Classification

Depending on the method of obtaining the material, veneer is distinguished:

- shelled;

- planed;

- sawn.

Rotary cut veneer

Produced on special machines by peeling. Its thickness is 0.1-10 mm. It is a cheap veneer as it is produced in the lowest cost way.

Peeled birch veneer

To begin with, a blank is prepared - the tree trunk is cleaned of branches, twigs, etc. Then they place it in the machine. Further, the primary processing of the trunk is performed with a cutter: the bark is removed and the workpiece is leveled along the length. After that, a layer of veneer of the required thickness is removed along the entire length of the trunk at the same time.

The resulting semi-finished product is sorted by quality, appearance, etc. This type of veneer, in comparison with others, is not beautiful enough. Therefore, so that it can be glued to the door, it is processed, for example, dyed or hot-printed.

Sliced veneer

It is obtained by planing bars perpendicular to the wood fibers on veneer planing machines, in contrast to peeled, which is obtained by cutting off the wood layer from a rotating log.

Production of rotary cut and sliced veneer

Veneer is made from hardwood and softwood such as birch, maple, pear, elm, oak, linden, mahogany, etc. The thickness of the material obtained in this way is 0.2-0.5 mm.

Beautiful veneer for interior and exterior doors is made of twisted wood. In a twisted tree, the fibers inside the trunk do not run smoothly, but intertwine, forming patterns in the form of knots, bundles, etc.

In the production of veneer from such a blank, a layer is removed simultaneously along, across and at an angle to the fibers. This gives a beautiful pearlescent shine to the material. Karelian birch and sugar maple wood are valuable for such veneer. If you stick such veneer on ordinary wooden doors, then they will look much richer and more beautiful.

Sawn veneer

It is made by cutting blanks. Get a quality product with a thickness of 0.1-1mm. However, this type of production is the most uneconomical, since about 60% of the timber goes into sawdust.

By the texture of wood veneers are distinguished:

- radial (the pattern of annual layers is parallel lines that are located along the entire plane);

- semi-radial (the pattern of annual layers is parallel lines that occupy at least ¾ of the plane);

- tangential (annual layers create a pattern of a cone, angles or curves);

- tangential-end (annual lines create closed curved lines).

According to the material used for the production of veneer, they are distinguished:

- natural;

- fine-line;

- multi-veneer;

- eco-veneer

Natural veneer

Made from a natural solid tree trunk. At the same time, the structure of the tree is preserved. The cost of natural material is in the middle price category.

Fine-line veneer

It is also made from inexpensive and fast-growing natural wood species, but has a high porosity of the structure. The appearance resembles plastic. By dyeing, fine-line veneer can imitate natural veneer made from expensive wood species. This material is often used to decorate interior doors. It is made as follows. First, natural veneer is produced. Then the veneer sheets are dried, sorted and dyed in a certain color. After that, the sheets need to be glued together.

Fine-line veneer

As a result, the resulting block of veneered sheets is sent under the press. From the finished dried pressed block, very thin sheets of fine-line veneer are cut, which are glued to the surface to be decorated.According to its composition, it consists of 92-94% natural wood. The rest is glue and dye.

Multi-veneer

Refers to the reconstructed type of veneer, like fine-line. Geometric patterns are most often applied on its surface.

Eco-veneer

It is a polymer film with the addition of wood fibers. Its surface imitates the surface of natural wood. It is resistant to abrasion, changes in temperature and humidity. Veneered doors using eco-veneer are durable and do not lose their performance for a long time.

Specifications

TECHNICAL SHEET KAINDLFURNIERTE E1 (veneered)

Application area:

Veneered chipboard (MDF) has a variety of applications in the production of furniture and interior decoration, but without a load-bearing function.

Design:

- valuable wood veneer

- carrier plate

- valuable wood veneer

Surface: fine wood veneer.

Dimensions:

|

Thickness |

Carrier plate |

Dimensions (edit) |

|

9/13/16/19/23/26/29/39 mm |

Chipboard P2 |

2800 x 2070 mm / cross veneering possible |

|

9/16/19/26 mm |

Special sizes: 3200 x 2070 mm 3600 x 2070 mm other sizes on request |

|

|

4/6/9/13/17/19/23/26/29/39 mm |

MDF |

2800 x 2070 mm / cross veneering possible |

|

16/19/23/26 / 29mm |

Joinery |

2800 x 2060 mm |

|

16/19 / 2530mm |

Birch plywood |

2500 x 1250 mm 3000 x 1500 mm |

The load-bearing slabs comply with the E1 emission class

general information

|

Options |

Unit |

Test Method |

|

|

Anti-scratch strength |

Coeff. 3 |

Degree 2 * / 2N |

EN 438-2: 2005 |

|

Stain resistant |

Degree5 Degree 3 |

Group 1 + 2 without visible change Group 3 moderate change in gloss and / or color |

EN 438-2: 2005 |

|

Behavior in relation to cigarette burning |

Degree 3 |

moderate change in gloss and / or moderate brown spots |

EN 438-2: 2005 |

|

Surface defects |

sq.mm / sq.m. mm / sq.m |

Dirt, stains Fibers, hair and scratches |

EN 438-2: 2005 |

QUALITY DESCRIPTION: fine wood veneer

Quality 1A: veneering quality A, but sorting at the request of the customer:

Definition of terms:

1. Frieze: calm - without a flower

2. Figure: flower - with veins

3. Contrasting stripes: half flower - half veined

4. Trunk: - at least 6 veneered slabs from the same trunk

- each barrel is packed separately

- the turn of the trunk is formed by a combination of figures, only beech and oak allow the opening of the trunk without a flower (a real rift).

Sheet width: production according to the specified widths of the boards, excluding the first and last sheet, tolerance +/- 2mm. Price on request

Quality A: face veneer with different textures (no flower, half flower, flower), mostly clean or having only the usual wood characteristics for face veneers (for example, light sugar in Canadian maple), without residual sheets.

Quality B: uniform color, different textures, used for the visible sides of furniture cases or the reverse side of the fronts, slight characteristics of wood, there are also residual sheets of similar structure.

Quality C: uniform color, different structures, used as the front side of the enclosures or the back side of the fronts, slight characteristics of wood, there are also residual sheets of similar structure.

GZ quality stabilizing layer - veneer

Back side veneer - at the choice of the factory

Small opening defects and crumbling areas, sapwood, accretions, etc.

KP quality stabilizing layer - paper

For sizes 2800 x 2070 mm only

Slight warpage is possible, we recommend the use of power paper only starting from a thickness of 16 mm

Quality A / B-LA on the front side there are veneers and quality A and B, on the back side B and C.

The product requires less sorting costs and can in any case be used for hulls and interior decoration

Separate sections can be used for fronts as well.

The qualities from 1A to KR can be combined in any configuration!

SURFACE: fine wood veneer.

Feature: at the request of the customer, several types of veneer shirt manufacturing are possible (symmetrical, longitudinal, staggered, inverted).

Seam Bonding: All veneer strips are glued back to back to ensure the perfect veneer jacket quality.

STORAGE RECOMMENDATIONS:

KAINDL veneered boards E1 veneered boards must always be stored horizontally across the entire area of the board in stacks, in closed warehouses, avoiding exposure to moisture and direct sunlight and UV rays.

TREATMENT:

KAINDL boards E1 veneered boards can be processed with conventional woodworking machines.

The surface of the veneered boards is processed with K 80 abrasive paper.

For cleaning from possible residues of glue, grease, oil, etc. it is recommended to carry out a final sanding before impregnation and varnishing. In any case, it is necessary to make a control sample of veneer with a treated surface (impregnation, varnishing, oil, etc.) in order to avoid possible surface defects.

If the above recommendations are not followed, subsequent claims will not be accepted.

Advantages and disadvantages

Veneer is a thin cut of natural wood, not exceeding 3mm in thickness. It is widely used in the production of modern furniture, musical instruments, and is also used as a finishing material in the creation of fashionable interiors. The popularity of this natural material is due to the optimal combination of price and attractive appearance of finished products. To make it easier to make a choice, let's take a look at all the pros and cons that veneer furniture possesses.

The advantages of the material are as follows:

- a variety of colors and textures. Various types of wood are used for production: from classic pine to the most expensive varieties;

- it is a natural, environmentally friendly material. Veneer - a covering made of natural wood;

- ease of processing allows the use of veneered blanks for products of various shapes and configurations;

- relatively low cost. Veneer furniture is much cheaper than solid wood furniture, which makes it more affordable;

- excellent appearance - high-quality products have the correct selection of patterns, beautiful textures, which give the veneered furniture a wonderful appearance;

- practicality, resistance of facades to temperature extremes, high humidity. Veneer facades are not subject to cracking, deformation as a result of external factors.

The material also has disadvantages:

- veneered coating is afraid of direct sunlight: under their influence, it can change color;

- it can be difficult to pick up a pattern at the joints, because each sheet has its own unique pattern;

- capricious in care, excludes the use of chemical cleaners that can damage the surface;

- products made from expensive veneer options (oak, ash, beech) are not cheap.

Cons and pros

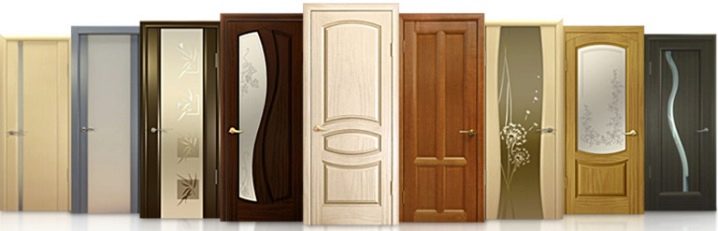

In appearance doors with veneer it is very difficult to distinguish from analogs made of wood, since they are covered with a natural cut of wood.

Such doors have many advantages:

- The product is 99% natural in composition, since it includes solid wood and a cut of valuable wood from the outside.

- Veneered doors are made from environmentally friendly materials, so they are often used not only for bedrooms or living rooms, but also for children's rooms.

- The attractive appearance of the product is achieved through the use of natural wood, which is characterized by an original and unique print and texture.

Wooden doors with veneer make it possible to create a good indoor climate. They perfectly pass air through micropores.

The lightness of veneered models allows them to be installed even on very thin walls. If the doors are installed correctly, then in rare cases they can sag.

A good combination of quality and price of the product.If we compare the cost of veneered and wooden models, then the option with veneer is much cheaper.

If a model with natural veneer is also expensive, then you can pay attention to options with eco-veneer or other artificial turf.

Models with veneer very often convey the texture of a valuable wood. Cherry, pine, wenge, mahogany or ash veneer looks beautiful

Expensive tree species include such as black walnut and madrona.

- Veneered models can be repaired if the canvas is damaged during transportation or operation. It is necessary to use a special compound for staining veneer or to polish the damaged area.

- The product with veneer is characterized by excellent sound insulation properties, as well as the ability to perfectly retain heat, if we talk about options made from solid pine wood.

- Modern manufacturers offer a wide range of veneered doors, among which you can choose not only the material, but also the color and the required dimensions. The doors are presented in natural colors. To give the veneer color depth, staining is often done.

Doors with veneer also have some disadvantages, which you should familiarize yourself with before choosing doors:

- Natural materials are always expensive, which is why veneered models are expensive. The popularity of the manufacturer also affects the price of doors.

- Natural veneer practically does not differ from artificial one, which allows fraudsters to pass off low-quality veneer as natural.

- To ensure long-term use of the product, careful care must be taken. To clean the doors, it is worth using special products developed on the basis of wax.

For the manufacture of laminated doors, a special laminate film is used. It perfectly conveys the texture of the array. Of course, such products are distinguished by affordable cost, increased wear resistance and reliable protection against moisture ingress.

What types of wood veneer are there

Sliced veneer

As for this product group, it has the following differences:

- sheets are made on special veneer planing equipment, which is characterized by high precision and cleanliness of processing;

- product thickness can vary from 0.2 to 5 millimeters, which is sufficient for most uses;

- this method of production is used when working with valuable species of wood, as it allows you to present their structure in the most favorable light. Most often, the work uses wood from oak, walnut, beech, Karelian birch, acacia, ash, yew and much more.

One simple rule should be remembered the thicker the veneer, the more reliable it is, therefore you should not save and purchase the thinnest options

Rotary cut veneer

The production of wood veneer using this technology has the following features:

- The production process is very simple: the logs are cut into pieces of small width, after which they are cut into a sheet of small thickness using a special knife. The quality of this option is noticeably lower than the first one, but the cost price is also lower, therefore it is the most popular;

- the following types of wood are most often used for work: pine, birch, alder and oak;

- the thickness of the finished elements can be from 0.1 to 10 millimeters, which allows you to choose the optimal solution for any type of work.

Sawn veneer

As for this type of product, the following can be noted regarding it:

- products are produced on special machines that cut the bar layer by layer, due to the large amount of chips that are formed during operation, the cost of the material is high;

- the thickness of the lamellas, and this is what the finished elements are called, can be from 1 to 10 mm;

- products of this type are of especially high quality, therefore they are very often used in the production of musical instruments, they can also be used in the interior and in the manufacture of furniture, such surfaces practically do not require additional processing.

It is important to choose the option that is best suited in a given situation, and if the manufacturer has recommendations for use or special instructions for carrying out work, then all requirements should be followed in order to get a guaranteed high result. One simple rule should be remembered: the thicker the veneer, the more reliable it is, so you should not save and purchase the thinnest options

Veneer is one of the materials, the popularity of which never decreases, moreover, with the rise in wood prices, the demand for this option will be even greater

One simple rule should be remembered: the thicker the veneer, the more reliable it is, so you should not save and purchase the thinnest options. Veneer is one of the materials, the popularity of which never decreases, moreover, with the rise in wood prices, the demand for this option will be even greater.

Interior doors from veneered MDF

MDF, veneer are those materials that, due to their properties, have become the most successful option for replacing natural wood, and when they are combined, objects are obtained of excellent quality, not inferior to the natural prototype.

In order to manufacture MDF veneered doors, a special technology is used using high pressure and temperature. It is she who provides such material properties as reliability, practicality and durability. Due to the very high pressing density, such doors are moisture resistant and practically do not deform. Compared to wooden models, they are more functional. Their advantages: light weight, aesthetic appearance and long service life.

Veneer is a modern finishing material that has recently become quite widely used in various finishing and joinery works. Over the years, he managed to establish himself only from the best side, and to this day it is the most widespread and demanded.

Colors

The colors of the slabs are offered in a wide range, so everyone can find what meets the design needs. You can choose transparent and translucent slabs, on which a lace pattern is applied. These slabs imitate glass and stained glass; this unusual decor is often used as a separate component that complements the overall interior. The dense monochrome coating of veneered MDF boards is presented in pastel and bright colors. If you need a light facade, you can safely choose panels with this design. The range of solutions can reach 200 options, while the execution can be both smooth and textured.

It should be noted that slabs in white are presented in several shades, which allows you to achieve an ideal design solution and interior decoration. Of course, slabs for solid wood, metal or natural stone are in great demand. This effect is created using films, patination, brushing and embossing.

Advantages and disadvantages

The kitchen is a place where furniture is exposed to special negative influences: temperature drops, grease stains, soot deposits will certainly accompany the cooking process. Housewives try to select a set that will most steadfastly endure all unfavorable factors, will not deteriorate or deform.

- Durability. Lacquered veneer fronts not only look stylish, but are also very durable and durable. Such a surface is not easy to scratch, it is shockproof, is not afraid of moisture, steam, direct sunlight.

- Maintainability. Furniture can be easily restored even at home.If there are scratches, they can be sanded, if there are chips, they can be removed using the same veneered patches. With regard to film or plastic, such surfaces cannot be repaired after serious damage.

- Acceptable price. Compared to solid wood, veneer kitchens are much cheaper, and in terms of characteristics, veneer significantly outperforms its expensive competitor.

- Stylish design. Veneered fronts look great in both small and small kitchens, as they look sleek and less bulky. The plasticity of the veneer material allows you to create unique shapes, so the furniture fits into the classic and modern interior. It is also possible to choose any color and texture you like, to make the surface matte or glossy. Veneer goes well with glass, acrylic, metal or plastic.

- Easy care. Natural wood sheets need the same care as solid wood. Stains can be easily removed with a damp cloth or sponge. In no case should you use aggressive household chemicals with abrasive particles so as not to damage the surface. It is advisable to use a simple soap solution or special furniture sprays. They will help to maintain shine and attractive appearance for a long time. Designers recommend choosing lighter shades, since stains and dust are much more noticeable on dark brown, black, dark blue facades.

- Environmental friendliness. The kitchen is the place where a person spends most of their time, so the quality of the material should come first. Veneered facades, unlike film or plastic, do not pose a threat to human health, since no harmful substances and chemical compounds are used in the manufacture.

Veneered facades are strong, durable and do not deform

Veneer varnishing provides additional protection for the facade

- The quality of a kitchen set is difficult to assess at first glance. Only during operation can one understand how conscientiously the manufacturer made the veneer. If raw materials were used in the work, then over time, the facades may deform, and the veneer may peel off from the substrate. When buying a headset, one should give preference to reputable companies that give a guarantee for the furniture purchased. However, it is necessary to adhere to certain rules for the care of the headset, otherwise the manufacturer may withdraw from itself warranty obligations in case of non-compliance with the instructions.

- Unfortunately, like any wood, veneer wood is susceptible to the negative effects of ultraviolet rays. Over time, facades can fade, for example, white becomes gray. Sanding and updating the coating will help solve the problem. Plus, it's a good way to tweak your kitchen design a bit and experiment with shades. For small kitchens, it is recommended to choose light colors; in large kitchens, you can combine different colors.

- The price of veneer significantly exceeds the price of plastic or vinyl coated products. Increasing consumer demand and wood shortages also lead to a constant and systematic increase in the cost of furniture from year to year.

Veneered panels are often combined with others, for example, with film or enamel

Where is it applied?

Wood veneer is used for decorative purposes in the furniture and woodworking industries. It is used to finish surfaces made of cheap materials. Coating with veneer creates the effect of natural wood at a low cost of finished products. Thin veneer is used in the manufacture of door leaves, as well as decorative wall panels. Boxes for matches are made of this material, boxes for fruit are made, and also used in the technology of production of plywood multilayer sheet.

As a basis for pasting with veneer, a sheet of chipboard, MDF, drywall can be.Wood-cut sheets are suitable for restoration work when repairing used furniture. Sliced veneer is used in the manufacture of sports equipment, designer souvenirs, household items and much more. Sawed veneer is used in the creation of cases of musical instruments, doorways and arched structures, exclusive models of furniture, boxes, panels, gift products. The veneer of noble wood species, which has a colored color, is a subject for creativity.

The main features of a high-quality veneered door

The choice of veneered doors can be called not so much a responsible matter as a delicate one - the fact is that it is rather difficult to determine the quality of such products by their appearance. But you don't have to buy a pig in a poke, and there are a lot of good reasons for that, or rather, ways to determine the quality of the door.

Hollowness. This has already been mentioned above - by slightly knocking on the door leaf, listening to the sound that the door makes at the same time, you can say a lot about this product. A full-bodied door is very good, it tolerates various operating conditions much better, but this indicator does not yet speak of quality. Hollow doors, if handled carefully and correctly, can serve for a long time, and at the same time they will cost much less. Visual inspection of veneer - it can tell a lot about the quality of the door leaf

Everything is quite simple here - you need to try to pry off the end pasting of the door with your fingernail. If it begins to peel off easily, then you have a poor-quality door. Also, a narrow dark strip at the corners of the door leaf can tell about the poor-quality finish of the door with veneer - in fact, this is a visible lining made of MDF, which manifests itself as a result of peeling off the veneer. Smell. Oddly enough, but the quality can also be distinguished by the smell - the door should not exude a pungent smell, which indicates the use of very toxic glue in its manufacture.

In addition to obvious indicators that allow us to talk about the quality of veneered doors, there are also hidden ones that cannot be seen. It is they who in most cases represent the main problem in the choice. For example, in their desire to earn more money, some manufacturers use natural timber in the manufacture of veneered doors, and not its glued analogue - such a timber is highly susceptible to changes in temperature and humidity, and these doors do not serve for a long time. Also, some unscrupulous manufacturers can exclude the gasket from MDF, replacing it with cheaper fiberboard. In general, there are many such nuances here, and the most offensive is that they are not visible. In this regard, you have to rely entirely on the reputation of the manufacturer. In my opinion, this is the main criterion for choosing a veneered door.