Plywood grades - classification by type of adhesive

The performance properties of plywood largely depend on the substance used for gluing the sheets. The quality of the impregnation affects the moisture resistance and environmental friendliness of plywood, as well as its ability to withstand temperature fluctuations, humidity and other external influences. Many types of plywood are distinguished on the basis of the adhesive components used in the production.

Plywood FBA

FBA is the least resistant material to a humid environment. However, the use of albuminocasein glue makes it absolutely safe from an environmental point of view. This plywood is only suitable for rooms with low humidity levels. In particular, it has found its application in the manufacture of pieces of furniture, and is also used to create all kinds of decorative elements of the interior.

Plywood FC

FC is a material with rather low moisture resistance. In this case, the function of a binder is performed by urea glue, which does not emit harmful substances, which makes it possible to use this type of plywood for finishing work inside residential premises. At the same time, a moderate level of humidity is allowed.

Plywood FKM

FKM - veneer sheets connected with melamine glue. According to the degree of moisture resistance, the material has average indicators.

Plywood FSF

FSF - especially durable wood-based panels, the layers of which are impregnated with phenol-formaldehyde resin. The material is able to withstand significant loads and resist moisture. However, the amount of toxins contained in the adhesive makes it possible to use such plywood exclusively outside the premises. In particular, it is ideal for cladding exterior walls in frame house building, erection of enclosing structures, and the manufacture of outdoor furniture.

Plywood FB

FB is a material in the production process of which bakelite glue is used. Sheets impregnated with such a composition are characterized by increased moisture resistance and are able to withstand almost any temperature conditions. The impregnation reliably protects wood from negative environmental influences, which makes it possible to use this type of plywood in almost any area.

At the same time, plates of the FB type may have characteristic differences, depending on the composition of the adhesive and the gluing technology that affects their characteristics.

Materials treated with alcohol-soluble impregnations are moisture resistant and are divided into three types:

- FBS - plywood of the highest quality, each sheet of which is impregnated as thoroughly as possible;

- FBS1 - plywood boards, in the manufacturing process of which the method of smearing veneer sheets is used, due to which the quality indicators of the material are reduced;

- FBS1A - belonging to the lowest class of bakelite plywood, in the production of which the amount of applied alcohol-soluble substance is limited, which implies the processing of exclusively longitudinally arranged sheets.

Another type is plywood FBV, in the manufacture of which water-soluble adhesives are used.

There are two types of such plywood:

- Plywood with coated inner layers but impregnated outer sheets.

- Plywood boards with the FBV1 marking, for all layers of which only the coating method is assumed.

Characteristic

Plywood sheet can be characterized by:

- Surface treatment.

- The degree of water resistance.

- The degree of environmental safety.

- Sort.

- The kind of wood used.

- The size of the product.

- The presence of weight.

Plywood characteristics table.

Surface treatment is sanding. Manufacturers offer a choice of plywood sanded on one side, marked Ш1, and on both sides, marked Ш2. If there are no such marks, the product will be unpolished.

The water resistance of plywood depends on the adhesives. For interior work, a material is used that is average in moisture resistance. It has the FK brand, where the letter K indicates the presence of urea resins in the adhesive base. They have a low hazard class, and they can be used in places of permanent residence of a person. Plywood FSF, which has increased moisture resistance, should not be present in the living room, even in utility rooms with high humidity. Other finishing materials are used there. Veneer layers of FSF products are glued together with glue with toxic additives based on phenol-formaldehydes. FSF is used only for external work.

GOST distinguishes between two classes of plywood in terms of formaldehyde content - E1 and E2. For internal work, class E1 is used, in which the content of the harmful substance is present in a minimum amount.

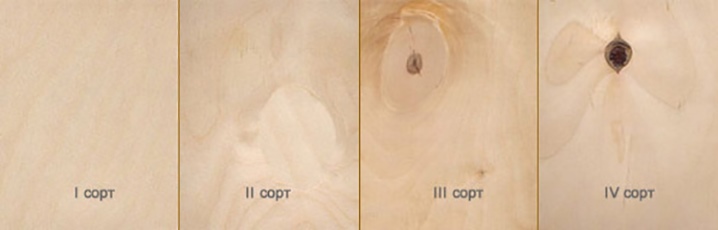

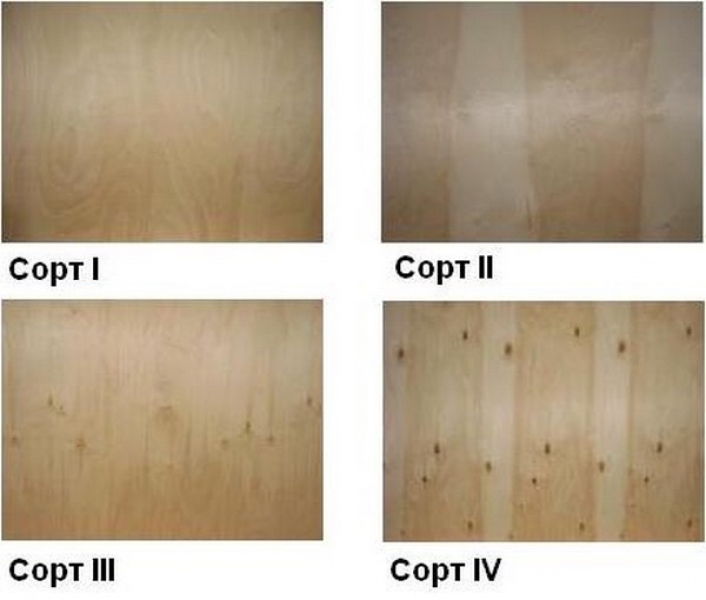

Groups and grade

The first group belongs to the "Extra" class and has no errors. Its surface is perfectly smooth. The second group belongs to the 1st grade. This type of product may have gluing points, and the maximum length of warping or cracks should not exceed 20 mm.

Types of plywood grades and their characteristics.

The third group belongs to the second grade. Cracks up to 200 mm are allowed here, wood inserts, can be leaked glue stains up to 2% of the total area.

The fourth group belongs to the third grade. It assumes the presence of up to 10 wormholes per square meter. The diameter of each should not exceed 6 mm.

The fifth group is the fourth grade of low-quality plywood. It may have knots on the surface of the upper layer, the number of which is not limited by anything. Wormholes up to 40 mm in diameter are allowed.

The edges of this type of product can be deformed up to 5 mm deep. It is used for the manufacture of containers.

For finishing work, second-class products are ideal as a basis on which some kind of coating will be applied.

Size, wood and weight

Dimensions of plywood sheets in millimeters.

General purpose plywood is used in the manufacture of furniture, various containers, as well as in construction and other industries. If the length of plywood exceeds 1800, it is called oversized. In the event that the larger sheet size coincides with the direction of the fibers of the outer layers, it is called longitudinal, if it does not coincide, it is called transverse.

Construction plywood is made from softwood. Larch and pine veneer is used. In an effort to increase the strength of products, manufacturers make composite plywood, alternating layers of coniferous veneer with layers of hardwood veneer. Birch veneer glued sheets are commercially available. They have a high degree of material density and a higher sheet weight.

A bundle of birch plywood 8 mm, measuring 1525x1525, contains so many sheets that they will be enough to cover an area of 53.8 m³. The weight of one product is 12.1 kg. The weight of m³ will be 651 kg. The weight of a sheet of plywood with dimensions of 2440x1220 mm will be 15.5 kg, and in a cube it will be 651 kg.

Plywood made of coniferous trees can have dimensions of 2500x1250 mm, the weight of one specimen is 13.8 kg, and 552 kg in a cube. The manufacturer can produce a product with other dimensions: 2440x1220 mm. The weight of one such unit will be 13.1 kg, and in a cube it will be 550.

What is the difference between sanded plywood and non-sanded plywood

Plywood is one of the most common materials for construction or interior decoration. It is made of wood and can be polished or unpolished. Each of these types has certain characteristics, on which the scope of their application depends.

Marking of sanded and non-sanded plywood

The material has its own designation depending on the type of outer surface treatment:

- NSh - unpolished plywood;

- Ш1 - sanded on one side;

- Ш2 - sanded on both sides.

According to the degree of water resistance of the adhesive composition, plywood can be:

- FSF - increased moisture resistance for indoor or outdoor use;

- FC - moisture resistant for indoor use.

Material with the designation "FSF" emits formaldehyde and phenol, which are characterized by a certain degree of toxicity.

There are 5 types of surface quality:

- E (elite) - no visible defects. Small deviations in the wood structure are allowed.

- 1st grade - there are practically no flaws, while no more than 3 per 1 m2 is allowed. These can be knots or holes from them, a wormhole 6 mm in diameter, cracks no longer than 20 cm.

- Grade 2 - in addition to defects of the first type, color changes, glue seepage, dents, scratches, prints can be observed;

- Grade 3 - there are the same disadvantages as in species 2, in the amount of 10 pieces per 1 m2, large intergrown branches are also possible.

- Grade 4 - is of low quality, since defects of any kind are allowed in it. Cracks, dents, leaked glue, hairiness, waviness are typical.

Grade E is quite expensive, so it is quite rare. Grades 1 to 4 are common on the market, where 1 is the highest, 4 is the lowest.

Factory markings may include the following:

- Name;

- brand;

- grade;

- emission class;

- type of surface treatment;

- length, width, thickness;

- designation of this standard.

The following marking designations are found:

- "ФК 1525х1525х9 mm, 4/4" - moisture-resistant material for interior work, 1525 mm wide, 1525 mm long and 9 mm thick, 4 grades on both sides.

- "FSF 10 mm thick NSh (1525x1525) grade IV / IV" - material of increased moisture resistance, 1525 mm wide, 1525 mm long and 10 mm thick, unpolished, both sides 4 grades

Sanded plywood

Thanks to factory polishing using specialized equipment, sanded plywood has a flat and smooth surface, and also has the following advantages:

- Aesthetics - the material Ш1 and Ш2 is characterized by an attractive appearance and absence of flaws.

- Technical characteristics - strength and moisture resistance. Also, the material is resistant to mechanical and physical stress, and various paints fit better on the treated surface.

- Practicality - the level of hardness allows the production of sheets of different thicknesses. The surface also does not crack and has no cracks through and through.

Grinding material is used in various directions:

- interior and exterior work, as well as the coating of bathrooms or showers;

- interior decoration;

- furniture manufacturing.

This type of material has the following characteristics:

- rough and rough surface, the presence of visible defects;

- high level of strength;

- ability to withstand loads;

- low price.

Such plywood is used where the appearance of the surface is not important:

- decoration of premises - insulation, strengthening, isolation of rooms from atmospheric manifestations and noise;

- leveling floors;

- creation of durable containers and packaging - used by the postal services due to its technical characteristics;

- the creation of the lathing.

Comparison of sanded and non-sanded plywood

The materials are used in various areas of construction and repair work and have a number of differences:

- Different state of the veneer from which the sheets are made.

- Differences in wood structure.

- Higher cost of sanded plywood.

- The polished material is used for interior and exterior work, as well as for the manufacture of furniture. Unpolished - used in construction work where appearance is not important.

- Differences in surface roughness.

Also, both types of plywood have the following advantages:

- less exposed to mechanical stress;

- less warped;

- resistant to cracking;

- a large selection of models;

- decorative look.

There are two types of plywood: sanded and unsanded. At the same time, the first one has a smooth, attractive surface, has a wider field of application, while the unpolished version is for the most part a building material, therefore it is used where appearance is not important.

Popular

Application area

The materials differ most significantly in the area of use.

Products with double-sided grinding are suitable for many tasks:

- Furniture manufacture. Cabinets, chests of drawers, tables, cabinets, kitchen sets - this is an incomplete list of what is made of such plywood. It is taken into account that you can create interior items with your own hands.

- Making crafts and souvenirs. The resulting decor can be purely decoration or perform some function.

- Wall cladding and the creation of partitions. The presence of sanding will facilitate the work during subsequent painting or varnishing.

- Laying on the floor. For this process, sheets with a thickness of 15 mm or more are used. The resulting surface can be a finishing coating or used as a base for laminate, linoleum and other products.

- Transport finishing. Due to the fact that the treated surface has fewer protruding fibers, the material is more resistant to moisture.

Application of sanded plywood

Application of sanded plywood

Plywood products that have not passed all stages of preparation at the factory are suitable for the following work:

- Creation of rough bases. This direction is the most popular. The boards are suitable for laying on the floor. Combination with subsequent cladding with sanded plywood is allowed, which is especially important for two-layer cladding.

- Manufacturing of hidden pieces of furniture. This method allows you to reduce the cost of interior items.

- Forming the formwork when pouring the foundation for buildings or fences.

- Creation of decorative and functional items for the home. To achieve the desired finish quality, you will need to additionally grind the slabs.

Unsanded sheets are used for rough cladding, in construction work or in the construction of elements of furniture that are invisible to the eye.

Unsanded sheets are used for rough cladding, in construction work or in the construction of elements of furniture that are invisible to the eye.

It is taken into account that raw products require a more careful selection: many manufacturers use raw materials that do not always correspond to the declared parameters.

How to work with plywood

Photo - DIY tools for working with plywood.

Photo - DIY tools for working with plywood.

The material is easy to process, and therefore its popularity is growing rapidly. However, in order to achieve flawless results, the instruction recommends adhering to the recommendations.

Plywood drilling

The structure is easy to drill, but it is necessary to act with extreme caution: the sheets are vulnerable to mechanical stress, chips and other damage are easily formed. It is quite problematic to eliminate defects

It is practiced to use chipboard or a backing sheet, which must be pressed tightly against the surface to be treated.

Particular attention should be paid to the choice of the drill, it must have a good sharpening and a front cutter

Fastening with nails and screws

The material is easily fastened with nails (threaded), but plywood screws are preferable. The use of wire nails is practiced. In order to prevent the plywood from splitting, you must first blunt the nail.

Bonding plywood sheets

You will need wood glue, the specific characteristics of which must be appropriate for the application. For example, for interior work - PVA.

Grinding

It is recommended to grind the surface with emery paper, movements should be carried out across the fiber or in a circular motion.

In the absence of practical work experience, it is recommended to use qualified advice, you will be helped to choose and carry out the correct calculation, eliminating unnecessary expenses.

DIY plywood sanding

Regardless of whether the wood is sanded by hand or using technical means, the process takes place in 2 stages, first the surface is treated with large emery and moistened, and when the micro-pile rises, it is removed with a fine sandpaper

Regardless of whether the wood is sanded by hand or using technical means, the process takes place in 2 stages, first the surface is treated with large emery and moistened, and when the micro-pile rises, it is removed with a fine sandpaper

The preparation of the material has a number of features:

- Small parts are processed without the use of equipment: first with coarse, and then with fine-grained sandpaper fixed to a block.

- For larger work, electrical tools are used. Sanding panels laid in the direction of the grain can be done with a tape machine, with an eccentric tool at different locations.

- Working on large areas (for example, adjusting the floor surface) requires the use of a parquet grinder or scraper.

For simplicity, the process is broken down into several steps. To achieve the best result, after the first treatment, the surface is cleaned and covered with a primer that will pick up the remaining pile.

Plywood for environmental safety

Since a substance such as formaldehyde is used in the manufacture of wood-based panels, a generally accepted scale has been developed that determines the level of permissible emission of formaldehyde... According to the level of emission of harmful substances, plywood can be classified as class E1 or class E2.

E1 grade plywood

Class E1 includes materials that emit no more than 10 mg of a harmful substance per 100 g of dry wood. Such indicators are considered acceptable for the use of plywood in a residential environment.

E2 grade plywood

Boards of class E2 are recommended for outdoor use only, as the emission level can reach 30 mg.

At the same time, some unscrupulous manufacturers often indicate in the annotations to their products a class that does not correspond to reality. Using such materials in certain conditions is quite risky, so it is advisable to give preference to trusted manufacturers.

Marking and dimensions

The parameters of FC plywood are determined by a special GOST 3916.1. Thanks to him, for example, we can learn that FC is not the final sign of material classification, and it also has its varieties. So, ordinary FC plywood is moisture resistant, but it would be silly to expect from it that it can be cladding on the street or in the bathroom. The FSF brand already mentioned above is much better suited for solving complex problems - this is facilitated by impurities such as formaldehyde and resins. At the same time, a low-quality FSF also has another marking - Air Force.

If the manufacturer also laminated the slab at the same time, then its marking will be still different - FOF, and then it can be used for the construction of formwork and even more durable structures. There is also FB - bakelized material, which is processed with special impregnations, which is why it is a cross between wood and plastic.

The most important indicator of the ability of plywood to be used in various places is the emission class. It is designated as E1 or E2 and shows how much formaldehyde is evaporated into the atmosphere. Such a compound is not at all useful for the human body, because the less it evaporates, the better, and in indoor conditions, as well as for equipment of playgrounds, it is wiser to use only the most environmentally friendly varieties. These usually include FBA, FK and FB - they have an emission class E1, which means that there is no more than 8 mg formaldehyde per 100 g of plate weight. Moisture-resistant FSF and FOF are mainly used outdoors, not only because they are able to withstand the domestic climate, but also due to the fact that their emission class is E2.

We have already considered the classes of plywood above, it remains only to figure out the dimensions of the sheet - in the standard version they exist in dozens of varieties.The width and length are usually indicated together, therefore it is difficult to confuse them with something else, especially since the numbers are given in millimeters and therefore turn out to be large - for example, 2440x1220 or 1525x1525 mm. The thickness is also indicated in millimeters, but for obvious reasons the values there will be much more modest like 15 mm, 4 mm, 9 mm.

Plywood specifications

Strength and density of plywood

The strength of the plywood depends on the characteristics of the original wood and the bond strength. Strength is indirectly indicated by the density of the material. As a rule, the density of plywood ranges from 550-750 kg / m3, that is, it roughly corresponds to the density of wood or slightly exceeds it due to the higher density of the resin with which the veneer is held together.

In GOST, for ordinary plywood, different density levels are provided - from 300 to 1000 kg. Low specific gravity is possible when using light wood and "loose" veneer. Weighting occurs due to the use of denser resins and other features of the manufacture of a particular type of material. For example, bakelized plywood can have a density of up to 1200 kg / m3. It is also distinguished by the greatest strength.

The main, most important indicators of the strength of plywood are the ultimate strength in bending, the holding strength of the fasteners. The flexural strength of plywood grades FSF and FK is approximately 3-4 times lower than that of solid wood. FBS and FBV grades are superior in strength to the original wood. The resistance of screws to pulling out is quite high due to the pronounced layered structure (when installed in the face) and reaches 6-8 kg for each millimeter of fastener length.

Environmental friendliness

The ecological properties of plywood are characterized by their emission class. The best brand in this respect is FBA. There are no synthetic materials in it at all.

All other plywood grades are sources of volatile formaldehyde to one degree or another. For residential use, materials with emission class E1 and lower should be selected. It is interesting that in GOST only class E1 is provided for film faced plywood.

Biological resistance

Plywood is not insured against rot, blue (for conifers), mold. However, the resistance of plywood to biological damage and damage is higher than that of ordinary wood. This is due to the fact that the veneer is in direct contact with phenolic or urea resins, which partially function as an antiseptic. Coniferous veneer has a higher resistance due to the characteristics of wood. Bakelized plywood has the greatest durability.

In any case, you should take into account the operating conditions of the material and choose the right one for them or carry out additional antiseptic treatment.

Flammability

Plywood is a highly flammable material. This must be taken into account when applying it. It is possible to increase the fire resistance of structures and products from it by special processing. There is also a special, difficult-to-combustible type of plywood - FSF-TV.

Moisture resistance

The moisture resistance of the most popular FSF and FK varieties is demonstrated by the leaf delamination test, which is carried out after strong moisture. Before testing, FC plywood is soaked in water for 24 hours, the FSF brand is boiled for an hour, and upon agreement with the customer, within 6 hours. FBS and FBV brands are also boiled for an hour.

After water treatment and drying, the shear strength on the adhesive layer for different brands is:

- FC and PSF - from 2 to 10 kgf / cm2 (0.2-1 MPa);

- FBV - 14.7 kg / cm2;

- FBS - 17.6 kg / cm2.

FBS grade is suitable for tropical climates and other difficult conditions.

Insulating properties

Plywood can be used as part of external enclosing structures. In this application, its insulating qualities are taken into account.

Moisture permeability.

Any plywood is capable of absorbing water, and therefore is permeable to moisture. However, the moisture permeability of the material is capillary and depends on the type of impregnation.In any case, when one side is moistened, moisture will penetrate to the opposite side and can be transferred to adjacent layers of the enclosing structure.

Thermal conductivity.

The thermal conductivity of plywood depends on its density and can range from 0.09 to 0.25 W / (m ∙ K). For the most used brands, the thermal conductivity of the material is close to that of wood.

Water vapor permeability.

Water vapor permeability is an important parameter that is taken into account when calculating multilayer structures that enclose rooms with an artificial microclimate.

The vapor permeability of plywood is approximately three times lower than the permeability of wood in the direction across the grain, and five times lower than the permeability of brickwork. In some cases, this property can be used for vapor barrier walls from the inside, and must be taken into account when using plywood for external cladding.

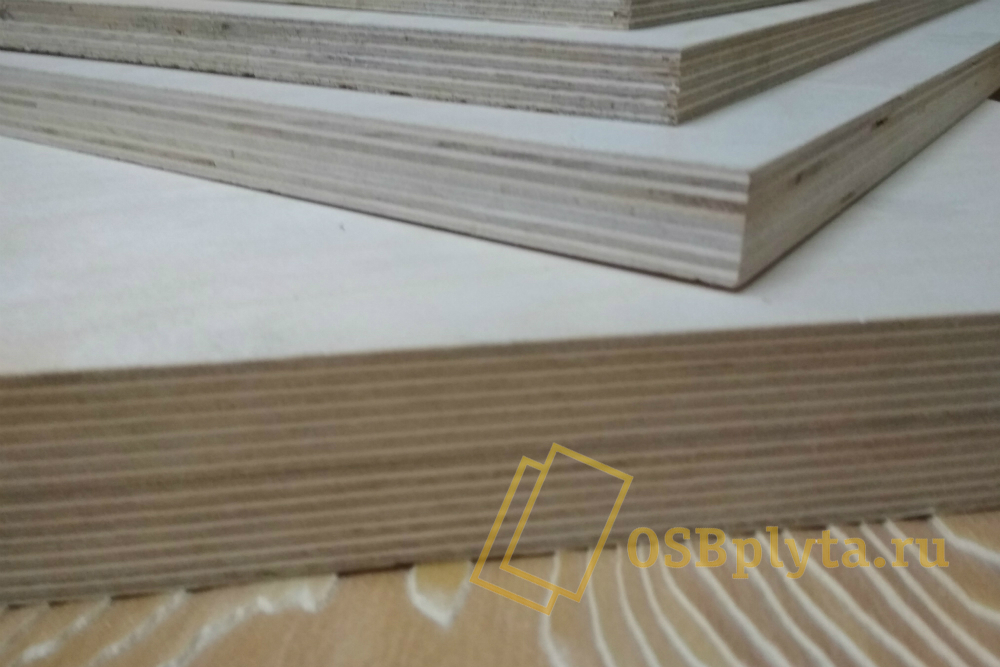

General information about plywood and rotary cut veneer

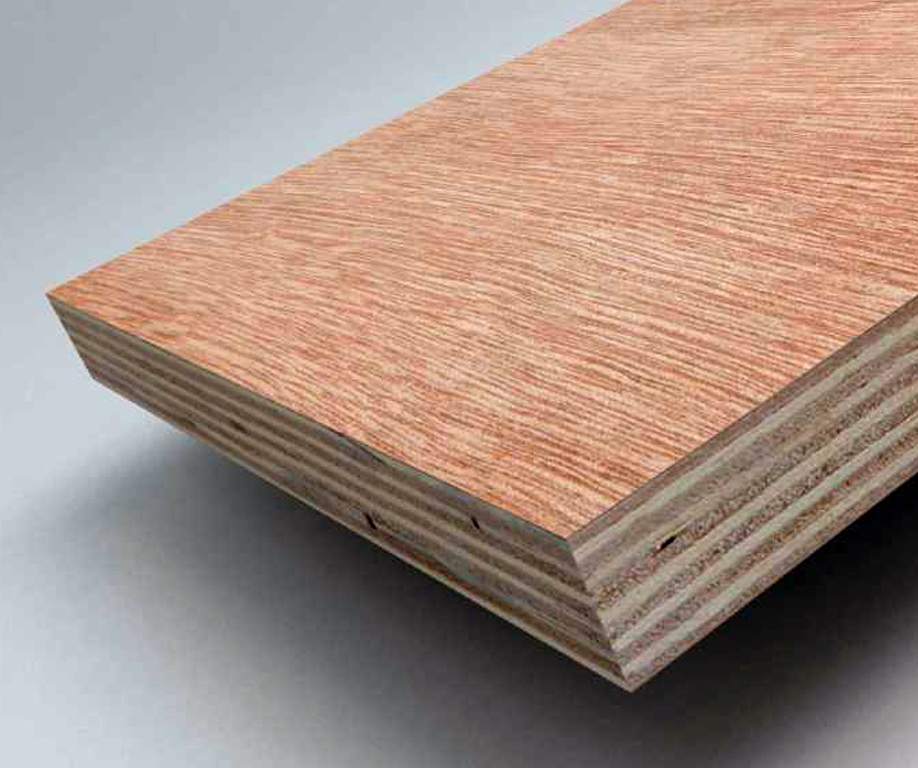

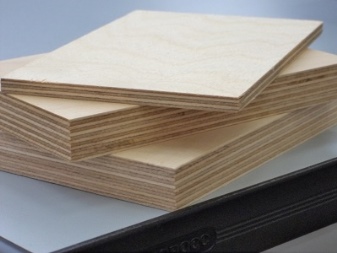

Plywood is a material obtained by gluing at least three sheets of peeled veneer with mutually perpendicular direction of fibers in adjacent layers

Construction of three-layer plywood sheet

When designing plywood, observe the following rules:

- The plywood sheet should be symmetrical about the middle layer.

- The number of veneer layers in plywood is usually an odd number (3, 5, 7, 9, etc.), although 4-ply plywood is also produced in which the two inner layers have parallel grain direction.

Distinguish between equal-layer plywood (the thickness of all veneer sheets is the same) and uneven-layer. For non-layered plywood, it is desirable to have a middle layer of thicker, low quality veneer, and the outer layers of thin, high quality veneer. The outer layers are divided into front and back, the quality of which determines the quality of the plywood sheet. Peeled veneer also has a front and a reverse side, while the quality of the front side of the veneer is higher than the reverse side, facing the center of the block during its peeling and having more cracks. When assembling a plywood sheet (package), the reverse side of the veneer must face the glue line.

Schematically, the construction of plywood is indicated with an indication of the thickness of the veneer, for example, the entry 1.15 x 2 + 2.20 denotes three-ply plywood with an outer layer thickness of 1.15 mm and an inner layer thickness of 2.2 mm.

Rotary cut veneer is not only a semi-finished product for the manufacture of plywood and plywood products, but also an independent commercial product, usually used in the furniture industry for facing panels and obtaining glued parts, as well as in a number of other industries, providing a more rational use of raw materials than when using sawn timber:

Specifications for peeled veneer are specified in GOST 99 - 96. The length of veneer sheets ranges from 0.8 to 2.5 m, width - from 0.15 to 2.5 m, veneer thicknesses are indicated in the table

Rows of rotary cut veneer thicknesses

|

Wood species |

Range of thicknesses, mm |

Limit deviation, mm |

|

Deciduous |

0,55; 0,75; 0,95; 1,15 |

± 0,05 |

|

1.25 - 4.0 in 0.25 steps |

± 0,10 |

|

|

Conifers |

1.2 - 4.0 in increments of 0.4 |

± 0,15 |

|

4.0 -.6.5 in steps of 0.5 |

± 0,20 |

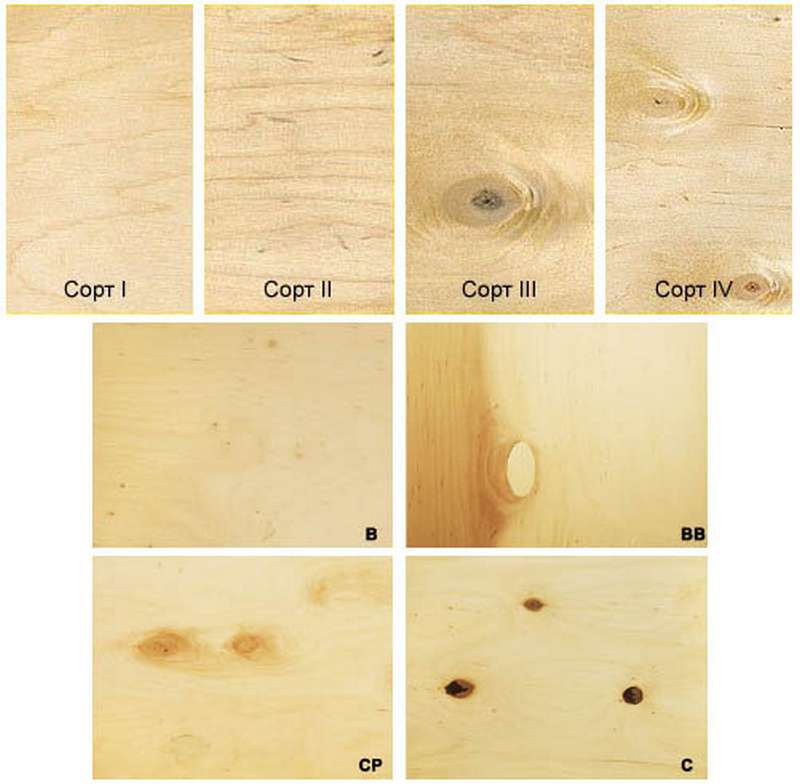

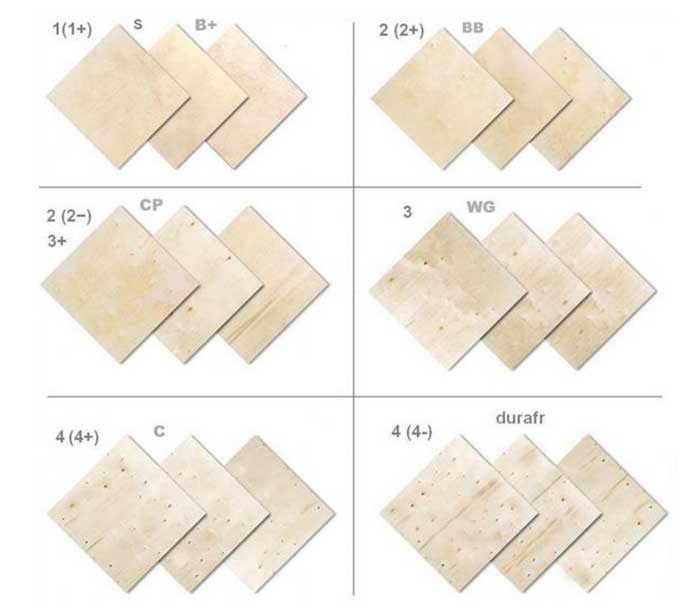

The quality of veneer sheets can be very varied due to the variety of wood defects and processing defects. According to the standard (effective from 1.01.98), the designation of varieties has undergone changes

Designation of grades of rotary cut veneer according to various standards

|

Hardwood |

Conifers |

|||

|

according to GOST 3916.1-96 |

For export plywood |

according to GOST 3916.1-89 |

according to GOST 3916.2-96 |

according to GOST 3916.2-89 |

|

E |

— |

A |

Ex |

— |

|

I |

B |

AB |

Ix |

AX |

|

II |

BB |

B |

IIx |

ABX |

|

III |

CP |

BB |

IIIx |

Bx |

|

IV |

C |

C |

IVx |

CX |

The moisture content of the commercial veneer should be 8 ± 2%. Veneer is made of birch, alder, maple, ash, elm, oak, beech, linden, aspen, poplar, spruce, pine, fir, cedar and larch wood. The following directions of use of veneer grades of external surfaces of plywood are recommended

Recommended directions of use of rotary cut veneer of various grades

|

Variety |

Direction of use |

| E, Ex, I, Ix | For front surfaces under a transparent finish |

| II, IIx | For surfaces of various purposes for all types of finishes |

| III, IIIx | For product surfaces predominantly for structural purposes for an opaque finish |

| IV, IVx | No requirements for the appearance of products |