Requirements

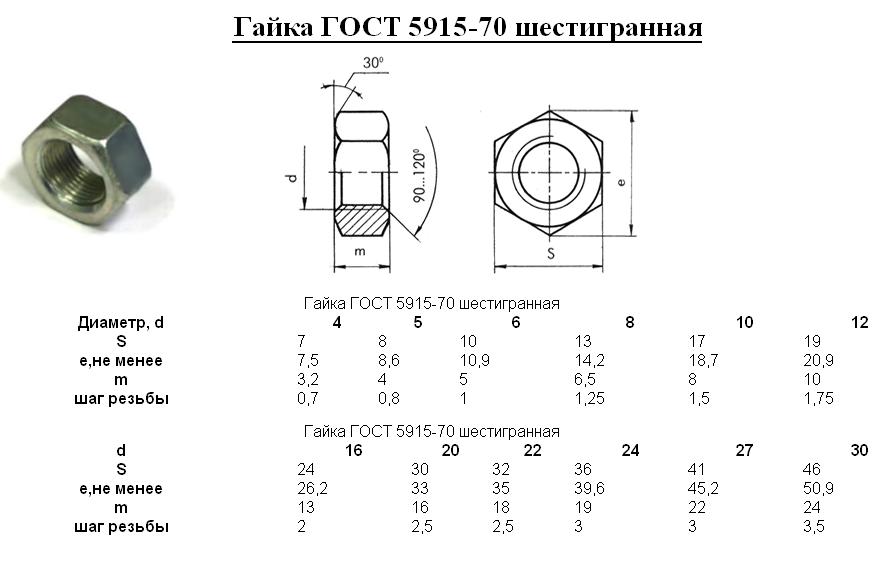

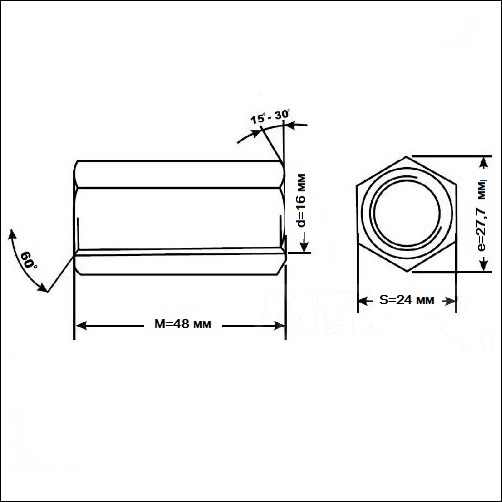

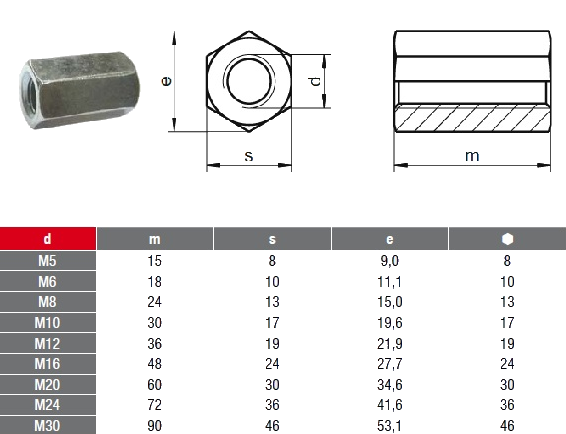

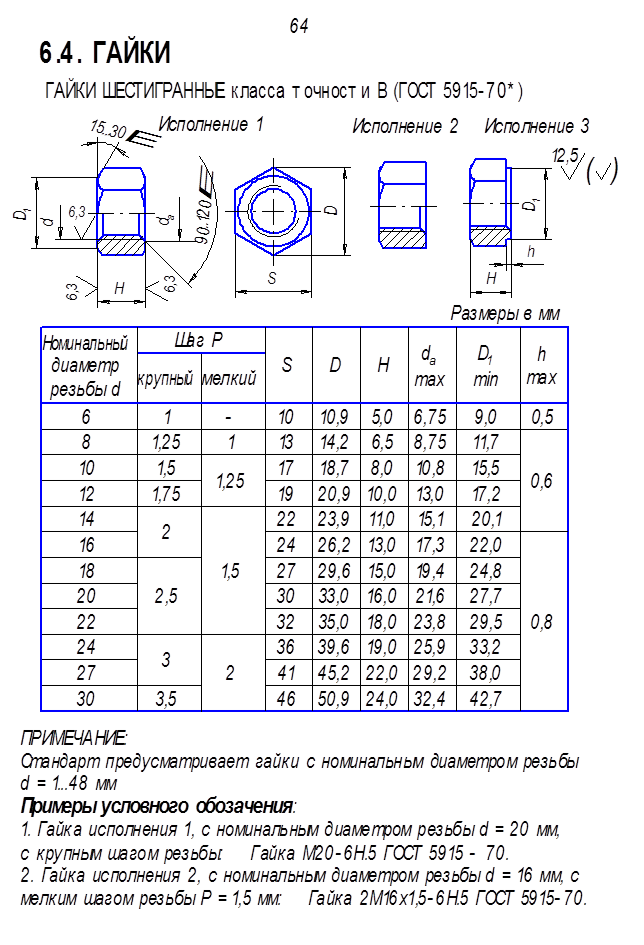

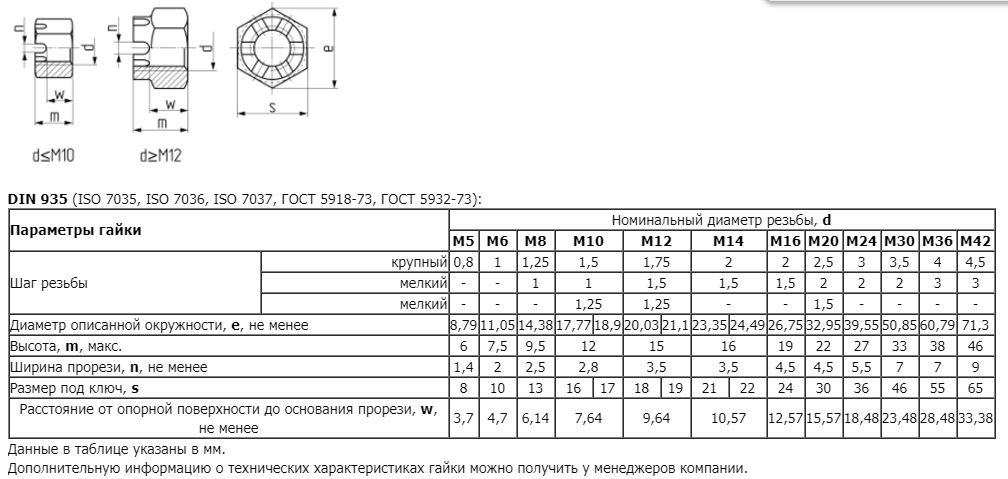

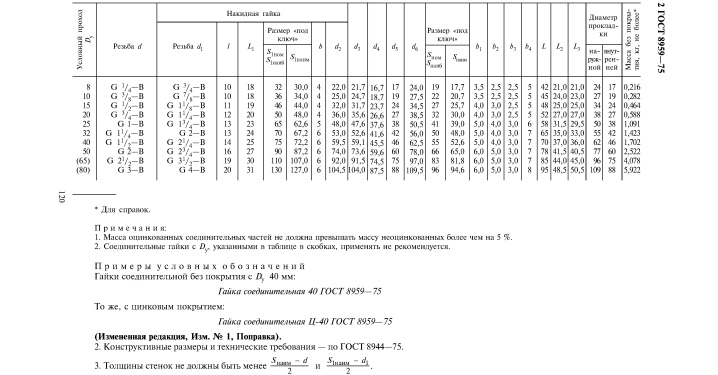

All the necessary requirements that must be observed in the production of connecting nuts can be found in GOST 8959-75. There you can also find a detailed table with all possible dimensions of these construction fasteners. In it you can also find an approximate diagram that reflects the most general design of these nuts.

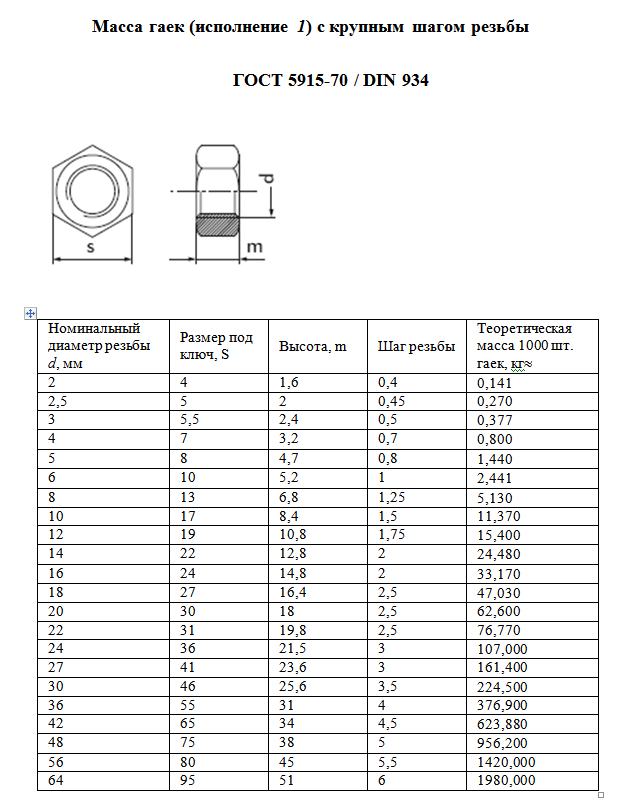

The weight of all zinc-coated connectors must not exceed the weight of non-zinc-coated models by no more than 5%. In GOST 8959-75, it will be possible to find the exact shape for calculating the optimal value of the thickness of the metal walls.

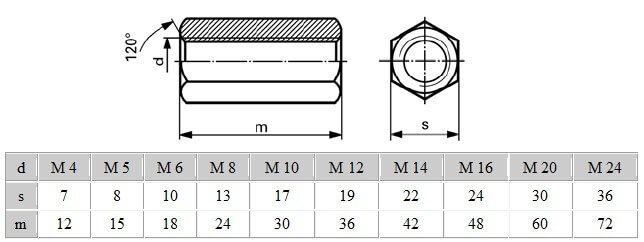

Also, there will be indicated the standard values \ u200b \ u200bof the diameters of the nuts, expressed in millimeters, such parameters can be 8, 10, 15, 20, 25, 32, 40, 50 mm. But there are also models with other parameters. In this case, you need to choose fasteners, taking into account the type of connection, the dimensions of the parts that will be attached to each other.

All manufactured connecting parts must fully comply with the dimensions specified in the GOST data.

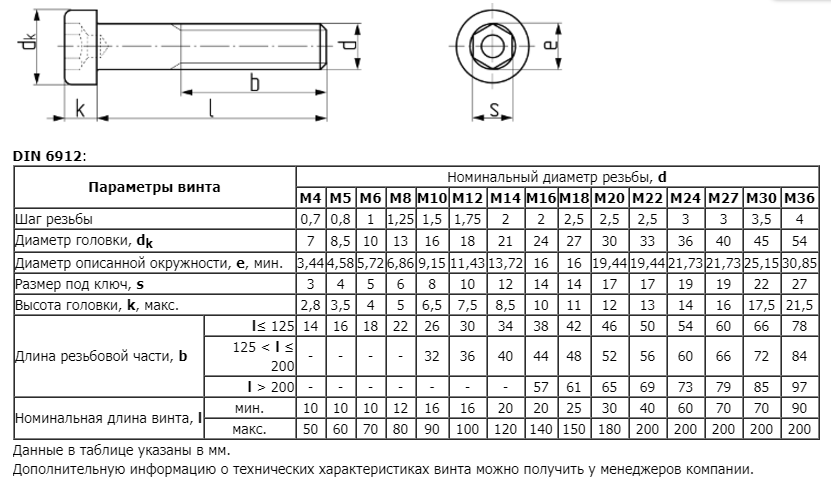

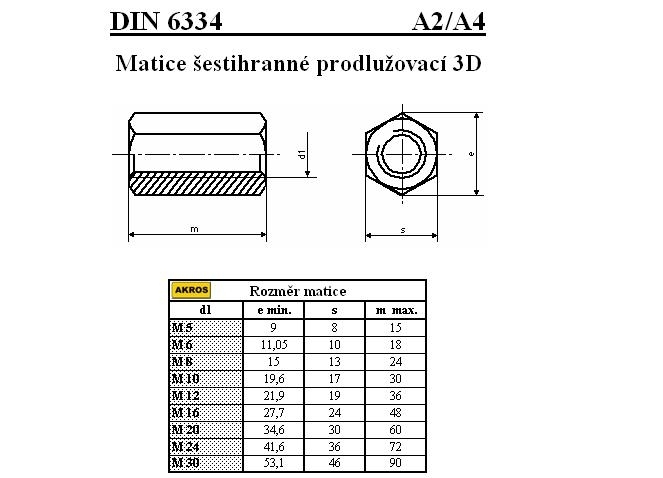

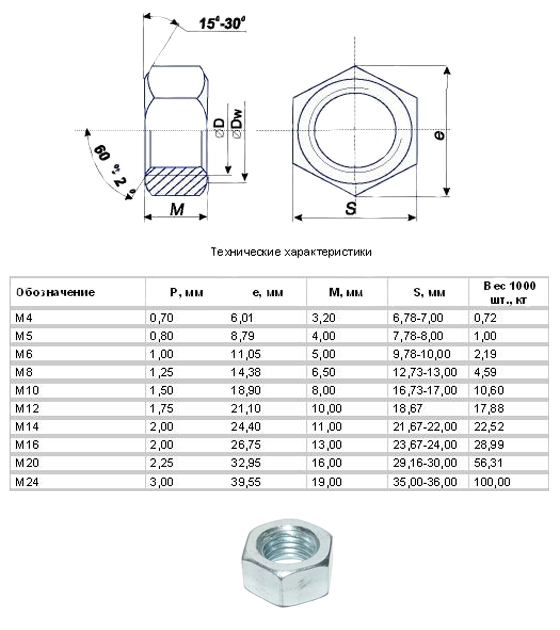

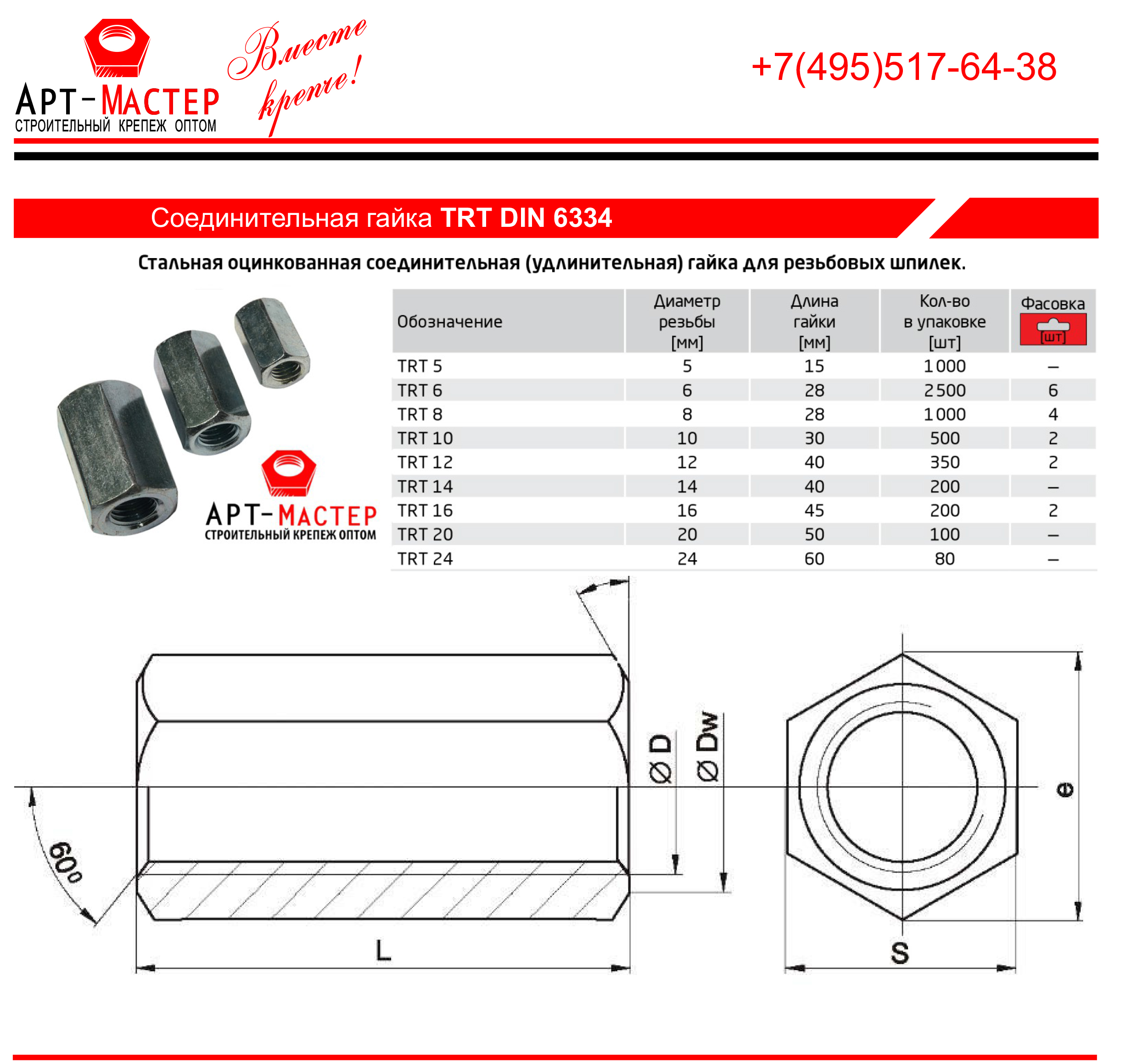

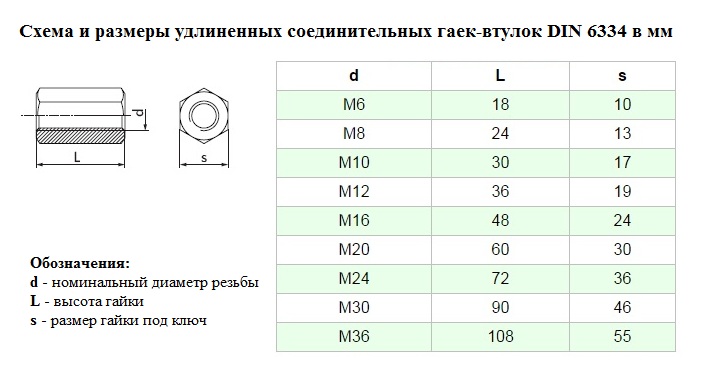

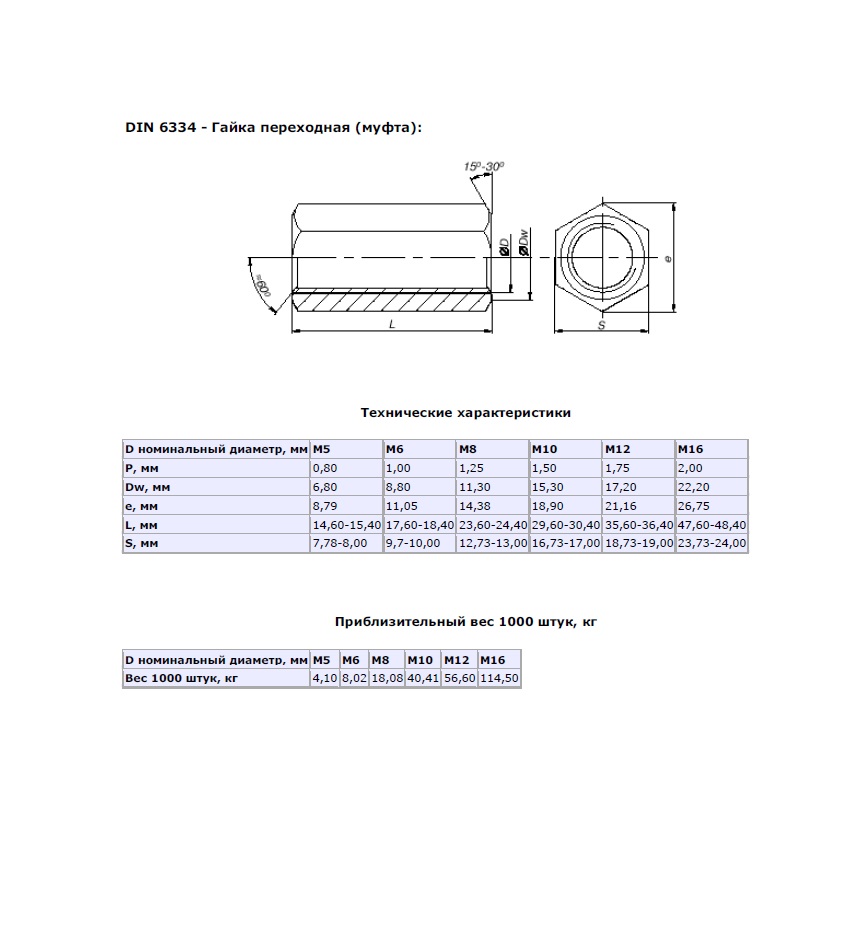

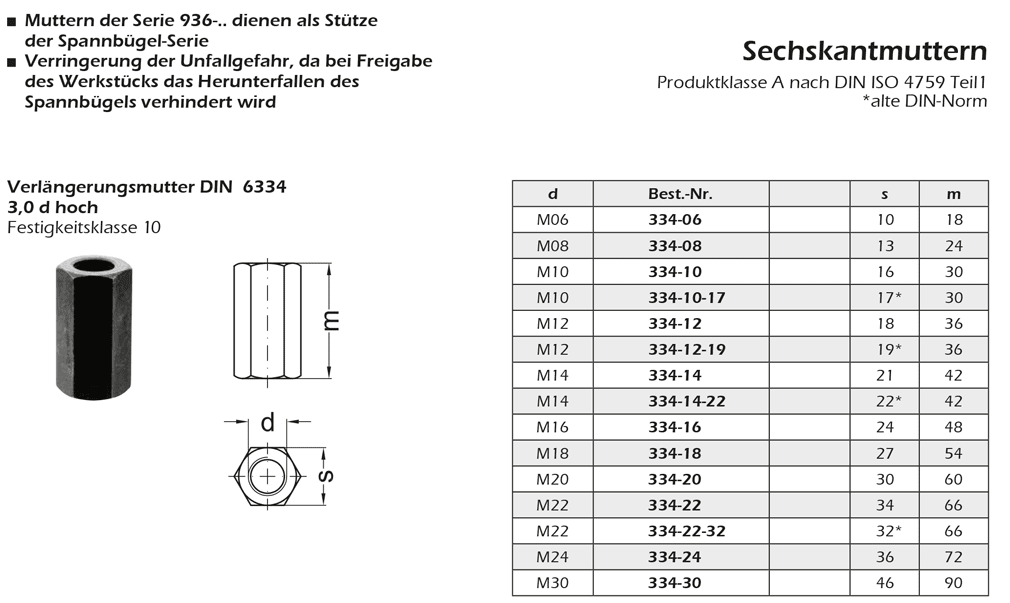

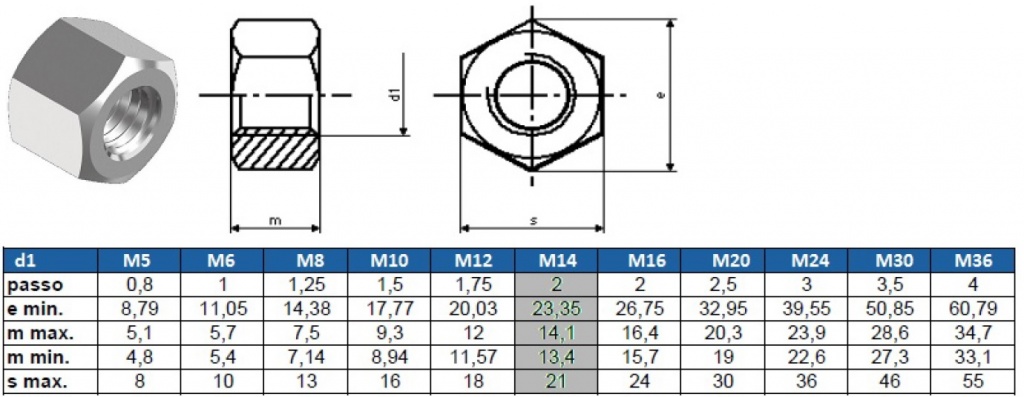

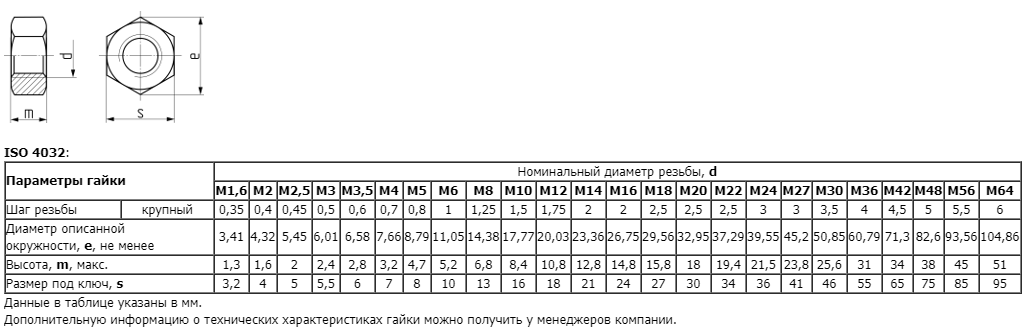

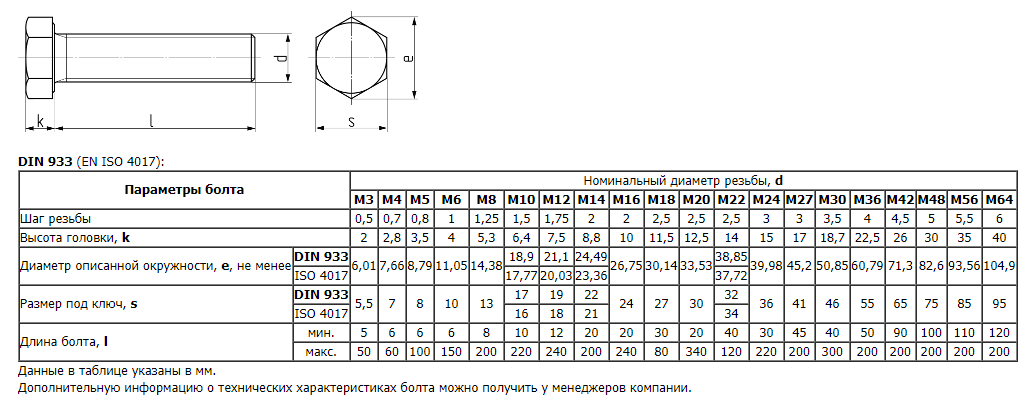

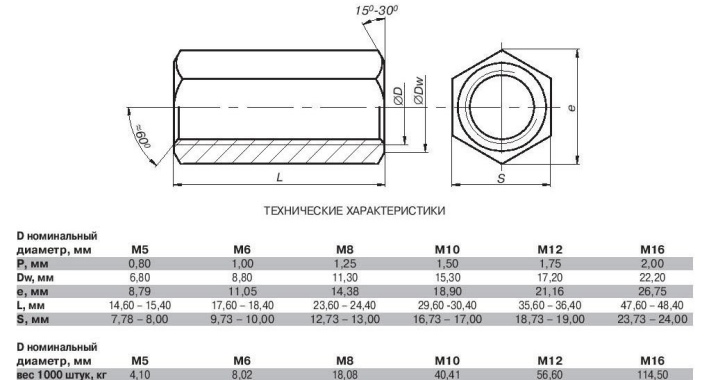

For the production of nuts, DIN 6334 must also be followed. All technical standards contained in this manual are developed by the German Institute for Standardization. So, the dimensions (diameter, cross-sectional area), the total mass of each of the elements are also spelled out there.

Marking

The marking is a special application that includes the basic symbols reflecting the most significant properties and characteristics of these nuts. It can be found on almost all models. Graphic marks of marking can be both in-depth and convex. Their sizes are approved by the manufacturer.

All signs are most often applied either on the sides of the nuts, or on the end parts. In the first case, all designations are made in-depth. All models that have a thread diameter of 6 millimeters or more are necessarily marked.

If three small dots are made on the metal, this means that the sample belongs to the fifth class. If there are six points on the surface, then the product should be attributed to the eighth strength class.

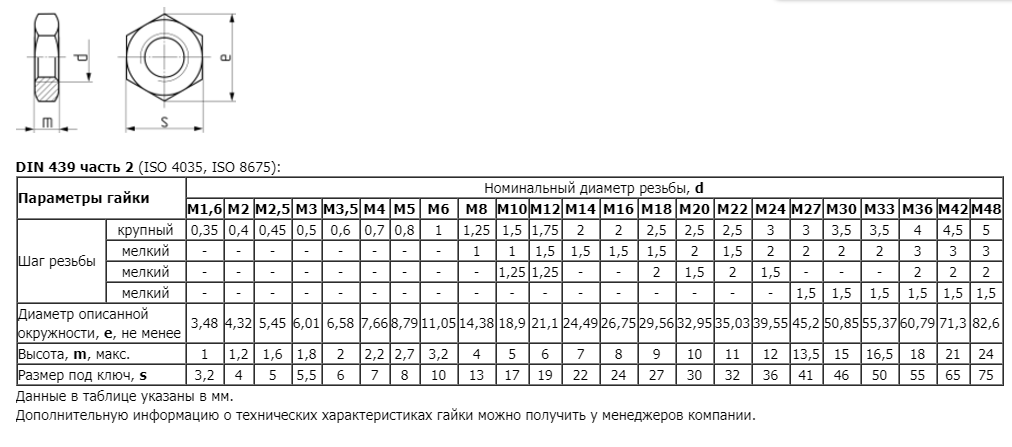

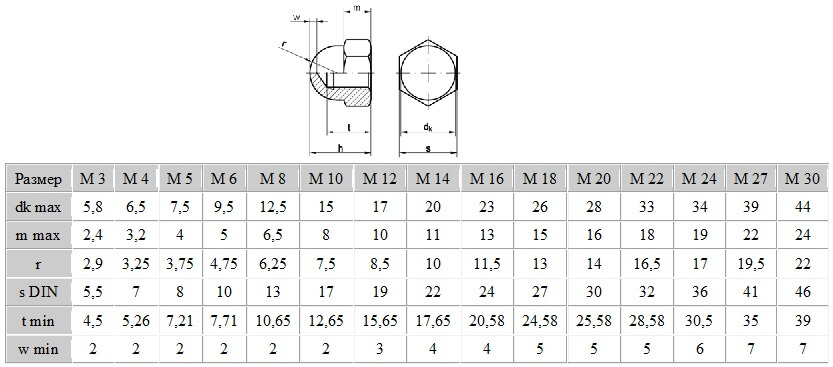

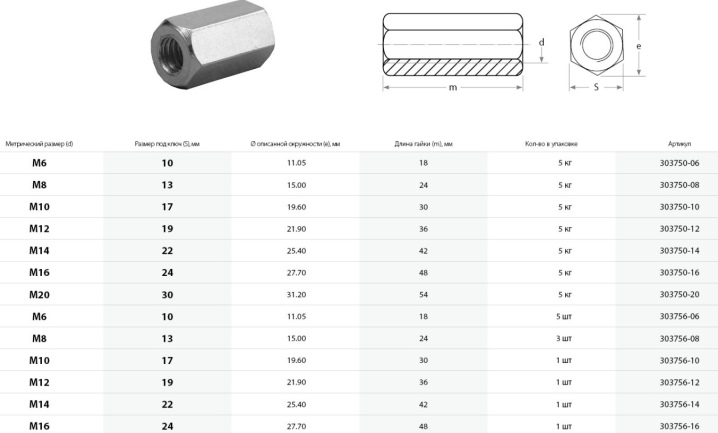

On the surface, nominal diameters can also be indicated: M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M25 and others. The thread pitch can also be prescribed. All of these parameters are expressed in millimeters.

For the types of nuts, see the video.

Peculiarities

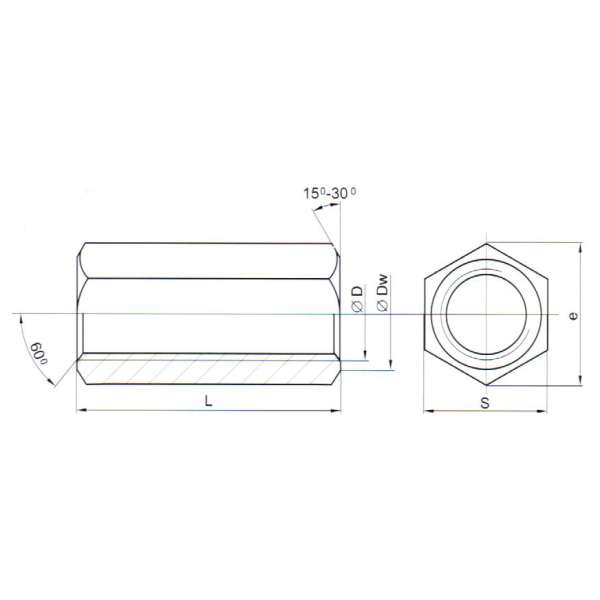

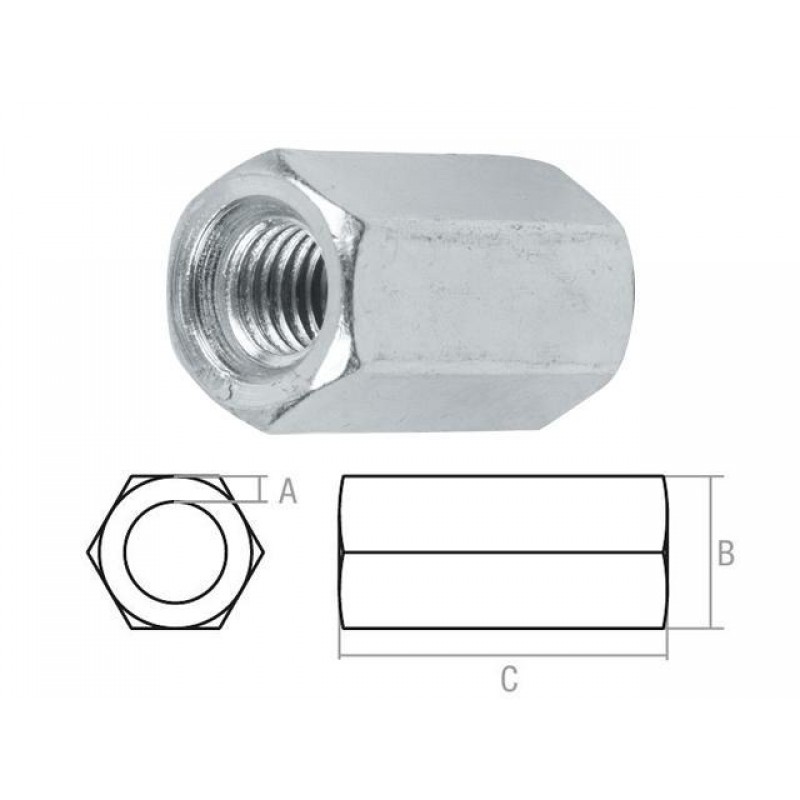

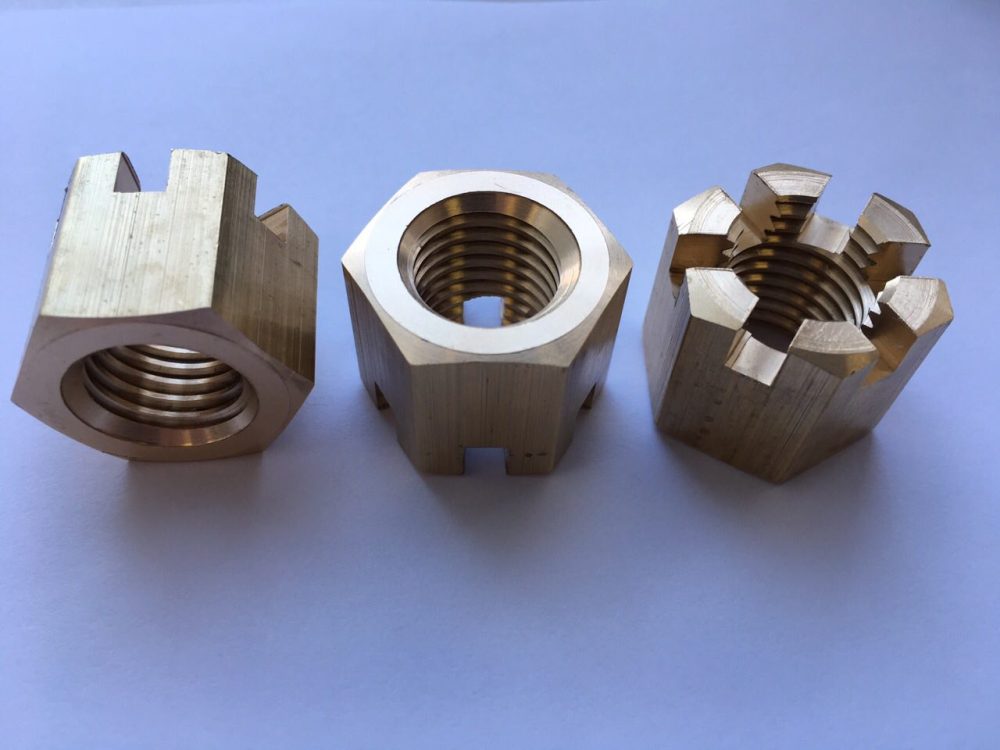

The union nut is a small circular retainer with a long thread on the inside. This part of the part is attached to the external thread of another product (screw, bolt, stud).

These types of nuts can have a different outer part. Models in the form of hexagons are considered a traditional option. There are also samples in the form of a loop or a small cap. Compared to other types of nuts, the connecting models have a longer length.

In this case, the fasteners provide additional strength and reliability.

The outer part of these fixing products is always equipped with several edges. They act as a solid support for the wrench during installation work.

Mounting nuts can differ significantly from each other in the type of material from which they are made, in terms of strength, and the cleanliness of processing. Most often, such fasteners are made from different types of steel (alloy, carbon).

Also in stores you can find models made of copper, aluminum, brass, bronze and even platinum base. Copper products are often used when working in the electrical field, they can act as a circuit connector. Specimens made from platinum are not used very often, they are mainly used in medicine.

According to the cleanliness of processing, all union nuts can be divided into several main categories.

- Clean. Such models of fixing parts outwardly look the most neat in comparison with other products. They are carefully processed from all sides with grinding tools.

- Medium. These models have a smooth and even surface on only one side. It is with this part that they fall into other details.

- Black. These samples are not processed with grinding wheels at all during the manufacturing process. Their production technology includes only stamping and threading.

As a rule, all union nuts are additionally zinc-coated during production. It acts as a protective layer that prevents possible corrosion on the surface of the fasteners.

In addition to zinc coating, nickel or chromium can also be used as a protective layer. Often, special flanges are included in the same set with such products. They are needed in order to protect the nut from possible deformations.

These fasteners are quite simple and convenient to use, they can be quickly installed with your own hands without much effort.

All models of such nuts have good resistance to various temperature conditions, chemical and mechanical stress.