliness - boards are made of natural materials without the use of adhesive solutions. The products have zero background radiation and do not emit toxic fumes during operation.

How is veneered MDF made?

The manufacture of such material is a rather laborious process, however, with the help of high-tech equipment and the skill of workers, excellent results are achieved. The factories use fully automatic mechanisms and high quality raw materials.

Natural veneer comes to factories in rolls or packs, packaging is carried out taking into account the required dimensions and properties that will differ in the final product. Experienced craftsmen put prepared veneer sheets on the prepared MDF surface treated with a special adhesive. When using roll raw materials, gluing is carried out in one step. When gluing veneer, which is brought in in packs, a special technology is used. It consists in longitudinal and transverse gluing, which resembles a fish bone. There are other gluing methods. But all processes are necessarily strictly controlled by employees and using a computer that carries out measurements and settings. The veneer is glued to MDF boards with an adhesive. The next step is press drying, after which the surface still needs to be sanded and varnished. Today, many industries use a high temperature drying press.It makes it possible to glue veneer on many MDF boards in a short time, therefore, much less time and money is spent on warehouses for drying the final product. Provided that the surface of MDF is uneven, for example, on curved door plates, the technique of vacuum gluing is used. However, this process is more costly and time-consuming.

After all these procedures, the resulting veneer plate must be sanded first across, and then along. Only after that a perfectly smooth surface is obtained. In addition, in order for the varnish to lay down more evenly, the veneered surface must be ironed with a hot roller. This must be done because there is a possibility that the wood grain on the veneer will rise during the application of paints and varnishes. As a result of this painted surface, bumps or depressions can form, which greatly spoil the appearance and quality of the final product. For this reason, ironing technology is used, during which excess fibers are soldered to the surface, and it becomes completely smooth.

The slab is painted with a transparent or opaque varnish, colored paint, as well as special wax.

Overview of types and sizes

The market offers a wide variety of interior decoration products. Fiberboard has advantages that distinguish the material favorably from competitors. With the help of panels, you can get a coating with imitation of other materials, choose colors and even texture. Fiberboard is a safe type of cladding that does not harm human health and the environment. Manufacturers often use the dry method to make panels.

It is impossible not to highlight the ease of installation, since you can work with the material independently without outside help. There are different installation options, each of them has its own characteristics. As for the cost, the panels are offered at an affordable price, this has influenced the increase in demand for the material. Thanks to fiberboard, you can insulate the room, as well as get sound insulation. If you choose the right wood fiber panels that meet high requirements and standards, their service life can reach 10 years, and this is not a short period.

To make the use of the cladding possible in a room with high humidity, it is necessary to select a special type, covered with a protective impregnation

It is also important to observe the storage conditions so that the material does not deform, therefore, products are often attached to the crate with self-tapping screws.

Stacked wall panels are one of the most popular types of fiberboard. With such material, work is carried out very quickly, you can choose a decor option from a wide range

It is important to pay attention to the dimensions of such boards: the thickness can be 6–25 mm, and the length reaches 4 m, the width range is 15–30 cm. Thanks to the choice of such parameters, finishing of any complexity can be performed. For fastening, a lock connection is used

You can find a product on the market with double-sided coating, so the protective functions are ensured

For fastening, a lock connection is used. On the market, you can find a product with a double-sided coating, so the protective functions are ensured.

Sheet moisture-resistant panels are presented in a large format, so they can be used in large rooms. Often, such a finish is chosen to decorate an apron in the kitchen. This material is attached with precise edge fits.

The tiled variety of fiberboard is a finishing material with parameters 300X300, 150X600 and 980X980 mm. Docking is used for fixing, however, panels with a lock connection can be found. If you need a decorative design of a room with interesting combinations, you can safely choose slabs that fit into the bedroom, living room and other parts of the house.

The laminated panel is offered in the size 2850X2070X3.0 mm.Such sheets have a protective film that is created from melamine or acrylic resin. It is this coating that is decorative and is offered in a variety of colors.

Characteristics of veneered MDF boards

The sizes of such veneered panels can be different for each manufacturer, however, the overwhelming majority produce panels to order according to the required specific and overall requirements.

By size and format, veneered panels can be of the following types:

- Rack and pinion. Such products are sold in the form of long strips of various sizes. This is the most popular material format. Installation is carried out using the “tongue-in-groove” technology - there is a recess on one side of the wall panel, and a ledge on the other;

- Leafy. Such products are produced in the form of sheets of various sizes, often of rather large dimensions. They are mounted on glue or on a frame using the joint-to-joint method;

- Tiled. Such products resemble ceramic tiles, only of larger dimensions. The assembly process is based on the “crest-in-groove” principle.

Since the basis of the material is either MDF board, or chipboard or plywood sheet, then its technical characteristics will depend on it.

Technical characteristics of veneered panels based on MDF

| Nominal plate thickness, mm | 3-4 | 4-6 | 6-9 | 9-12 | 12-19 | 19-30 | 30-40 |

|---|---|---|---|---|---|---|---|

| Swelling in thickness in 24 hours,% | 35 | 30 | 17 | 15 | 12 | 10 | 8 |

| Tensile strength across, MPa | 0,65 | 0,65 | 0,65 | 0,6 | 0,55 | 0,55 | 0,5 |

| Flexural strength, MPa | 23 | 23 | 23 | 22 | 20 | 18 | 17 |

| Flexural modulus, MPa | — | 2700 | 2700 | 2500 | 2200 | 2100 | 1900 |

| Surface separation, N / mm | 1 | ||||||

| Specific resistance to pulling screws out of the panel, N | At a given thickness, it is not measured | 100 | |||||

| Specific resistance to pulling screws out of the edge, N | 800 | 800 | 750 | ||||

| Humidity, % | 4-9 |

Important! It is worth noting that each manufacturer can use unique stages in the technological process, and this affects some of the properties and characteristics of the material. Veneered panels do not attract dust to their surface

Caring for them is very simple - just wipe them with a dry cloth

Veneered panels do not attract dust to their surface. Caring for them is very simple - just wipe them with a dry cloth.