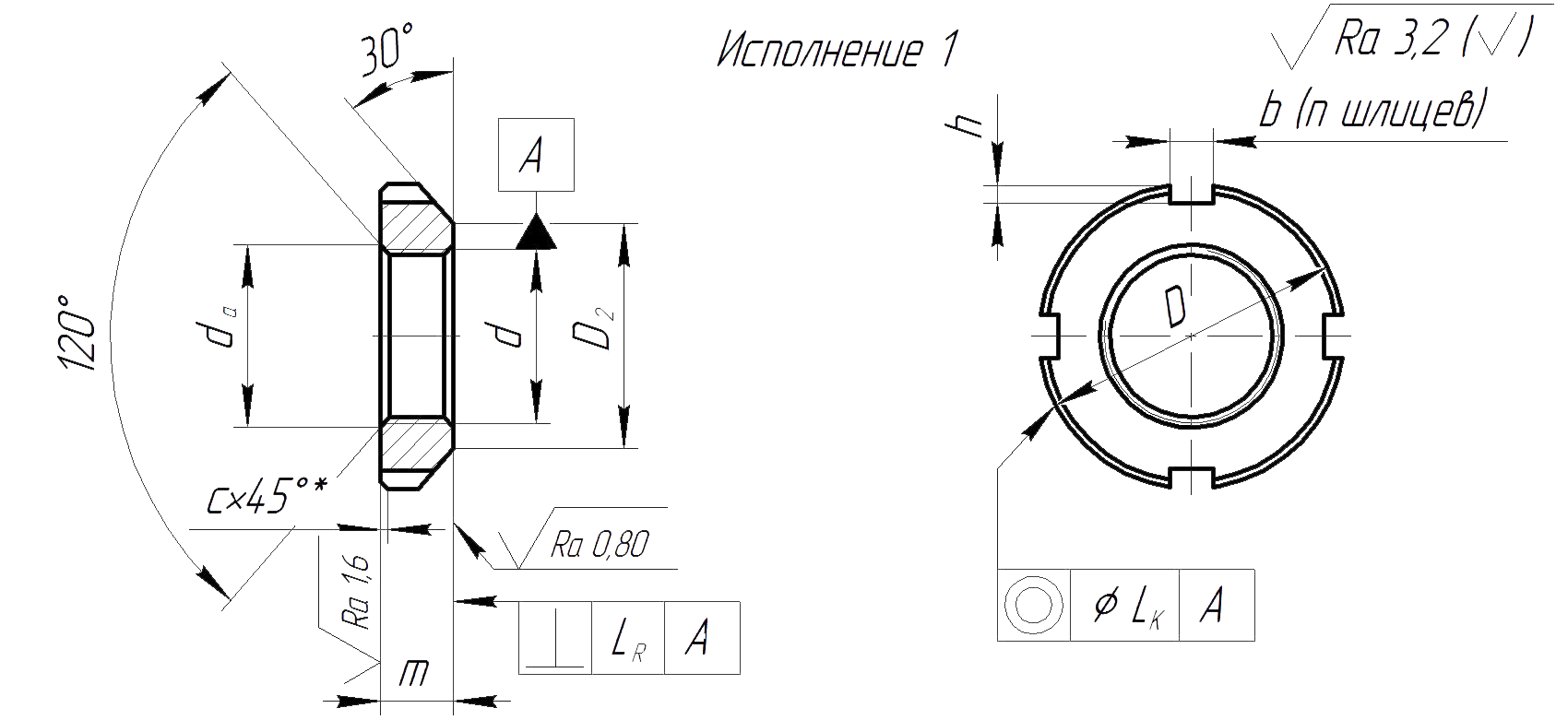

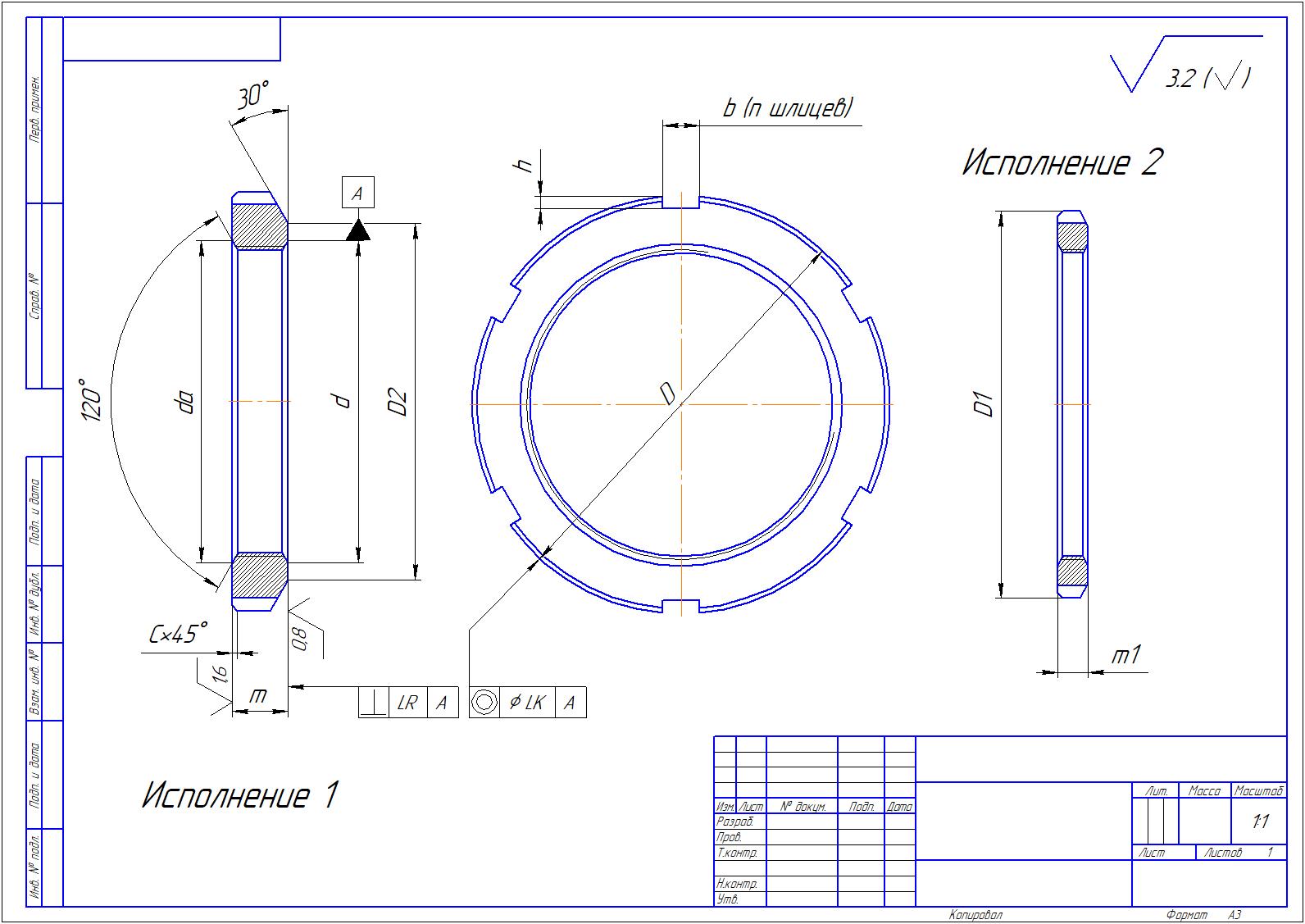

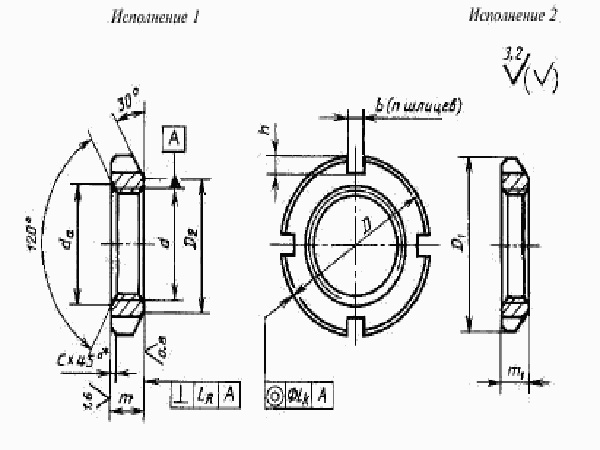

Coating of slotted nuts GOST 11871-88

As a coating of the nut GOST 11871-88, it is allowed to use galvanic galvanizing, nickel plating, chrome plating and others. In order to get acquainted in more detail with what other coating options may be present in the manufacture of this product, we recommend that you contact our specialists.

We are ready to offer you not only nuts according to the domestic standard GOST 11871, but also other products in bulk. Moreover, they can be standardized both according to GOST and other systems. In addition, there is also an opportunity for you to purchase custom products. To do this, provide us with the necessary parameters and drawings.

| Nominal thread diameter d | Thread pitch P | D | m | D1 | m1 | D2 | da | b | h | c, no more | Number of splines n | |

| not less | no more | |||||||||||

| 6 | 0,50 | 16 | 5 | 16 | 4 | 11,5 | 6 | 6,75 | 4 | 1,5 | 0,6 | 4 |

| 8 | 1,00 | 22 | 6 | 18 | 5 | 13,5 | 8 | 8,75 | ||||

| 10 | 1,25 | 24 | 8 | 20 | 15,5 | 10 | 10,80 | |||||

| 12 | 26 | 22 | 6 | 17,5 | 12 | 13,00 | 6 | |||||

| 14 | 1,50 | 28 | 24 | 18,5 | 14 | 15,10 | 2,0 | |||||

| 16 | 30 | 28 | 22,0 | 16 | 17,30 | |||||||

| 18 | 32 | 30 | 24,0 | 18 | 19,40 | 1,0 | ||||||

| 20 | 34 | 32 | 26,0 | 20 | 21,60 | |||||||

| 22 | 38 | 10 | 36 | 7 | 29,0 | 22 | 23,80 | 2,5 | ||||

| 24 | 42 | 38 | 31,0 | 24 | 25,90 | |||||||

| 27 | 45 | 42 | 35,0 | 27 | 29,20 | |||||||

| 30 | 48 | 45 | 38,0 | 30 | 32,40 | |||||||

| 33 | 52 | 48 | 8 | 40,0 | 33 | 35,60 | 8 | 3,0 | ||||

| 36 | 55 | 50 | 42,0 | 36 | 38,90 | |||||||

| 39 | 60 | 56 | 48,0 | 39 | 42,10 | |||||||

| 42 | 65 | 60 | 52,0 | 42 | 45,40 | |||||||

| 45 | 1,5 | 70 | 63 | 55,0 | 45 | 48,60 | 6 | |||||

| 48 | 75 | 12 | 67 | 58,0 | 48 | 51,80 | 3,5 | |||||

|

(50) |

78 | 70 | 61,0 | 50 | 52,00 | |||||||

| 52 | 80 | 52 | 54,00 | 10 | ||||||||

| 56 | 2,0 | 85 | 75 | 65,0 | 56 | 58,00 | 4,0 | 1,6 | ||||

|

(58) |

90 | 80 | 70,0 | 58 | 60,00 | |||||||

| 60 | 60 | 62,00 | ||||||||||

|

(62) |

95 | 85 | 75,0 | 62 | 64,00 | |||||||

| 64 | 64 | 66,00 | ||||||||||

| 68 | 100 | 15 | 90 | 80,0 | 68 | 70,00 | ||||||

|

(70) |

70 | 72,00 | ||||||||||

| 72 | 105 | 95 | 10 | 85,0 | 72 | 75,00 | ||||||

| 76 | 110 | 76 | 80,00 | |||||||||

| 80 | 115 | 100 | 90,0 | 80 | 84,00 | |||||||

| 85 | 120 | 108 | 98,0 | 85 | 89,00 | |||||||

| 90 | 125 | 18 | 112 | 102,0 | 90 | 94,00 | 12 | |||||

| 95 | 130 | 118 | 108,0 | 95 | 99,00 | |||||||

| 100 | 2 | 135 | 125 | 115,0 | 100 | 104,00 | ||||||

| 105 | 140 | 130 | 120,0 | 105 | 109,00 | |||||||

| 110 | 2 | 150 | 22 | 138 | 12 | 125,0 | 110 | 114,00 | 14 | 5,5 | ||

| 115 | 155 | 145 | 132,0 | 115 | 120,00 | |||||||

| 120 | 160 | 150 | 137,0 | 120 | 125,00 | |||||||

| 125 | 165 | 155 | 142,0 | 125 | 130,00 | |||||||

| 130 | 170 | 160 | 147,0 | 130 | 135,00 | 8 | ||||||

|

(135) |

175 | 26 | 165 | 152,0 | 135 | 140,00 | ||||||

| 140 | 180 | 170 | 157,0 | 140 | 145,00 | |||||||

|

(145) |

190 | 175 | 162,0 | 145 | 150,00 | 2,5 | ||||||

| 150 | 200 | 180 | 167,0 | 150 | 155,00 | 16 | ||||||

| 160 | 3 | 210 | 190 | 177,0 | 160 | 162,00 | ||||||

| 170 | 220 | 30 | 202 | 189,0 | 170 | 172,00 | ||||||

| 180 | 230 | 215 | 14 | 202,0 | 180 | 185,00 | 7,5 | |||||

| 190 | 240 | 230 | 213,0 | 190 | 195,00 | |||||||

| 200 | 250 | 240 | 223,0 | 200 | 205,00 |

Slotted nut GOST 11871-88 is in constant availability in our warehouses not only in St. Petersburg and in other cities. We also have the ability to supply our products anywhere in our country. You just have to agree on your order, delivery time and cost with us. The OPM company has a wide range of products in accordance with GOST, DIN, ISO and other standards. Sale is carried out in large and small wholesale.

Our experts will not only select the required product for you, such as the GOST 11871 nut with the parameters you need, but also offer acceptable analogs * and various accompanying elements. Some versions of these nuts are partially interchangeable with other DIN-standardized products. But do not forget that both nuts and other hardware, products may differ in some way by the characteristics described in their different standards.

Back to section

V (V)

V

-77,

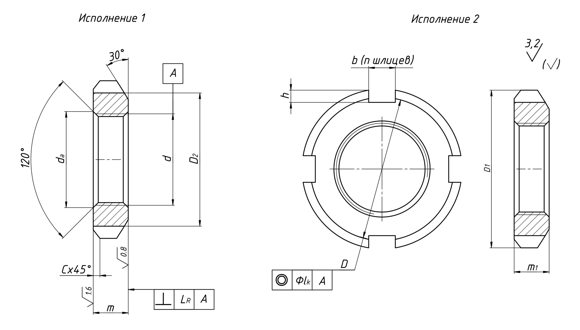

* Allowed instead of a chamfer with a rounded radius R = c and no chamfer for version 2.

Official edition

★

Reprinting prohibited

og

NM

Table! R

to

|

6 |

0,50_ |

16 |

5 |

16 |

4 |

11,5 |

6 |

6,75 |

|||

|

4 |

|||||||||||

|

8 |

1,00 |

22 |

6 |

18 |

c |

13,5 |

8 |

8,75 |

1,5 |

||

|

10 |

24 |

20 |

15,5 |

10 |

10,80 |

0,6 |

|||||

|

—»— |

1,25 |

—— |

——- |

||||||||

|

JL |

jL |

jL |

17,5 |

12 |

joe. |

||||||

|

L- |

jL |

JL |

18,5 |

14 |

j5j |

||||||

|

_ IS |

JL |

8 |

JL |

6 |

22,0, |

16 |

17|_ |

2,0 |

|||

|

18^ |

32 |

30 _ |

24,0 |

18 |

jL |

||||||

|

JL |

jL |

32 v |

26,0 |

20 |

21,60 _ |

6 |

|||||

|

JL |

38 |

36 |

29,0 |

22 |

jL |

||||||

|

24 |

42 |

38 |

31,0 |

24 |

25,90 |

||||||

|

JL |

1,50 |

45 |

JL |

7 |

35,01 |

27 |

_29,20 |

2,5 |

1,0 |

||

|

jL |

48 _ |

10 |

JL |

38,0 |

30 |

32,40 , |

|||||

|

33 |

52 t |

4L |

40,0 |

33 |

35,60. |

||||||

|

36 |

55 |

50 _ |

42,0 |

36 |

38,90 ^ |

||||||

|

8 |

3,0 |

||||||||||

|

30 |

60 _ |

56 |

48,0 |

39 |

42,10 |

||||||

|

42 |

65 |

60 |

52,0 |

42 |

45,40 |

88-IZS I I -LOO J

21

Continuation of table. 1

mm

|

Nomi cash diameter carvings a |

Step carvings R |

D |

m |

D1 |

I1 |

O2 |

i not less |

H not more |

b |

h |

with, not more |

Number walked tsev NS |

|

45 |

70 |

10 |

63 ( |

55,0 |

45 |

48,60 |

3,0 |

|||||

|

8 |

||||||||||||

|

48 |

75 |

67 |

58,0 |

48 |

51,80 |

1,0 |

||||||

|

(511) |

1,5 |

78 _ |

70 |

61,0 |

50 |

52,00 |

3,5 |

|||||

|

52 |

80 |

52 |

54,00 _ |

|||||||||

|

56 |

85 |

12 |

75 |

31 |

56 |

58,00 |

||||||

|

(58) |

58 |

60,00 |

||||||||||

|

90 |

80 |

8 |

70,0 |

|||||||||

|

60 |

60 |

62,00 |

||||||||||

|

1 ■ |

—■- |

6 |

||||||||||

|

(62) |

62 |

64,00 |

||||||||||

|

95 |

85 |

75,0 |

—— |

|||||||||

|

64 |

64 |

66,00 |

10 |

|||||||||

|

68 |

68 |

70,00 |

||||||||||

|

PL |

100 |

90 |

80,0 |

|||||||||

|

JL |

2,1) |

JL |

_ 72,00_ |

4,0 |

i, 6 |

|||||||

|

NS |

185 |

15 |

72 |

75,00 |

||||||||

|

—- |

95 |

85,0 |

||||||||||

|

76 |

ON |

76 |

80,00 _ |

|||||||||

|

80 |

115 |

100 |

10 |

90,0 |

80 |

84,00_ |

||||||

|

,85 |

120 |

108 |

98,0 |

85 |

89,00_ |

|||||||

|

90 |

125 |

18 |

112 |

102,0 |

90 |

94,00_ |

10 |

|||||

|

12 |

||||||||||||

|

95 |

130 |

118 |

108,0 |

95 |

99,00 |

8S-IZ.8U XOOJ

ss

Continued so 1 p

|

11 |

135 |

1$ |

125 |

10 |

115,0 |

100 |

101,00 |

12 |

4,0 |

|

|

105 |

BUT |

130 |

120,0 |

105 |

109,00 |

|||||

|

ON |

150 |

13L |

125,0 |

ON |

114,00 |

|||||

|

115 |

155 |

i "_ |

132,0 |

115 |

120,00 |

|||||

|

120 i |

160 |

22 |

_150 _ |

’ 137,0 _ |

120 |

125,00 |

||||

|

125 _ |

165 |

155 |

_ 112,0 |

125 |

130,00 |

|||||

|

130 |

2 |

170 |

«160 |

” 147,0 |

130 |

‘ 135,00 |

14 |

|||

|

(135) . |

175 |

165__ |

152,0 |

135 |

140,00 |

5,5 |

||||

|

BUT |

_ 180 |

170 |

12 |

’ 157,0_ |

BUT |

145,00 |

||||

|

(!«) |

190 |

26 |

175_ |

162,0 |

145 |

150,00 |

||||

|

150 |

200 |

1st_ |

‘ 167,0 |

150 |

155,00 |

|||||

|

11 |

J10_ |

190_ |

177,0. |

160 |

162,00 |

|||||

|

ha |

220 |

202 |

~ 189,0 |

170 |

172,00 |

|||||

|

NS |

3 |

230 |

30 |

215 |

202,0 |

180 |

185,00 |

16 |

||

|

90 |

240′ |

230 |

14 |

213,0 |

190 |

195,00 |

7,5 |

|||

|

200 |

250 |

210 |

223,0 |

200 |

205,00 |

Notes:

1. It is allowed by agreement between the manufacturer and the consumer to manufacture nuts М45 * 1 -S-M125 with 4 splines.

2, Hook with the dimensions indicated in brackets is not recommended to be used,

GOST 11871-88

An example of a symbol for a nut of version 1, with a thread diameter d = 16 mm, with a fine thread pitch of 1.5 mm, with a thread tolerance of 6H, made of steel grade 35, coated with a chemical oxide impregnated with oil:

Nut М16X1,5-6N.05.05 GOST 11871-88 The same, made of brass L63, without coating:

Nut M16XL5-6H.32 GOST 11871-88 Same, version 2, with zinc coating 9 μm thick, chromated:

Nut 2 M16x 1.5-6N.019 GOST 11871-88

1.2. Thread - in accordance with GOST 24705.

1.3. The theoretical mass of steel nuts is shown in Appendix 1.

2. TECHNICAL REQUIREMENTS

2.1. The thread tolerance field is 6H in accordance with GOST 16093.

2.2. Fields of dimensional tolerances and tolerances of the location of surfaces must correspond to those indicated in table. 2.

Angle tolerances ± ■ -t; - according to GOST 8908.

It is allowed, by agreement between the manufacturer and the consumer, to manufacture nuts with a tolerance of perpendicularity of the supporting surface to the thread axis L # - according to the 11th degree of accuracy and surface roughness Ra: 1.6; 3.2; 6.3 instead of Ra\ 0.8; 1.6; 3.2 - respectively.

table 2

|

Size or tolerance designation |

Tolerance field or tolerance |

|

D; Di |

N2 |

|

d2 |

N4 |

|

tp \ tp \ |

N4 |

|

B |

H14 |

|

h |

H14 |

|

According to the 9th degree of accuracy GOST 24643 |

|

|

L to |

According to the 11th degree of accuracy GOST 24643 |

2.3. Grades of materials and their designations must correspond to those indicated in table. 3.

T a b l i

so-ts a 3

|

Material |

Brinell hardness HB, not less |

Conditional designation stamps (groups) |

||

|

view |

brand |

designation standard |

||

|

Carbonaceous become |

St 3 bn, St 3 kp |

GOST 380 |

90 |

02 |

|

20 |

GOST 1050 |

110 |

04 |

|

|

35 |

140 |

05 |

||

|

45 |

170 |

06 |

||

|

Alloyed become |

35X |

GOST 4543 |

197 |

11 |

|

ZOHGSA |

217 |

|||

|

Corrosion resistant steels |

12Х18Н9Т 12X18HI0T |

GOST 5632 |

— |

21 |

|

14X17N2 |

23 |

|||

|

Brass |

L63 |

GOST 15527 |

— |

32 |

2.4.Nuts should be manufactured with coatings: zinc chromated; cadmium chromated; oxide impregnated with oil; phosphate, oil-impregnated or uncoated. The choice of coating for a specific material is in accordance with GOST 9.303. Technical requirements for coatings - in accordance with GOST 9.301.

The conventional designation of coatings is digital in accordance with GOST 1759.0.

2.5. Surface hardness of nuts splines - not less than 372HV or 38HRCa... The depth of the hardened layer is at least 1 mm.

By agreement between the manufacturer and the consumer, it is allowed to manufacture nuts without heat treatment.

2.6. Surface defects of nuts - in accordance with GOST 1759.3.

3. ACCEPTANCE

Marking

The dimensions of the nominal thread diameter can be:

- 6;

- 8;

- 10;

- 12;

- 14;

- 16;

- 18;

- 56;

- 80;

- 95;

- 170;

- 200 mm (there are also other dimensions).

Fastener packaging shall include the following:

- official trademark (sometimes in combination with the name of the company);

- conventional signs of hardware;

- net weight or quantity in pieces.

Only fasteners of a completely uniform type may be inserted in each package. That is, if round models are placed there, then square and any other shapes cannot be used. The same applies to dimensions, materials and coatings used. For the manufacture of slotted nuts, either stainless steel or brass can be used. Various coatings can be applied over the stainless steel.

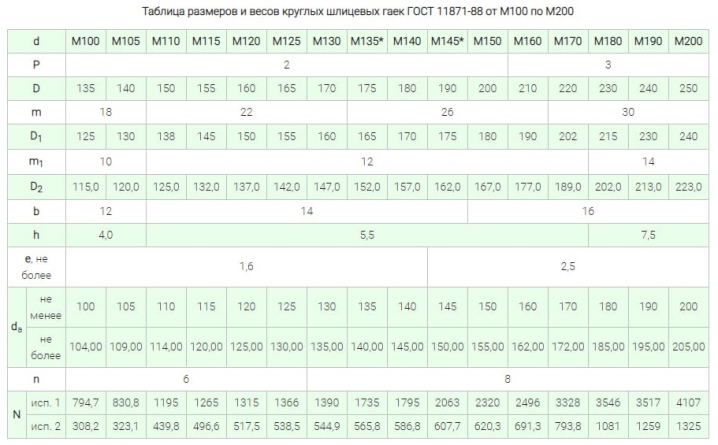

Lock washer nuts are available in HM 3044 to HM 3192. Another range is HM 30/500 to HM 30/710. The mass of nuts in the marking is calculated on the assumption of a steel density of 7.85 g per 1 sq. see Sometimes it is practiced to apply not trapezoidal, but metric threads - which should also be marked.

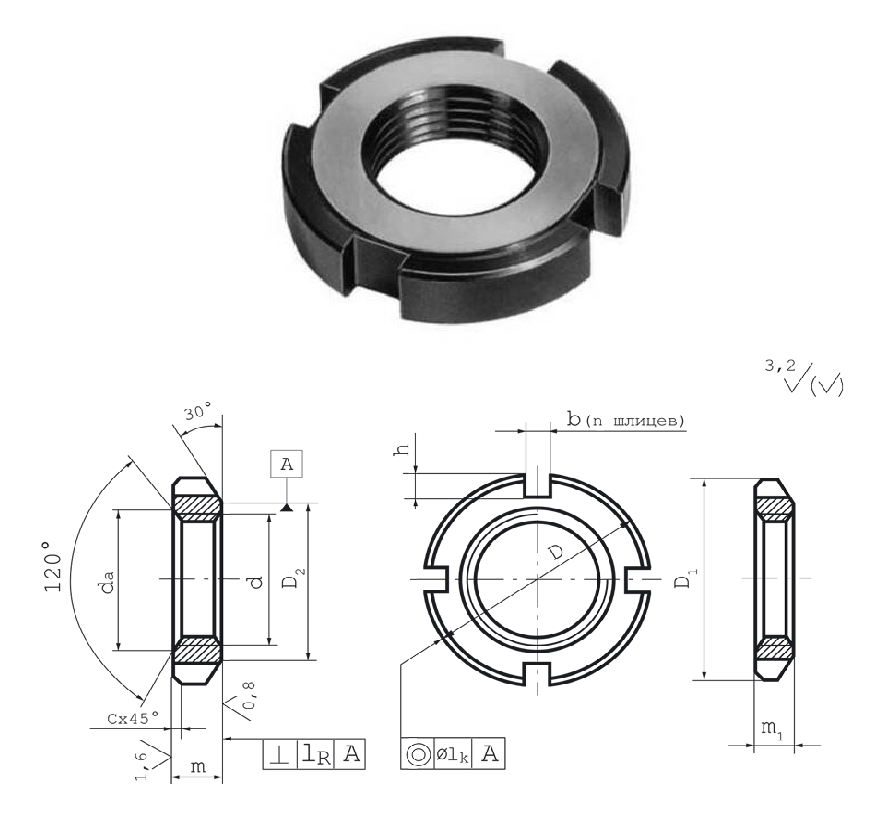

Peculiarities

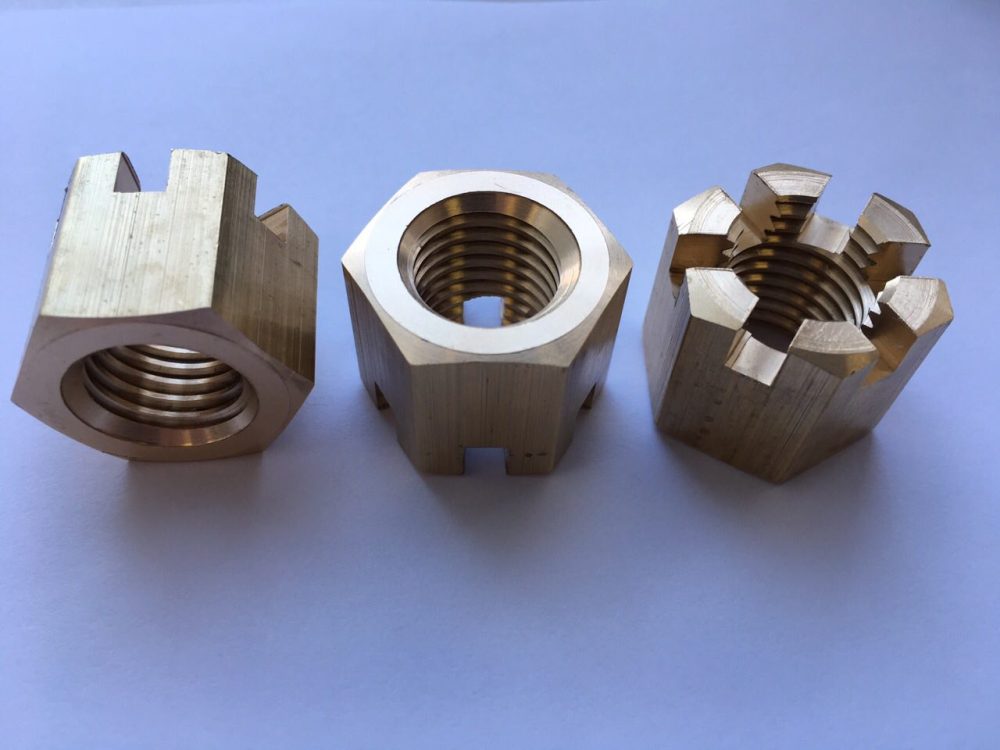

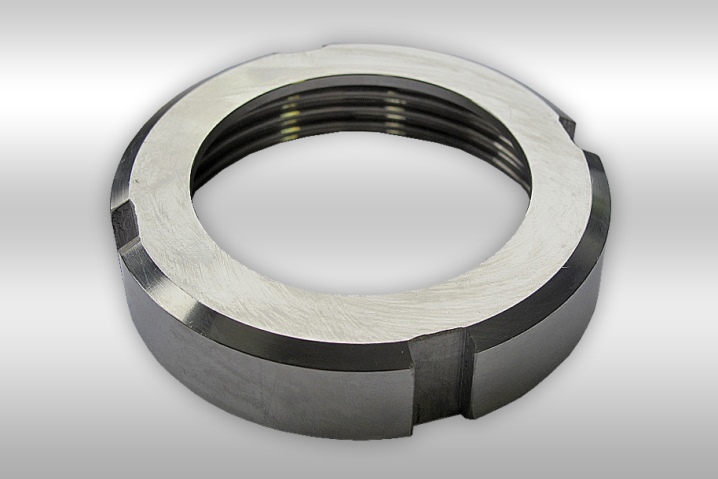

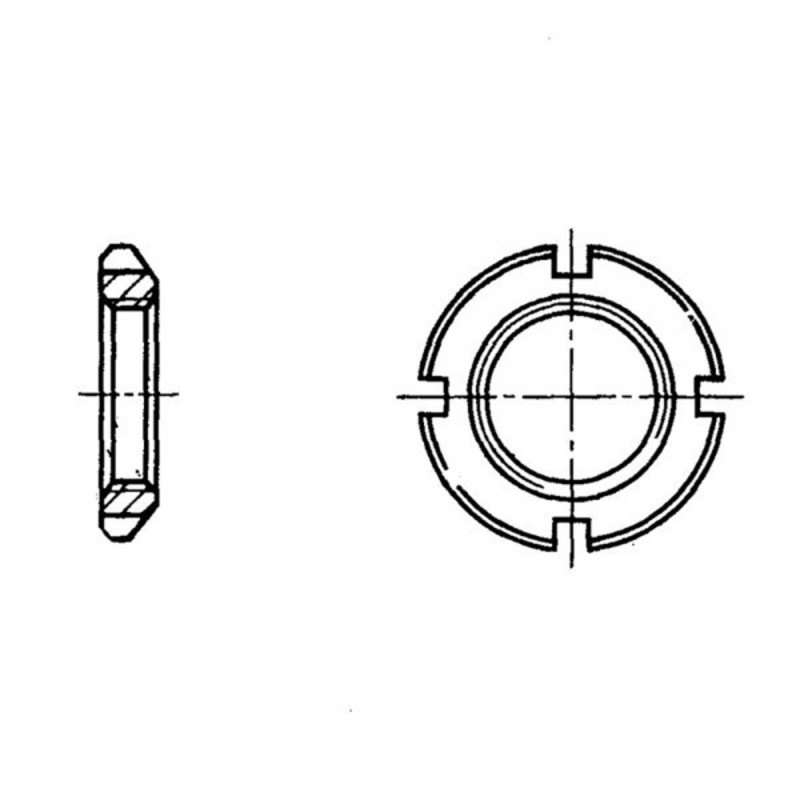

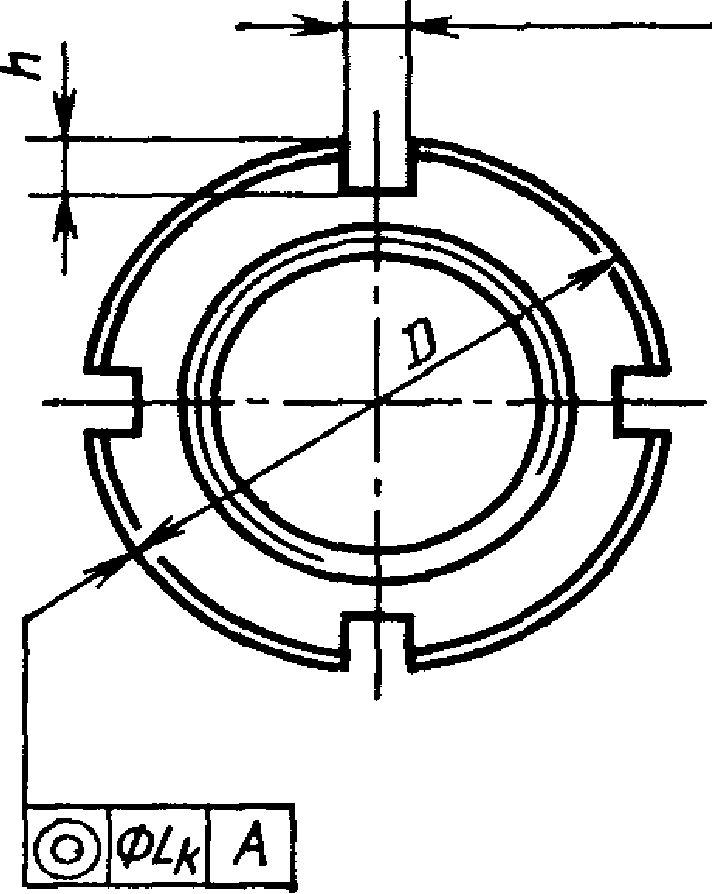

The slotted nut is supplied by a wide variety of companies and is present in the range of all leading manufacturers. Technically, it is "just" a metal ring. A thread is applied to the hole of the product from the inside. In this case, special slots are applied outside, which gave the name to such fasteners. These grooves are formed using milling.

The role of the grooves is to ensure the scrolling of the hardware around its axis. The number of slots must correspond to the section of the product. Slotted hardware is rarely used for conventional threaded joints, but they are in great demand in various industries, namely:

- machine tool building;

- automotive industry;

- other branches of mechanical engineering.

These are primarily units that contain shafts and other intensively rotating parts. The load on the slotted fastener is very high, so it must be extremely reliable and stable. For its manufacture, only steel with a strength of at least 36 HRS is used. The minimum hardening depth is 0.1 cm.

How to twist them?

Application is perhaps the most important point when it comes to slotted nuts. By default, they are used to fix strictly coaxial parts. It is common practice to use radius (also called collet) keys. They have a grip in the form of an arc, ending in a trailer that looks like a hook in appearance. Of course, there can be no question of using a screwdriver.

The state standard has fixed 21 key formats for any nuts. These keys are necessarily made of steel with the addition of chromium. A swivel tool is sometimes used. It is sufficient to have one key for each size group and apply it as needed. In some cases, socket heads help to work with slotted nuts.

You can find out how to make a key for slotted nuts with your own hands from the video below.