Peculiarities

The company produces powdery building mixtures, which are widely used in decoration and construction. The most popular are the finishing putty and screed of this brand, as well as tile adhesive. In our country, there is an industry division of the international group of companies Saint-Gobain called Weber-Vetonit, which represents dry mixes of the Vetonit brand on the domestic market.

Putty

The mixture is used at the stage of final leveling of various surfaces. The quality and general appearance of the finished work depends on the correct application. Vetonit putty is designed to fill cracks and crevices and create a perfect surface after basic work.

Depending on the composition, there are three types of such a mixture: gypsum, polymer and cement. They can be applied both on ordinary concrete or brick, and on drywall and even on painted walls, both inside and outside the room. And on the putty itself, it is allowed to apply any decorating coatings - tiles, wallpaper, various paints and decorative plasters.

The advantages of Vetonit products are the versatility and environmental friendliness of the putty. Created from components that are safe for both nature and humans, it can even be used for decoration in the pool room. The powder particles of such a mixture are so small that the finished putty layer has an almost mirror-like smoothness. It is resistant to aggressive weather conditions such as frost or hail, therefore it is suitable for facade decoration and can be applied even at sub-zero temperatures.

Plaster

On the domestic markets, there are several types of dry plaster from the Vetonit company, which are supplied both from abroad, for example, Finnish mixtures, and are made directly at Russian factories. As a rule, these are cement mixtures with sand or limestone and additional components in the composition in the form of various microfibers.

One of the advantages of Vetonit dry mix is the ability to apply to almost any surface, from concrete and brick to ceramics and plaster. Subsequent finishing is also possible with most of the known coatings - wallpaper, tiles, putty and even glass decorative plates. The plaster is waterproof and not subject to deformation in frost, which makes it possible to use it for exterior decoration of facades and rooms with high humidity. It adheres perfectly to most surfaces and hardens without shrinkage.

Self-leveling floors

The self-leveling Vetonit mortars, used as screeds, make it possible to create an ideal self-leveling floor with a thickness of 1 to 250 mm in one pass. The mortar is suitable for the renovation and decoration of both new residential and office premises, as well as buildings with a long service life.

The advantage of the brand is its high compressive strength, which allows the coating to withstand significant loads. Additional internal regulation will further strengthen this indicator. The self-leveling floor can be covered with even very thin finishing materials or left without finishing at all, since it has a smooth surface and does not require sanding.

The mixture quickly gains strength, which implies the ability to walk on such a floor within two to three hours after laying. It can be poured even over wood or ceramics due to the presence of special polymers in the composition.

Views

"Vetonit" supplies the following options for finishing putty to the building materials market:

- "B" - cement plaster with high moisture resistance.

- "BX" is suitable for facade work, having powerful waterproofing qualities.

- "JS" and "LR" - putty for finishing and superfinishing with increased durability and excellent appearance.

- "T", "KR" - types intended for rooms with low humidity.

- "LR Fine", "LR +" are used for places with low and normal humidity levels.

- "VH" and "KR" - lime topcoat.

"Vetonit LR +"

Finishing putty made of high quality white limestone, finely ground marble and polymer additives. It is used for clean, pre-leveled surfaces; before application, the coating should be degreased and cleaned of small debris.

The main features include:

- particle size up to 3 millimeters;

- the thickness of the applied layer is from 1 to 5 millimeters, a thicker layer is recommended to be used on small surfaces and to thin out with an increase in the processed canvas;

- the speed of complete drying at a temperature of 20C - 24 hours;

- must be used in rooms with low humidity levels, otherwise the color will take on a yellow tint;

- consumption of putty with a layer thickness of 1 mm - 1.2 kg / sq. m;

- the shelf life of the mixed solution is a day in an open container, 48 hours in a closed container;

- sold in bags weighing 5.25 kg;

- dry, the mixture can be stored for 1.5 years.

"Vetonit JS"

A putty mixture on polymer glue with finely ground marble, used for finishing and superfinishing puttying for painting and wallpapering.

Other features include:

- intended for:

- filling drywall and grouting;

- application on a surface previously painted with any kind of paint.

- drying speed ranges from 3 to 24 hours;

- very strong structure, reinforced with reinforcing microfibers;

- strong adhesion;

- complete absence of cracks;

- great appearance, perfectly smooth and even surface.

"Vetonit LR"

Polymer putty mixture, the specific differences of which are:

- use for wall and ceiling work;

- excellent compatibility with plastered and concrete surfaces;

- applied in one layer;

- not applicable at high humidity;

- sold in 25 kg bags.

"Vetonit VH"

The characteristic qualities of this facade finishing putty include the following features:

- The composition is used on concrete and brick surfaces.

- Do not apply it on surfaces treated with lime and water-soluble agents.

- It is better to prepare the solution using a drill with a mixing attachment.

- It should sit for about 3 hours after cooking.

- The mixture is applied in two layers no thicker than 3 millimeters, each next is applied after the previous one has dried.

- There is a high level of waterproofing.

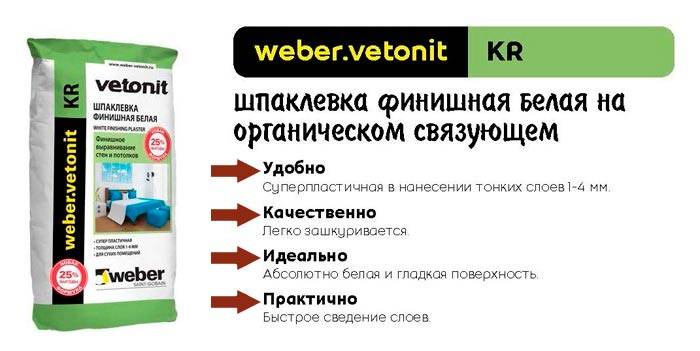

"Vetonit KR"

Putty from organic components for the finishing stage of finishing is used in rooms with low humidity.

Other features include:

- used for walls and ceilings;

- great for drywall work before painting or wallpapering;

- average consumption with a layer of 1 mm - 1.2 / sq. m;

- does not apply for:

- floor finishing;

- on a tiled surface;

elimination of seams and cracks.

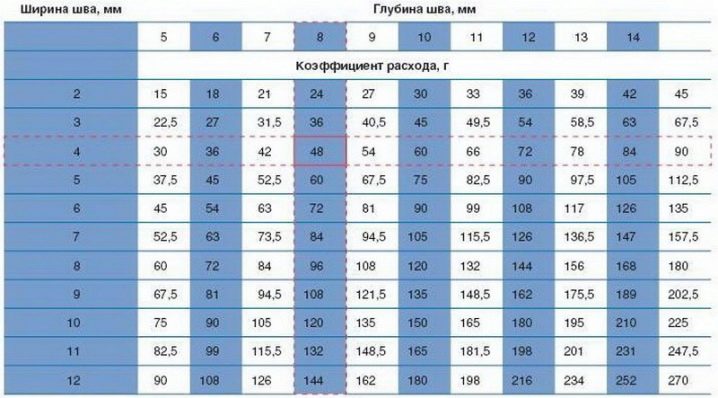

Starting putty - consumption per 1 m2.

For the initial leveling of the base, a starting putty is used. It is applied as an intermediate coating between plaster and finishing putty. At the same time, the starting putty contains a rather coarse fraction, since it is most often based on gypsum or lime. Therefore, its consumption will be the greatest. Starter putty is on sale in paper packages of 25 and 30 kg.

It has been proven by practice that one standard bag for 30 kg of any starting putty with minimal irregularities, and even under a paint net, is quite enough for 10-20 square meters. m walls.

But if the walls are in poor condition and not leveled, then the consumption of the putty mixture will increase. For example, if the layer of starting putty is planned to be 5 mm, then its consumption will increase to approximately 4-8 kg per sq. m.

Features for the consumption of starting putty

An important point should be taken into account: it is not recommended to apply a starting putty composition thicker than 5-10 mm in one pass, otherwise it may crumble in the future. The description for any putty usually indicates the minimum and maximum permissible level of interlayer at a time.

For example, for "Polimin SHG-11" putty, the calculated thickness at a time is taken not less than 3 mm, but not more than 10 mm. Composition yield: 1.05 kg per "square" with an interlayer of 1 mm.

But the putty "SATYN PW-01" has a maximum allowable layer thickness of 8 mm, consumption per sq. M. m is 1.3 kg.

The instructions for the starting polymer-cement putty "Ceresit CT 29" indicate that the thickness of the application of one layer varies from 2 to 20 mm, and in fact, the consumption of this mixture per sq. M. meter goes by 1.8 kg at a millimeter layer

By the way, the popular Knauf HP Start mixture based on lime and gypsum can be chosen as an initial leveling compound. It is very convenient and is suitable both as a plaster and as a starting putty. The declared borders of the coating are 1-3 cm. With a mortar thickness of 10 mm, a 30-kg package of the mixture is enough for 3.8-4.0 sq.m.

- Applying a layer of material to the wall

- Leveling the walls with putty

Factors affecting material costs

Consumption depends on many factors:

- Wall conditions (presence and depth of cracks, curvature, roughness).

- From what you will do with the wall then: glue wallpaper, paint, whitewash.

- From the experience and qualifications of the master.

The correct selection of materials will reduce costs and speed up the process.

First of all, you need to consider the place of work. For outdoor use or for damp rooms, cement putties are used. Paint primer enamel on rust 3 in 1 consumption per 1 m2?

Due to the significant layer thickness, they will be required more than gypsum ones.

Gypsum mixes are used in dry indoor spaces. Distinguish between dry mixes that need to be diluted with water, and ready-made putty mixes that do not require any additional action. Ready-made consumption is much less, however, and they are relatively expensive.

Depending on the type of work, putties can be divided into groups:

- Start - for the primary elimination of cracks, depressions and surface errors. It is this group of putties that accounts for the greatest consumption of materials.

- Universal - its consumption is slightly less than the starting one, but it is also used after the starting one or instead of it on good walls, sometimes it replaces the finishing one.

- Finishing - Brings gloss to an almost finished wall to create a smooth surface for painting or wallpaper. Very little of it is required.

These are just preliminary factors to keep in mind. More accurate estimates can be obtained taking into account the recommended rates.

What to do if mold appears on the walls in the apartment? Read here.

Types of Vetonit putty

Check out these articles as well

- Corrosion-free sectional fences

- Practicality of ceramic tiles in bathroom decoration

- Advantages of modern magnetic contact sensors

- Boiler OKC DRAZICE 200 NTR

Finishing putty Vetonit comes in different options. To begin with, there is a distinction between gypsum, polymer and cement mixture. According to the form of release, there is a pasty mass in buckets and dry, not diluted. The latter is sold in paper, three-layer bags of 5 and 25 kg.

Different types of finishing putty are available under different markers.

- "VH" is a mixture made from binder cement and limestone aggregate. Can be used in damp rooms.

- "KR" is used only in dry rooms. Requires correct application. After drying, it has a long-lasting, white color.

- "LR Pasta" and "LR +" are polymer putties intended for work in dry rooms with normal humidity.

Photo of putty Weber Vetonit LR +, VH, LR Pasta

Weber Vetonit LR +

Weber Vetonit LR + finishing putty is sold in three-layer paper packaging, weighing 20 and 25 kg. The shelf life is 1.5 years.The mixture is white, crumbly, consists of polymers and finely ground marble.

This type of putty is suitable for leveling surfaces indoors (where it is dry). For the street or bathroom, kitchen, it is not recommended, because it turns yellow with prolonged exposure to moisture.

To obtain the working mass, water is added to the mixture. For 25 kg, you need about 8-9 liters of water. The result is a snow-white mass that can be used for 24 hours, then it will deteriorate. It is always applied only to a clean wall, free of grease. It must be dry and firm. Application layer - 1-5 mm. Movements should be smooth, from bottom to top. In order for Weber Vetonit LR + polymer finishing putty to dry quickly (within 24 hours), the room must be + 10 ... + 30 degrees and good ventilation.

Vetonit LR Pasta

This type of filler is necessary for super-finishing leveling of walls or ceilings. Can only be used in dry rooms. Allows you to create a perfectly flat surface for paint. Made from limestone and polymer glue. Suitable for leveling concrete and plastered surfaces.

It is a white paste in 20 kg (12 l) and 5 kg (3 l) buckets. It is already ready for use, no dilution is required. Conveniently applied in a layer of 0.2-0.3 mm. At a temperature of +20 indoors, and a layer thickness of 0.5 mm, this polymer finishing putty dries in 4 hours.

Weber Vetonit VH

This type of putty is convenient because it can be used in rooms with any humidity. It is suitable for the finishing of concrete and bricks inside or outside buildings. However, on surfaces treated with water-soluble agents or limescale, it will not lie down!

Before using this putty, it is necessary to clean the wall, then the working composition is prepared. It is diluted with water, whipped with an electric drill for 5 minutes and then defended for 3 hours. It can be applied with a spatula, which is convenient for work. Movements should be smooth to avoid unevenness. One layer dries up to 3 days.

Vetonit KR

Finishing putty Vetonit KR is created on organic glue (binder). She is completely white and looks beautiful. Suitable for final leveling of surfaces. The advantages include the smoothness of the surface after drying, plasticity, ease of work. If the container for the diluted mixture is closed, then it can be used for 2 days in a row! Sold in 5 kg and 20 kg paper bags. Shelf life up to 1.5 years.

The mixture can be applied mechanically or manually. It is used on walls and ceilings that have been pre-leveled or on gypsum boards. It is recommended to apply in a layer of 0.3 mm, but thicker is possible. The layers dry for 24 hours.

Tips & Tricks

In general, work with dry building mixes Vetonit is carried out according to the same algorithm as work with mixes from other manufacturers. The instructions for creating a solution are always indicated on the manufacturer's packaging and is the best option for its preparation.

- Putty of this brand can be applied to the work surface both with the help of special mechanisms and installations, and manually, using a rule and a spatula.

- The surface must be pre-prepared - free from old finishes, dirt and dust. It must be dry, free from oil or grease stains, and sufficiently firm.

- There should be no drafts in the room being finished, so it is better to close windows and doors.

- The mixture does not have harmful vapors or strong odors, so working even in a completely closed room will not cause any deterioration in well-being.

In order to prepare the mixture according to the instructions on the package, it is best to choose a plastic container. The water into which the powder is gradually poured should be at room temperature 20 - 25 degrees. Do not change the sequence and pour water into the powder, as this can lead to the mixture becoming too liquid, and there will be no excess powder left to correct the error.

The resulting solution must be thoroughly mixed with a drill with a special nozzle or mixer for 5 minutes and let it brew for 5-10 minutes. After that, the solution is mixed again and set to work.

Vetonit plaster

- When working with plaster, the surface cleaned of dust, old coating and dirt, if necessary, is additionally reinforced with a special mesh. Grease and oil stains are removed, irregularities are putty. If the surface of the wall or ceiling is concrete, then a primer must be applied to them in front of the plaster in two layers so that the concrete does not draw moisture from the applied solution.

- Dry powder is added to warm (20 - 25 degrees) water and stirred with a drill or mixer. In order to increase the adhesion coefficient of the plaster, 10% of the water in the solution can be replaced with a liquid primer. Stir the plaster until all the lumps disappear. It is not necessary to insist on such a solution, otherwise it will immediately begin to harden. In the process of working with plaster, you should not add water to the solution; stir it without adding liquid.

Self-leveling floor

- The prepared surface is best treated with a primer of the same brand. If the floor is applied in several layers, then each of them is primed after drying. Such processing will avoid the appearance of air bubbles inside the frozen solution and will improve the adhesion of the self-leveling floor to the base. A solution is prepared in a plastic container or a special silicone container. Pour dry powder into warm water and stir the solution with a drill or mixer.

- The prepared solution should not be left "to infuse", you must use it immediately. Filling is done manually or using special installations in separate strips with a width of 30 to 50 centimeters, starting from the corner. The solution poured onto the base is leveled with a metal spatula. To release random air bubbles from the solution, you can roll a needle roller over an uncured surface.

According to the reviews of real buyers, the products of the Vetonit trademark, at a fairly affordable price, are superior in quality to many analogues in the domestic market. Dry mixes allow you to quickly and easily solve repair and construction issues both in small private apartments and in huge warehouse and industrial premises.

The assortment of goods is so wide that you can choose the material to work in any weather conditions, with any bases and decoration. The ease of use of Vetonit mixtures allows not only professionals to work with them, but also those who first undertake to make repairs in their own home.

In the following video, Vetonit presents a complete solution for the perfect wall in a living room or bedroom.

Advantages and disadvantages

As with other plastering materials for finishing floors, Vetonit LR putty has its pros and cons.

- It is created on modern equipment using new technologies, which increases the quality and performance of the material.

- It is easy to use. It is not difficult to apply the material to the floors, the mass does not stick to the trowel and does not fall off from the base during operation.

- With a small thickness of the applied layer, it trims the base, smoothing out minor irregularities of the starting level.

- Environmental friendliness is inherent in the material. The composition is harmless to health, the coating will not emit toxic substances during operation.

- Fine-grained mixture. Due to this, it is uniform, has a pleasant texture and smoothness of the finished coating.

- In some cases, with sufficient work experience, it does not need to be additionally sanded.

- It is economical. At the same time, due to the powder form, it practically does not form an overrun. Portions can be diluted in portions to eliminate excess mixture.

- The composition has a long life cycle. After preparation, it is suitable for work during the day, which allows the master to complete the finishing without haste.

- The material has noise and heat insulation properties, despite the thin layer of application.

- It is suitable for further finishing surfaces for painting or wallpapering.

- The mixture is available to the buyer.It can be bought at any hardware store, while the cost of finishing putty will not hit the buyer's budget due to its economy.

In addition to the advantages, this material also has disadvantages. For example, Vetonit LR putty must not be re-diluted. From this, it loses its properties, which can negatively affect the quality of work.

In addition, it is important to take into account the storage conditions of the dry mix. If it is in a room with high humidity, it will become damp, which will make the composition unsuitable for work.

Vetonit LR is picky about the substrate. The putty will simply not adhere to surfaces that are not properly prepared. On the vastness of the World Wide Web, you can find reviews talking about poor adhesion. However, few online commentators describe preliminary preparation, considering it a useless stage, a waste of time and money. They also ignore the fact that there should be no drafts in the room during work.

In addition, they exceed the application layer, believing that the mixture will withstand everything. As a result, such a coating turns out to be short-lived.

A prerequisite that the manufacturer pays attention to is the compliance of the characteristics of the material with the construction work. This mixture does not level the base, it does not mask serious defects, which novices in the field of repair and decoration do not think about.

If the rules of preparation are not followed, difficulties may arise in further work with such a basis. For example, according to the opinions of the masters, when trying to paste wallpaper, the canvas can be partially removed with putty. It is necessary to enhance adhesion, even if the base looks good, and the overlap is made according to all the rules of construction and does not have a porous structure with crumbling. Sometimes an ordinary buyer with a limited budget may not like the price of a large bag (about 600-650 rudders), which forces him to look for cheaper analogs on the market.

Tips for preparing a solution of a putty mixture

When preparing putty from a dry mixture, follow all the recommendations of the instructions: you need to add water in a given proportion, use clean containers, mix correctly, make intervals so that the mixture is infused a little, make sure that no foreign objects get there, etc. Incorrectly prepared mixture is not will only increase the consumption of building materials, but may cause a poor quality of repairs. Also be aware of the density of the mixture. If it is necessary to even out rather significant irregularities, then the putty should be sealed to a thicker consistency. In this case, the consumption of the composition per unit area will be greater.

Finally, the consumption of the mixture also depends on the quality of the putty application. In particular, novice craftsmen often sin with some overspending of building materials. Of course, in general, do-it-yourself putty will cost much less than hiring a repair team: buying another bag is not as scary for your pocket as paying a bonus to an outside foreman. But there may be a risk of inadequate work performance. Therefore, if you putty yourself, carefully follow the technology and sequence of work. Specialists of the construction company RUSSTROY-GROUP have putty thousands of square meters of walls and ceilings, and they will do it with high quality when carrying out repairs in your house!

Putty and leveling the walls

Putty and leveling the walls

How to calculate the expense?

The consumption of material applied to the wall is calculated in kilograms per 1 m2. The manufacturer sets its own consumption rate, which is 1.2 kg / m2. However, in reality, the rate is often at odds with the real expense. Therefore, you have to buy raw materials with a margin, taking into account the formula: norm x facing area. For example, if the wall area is 2.5x4 = 10 sq. m, putties will need a minimum of 1.2x10 = 12 kg.

Since the indicators of the norm are approximate, and in the process of work, a marriage is not excluded, it is worth taking more material.If the putty remains, it's okay: it can be stored dry for up to 12 months. In addition, we must not forget that the application layer is actually larger than the manufacturer's recommended one. This will also affect the total consumption.

Therefore, when buying, it is important to pay attention to the recommended thickness