How long does silicone sealant dry?

If there is any crumbling material on the surface, remove it with a spatula and sand the surface, and then collect all the dirt with a vacuum cleaner. It is also worth ridding the surface of moisture, for this you need a solvent or alcohol, which must be applied to the surface with a soft cloth.

In order to make it easier for yourself, you can use masking tape, which must be glued on both sides of the future seam, leaving a strip of free space between them. After the sealant is applied, you just need to remove the tape. Before you stick the tape, you need to know exactly how thick the seam should be. And when applying, make sure that the length of the sealant seam does not exceed the length of the glued strips of adhesive tape.

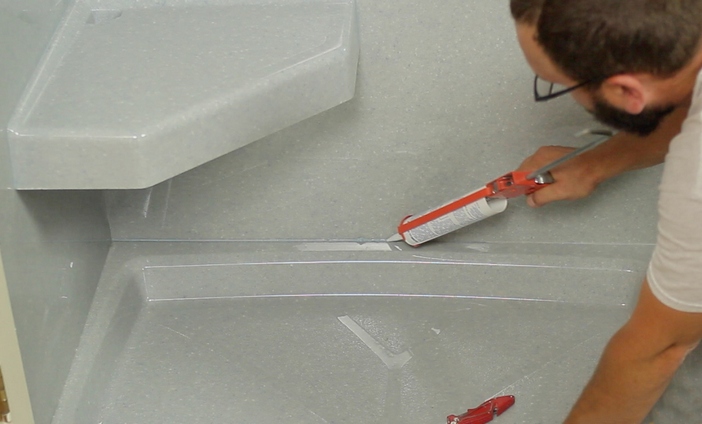

How to use sealant in a gun?

How to properly install the sealant in the gun? First, you should cut off the cartridge, considering that the more is cut off, the thicker the seam will turn out. In case if for material application using a conventional skeletal tool, then to install the cartridge, you must first, by pressing the lever at the top, pull out the piston, and only then can the cartridge be installed.

To ensure maximum line evenness, the gun should be held at a 45 ° angle to the seam. To release the material from the pipe, the trigger of the pistol must be pressed smoothly. When applying sealant, move the gun towards you slowly without interrupting the lines. After the line ends, you must release the trigger, and then press the lock lever. At the end of all sealing work, a special cap must be put on the pipe nose to protect the sealant in the cylinder from drying out.

After applying the material, the resulting seam should be lightly sprinkled with soapy water and shaped using a spatula. Only then can the masking tape be removed.

How long does silicone sealant dry?

The time it takes for the joint to dry completely depends on the conditions, namely the ambient temperature.

The stages of this process:

- In general, surface drying, that is, the formation of a non-sticky film, occurs in about 15-20 minutes, the manufacturer in most cases indicates the exact data on the packaging;

- Partial (in some places) hardening occurs after 3 hours, if the layer is thin, then the sealant can harden completely;

- At room temperature, complete hardening is achieved within 24 hours. If the seam is deep enough, has a rather large width, then the process may take longer.

After final drying for a week, the strength of the seam increases, so it is recommended to leave it for a longer time.

You can speed up this process by airing the room.

We have sorted out the question of how long the silicone sealant dries, but it is worth recalling that the indicators presented do not apply to all sealants. Sometimes it takes up to 4 weeks for the silicone mortar mixture to solidify completely, for example, when using a parquet mixture.

Material features

Silicone insulating material, depending on the course of the vulcanization process, is of two types: acidic and neutral. The acidic composition polymerizes with the release of acid, which is included in the solution as a solvent. Such a composition can destroy the amalgam or non-ferrous metal coating.

The acidic form of the mixture is suitable for:

- Installation and insulation of plastic pipes in the bathroom, shower.

- Seals for connections of sinks, bathtubs, shower trays with water pipes.

- Closing the joints of wooden and plastic structures.

- Installation of window and door double-glazed windows.

- Protection of threaded connections and branch pipes from the formation of mold and decay.

Neutral (sanitary) mortar creates an elastic joint that can withstand vibration loads, pressure drops and temperatures.

- For processing and insulating the joints of bath bowls, sinks, shower trays and tiles.

- Waterproofing and sealing of heating systems.

- Repair and installation of metal plumbing communications in the kitchen, in the bathroom.

- Restoration and sealing of gaps in natural stone finishes.

- Insulation of cables when laying power grids.

- Protection of parts from decay and mold.

Silicone compounds are used in the mechanical engineering industry to join plastic elements.

Types and characteristics

The basis of the silicone sealant is rubber.

In addition to him, the composition includes:

- plasticizer - a substance that makes the sealant plastic;

- vulcanizer - an element that changes the state of the sealant from a pasty version to a rubber-like one;

- amplifier - is responsible for the viscosity of the composition and for its strength characteristics;

- adhesion primer - promotes perfect adhesion of the sealant to the processed materials;

- filler - turns a colorless composition into a colored one (not available in all types of sealants).

All sealants are divided into one- and two-component according to the nature of their use. The former are used directly, their stable state is formed under normal conditions under the influence of moisture and air. And in order for the two-component species to solidify, an additional substance is required that plays the role of a catalyst.

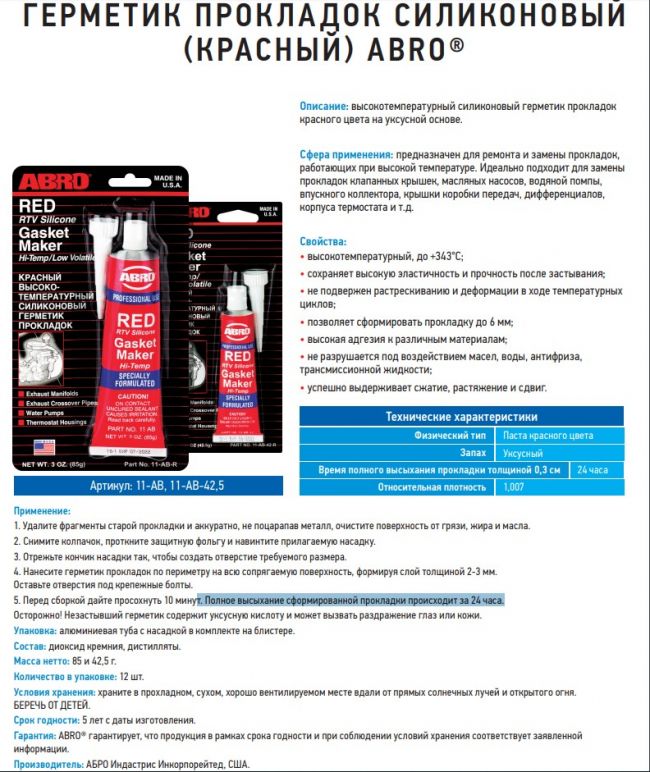

According to their composition, silicone-based adhesives are divided into three types.

- Acetic sealant. Contraindicated in concrete and metal products. The material emits acetic acid, which can cause significant damage to the metal and cause its corrosion. Used when working with plastics, wood and ceramics.

- Neutral (or universal) sealant. It is marked on the packaging in the form of the Latin letter N. It is applicable for all types of materials. The transparent composition is water-resistant, adheres well to metal, can be used for aquariums.

- Sanitary sealant. Fully corresponds to its name. Its purpose is the plumbing range of operations. Everything that needs to be sealed in the bathroom is done with just such a tool. The waterproof sanitary sealant does not deteriorate under the influence of cold and hot water, it is resistant to temperature extremes and ultraviolet light. But its main property is resistance to cleaning and detergents, which housewives love to use, keeping an eye on the cleanliness of bathrooms and kitchens.

The sealant may be white, colorless, or discolored. The color of the pasty substance is imparted by the filler.

Colored sealants can be divided into three types of application:

- construction;

- automobile;

- special.

Views

There are several varieties of sealant, each designed to work with a specific area.

Acrylic. Such sealants belong to the category of the most affordable materials, since they can only be used for internal work. The material is not resistant to atmospheric precipitation, temperature extremes and is not able to withstand mechanical stress. However, these sealants exhibit excellent adhesion to materials with a porous surface. It can be used to work with wood, brick, concrete, aerated concrete, aerated concrete, drywall and plaster. Based on the quality of the mix, it can be used when installing wooden skirting boards, doorways, and also during flooring.

Polyurethane.This material is an elastic mixture with adhesive qualities, which is characterized by an increased level of adhesion in relation to metal, stone, ceramic, plastic, wood and concrete surfaces. Craftsmen use this look for external and internal work. The mixture is not afraid of temperature drops, as well as the effect of atmospheric precipitation. It is highly resistant to corrosion and can be painted over.

Thiokol. It is characterized by high resistance to solvents, acids, alkalis, gasoline, kerosene and other oil lubricants. The mixture withstands the effects of precipitation, and is also capable of withstanding temperatures from -500 to +1300 degrees. Due to its special qualities, the sealant is used for activities with objects that require exclusion of contact with various substances of chemical origin.

Bituminous. Such material is often used during construction work. It has high-quality adhesion to surfaces made of foam concrete, brick, metal, wood and other roofing materials for waterproofing. When choosing a bituminous sealant, keep in mind that it is not resistant to high temperatures and takes on a liquid form.

There are two types of silicone sealant:

- acid;

- neutral.

Acidic products are not suitable for working with metal objects because the ingredients list contains acetic acid, which can be corrosive. It is also not recommended to use this type of material when sealing cement items.

A neutral mixture is considered universal. It is used in various fields. It can be used to seal the car engine and mirrors. Also, the material has another name - glass sealant. There are heat-resistant varieties on sale that can withstand up to +4000 degrees.

If fungicides are present in the silicone sealant, the material is called "sanitary" or "plumbing". It is able to exclude the appearance of fungi, therefore it is actively used when working in the bathroom, kitchen and swimming pools. It is the best joint sealant that can make the shower room airtight again as it was at the time of purchase.

Views

Silicone sealant is used for outdoor and indoor use. It is indispensable for the installation of plumbing and kitchen furniture. In rooms with a high level of humidity, it is recommended to use a neutral sanitary compound, which perfectly copes with the task of sealing joints around a shower stall, washbasin or glassware. It is possible to exclude the blowing of window frames made of wood by using this tool, intended for external sealing. Such products do not deteriorate from exposure to sunlight and perfectly withstand various temperatures. The colorless composition will be invisible on dark woods.

Among the assortment of these products there are special heat-resistant compounds operating in the temperature range from -50 to +300 degrees. The tool is used in electrical work, in the assembly of industrial structures. For work with the roof, there is a bitumen-based sealant, it perfectly seals cracks and other kinds of defects, the formation of which is possible on the roof, basement or foundation of a building. The product is frost-resistant and adheres well to metals, plastic and wood.

The products are divided into two groups: two-component and one-component sealants, which differ in their area of application.

One-component products are classified according to the base.

- Alkaline - the composition is produced on the basis of amines. This type is a specialized material.

- Acidic formulations, where the main component is acetic acid. Its smell is present during the hardening of the sealant on the surface.The main disadvantage of the product is considered incompatibility with a number of metals, since it provokes corrosion. It is not recommended to work with the sealant on cement surfaces that contain alkali.

- Neutral products work well with all surfaces thanks to their ketoxime or alcohol.

When purchasing a product, you should pay attention to the presence of additives - it can be a colorant, mechanical fillers that provide adhesion of the substance to the base, extenders that reduce viscosity, and fungicides that protect against the development of fungus and mold. The presence of such components greatly expands the range of product use.

The composition is perfectly stretchable, due to which it can be used on moving elements.

Possessing a number of advantages, the disadvantages of the product still include minimal adhesion to narrow polypropylene plastics, fluoroplastic and polyethylene.

Since the field of application of the products is very diverse, the types of sealants are divided according to their application.

Special formulations are products designed for work in conditions of maximum humidity. Specialty sealants have good adhesion to non-uniform surfaces and also withstand contact with aggressive cleaning agents.

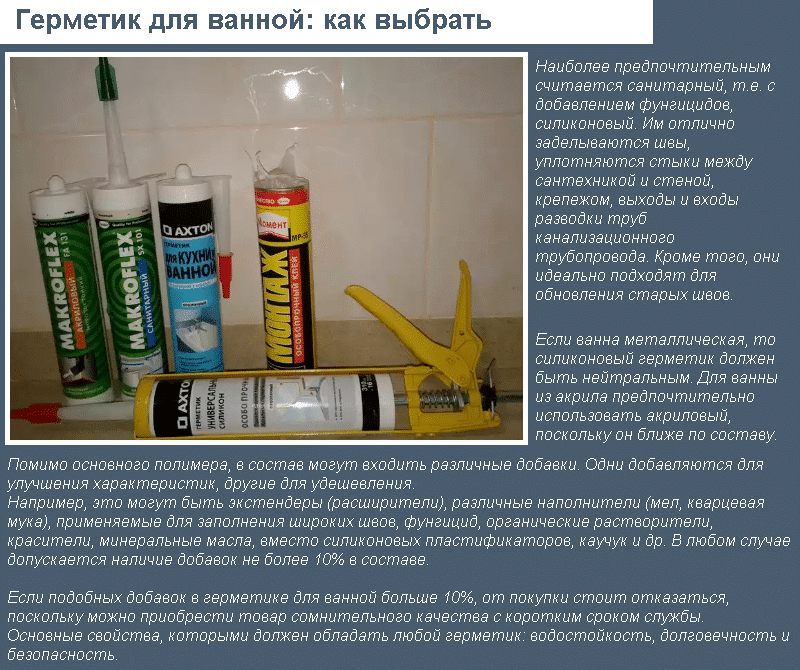

Types of Silicone Sanitary Sealants

Absolutely any bathroom sealant is a mixture that contains a hardener, polymer, filler, dye and other components.

When choosing this tool, you should immediately pay attention to the type of polymer that is part of it. There are several types of them at once:

- Silicone sanitary. This is a popular and expensive material. Has a strong surface adhesion to many materials, therefore it is suitable for all types of work in the bathroom. He is not afraid of moisture, ultraviolet light, is able to easily withstand high and low temperatures, has a long service life.

- Acrylic. In terms of service life, it is not much inferior to silicone, it also has good adhesion, but the price is much cheaper. Stably withstands ultraviolet radiation, elastic, withstands from -25 to +80 degrees. But it is better not to use it to seal joints that are subject to deformation.

- Silicone acrylic. This type is considered a hybrid that has absorbed all the best properties of two types of sealant - long service life and strength. Can be used as an adhesive for joining surfaces.

- Polyurethane. Resistant to mechanical damage, elastic. It is often used to replace seams, including silicone ones.

Thus, the market offers a wide range of silicone sealants for various purposes. Let's take a closer look at the most popular brands from well-known manufacturers for successful repair work in rooms with excessive moisture.

Popular brands of silicone sealants

Among the huge variety of seals, such brands are especially popular.

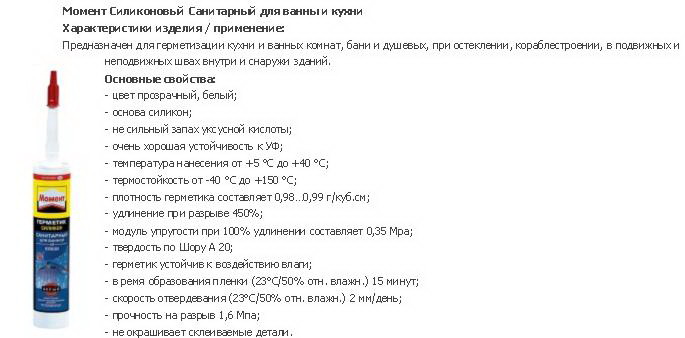

- Moment Herment is an affordable and reliable silicone sealant recommended for sealing seams and joints. It contains components that prevent the formation of mold and mildew. It is a flexible material that is easy to apply and dries quickly.

- Ceresit CS 25 is a heat and water resistant sanitary sealant. The main component is silicone. A unique additive in the composition slows down the appearance of mold and mildew in places with high moisture levels. This hermetic composition has high adhesive properties in relation to various coatings: glass, porcelain, ceramics. It will become a reliable tool for high-quality sealing of seams.

- Tangit S 400 is another silicone based acetate sealant.Fungicides are added to it, which prevent the formation of mold and the growth of harmful bacteria. The substance is characterized by high elasticity, good adhesion and resistance to high humidity.

It is important to note that these types of seals have appeared on the market for a long time. During this time, the brands reviewed have already shown themselves to be reliable means and managed to win the trust of consumers.

How long does the composition dry?

Gradually we came to the main question: how long does silicone sealant dry? Its hardening period is highly dependent on the field of application and the composition of the product itself.

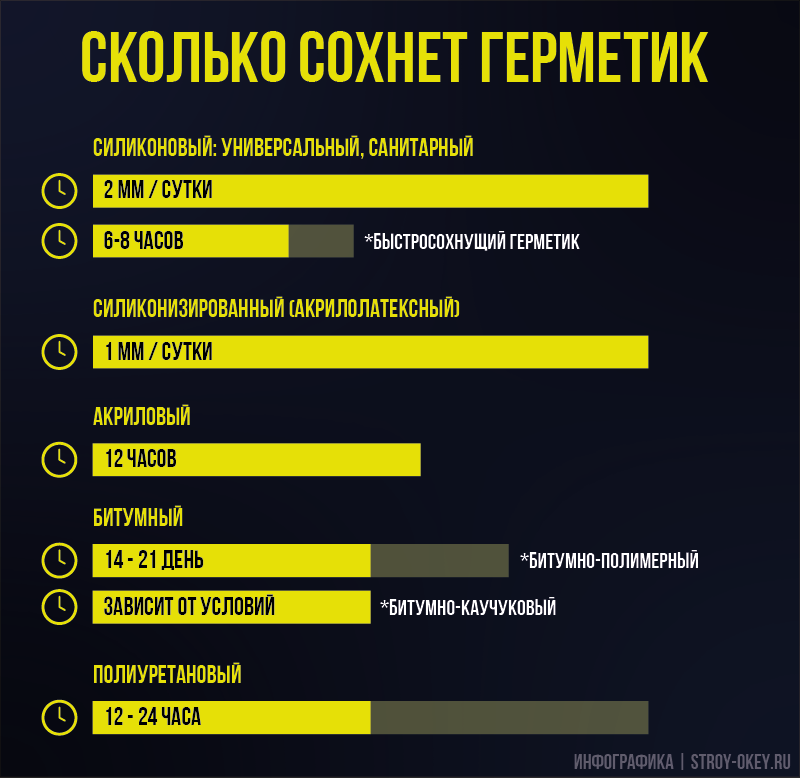

The polymerization time of the sealant, depending on the type:

- The acid based sealant takes about 4-6 hours to dry.

- The neutral silicone sealant will take longer to dry completely, about 24 hours. In addition, an important condition is a positive temperature - from 5 to 40 degrees.

Depending on the area of use, the drying time of the sealant can be as follows:

- If you apply this material generously enough, then its outer layer hardens and does not stick to your hands after 15 minutes. And in the inner layers at this time, the polymerization process is just starting. It passes at such a speed: every 2 mm of the inner layer hardens in 24 hours.

- If the room temperature rises significantly, the sealant will dry twice as fast. And if you carry out outdoor work in the cold season, then the sealant should be given more time to dry.

Bathroom sealant

How long does the sealant dry in high humidity conditions in the bathroom? Again, this depends on the choice of the product itself:

- Silicone acid sealants dry the fastest - in 4-6 hours. But such a material cannot be used to work with metal structural elements so that metal corrosion does not occur.

- Neutral sealant is more versatile, but also more expensive. Its layer 2 mm thick finally dries up in a day, but at the same time there should be only a positive temperature. Most favorable range: 5 to 40 degrees.

Applying sealant to joints in the bathroom

- Sanitary neutral sealant is often used in the bathroom. Fungicides have been added to it, which prevent the formation of mold on the treated surfaces.

- When you seal the seam between the tub and the wall it is against, the layer usually needs to be quite thick and wide. The time indicated on the package may be short for the complete polymerization of such a thickness. Craftsmen who install plumbing, as a rule, give not 24 hours for this, but a little more. Most often - 2 days.

It is interesting: FineВer siding - material review

Drying time of silicone sealant

How long the material dries depends on its type and place of application:

How long does the sealant dry in the bathroom?

In wet rooms special types are used

sealing silicone. Each of them has its own drying time:

- Universal neutral material in a layer of 2 cm in the bathroom will dry in 24 hours. The air temperature in the room should be at least +5 C and not more than +40 C.

- The acidic composition dries faster in humid conditions. It is enough for him from 4 to 6 hours. But it is not recommended to use it for metal products, as metal corrosion can occur.

- When sealing the gap between the wall and the bathroom, a wide, thick layer is obtained. Therefore, the seam will harden for 24 hours, and not less than two days. All its inner layers should dry well.

If a situation arose

, in which it is necessary to accelerate the drying process of the material, then this can be done in the following ways:

- create maximum ventilation by opening all windows and doors in the warm season;

- increase the air temperature in the room to +40 C;

- speed up the drying process by spraying the seams with water (silicone damp on top will dry out faster).

In the bathroom, the material is mainly used for sealing the gap between the bathroom and the wall, processing joints shower cabin parts

In the bathroom, the material is mainly used for sealing the gap between the bathroom and the wall, processing joints shower cabin parts

and similar works. The installation of silicone is quite simple. It is only necessary to observe the following rules:

- Clean and dry the surfaces and edges of the tub or shower.

- With masking tape as close as possible to the seam, paste over the places of the surfaces. In this case, the seam will turn out to be even, and the silicone will not stain the bathtub and walls.

- The silicone compound is filled into a special gun. To match the diameter of the seam and the hole, the nose of the tube with the material is cut at a certain angle.

- The tip of the gun is inserted into the joint and the compound is gently spread over the joint.

- Until the sealant has set, the seam can be corrected if it does not turn out to be very even. To do this, you can use a soapy finger or a rubber spatula.

- At the end of the installation, the molar tape is torn off.

Bath or shower it will be possible to use

after the silicone sealing material has completely cured.

To know how long it will take after installation

the silicone sealant will dry out, you should read the instructions when buying it. Manufacturers indicate the approximate drying time of the material on the packaging.

Acid and neutral type sealants

Silicone sealants are classified into two main types, each with different properties and drying times:

- Acid. Easily recognizable by its characteristic strong vinegar odor. Resistant to high temperatures and ambient humidity. However, it reacts violently to the proximity of lime or other alkalis, so it cannot be used everywhere.

- Neutral. They do not have any smell. They are more resistant to external active substances, but they do not tolerate high air humidity.

And now we will consider both species in more detail, especially since they still have subspecies.

The most common type of acidic silicone sealant is sanitary, also called plumbing. It does not lend itself to the harmful effects of excess moisture, as well as mold and mildew. Ideal for sealing gaps in the bathroom or kitchen. Adheres firmly to glass, enamel, ceramics, bricks, most types of metal.

Also, acidic silicone sealants are high-temperature (capable of withstanding up to 280 ° C), glass (well suited for porous or smooth surfaces, UV-resistant) and universal. From the name of the latter, it is clear that such a tool is suitable for almost any purpose. It is not recommended to use the universal look only with acrylic, polyvinyl chloride and metals that corrode.

As for neutral sealants, they are divided into sanitary (good for sealing various building materials, but sensitive to moisture), bricklayers (prevent the occurrence of fungus), construction (powerfully attached to metal or gypsum) and more rare types (for mirrors, for increased hygiene , aquarium, roofing).

Types and characteristics

All sealants today are divided into only 2 main types:

- One-component composition. This type is sold in any hardware store and is one of the most common. Compounds of this type are sold in metal or polyethylene tubes. This component hardens due to the presence of moisture in the air. The main disadvantage of this type is high-speed hardening, but only if the surface is treated with a thin layer. And if the layer is more than 1.2 cm, then the sealant hardens for a long time.

- Two-piece type. Such mixtures freeze in any layer, but the cost of such a composition is higher, since they are mainly used for industrial purposes.

Moment sealants are one-component types, as they are intended for domestic use.

The Moment manufacturer produces two types of sealants.The first type is silicone based sealants, and the second type is made from acrylic water dispersion.

Acrylic-based sealants are more resistant to frost and various adhesions of the processed surfaces. The main disadvantage of acrylic compounds is the impossibility of using in an environment with constant moisture. As for the color of this sealant, it is mostly white.

Silicone sealant is made on the basis of a rubber polymer. Such a component makes the mixture more elastic and makes it possible to solidify in a short time, even at room temperature. Due to this characteristic, Moment silicone sealants are sold in special plastic tubes, which retain its liquid and plastic state for some time after production. The tubes can be produced in volumes from 85 ml to 250 ml.

If you divide the compositions, starting from the scope of use, then they are construction, automotive and special.

According to their composition, they are divided into two types:

- Neutral. Alcohol is added to the composition of such a material instead of acetic acid and thus a less pungent odor is obtained. They can be used outdoors and indoors. Such mixtures are used in the field of shipbuilding, to seal freezers, they can be transparent and white.

- Universal sealants. The manufacture of such a composition takes place with the addition of a vinegar mixture, which gives an unpleasant and pungent odor, and when interacting with non-ferrous metals, cement and similar materials, which include alkalis, causes corrosion. This type of sealant is produced in white or transparent color. It can be used for interior processing, that is, indoors, and for outdoor use, as it is moisture and heat resistant. The cost of such a composition is lower than that of a neutral one.

And also the Henkel company produces the Moment Herment sealant, it can be used both for domestic use and for professional use. Such a sealant is divided into several types:

- Premium white, which is highly resistant to moisture, and consists of silicone. This type can be called the most heat-resistant.

- The next type, which is made on the basis of silicone and sodium silicate, copes well with oil, gasoline, high temperatures, which can reach 300 degrees. It dries quite quickly, and its color may even be red.

- The type of sealant Sanitary is used for the manufacture of glazing for shower stalls and bathtubs, but it cannot be used for processing stone and rusty surfaces, its curing speed is about 15 minutes.

- Aquarium look, used for the treatment of painted and glass surfaces that are subject to frequent vibrations. It is popular, since it has an increased level of moisture resistance, and the color of such a composition is extremely transparent.

The same series of materials "Moment" includes a gray sealant, which is made on the basis of polyurethane. It is often used as a grout for moving joints and as a tile adhesive. It is resistant to moisture, acids, alkalis, water and similar negative factors. But it has a drawback, since it burns out in direct sunlight and loses its elasticity over time.

Description, characteristics, pros and cons

Any silicone sealant is necessary to create a strong and reliable insulating joint, therefore many different requirements are imposed on these products. When it is necessary to create high-quality and durable insulation of heated elements, heat-resistant silicone sealants are used, as well as materials based on other components.

Heat-resistant sealants are made from special polymer materials, which include silicone and other additives, such a tool looks like a plastic paste. Additional components give the composition certain characteristics.

Typically, silicone sealants are supplied in plastic pipes and come in two flavors. From some tubes, the composition is simply squeezed out, and in order to use other pipes, an assembly gun is required. In addition, one-component and two-component adhesive sealants are manufactured.

Heat-resistant compounds have a wide scope of use, they are used in various construction, finishing, installation and repair works, since these funds have excellent characteristics:

- have a high rate of plasticity;

- heat-resistant silicone-based sealants can be operated at a maximum temperature of 350 degrees;

- fireproof, non-flammable, some types of heat-resistant adhesives - sealants can withstand temperatures of +1500 degrees;

- withstand huge loads without damage, while the sealing characteristics are not lost;

- high resistance to ultraviolet rays;

- the ability to withstand both extremely high and very low temperatures, up to -50 degrees;

- an excellent indicator of adhesion (adhesion), due to which heat-resistant silicone is used for application to many building materials. The main condition for good adhesion is absolute dryness of the materials;

- waterproof, resistance to moisture, alkalis, acids and other chemical products;

- long period of use;

- safety for humans, silicone does not release any toxic or harmful substances into the air;

- there is no need to use personal protective equipment while applying the adhesive.

Despite all of the above advantages, heat-resistant sealants have some disadvantages:

- can not be applied to wet materials, this will cause a decrease in the adhesion rate;

- before application, the surface is thoroughly cleaned of any debris, including dust, dirt, grease stains, etc., otherwise the adhesion will significantly decrease;

- long hardening period, which is 1-2 days. If you apply glue - silicone at a low air temperature and low humidity, then the curing period will be significantly increased;

- heat-resistant silicone cannot be painted, since any paint will begin to crumble after drying;

- silicone sealants are not suitable for filling wide and deep joints. During curing, these compounds use the moisture in the air, and if you apply a very deep seam, the silicone may not harden.

The instructions on the packaging will indicate what the maximum width and thickness of sealed seams... Do not exceed the maximum allowable value, otherwise the heat-resistant sealant will begin to crack over time

How to properly seal the seams in the bathroom: instructions

Silicone sanitary sealant is convenient to use for high-quality sealing of any seams in a damp room. It is sold ready-to-use in special cartridges that fill the sealant gun.

In order for the work to be done efficiently, prepare in advance:

Now let's look at the step-by-step instructions on how to apply the seal with your own hands.

- Surface preparation. The work area is cleaned of dirt and degreased.

- Application of the sealant. Armed with a pistol loaded with a cartridge with a sealant, carefully apply the product along the seam through a special tip. The composition should be fed by smoothly pressing a special lever located on the pistol. The seam is filled with the compound to the maximum depth. If the groove is too wide, then it is recommended to reduce it with foam.

- Seam alignment. This manipulation is best done with a finger dipped in a solution of water and soap. Excess sealant can be easily removed with a wet cloth. You can use the plumbing for its intended purpose only after the composition has completely hardened.

Next, consider the question of how long it will take for the silicone product to completely solidify.

How long does a bath sealant dry

How long does a bath sealant dry

Every DIYer should know how long a bathroom silicone sealant dries. It is mainly used in kitchens, baths and other non-residential premises with high humidity. One-component sealant is by far the most common material for sealing various joints from moisture, insects, dust, gluing homogeneous or dissimilar materials, etc. Only when using a sealant is a high-quality waterproofing or fastening of sides, moldings, skirting boards, etc. guaranteed. to the surface.

How long does silicone bath sealant dry

How long does the sealant dry in the bathroom? To answer this question, you need to understand that they are all divided into neutral and acidic. Each has its own characteristics and primary purpose. A neutral sealant is made with alcohol or its analogue (ketoxime). Some "models" contain anti-fungal additives. The sour smell during work is from there. Heating pipes and radiators, squeegees, seams between sinks in the kitchen and bathroom, etc. - this is the whole area of application of the neutral sealant. Acidic ones are made on the basis of one or another acid. Its main purpose is gluing parts together. Acid has a bad effect on metal (causes corrosion), natural stones (the natural color fades), so such sealants cannot be used on them.

Drying time

How long does a bath sealant dry? Drying time directly depends on the composition and the recommended area of application.

Acidic silicone sealant usually dries up in 4-6 hours from the moment of application, provided that the work surface has been prepared according to the rules (degreased, free from dirt and dust). Conventional neutral sealant dries within 24 hours. A prerequisite is the absence of negative temperatures! The room should be from 0 to 40 degrees (sweat at high temperatures is likely to break the structure of the sealant). In principle, each manufacturer gives its recommendations on the packaging. But still, certain technical points must be taken into account:

whatever the thickness of the seam, the material is applied in one pass. Multi-layer application is unacceptable (in the end, delamination of the seams will occur),

By the way, you can order such a nozzle HERE. Many asked, accidentally stumbled upon

after the initial reaction, i.e. contact with air, the upper "crust" is formed after 15 minutes

On average - 2 mm layer (thickness) per day, the joint between the bathroom, sink, sink, stove, etc. can be wide. Consequently, the time for final hardening may take 1.5-3 times more than the manufacturer stated. Be patient, and if you need to check, check very carefully. External hardness can be very deceiving

If you inadvertently hook or pull on the edge of the bar, you run the risk of zeroing out all your work (you will have to remove and reapply the sealant)

How to speed up the drying time of the sealant

There are situations when repair work, for various reasons, needs to be accelerated, and as a result, the drying time of the silicone sealant should be accelerated. The following are basic ways to help your sealant dry faster.