Reconstructed veneer

Advances in technology have led to the production of full-thickness dyed veneers. This made it possible to create

reconstructed veneer (sometimes referred to as "reconstituted veneer").

For the production of the reconstructed veneer, wood from fast-growing trees from areas of controlled reforestation (for example, Italian poplar and Cameroon ayus are used) are used.

Many thin layers of peeled veneer, painted over separately, are glued into a stack using a special technology in such a way that a reconstructed solid is obtained, from which a reconstructed veneer is then produced by planing.

|

|---|

| Rice. 8. Reconstructed veneer |

One of the advantages of the reconstructed veneer is that it has its own face with a distinct structure, pattern and color, the most

suitable for modern trends and fashion in the production of doors, furniture and so on

Further.

Fine-line veneer and multi-veneer

Fine-line is a type of reconstructed veneer made from

natural wood, imitating certain species.

|

|---|

| Rice. 9. Fine-line veneer |

Features of fine-line veneer grinding

It is recommended to grind fine-line veneer in 2 passes. In 1 pass, use sandpaper with a grain size of 90-120 (leveling the surface), and in the 2nd pass, use a grain of 150-180.

Keep in mind that fine-line veneers are thinner and softer than traditional veneers.

Multi-veneer is a reconstructed veneer made from natural

wood, creating the effect of a harmonious combination of specified color shades in a simple or

complex drawing.

What are the benefits of a reconstructed veneer?

The main advantage of the reconstructed veneer is its homogeneity for a large

area (sheets of reconstructed veneer can have dimensions of about 3 m per 1

m), which allows you to bypass the stage of "sewing shirts" from

stripes, repeatability of decorative and geometric features.

This allows you to use

veneer is practically waste-free and significantly reduce the duration of the veneering technological stages.

What are the features of painting the reconstructed veneer?

Compared to traditional natural veneer, the reconstructed veneer is an even more porous and less hard material. The pores in the reconstructed veneer may not be straight, but winding, contain glue, which may require a special technology to fill them.

To increase the uniformity of paintwork on the reconstructed veneer, sometimes it is necessary to apply special adhesion primers.

|

How to distinguish reconstructed veneer from natural veneer? The main differences between natural and artificial veneer:

The pattern of the artificial veneer has fine structural notches (representing the pores of the wood),

Despite the name of the artificial veneer, be it rosewood, The pattern of natural veneer is not so repeatable and has pronounced growth rings, depending on the type of wood. The pattern of natural veneer will always be more distinct "live" than the artificial one, which is more blurred "dead". |

Manufacturing methods

The core of the door, or its "body", can be solid and hollow.Solid door - solid or spliced solid pine or spruce (or any other coniferous wood). The spliced core of the canvas is made as follows: a frame is created from a pine bar, the beams are placed in it close to each other. The resulting structure is sent under the press and fixed with glue. For this, high temperatures are rarely used, more often microwaves.

Then the future canvas is ground and calibrated. A plywood sheet or MDF is glued onto it and sent under a cold press to dry the glue. Next, the wooden canvas is sent to the machine and adjusted to the required size.

On the machine for hollowing out grooves for hinges and fittings (if the fittings are factory cut-in). After that, the door is sent to the next point for grinding, polishing and varnishing. Several such stages pass, after which the door is considered ready and sent to the factory.

A hollow canvas is made as follows: a frame is created from a bar and filled with a honeycomb filler - cardboard. Another common veneering option is polystyrene foam boards. The future canvas is closed with MDF plates and veneered with veneer, often artificial.

Veneered canvases can be cold pressed or hot pressed, often these two methods are combined. Self-adhesive veneer is a film that is applied to the finished canvas and does not always imitate wood. It often resembles a marble, stone covering.

Veneered doors what are they?

Veneer door - a structure made of frame, filler and veneer. It plays the same role as furniture upholstery. Under such cladding there can be a door leaf made of wood or, more economically, of MDF.

Such products are popular in the construction market. They have good quality characteristics: decorative data, durability, easy maintenance and versatility. Their appearance organically fits into the classic interior, which cannot be said about plastic products. And the price of interior doors made of natural veneer is lower than that of analogues made of solid wood.

Production technology

Veneer doors consist of a frame, a filler and a cladding layer. Two types of construction are popular: from MDF panels (economical option) and solid wood (more expensive option).

Manufacturing technology of veneered doors from MDF:

- A frame is assembled from an inexpensive tree, for example, from pine.

- Fill with filler - corrugated cardboard;

- Fasten MDF panels to the door frame;

- A layer of veneer is applied.

- A layer of varnish is applied to protect against moisture.

The process of creating products from solid wood differs in that instead of a frame, a wooden canvas is used - often assembled from small pieces. This reduces the cost.

Veneering - the technology of fixing veneer on the base - is of two types:

Hot pressing. The veneer sheet is glued with a chemical composition with formaldehyde at temperatures above 100 ° C. This method is widely used due to its low cost.

Cold pressing. More environmentally friendly, but also expensive. Use glue without formaldehyde, which cures at a temperature of 30–35 ° C.

These methods are used for all types of veneer in the manufacture of interior doors: this is how both natural and multi-veneer are fixed.

Advantages and disadvantages

Veneered doors have their own advantages and disadvantages. They need to be studied before buying in order to make the right choice.

Dignity

The veneer covering the interior doors has many advantages:

- Attractive appearance and variety of shades. Without detailed consideration, the door appears to be made of natural wood. The veneer retains its color, the original grain and knot pattern. Unlike laminated flooring, the pattern is unique and natural.

- Affordable cost: by purchasing doors with veneer, you can save money and decorate your house with valuable species without hitting your budget.

- Health safety, especially for cold-pressed doors.

- Durability: the service life reaches at least 10 years, and with careful use it increases to 15–20 years. Additional coating with paints and varnishes protects the door from moisture and mechanical damage.

- Environmental friendliness. Buying a veneer door, a person indirectly participates in nature conservation. The production of a product requires much less wood material than a solid wood door. There is practically no visual difference.

All this makes veneered interior doors deservedly in demand.

disadvantages

Before buying, you need to remember about the shortcomings of the material:

- When gluing to the door leaf by hot pressing, formaldehyde is used. In a large amount of evaporation, substances can be toxic to humans. Therefore, you need to choose a reliable manufacturer with a good reputation, who monitors the safety of their products.

- Veneer is susceptible to sunlight: its color fades under excessive light.

- The material does not tolerate contact with moisture and temperature extremes. It is used only in indoor heated rooms.

How to know which veneered door is better and better

There is one more way to diversify the collection of doors to an apartment, but it is used within the very category of "veneered doors". The classification is carried out according to the type of veneer used. As you know, there are 3 of them:

- Natural (natural);

- Fine-line;

- Eco-veneer.

The first is the most expensive because it is made by cutting off a thin layer of wood. The same array, but in the form of a film up to 1 mm thick. The second option is also made from wood, but using a different technology. First, the cuts of wood are glued into one sheet of plywood and already cut into thin layers. Eco-veneer is made from waste of the cellulose industry and polypropylene. Materials for door covering are listed in descending order of price.

Ash veneer interior door

Ash veneer interior door

How an ordinary person can distinguish a door made of natural veneer from eco-veneer and fine-line:

- Veneer - an exact imitation of an array, with the same beautiful pattern and texture;

- The fine line has many repeating fragments on the surface;

- Eco-veneer is a polymer. Look at the end cuts, you can see that this is a film, not a cut of wood. And the second point - eco-veneer comes in a wide palette of colors, including those that are not found in nature.

How do you know which veneer doors are better and of better quality? Do not be afraid to touch the canvas, even smell what it smells like. A good door has an absolutely flat surface and no pungent chemical odors.

Which is better - solid or veneer doors

It is believed that the choice between veneer and solid wood doors is made solely because of the price. The statement is correct, but in part, and does not work in all cases. For example, models made from inexpensive solid pine can have the same or less cost than beautiful paneled doors made from natural oak veneer.

Interior doors with oak veneer finish

Interior doors with oak veneer finish

Which is better - solid wood or veneer? We offer to make a comparison by key parameters:

- Scope of application: solid wood doors are installed in richly decorated living rooms, halls, as well as in houses and offices with luxury finishes. Veneered models are less picky about their surroundings, although in order to install a door in the middle and middle + price segment in the room, you need to match. They are also ordered in apartments, offices, country houses, but they do not necessarily fit into exquisite interiors and are selected as a background with expensive antiques;

- Moisture resistance - it is believed that veneer copes better with high humidity, although this criterion depends not so much on the material itself, but on its protection. Nevertheless, if you need a door to the bathroom, it is better to do with veneer, so as not to risk a lot of money;

- Price is an indisputable priority here on the side of veneered doors.Solid wood is always more expensive than a thin cut of wood, although if the two models are identical in design, is it worth the extra charge;

- The ability to eliminate defects on the surface: there are more of them on solid wood doors, although there are special compounds with which you can, if not eliminate, then make invisible scratches on the veneer.

Another advantage of veneered doors is their low weight. The installation of solid wood products is usually performed on three hinges. In the case of veneer, no reinforcement is required.

Advantages and disadvantages

Raw material sheets

The main advantages of fine line veneer include the absence of defects of a different plan on it. Thanks to this, users leave positive reviews, which cannot be said about natural veneer. Many people take this advantage as a disadvantage, because defects of this kind make the material more natural and thereby give it uniqueness and value. But this is a matter of personal taste. For many, the rich color spectrum of this material can play an important role.

The important advantages of this type of veneer include its environmental friendliness.

Even if we take into account the fact that the appearance of a fine line is similar to plastic, it has every reason to belong to the class of natural materials of natural origin.

Fine line veneer is able to withstand temperature extremes. Even in such conditions, its properties and appearance remain unchanged. This raw material is also moisture resistant. This advantage is especially useful in rooms with high humidity, where veneer doors have shown themselves well.

The next group of advantages includes its economical cost and ease of use. In the process of finishing, it does not need a lot of varnish for it. In addition, this veneer is quite ductile.

The following facts also include the advantages:

- Color and pattern are created evenly.

- With the help of the picture, you can create an imitation of any type of wood.

- It is possible to create a complex of materials with identical surfaces.

- The obtained sheets are convenient to use in the manufacture of interior doors.

If we talk about the other side of the coin, then disadvantages can be distinguished such as low strength. Often, soft tree species, such as poplar, are used as a material for the manufacture of veneers of this kind, so you should not expect high wear resistance. This disadvantage is not eliminated even by many layers of varnish. Such a coating can, on the contrary, harm the raw materials. Hardened varnish layers increase the likelihood of cracking.

Classification

Depending on the method of obtaining the material, veneer is distinguished:

- shelled;

- planed;

- sawn.

Rotary cut veneer

Produced on special machines by peeling. Its thickness is 0.1-10 mm. It is a cheap veneer as it is produced in the lowest cost way.

Peeled birch veneer

To begin with, a blank is prepared - the tree trunk is cleaned of branches, twigs, etc. Then they place it in the machine. Further, the primary processing of the trunk is performed with a cutter: the bark is removed and the workpiece is leveled along the length. After that, a layer of veneer of the required thickness is removed along the entire length of the trunk at the same time.

The resulting semi-finished product is sorted by quality, appearance, etc. This type of veneer, in comparison with others, is not beautiful enough. Therefore, so that it can be glued to the door, it is processed, for example, dyed or hot-printed.

Sliced veneer

It is obtained by planing bars perpendicular to the wood fibers on veneer planing machines, in contrast to peeled, which is obtained by cutting off the wood layer from a rotating log.

Production of rotary cut and sliced veneer

Veneer is made from hardwood and softwood such as birch, maple, pear, elm, oak, linden, mahogany, etc. The thickness of the material obtained in this way is 0.2-0.5 mm.

Beautiful veneer for interior and exterior doors is made of twisted wood. In a twisted tree, the fibers inside the trunk do not run smoothly, but intertwine, forming patterns in the form of knots, bundles, etc.

In the production of veneer from such a blank, a layer is removed simultaneously along, across and at an angle to the fibers. This gives a beautiful pearlescent shine to the material. Karelian birch and sugar maple wood are valuable for such veneer. If you stick such veneer on ordinary wooden doors, then they will look much richer and more beautiful.

Sawn veneer

It is made by cutting blanks. Get a quality product with a thickness of 0.1-1mm. However, this type of production is the most uneconomical, since about 60% of the timber goes into sawdust.

By the texture of wood veneers are distinguished:

- radial (the pattern of annual layers is parallel lines that are located along the entire plane);

- semi-radial (the pattern of annual layers is parallel lines that occupy at least ¾ of the plane);

- tangential (annual layers create a pattern of a cone, angles or curves);

- tangential-end (annual lines create closed curved lines).

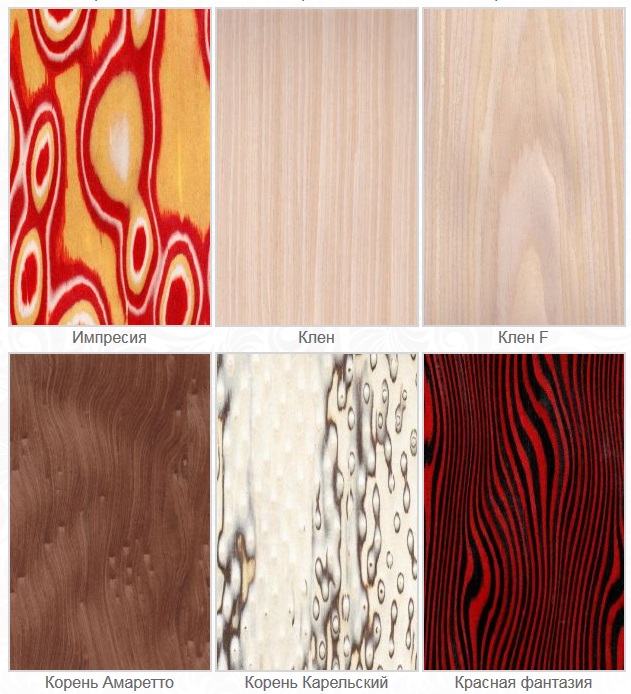

According to the material used for the production of veneer, they are distinguished:

- natural;

- fine-line;

- multi-veneer;

- eco-veneer

Natural veneer

Made from a natural solid tree trunk. At the same time, the structure of the tree is preserved. The cost of natural material is in the middle price category.

Fine-line veneer

It is also made from inexpensive and fast-growing natural wood species, but has a high porosity of the structure. The appearance resembles plastic. By dyeing, fine-line veneer can imitate natural veneer made from expensive wood species. This material is often used to decorate interior doors. It is made as follows. First, natural veneer is produced. Then the veneer sheets are dried, sorted and dyed in a certain color. After that, the sheets need to be glued together.

Fine-line veneer

As a result, the resulting block of veneered sheets is sent under the press. From the finished dried pressed block, very thin sheets of fine-line veneer are cut, which are glued to the surface to be decorated. According to its composition, it consists of 92-94% natural wood. The rest is glue and dye.

Multi-veneer

Refers to the reconstructed type of veneer, like fine-line. Geometric patterns are most often applied on its surface.

Eco-veneer

It is a polymer film with the addition of wood fibers. Its surface imitates the surface of natural wood. It is resistant to abrasion, changes in temperature and humidity. Veneered doors using eco-veneer are durable and do not lose their performance for a long time.

Advantages and disadvantages

If you put fine-line on the same board with PVC films or other similar facing materials, then it significantly surpasses these materials. We have already learned what the fine-line veneer is, now it remains to consider its pros and cons in order to specifically make sure of the need for this product.

The advantages include a number of important points.

- Ecologicaly clean. Due to the fact that more than 92% of the texture is allocated to natural wood, the material is classified as environmentally friendly. Moreover, its production does not cause any particular harm to nature, since the material is produced from fast-growing tree species.

- Quite good aesthetic performance. As mentioned above, the canvases have a plastic-like surface, since there are no roughness or knots on it. After processing, the surfaces look fashionable and expensive.

- Plastic.Due to the bending structure and high plasticity parameters, the sheets are able to take different geometric configurations and restore their original size and shape after deformation. Sheets are used to refine almost any surface (door cladding, columns, table tops, decorative elements).

- Price. In comparison with classic natural veneer, the fine-line line is relatively inexpensive.

- Stability and operational period. The material is highly resistant to temperature fluctuations. In addition, the finish works well in places with high levels of humidity.

- An impressive assortment. There is a wide selection of various textures, ornaments, colors on the market. This makes it possible to select sheets with the most optimal design, corresponding to the general style of the interior interior.

However, despite the mass of positive qualities, the material also has errors.

- Strength. Due to the fact that most of the structure of the material is softwood, it cannot be called durable. Therefore, a rather fragile coating is obtained, which has a low resistance to mechanical stress. To fix this somehow, several layers of wear-resistant varnish are applied to the surface of the material.

- Inhomogeneity. Even when the canvas is made from the same type of wood, its structure and color may vary. In this regard, when purchasing wholesale, it is advisable to order a fine-line from one batch.

Recommendations for choosing doors

The production technology of entrance groups is based on gluing an eco-veneer to the door leaf. The door itself is made of wood or MDF boards. There are conventional and sliding models, accordions and coupes. Such designs are inexpensive. Entrance groups covered with such a finishing material can replace expensive natural wood products.

The choice of interior doors made of eco-veneer from the manufacturer must be done, guided by the following rules:

- Determine for yourself what function the future structure should perform. Models with transparent glass inserts should not be installed in a shower, bathroom, restroom.

- Choose products according to the style of the room.

- Select the texture, accessories and tone in accordance with the color of the floor, baseboards, and other decorative elements in the room.

Ask the seller for a quality certificate for the product. Ask about the environmental and safety level of the model. Inspect the ends of the door leaf - they are never processed. All layers of the product and finishing will be visible at these joints.

Distinctive characteristics

Eco-veneer is an environmentally friendly material with a visually attractive texture. It imitates the texture of natural wood and has positive quality characteristics.

Among them:

- the presence of a unique 3D effect;

- a wide selection of decor and color palette;

- glossy, matte or silky surface structure;

- long term of use;

- strength - no cracks appear on the coating, doors do not change texture for a long period and retain their original appearance;

- environmental friendliness - products do not pose a threat to humans.

Among other features of door structures, it should be noted that the drawers are made in the form of "sandwiches". They use a bar with a homogeneous structure, which has good resistance to deformation, excellent mechanical properties, excellent refractoriness, low weight.

Door construction

All models of eco-veneer doors are multilayer and consist of:

- bases made of natural pine or high-strength glued beams;

- upholstery (MDF panels);

- decorative covering made of eco-veneer.

Most eco-veneer doors are structures with four drawers - two vertical and two horizontal.They are connected into a frame, into which glass inserts or MDF boards are inserted.

Production technology

Eco-veneer is produced by a unique method. Woodworking waste is used, which is crushed on specialized equipment, turning into small fibers. The material is dyed and thoroughly mixed, followed by gluing into a solid thin sheet. With the help of this technology, products can be given absolutely any shade, with or without wood imitation.

The sheet material is wrapped around the door leaf from all sides. All structural details are covered with a film prior to assembly. The elements are assembled so that the joints of the material remain inside. It leaves a one-piece coating without edges, significantly increasing the resistance of the model to moisture and extending the life of the model.

Advantages and disadvantages of eco-veneer doors

Buyers often doubt the quality of eco-veneer due to its low price. Products made from this material are durable, durable, and environmentally friendly. They can be installed in all types of premises. It is worth mentioning separately that eco-veneer allows you to imitate any exotic wood species. Therefore, these doors look great in non-traditional interiors, for example, in the style of pop art or High-tech.

Among the competitive advantages of the products:

- lack of specific odors;

- resistance to sudden changes in temperature indicators;

- moisture resistance;

- lack of pores;

- ease of care - can be treated with a soft cloth dipped in soapy water;

- visual similarity with natural veneer;

- mechanical resistance - cracks and other damage, like natural veneer, are not formed;

- impact resistance;

- the material successfully resists chips, impacts, scratches;

- immunity to ultraviolet radiation;

- low price.

As already noted, the material is environmentally friendly. It is worth noting the external characteristics of such doors. The cladding faithfully mimics the structure of the wood species, so customers can choose the finish according to their taste.