Calculation for the application of the material outside the building

In this case, the calculations are carried out according to the same principle. The only caveat: much less surfaces will be taken into account. And if you do everything yourself, then difficulties may arise at the stage of determining the area of the pediment.

So, you need to determine the area of the walls, having previously learned the height and length of each. That is, the procedure is the same. To determine the area of the gables, multiply the height by the length of the base, and then divide by two.

After that, the obtained figures must be summed up, and then the area of the openings must be subtracted.

Recommendation: since the installation is carried out according to the groove-tenon principle, and the calculations should use the value of the useful width of the lining.

How many boards in a cube: calculation of unedged lumber

The calculation of the cubic capacity of an unedged board has some nuances, since its shape is not correct. Such material does not have a rectangular section along its entire length, therefore it is used to organize temporary structures. The lower and upper surfaces of the unedged board must be processed along the entire length. Otherwise, this product is a side part of the log (slab).

The calculation of the cubic capacity will depend on the degree of processing of the material, type and grade, for example, edged and unedged boards are calculated differently

To find the volume of unedged lumber in 1 cubic meter, as well as its amount, there are several methods. It should be noted right away that it is rather difficult to determine how many boards are in one cube when it comes to irregular geometric shapes. Therefore, the initial numbers obtained when calculating unedged parts will be an approximate figure.

Consider what methods are used to calculate the cubic capacity and the amount of unedged sawn timber:

- batch;

- piece by piece;

- sampling method.

In the first case, you will need to load the lumber into a bag, which must have the correct shape. After the bookmark, you need to measure the desired indicators. The following is a standard procedure for determining the volume using the measured values. This method is most common for products that do not have clear edges. For example, using it you can calculate the cubes of a 25x150x6000 board in a cube (unedged).

For the width of the unedged board, when calculating, take the average indicator

It is worth noting that this type of mathematical expression uses a special coefficient (for the width), which is the arithmetic mean. Although this option is not fast, it allows you to answer the question of how to calculate the cube of the board.

The piece-by-piece method involves the use of numbers corresponding to the arithmetic mean of the height and width of the trimmed product. These values are calculated in meters.

In order to find the arithmetic mean, it is necessary to measure the board. The minimum width (at the narrowest point) and the maximum are measured. Further, both indicators are added and divided in half. After that, the same height manipulation is performed. The numbers obtained during the calculation must be multiplied by each other and by the length of the product.

Let's see how it looks like a mathematical expression:

(b max + b min) / 2 x (h max + h min) / 2 x L = V

When calculating large consignments of wooden building materials by the method of determining the volume, the sampling method is taken

Using such a formula, it will not be difficult to determine the volume of 1 unedged element and answer the question of how to calculate the cubic capacity of a part. After obtaining this value, you can calculate the total number of boards in a cubic meter.For such a calculation, you will need to use a formula similar to the trimmed part (a cubic meter is divided by the volume of the product).

Useful information! When buying raw boards, you need to be careful. Sellers should use a factor that affects the reduction in total volume, taking into account future shrinkage. To calculate wet coniferous products, 1 cubic meter must be multiplied by 0.96. In turn, the coefficient for hardwood is 0.95.

The last way to determine the volume of lumber and its quantity in 1 cubic meter is the sampling method. It is used when calculating large batches of wooden building materials. The essence of this method is that several boards are selected from the total mass of boards. Then the parts are measured and calculated in accordance with the piece-by-piece method. The resulting numbers are multiplied by the total number of parts in the batch.

An unedged board has a large run-up in width at opposite ends, therefore, when calculating an unedged board, the average width must be substituted into the formula

The formula for the volume of a cube: how many edged boards in 1 cubic meter

A cube is a geometric figure that consists of 6 equivalent faces. Each of them is a square. To determine the volume of this figure, it is necessary to multiply 3 indicators among themselves:

length;

To determine the number of trimmed boards in 1 cube, you need to find out the volume of one of them by finding the product of three quantities, and then divide 1m3 by it

- width;

- height.

In order to find out how many boards are in 1 cube, you need to multiply several values. The result is a mathematical expression that looks like this:

V = h x b x L, where:

h is the height of the cut product (m);

b - element width (m);

L - length of one part (m).

Using this formula, you can determine the volume of 1 element

It is important to remember that when carrying out the calculation, it is necessary to convert the millimeter values of the product into meters. For example, in order to determine how many 25x150x6000 boards are in a cube, you will need to convert the numbers by multiplying them by 0.001

The finished mathematical expression after such a transformation will look like this:

V = 0.025 x 0.15 x 6

The calculation algorithm is the same for all sawn timber of a certain group, regardless of their features.

The result is that the volume of one piece of wood is 0.0225 cubic meters (m³). Next, it remains to calculate how many pieces of edged boards are contained in 1 cubic meter. There is a simple formula for this. It means dividing 1 cubic meter by the volume of 1 board, which was obtained using the previous mathematical expression. Let's consider the calculation using an example:

1 m³ / 0.0225 m³ = 44.4

Thus, 1 cubic meter contains approximately (if rounded off) 44 boards. After that, it is already possible to independently determine the amount of material required for the construction of a specific structure. And also at this stage, you can draw up a general estimate indicating the price of edged boards per cubic meter.

To calculate the cost of 1 edged board, a mathematical expression is used, which implies multiplying the volume of 1 part by the price of a cubic meter. Let's take an example:

0.0225 x 8200 rubles. = RUB 184.5

The calculation showed that the cost of 1 edged product will be approximately 184 rubles. If you know the cost of 1 part, but you need to calculate the price of a cube of a board, you need to do the reverse manipulation. In this situation, you will need to divide the price for 1 item (184.5) by its volume (0.0225).

After some calculations, you can find out that 1 cubic meter contains approximately 44 boards

Note! Sometimes, especially when buying a small batch of boards, there is confusion with the decimal places. In some cases, sellers of sawn timber deliberately expose the cost, calculated when rounded to 3 numbers.

However, by law, this value is only suitable for large batches of boards.When purchasing several products, it is recommended to round in accordance with GOST, namely to 0.000001 m³.

When calculating the amount of boards and the cost of lumber per cubic meter, it is advisable to take into account unplanned losses, which very often occur during construction. Therefore, it is recommended to buy edged products with a small stock (several pieces).

Types of materials

One cubic meter of wood per quantity will differ for different types of materials. When it comes to perfectly flat beams and edged boards, they can be folded into a fairly dense stack that will be completely filled with wood. In practice, you have to deal not only with beams or edged, but also with more complex lumber.

What are the types of materials:

- timber or edged;

- grooved board;

- block houses and different types of lining;

- OSB plates;

- unedged.

For beams and edging, the principle of calculating the amount is clear and described above.

When calculating the number and area of grooved boards, only the parameters of their working surface are taken into account, excluding protruding ridges or grooves. In practice, this area corresponds to the area of laying these materials, while the thickness remains stable.

For block houses and lining, it is preferable to use measurements in linear meters, as most sellers and manufacturers often do. Differences in different parts can be difficult to measure.

OSB slabs are also often measured in running meters, although the volume of cubic capacity for them is quite easy to calculate.

There is a difference between tight and loose storage, when there is some air between the lumber. A certain approach to storage is caused by the need to maintain a stable temperature and humidity inside the lumber, and when calculating the volume and quantity in one cube, additional coefficients will be calculated that specify the volume, adjusted for the percentage of air volume.

Sometimes, when calculating the number of parts of complex shapes in one cubic meter, they can resort to another method:

This method of finding out how many boards are in a cube is quite effective, provided that the density value and other indicators are known.

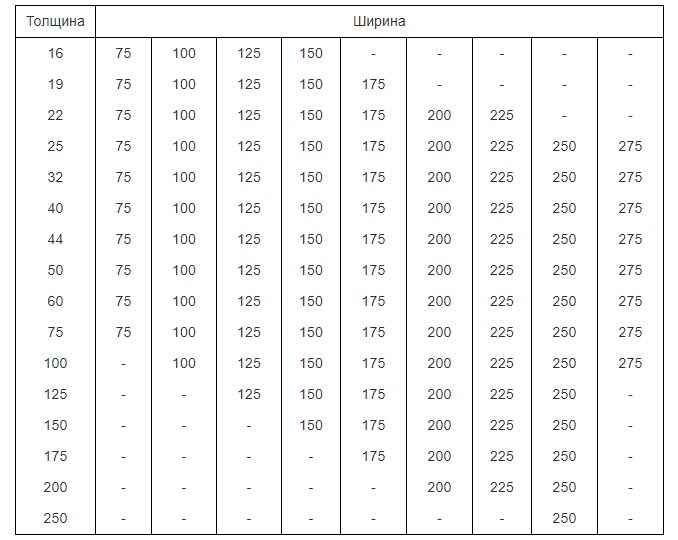

table

For most standard sawn timber, standard tabular volumes are provided, which allow you to quickly and without lengthy calculations find out the number of boards in one cube. To do this, it is enough to find the corresponding values in the table, which is given in all construction textbooks.

With a mobile phone or calculator at hand, it becomes possible to quickly and easily determine all quantitative and volumetric indicators. The knowledge of the tricks described here that manufacturers go to in order to increase profits will definitely come in handy for the owner of a new home. A rational approach and mathematical accuracy will solve a number of problems, helping to carry out all repair and construction work according to plan and on time.

Prices of edged boards per cube: 50x150x6000 and other varieties

Today in the construction market you can find many types of lumber. All of them are differentiated not only by size, but also by the type of wood from which they were made. And also the cost of these products is influenced by the production technology and their purpose. In order to find out how much a cube of a board costs, you need to familiarize yourself with all the varieties of these parts.

1st grade sawn timber, made in accordance with technical specifications, costs an average of about 7,000 rubles. per cube

The most popular in the construction of private houses, summer cottages, as well as other structures is the classic edged board. It can be of 1st and 2nd grade. The first option is more expensive, as it has higher technical characteristics and durability.

Useful information! The price for an edged board of the 1st grade is approximately 7,500 rubles. for 1 cubic meter Products that belong to a lower quality group cost about 4-6 thousand rubles. for 1 m³.

The width and height of the boards, as a rule, do not affect their value. This is due to the fact that in a cubic meter, regardless of the dimensions of the timber, there will be the same number of parts. In the sense that for the same price you will receive 44 edged boards 25x1500x6000 (price per cube: 7500 rubles) or 22 parts 50x150 having the same length.

Separately, it should be said about edged boards made in accordance with technical conditions (TU). Lumber of this type costs an average of about 7,000 rubles. per cubic meter Such boards have good quality characteristics and can be used in the construction of various structures.

Building board is often used in interior decoration

Unedged products are cheaper because they are of lower quality. Their cost is calculated using averaged values. The price of unedged sawn timber ranges from 4 to 5 thousand rubles. However, they are not recommended for construction. It is better to use better quality lumber, for example, edged board 40x150x6000 (price per cube: 7500) or similar products with other dimensions.

When buying wood lumber, you need to pay attention to some points. For example, the board must be flat.

The curvature of the product most often indicates that the technology was violated during its production. Such parts are not used in construction, as they do not have the required quality.

How much does the cube of the board weigh? When purchasing this building material, its weight should be taken into account. For example, an edged board made from dry spruce weighs 450 kg (1 cubic meter). 1 m³ of raw product has a mass of 790 kg. Dry pine has a weight of 470, and wet pine - 890 kg. This knowledge will be needed when transporting products.

When choosing a board, it is necessary to check if there are knots on it, since their presence greatly disrupts the internal structure and leads to a decrease in strength characteristics

When choosing lumber and calculating it, you need to be careful. The board should not have cracks, chips or other defects. Small cracks are allowed, but it is recommended to buy a solid, high-quality product that meets GOST

And also you should pay attention to the presence of knots. This is due to the fact that they negatively affect the strength of the wooden part.

The choice of the calculation method depends on the specific case. If necessary, you can always use the services of specialists who will help you perform the correct calculation and make an estimate.

Read on Dacha with your own hands: Terrace board: photos, videos, varieties and application features

The thickness and height of the timber.

Before calculating the amount of timber, it is necessary to determine the thickness and height of the product.

The material can have different thicknesses and heights, the following are the main dimensions:

- 100 * 100 mm.

- 100 * 150 mm.

- 150 * 150 mm.

- 150 * 200 mm.

- 200 * 200 mm.

If everything is clear with the height, the higher the timber, the fewer the joints between the joints, the faster the construction work is done, and naturally, the number of pieces of timber for building a house decreases. But the width in this case is more important, especially when building for all-season living.

Attention: Sometimes timber manufacturers indicate the dimensions of the timber, which may differ from the real ones, for example, a timber of 150x150 mm actually has a size of 140x140 mm. The consequences of buying such a bar will be very deplorable, if 20 pieces of 150x150 mm timber are needed for a height of 3 meters, then with a size of 140x140 mm - 21 pieces and a half, and this is one and a half crown rows

The consequences of buying such a bar will be very deplorable, if 20 pieces of 150x150 mm timber are needed for a height of 3 meters, then with a size of 140x140 mm - 21 pieces and a half, and this is one and a half crown rows.

If you plan to live in the house all year round, then it is recommended to use a bar 200 mm thick. It is also necessary to take care of the insulation of walls from a bar, the best option would be foam or mineral wool 10 cm thick.

Lining cube, how many lining are in a cube?

The thickness of the lining varies from 12 to 15mm, sometimes this size reaches 20mm (such boards are used for exterior decoration). This is quite enough so as not to break or push through the installed lining. This size should be taken into account when calculating the required volume of material.

The calculation of the cost directly depends on the material from which the finishing element is made and on its thickness. The standard length of the board is 2-3 meters, but sometimes you can find six-meter elements

When calculating the number of units of production, you need to pay attention to the useful width of the lining. Usually it is 80 or 88mm

But sometimes this size reaches 190mm. Such an indicator is wide for the lining.

This finishing material is produced from various types of wood. The better it is, the less waste will be obtained when performing work. Therefore, when choosing and calculating a board, you must make sure that its appearance meets certain requirements for the corresponding tree species and grade.

When calculating the material, you should also take into account the weight of the lining. It directly depends on the wood used. One square meter of poplar, for example, weighs 5.7 kg, and ash - 11 kg.

Calculation of the number of lining for example

- Let's say we have a room of 3x2 meters and with a ceiling height of 2.5. In this case, it is advisable to use products with a length of just 2.5 meters.

- For example, a lining with a useful width of 10 cm will be used.Let's find the values for how many products are needed for each wall:

- 3: 0.1 = 30 pieces.

- 2: 0.1 = 20 pieces.

Now we multiply the obtained values by 2 and add up: 30x2 + 20x2 = 100 boards. If there are ten products in a pack, ten packs of lining are needed.

- It is unlikely that our room does not have at least one door and window. And these areas should also be taken into account.

Let's say there is a 1x2 meter doorway and a 2x1 meter window. Then we perform the calculation:

(1 + 2): 0.1 = 30 pieces.

Therefore, this value must be subtracted from the obtained value of the total number of products:

100-30 = 70 products. This means 7 packs.

Outcomes

Thus, the necessary calculations can be made quite simply, especially based on the information provided. Only one cannot but add an important note to the above information. It is recommended to add another ten percent to all the resulting final data in reserve. This is a prerequisite if you do not want to run to the store during the installation process for a batch of material similar to the purchased one, which, by the way, may not be available.

Calculation procedure and method

To calculate how many boards there will be in one cube, it is enough to brush up on knowledge from a high school math course. Let's move on to the calculation procedure.

Initial data

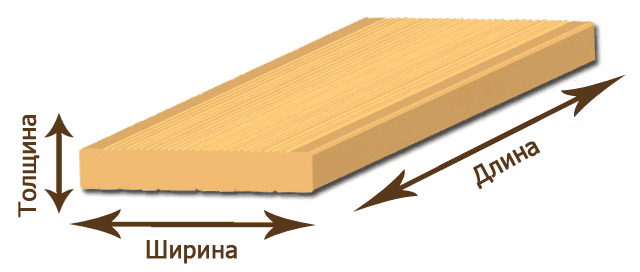

In the calculations, we will start from the size of the board. Three values are used: height (thickness), width, and length. In the designation of the assortment, they are given in the same order, for example, 25 × 150 × 6000 and are indicated in millimeters.

The height and width (section) of edged sawn timber are regulated by GOST 24454-80 “Softwood lumber. Dimensions ", although they may have other meanings for sellers.

Note that for calculations of special-purpose sawn timber, which differ from the standard rectangular shape in cross-section (for example, grooved floorboard), the values of the dimensions of the height and width should be taken according to the front, "working" width of the surface.

For the length of edged lumber, the most popular offers on the market are 4 and 6 meter boards.

Calculation of the number of boards in a cube

We will start from a simple geometric formula: the volume is equal to the product of the lengths of the three sides. From it, using the initial data, we calculate the volume of one board. Then we divide 1 by the obtained value and we get the final figure of how many boards are contained in the cube in pieces.

With a symbolic formula, the calculation of the cubic capacity of the board can be written as follows:

1 / (L * h * b) = N, where

h, b, L - height, width and length of the board, respectively, m;

N - the number of boards in 1 m3, pieces.

It should be understood that the calculation according to the indicated formula is approximate. The number can also turn out to be a fractional one, although when buying, you will take the number that is a multiple of an integer and rounded down. Also, the lumber manufacturer may not clearly observe the nominal values of the geometric dimensions, and the actual number of boards in one cube can be either greater or less than the calculated one. In addition, you should not be guided by the "back to back" calculation. Not all purchased sawn timber may be suitable for use, therefore, 10-15 percent of the stock in terms of quantity, especially with large purchases, should be pledged for marriage.

Calculation of coverage in m2 with one cubic meter of board

This calculation is a special case, in demand when you need to know how many square meters one meter of cubic lumber can cover, for example, for a floorboard or wall lining.

The formula is still simple - you need to multiply the number of boards in a cube (rounded to an integer) obtained from the results of the previous calculation by the area of one board (product of length by width). In symbolic terms, it looks like this:

S = N * b * L, where

S - area in m2, "sewn up" 1 m3 of the board.

Calculation examples

Number of parts in a cube

Lumber is usually sold by volume

So, we will devote the first part of this section to determining how many boards are in a cubic meter. This task is quite simple, since it is enough for us to divide 1 m3 by the volume of one part.

The unit volume is calculated by the formula L x W x T, where:

Note! When calculating how many boards are in one cubic meter, one must not forget about the conversion of units, since usually the cross-section parameters are indicated in millimeters, and the length - in meters. Photo of a calculator used for calculations

Photo of a calculator used for calculations

As an example, let's calculate how many 4 meter boards 150 mm wide and 25 mm thick are in a cube:

- We calculate the volume of one workpiece: 4 x 0.150 x 0.025 = 0.015 m3.

- Determine the number of parts: 1 / 0.015 = 66.7.

- Round to the nearest whole value, getting 66 pieces.

Note! Usually rounded to the last whole number. This, of course, somewhat contradicts the rules of mathematics, but in this case it is worth focusing on the prevailing practice

To make it easier for you to calculate the number of boards in a cube - the table 4 meters / 6 meters is given below:

Naturally, having such a table at hand, it will be very easy to calculate how many meters of a board in a cube (running meters, we will talk about square ones below): we take the number of boards and multiply by their length.

So, for parts 4000x50x100 this indicator will be equal to: 50 x 4 = 200 m.

Another version of the table of the ratio of volume and quantity

Volume and area

The following instruction is devoted to determining the area that can be sheathed / covered, using one cubic meter of lumber.

To equip the flooring, as in this photo, you need to calculate in advance the amount of material for finishing the required area

- Here, first of all, it is necessary to determine the area of one element, simply by multiplying its length by width. So, if we plan to sheathe a wall with wooden clapboard 3 m with a width of 220 mm and a thickness of 20 mm, then the area of one board will be 3 x 0.22 = 0.66 m2.

- Then we determine the number of such products per cubic meter. The volume of one board will be equal to 3 x 0.22 x 0.02 = 0.0132 m3. Therefore, in a cube, we will have 1 / 0.0132 = 75 parts of a given size.

- Next, we multiply the resulting amount by the area of one board. 75 x 0.66 = 49.5 m2.

Note! When calculating how many square meters in 1 cube of a board - lining, you need to take into account not the actual dimensions of the panels, but the dimensions of the "visible part". This is due to the fact that during installation, the spikes of the locking elements are hidden in the grooves, and the width decreases, so that the discrepancy between the theoretical calculation and the actual one can reach 8 -10%

When calculating with clapboard, the length of the spike is not taken into account

Also, when converting cubic capacity to volume, you need to remember that sometimes it becomes necessary to lay boards without joints. In this case, you should select parts with such a length that will ensure the appearance of a minimum amount of waste, otherwise our costs for the purchase of material will significantly (and unjustifiably!) Increase.

Volume to moisture ratio

The cost of delivery of sawn timber directly depends on its weight, and therefore on humidity. Wood tends to accumulate and release moisture quickly enough. For a large order, an increase in wood moisture by 3-4% means an increase in the cost of delivery by several thousand.

In order not to be fooled, count the number of lining and its weight relative to the standards. So, for wood that is stored in a warehouse, the permissible moisture content is about 12%. Weighing of lumber takes place immediately before shipment, but if the conditions in the warehouse do not correspond to the standards, then the humidity will rise, and with it the price for delivery. You can not be fooled by recalculating the weight of the required volume of materials relative to its standard weight. Tables with accurate data on the weight of 1m3 of any wood can be found in the public domain on our website.

1 m3 of finished oak board weighs 700 kilograms. If the seller requires the buyer to pay the cost of transporting one ton, and not the declared 700 kg, then the wood has high humidity or is damaged. Overpaying to an unscrupulous seller can not only increase the cost of repairs, but also receive defective goods, especially if the order arrived at the construction site from afar.